Why doesn’t the circulation pump press through the heating system?

You are here: >> Do-it-yourself radiator heating >> Designing home heating >> There is no coolant circulation in the heating system - what are the reasons?

If there is no circulation of coolant in the heating system, then there is nothing to talk about any comfortable living in the house in winter. Because no matter how much you heat up the boiler, the radiators will still be cold.

However, you need to think about this not when the system “worked, worked and suddenly stopped,” but at the design stage, i.e. now.

In this article we will deal with the problems that lead to poor coolant circulation.

Causes of poor coolant circulation

There may be no coolant circulation in the heating system for the following reasons:

- insufficient power of the circulation pump (or pumps, if there are more than one). For this reason, the coolant simply does not reach the radiators furthest from the boiler, so they are cold (or slightly warm, which still doesn’t make it any easier). There are several articles and videos on how to select the power of a circulation pump in the section on heating calculations;

- check valves are not installed. Usually their absence is “painful” for complex systems with several circuits. Check valves are used to ensure that the coolant moves along the desired circuit and in the desired direction (read more below);

- system contamination. It happens that the pipes are clogged along the entire diameter - what kind of circulation is there! There is only one way to treat this: replacing the pipes. This is exactly the case when the best treatment is prevention. And “prevention” should be carried out at the stage of installation of the pipeline and radiators. First, make sure that no debris gets inside the pipes. To do this, after first making sure that there is nothing inside, we close the ends of the pipes with something before installation. For example, it is convenient to use simple plastic bags. Secondly, there may be debris in the radiators. Even new ones! So we check and get rid of it;

- pipe diameter is too small. Small pipe diameter - high hydraulic resistance - the pump is not able to “push” the coolant throughout the pipeline - there is no circulation in the heating system (well, or it is so bad that it’s the same as if it doesn’t exist). Again, at the design stage it is necessary to calculate the hydraulic resistance;

- accumulation of air in the system (airing). Air, of course, is not garbage, but air pockets will also prevent the coolant from circulating freely. Air locks may appear due to violations of the rules for installing the heating system. Getting rid of air is simple - install an automatic air vent at the highest point of the system and Mayevsky valves on the radiators.

Coolant circulation in a combined (branched) heating system

Let's start analyzing the coolant circulation with a complex system - then you will understand simple circuits without problems.

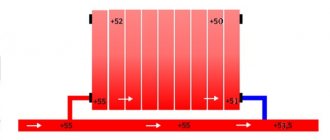

Here is a diagram of such a heating system:

It has three circuits:

1) boiler - radiators - boiler;

2) boiler - collector - water heated floor - boiler;

3) boiler - indirect heating boiler - boiler.

Firstly, it is necessary to have circulation pumps (H) for each circuit. But this is not enough.

For the system to work as we want: the boiler is separate, the radiators are separate, we need check valves (K):

Without check valves, let’s say we turned on the boiler, but the radiators “out of the blue” began to heat up (and it’s summer, we just needed hot water in the water supply).

Cause? The coolant went not only to the boiler circuit, which we now need, but also to the radiator circuits.

And all because we saved on check valves, which would not allow coolant to pass where it was not needed, but would allow each circuit to operate independently of the others.

Even if we have a system without boilers and not a combined one (radiators + water heated floor), but “only” branched with several pumps, then we install check valves on each branch, the price of which is definitely less than reworking the system.

Coarse filter

As mentioned above, one of the reasons that there is no coolant circulation may be the accumulation of debris in the pipeline. To completely avoid this, again, we don’t save on pennies, but install a coarse filter in front of each device:

Using a filter, catching dirt is easier than correcting the consequences of clogged pipelines or boiler heat exchangers.

The filter needs to be cleaned regularly. And this is very simple to do: close the valves before and after the filter - unscrew the plug (1) on the filter - remove and rinse the mesh under the tap - put it in place and tighten the plug. All. Not like changing pipes

Heating system diagrams

The layout of the heating system depends on several criteria:

- method of connecting batteries to supply risers. There are one-pipe and two-pipe systems;

- the location of the line that supplies hot water. You need to choose between upper and lower wiring;

- line laying schemes: dead-end system or associated movement of water in routes;

- risers can be located horizontally or vertically.

What is the difference between forced and natural circulation?

Forced movement of the coolant implies the circulation of liquid along the line due to the working force of the pump. The natural system does not require the use of any equipment; here the coolant moves due to the difference in the weight of the hot and already cooled liquid.

Single-pipe circuit: how to regulate the temperature?

To ensure the same temperature in rooms on different floors, the surface of heating devices on the lower floor should be slightly larger than on the upper floors. The liquid that is hot and cooled in the upper heating devices enters the lower radiators.

In a single-pipe system, there can be two versions of fluid movement: in the first case, part goes to the battery, the other part goes further along the riser to the lower radiators.

In the second case, the entire coolant passes through each device, starting from the top. The peculiarity of this wiring is that the batteries on the lower floors receive only cooled coolant.

And if in the first option you can regulate the temperature in the rooms using taps, then in the second you cannot use them, since this will lead to a decrease in the supply of coolant to all subsequent radiators. In addition, completely shutting off the tap will stop the circulation of liquid in the system.

When installing a single-pipe system, it is better to choose a wiring that makes it possible to regulate the water supply to each battery. This will allow you to adjust the temperature in individual rooms and make the heating system more flexible, and therefore more efficient.

Since a single-pipe system can only be top-mounted, its installation is only possible in buildings with an attic. This is where the supply pipeline should be located. The main disadvantage is that heating can only be started throughout the entire house at once. The main advantages of the system are ease of installation and lower cost.

Components of equipment

It is worth taking a closer look at the parts of the system that were mentioned above.

Disassembled crane

The operating principle is described in the air release instructions. The design of the Mayevsky crane is easier to study using this drawing. Such a miniature product is installed instead of a plug in the upper part of the collector comb. There is a carving in the central part. A screw is screwed in there, pressing the plastic seal.

To ensure the tightness of the connection, a rubber ring is used. All listed parts are included as standard with the product. No additional consumables are required for installation and operation.

The use of automated devices greatly simplifies the task. Without careful user control and additional settings, they are able to perform their functions over a long service life.

Automatic gas vent

Here is a schematic diagram of one of the devices in this category:

- The node (1) creates a rigid fastening of the rod (2) to the inside of the body with the desired angle. They regulate the opening level of the exhaust valve.

- During operation, air accumulates in the upper part. The float goes down. In a certain position, it will open the shut-off device, which will release the gas out.

- Next, the float rises to its original position, and the cycle repeats again.

- A soft seal (4) is installed in the lower part, ensuring the tightness of the connection.

Separator

The following device performs similar functions more effectively:

- Here is an example of a flow separator. It is installed at the top point in the pipeline section using threaded connections (4, 5).

- A mesh (3) is fixed in the central part. When a stream of water passes through such a structure, air bubbles are released from it (2).

- They rush upward. The same unit is installed in this part as in the automatic gas vent. When the float drops below a certain level, the draft will open the valve (1) to release air to the outside.

- The cell sizes and other mesh parameters are selected so as not to create unnecessary obstacles to the movement of the coolant. However, this design traps rust particles (6). They accumulate at the bottom (7). There is a screw-on cap that can be opened to remove contaminants when performing routine maintenance.

Removing mechanical impurities reduces the load on different parts of the heating system. If you install a simple filter on the main water supply line, clogging of radiator ducts and boiler heat exchangers will be prevented. This will also extend the life of the valve jets of automatic air vents.

Mechanical or automatic replenishment - which one to choose?

The make-up valve can be mechanically or automatically controlled. The first option is installed where small heating systems operate. In them, as a rule, any surges in the operating pressure of the coolant are regulated using membrane tanks. And the easiest way to compensate for the loss of water volume is to manually open the supply tap in a cold water supply. The main inconvenience of this option is the need for experience to perform the described operations, as well as the possession of certain technical knowledge and skills.

Note! In this case, you will have to independently control the pressure inside the closed heating system. An excessive increase in the volume of coolant can lead to an emergency situation

Automatic make-up valves are installed in large branched systems. They are often included in the heating boiler package, becoming part of its automation. Installation of such a device does not cause any particular difficulties. But its implementation makes the entire scheme volatile. And this must be taken into account when choosing one or another type of technical unit.

Operating principle of automatic valve

Auto make-up valve

The operating principle of the automatic valve is extremely simple. The operating parameters are pre-configured. Water losses are programmed in advance - the lowest pressure indicators are set. If the volume of coolant drops, say, by 10%, the valve is activated and starts the pump. The latter pumps the required volume of liquid from the cold water supply line. When replenishment occurs, the valve is activated again and shuts off the supply automatically.

The described device is easy to install. First, a measuring pressure gauge or any other electrical contact sensor is installed on the cold water supply line, which allows you to regulate the pressure in two directions. One of its groups is adjusted to lower operating pressure. This is where the intermediate relay or contactor is installed. When the volume of hot water drops inside a closed circuit, it turns on a mechanism that starts the suction pump. The second group turns off all these links when the water volumes are replenished. An electric valve—a valve with an electric motor—can be used as an actuator.

Note! When using an automatic make-up valve, the heating system independently controls the pressure and also independently calculates the compensating volume of water. This is the main advantage of this technical unit

When is it necessary to organize make-up using a bypass circuit?

Automatic recharge of systems and its efficiency

As a rule, all closed heating systems can function effectively only with high operating pressure of the coolant. But the deciding factor here is also the temperature of the hot water.

As it increases, the thermal expansion of some technical components increases. It can be compensated by installing an expanzomat - a hydraulic accumulator capable of accumulating hydraulic energy when there is an excess of it and releasing it when there is a shortage. It must be connected using a bypass circuit. Read how to do this here.

Scale deposits inside the heat exchanger

The heat exchanger can be clogged not only with combustion products, but also with scale and limescale that forms with each portion of water entering the boiler. Scale is formed as a result of heating hard water.

Inside the heat exchanger, solid deposits of salts turn into a kind of insulator, reducing heat transfer from heating. The larger the scale layer in the heat exchanger, the worse the heat transfer from fire to water will be, because heat will not be able to penetrate a thick layer of solid deposits. This significantly reduces the energy efficiency of the entire system and the boiler stops reaching the desired temperature.

To remove scale, the heat exchanger must be removed and descaled using a special acid. As a preventative measure, it is recommended to maintain the operating temperature in the boiler.

Traditional methods for descaling include the use of ordinary table vinegar (3-10% acetic acid solution). Table vinegar is poured in equal parts with water, the solution is left to interact with the scale overnight. Cationation and reverse osmosis methods are also used.

Advantages and disadvantages

The open heating system has not yet lost its relevance, and recently it has even experienced a rebirth, and there are reasons for this. Many homeowners are concerned about the energy independence of their communications, and the open tank scheme allows this to be achieved. She has other advantages:

- Filling an open heating system and bleeding air is easier than in a closed one. There is no need to monitor the maximum pressure, and when filling, the air leaves the pipelines very quickly through the open expansion tank. All that remains is to ventilate the radiators;

- it’s easier to refill: again, pressure control is not required, and water can be added to the container even with a bucket;

- the operation of the system does not depend on the presence of leaks: here the operating pressure is very low, so as long as there is water in the heating network, it will function properly.

As usual, there were some drawbacks, due to which such systems began to be gradually replaced by closed-type circuits with a membrane expansion tank. Due to the direct contact of the coolant with atmospheric air, two processes occur in the container at once: natural evaporation of hot water and its saturation with oxygen. This leads to the following requirements:

- you need to monitor the water level in the tank and replenish it on time;

- Do not fill the heating network with antifreeze, which releases harmful substances when evaporated.

Oxygen saturation of the coolant leads to a decrease in the service life of steel parts of the boiler. For the above reasons, the open system has not been used in apartment buildings for a long time, although in the 60-70s of the Soviet era such practice took place in low-rise residential buildings. It is also undesirable to operate it with high-temperature heat sources when the coolant is close to the boiling point. The fact is that with increased pressure in a closed network, this threshold increases, and there is nowhere for water to evaporate. In an open system, the amount of water will quickly decrease, freeing up the entire volume of the expansion tank for air.

Natural circulation

Approximate system diagram

The main issue of the natural circulation system is the issue that determines the force of movement of the coolant to the heating devices and back to the boiler. The force of movement of the heated coolant appears due to the fact that the coolant is heated in a heat generator, whereas in heating devices this coolant cools down and is squeezed out by the heated coolant. In other words, the coolant, which has been heated in a heat generator to a certain temperature, has less mass than the coolant in a cold state.

So, water heated to the required temperature rises in a certain direction in the main riser and is distributed by piping to all heating devices, that is, radiators. After some time, the coolant in the radiators cools down, giving off its heat to the metal, which makes it heavier. Through specially installed return pipes, the cooled coolant is transported back to the heating boiler, where its mass displaces hot water from the heat generator.

This cycle of coolant movement in the heating system will be repeated until the heating boiler is operating, as a result of which the coolant will circulate through the pipe line. Heating systems with natural circulation have different pressure forces, which leads to different rates of circulation and heating of heating devices. The force of movement of the coolant in the heating system depends on the different densities and weights of the cold and hot coolant.

From this we can conclude that the pressure in the heating system and the force of water movement depend on the overall difference between the hot and cold coolant. In other words, the greater this difference, the greater the force of movement of the coolant in the heating system, in which the coolant circulates naturally. Among other things, the pressure in the heating system and the force of movement of the heated coolant depend on the height at which the heating device is located relative to the thermal energy generator.

As a rule, the coolant in a simple water-type heating system heats up to 95 degrees, while the cooled coolant has a temperature of no higher than 70 degrees. From such indicators it is possible to determine the total pressure in the heating system and the force of movement of the coolant to the upper and lower heating devices. In order to visually imagine the distribution between the upper and lower radiators in the heating system, it is necessary to draw some kind of diagram.

In the center we denote the heating boiler, from which there is wiring to the upper and lower radiators, which closes opposite the boiler itself. By drawing a line between the upper and lower heating devices (radiators), we get a temperature difference from 95 to 70 degrees. Next, we will consider the heating process.

System diagram

The heating boiler heats the coolant, in our case water, which, due to the resulting pressure, begins to move from one heating device to another. When the coolant crosses the line we have drawn and goes to the heating devices on the lower floor, its temperature will be significantly lower, and the coolant with a temperature of only 70 degrees will come out of the last radiator. When moving coolant from radiator to radiator, do not forget that part of the temperature is transferred to the pipes themselves, as a result of which the temperature of the coolant is constantly decreasing.

From this we can safely conclude that heating devices that are located above the system separation line will heat up more than those located on the lower floor.

All this leads to the fact that the use of this heating system for two-story houses is irrelevant, because the first floor will be constantly colder than the second. In addition, when using a two-pipe heating circuit, when the radiators are located below the boiler itself or at the same level with it, it is almost impossible to achieve proper coolant circulation without the use of auxiliary mechanisms.

For these obvious reasons, the location of the heating boiler should be such that the heating devices are located at a level above the boiler itself. To do this, heating boilers are placed in a small recess, and the heating system is raised slightly at a certain angle in order to achieve the proper pressure and proper natural circulation of the coolant. Standard single-pipe heating schemes do not have such obvious shortcomings.

Bypass

The bypass is the same pipe that stands in front of the installed heating device. Everyone has one, it’s needed to bypass water past the battery. If installed incorrectly - too far from the radiator, or in line with the central riser, it does not allow water, which tends to travel along the shortest path, to circulate normally, heating the radiator sections. In this situation, they will either not heat at all or will be very bad. Check how your bypass is installed. Perhaps this is the direct reason why the batteries do not heat up

How do open systems differ from closed systems?

Any hydraulic heating system can be represented as a complex of heating equipment and heating devices, combined in a certain order into one whole using pipes.

In heating systems, an expansion tank is installed, since the heated coolant increases in volume. If the tank communicates with outside atmospheric air, then the heating system is called open. By isolating the expansion tank from interaction with atmospheric air, a closed-type heating system is obtained. In open systems, the coolant evaporates, so you have to monitor the water level in the tank and top it up when the need arises. In closed systems. equipped with membrane-type expansion tanks, this problem does not arise.

Installation of a heating system, including a boiler, an open expansion tank, radiators, shut-off valves, air vents, a circulation pump providing forced circulation of the coolant

Video

In any case, the heating system should be inspected regularly. To remove air, you must follow the instructions exactly. If an engineering structure is highly complex, and independent actions cause difficulties, you need to seek help from specialized specialists. In addition to removing air, they can be entrusted with adjusting the manifold comb.

If the floor heating pump stops

And if the first problem can be solved in fairly simple ways, then what to do if the underfloor heating pump stops? What to do in this situation?

Consequences of cold return

Circuit for heating return

Sometimes, with an incorrectly designed design, the return flow in the heating system is cold. As practice shows, the fact that the room does not receive enough heat with a cold return is half the trouble. The fact is that at different supply and return temperatures, condensation may form on the walls of the boiler, which, when interacting with carbon dioxide released during fuel combustion, forms acid. It can also damage the boiler much ahead of time.

To avoid this, it is necessary to carefully consider the design of the heating system, special attention must be paid to such a nuance as the return temperature. Or include additional devices in the system, for example, a circulation pump or boiler, which will compensate for the loss of warm water

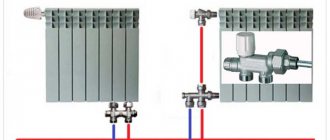

Radiator connection options

Now we can more than confidently say that when designing a heating system, the supply and return must be perfectly thought out and configured. If the design is incorrect, more than 50% of the heat can be lost.

There are three options for inserting a radiator into the heating system:

- Diagonal.

- Lateral.

- Bottom.

The diagonal system gives the highest efficiency coefficient, and is therefore more practical and efficient.

The diagram shows a diagonal inset

How to regulate the temperature in the heating system?

In order to regulate the temperature of the radiator and reduce the difference between the supply and return temperatures, you can use a heating system temperature controller.

When installing this device, do not forget about the jumper, which must be located in front of the heating device.

Incorrect boiler gas valve setting

Settings can be made on any gas valve. Errors in the settings include setting the output pressure below the permissible norm for your system according to the regulations. If the valve is set incorrectly, the boiler will not operate at full capacity. Accordingly, it will not be able to reach the desired temperature. The valve adjustment is usually done by the boiler installer.

Types of open systems

Such water heating schemes are divided into types depending on the method of circulation and delivery of coolant to the radiators and its subsequent return back to the boiler. Heated water can move through pipelines in two ways:

- using natural circulation;

- artificial stimulation from the pump.

Due to the design features, there is practically no excess pressure in an open heating system. At the highest point it is equal to atmospheric pressure, and at the lowest it increases slightly due to the hydrostatic effect of the water column. The value of this pressure is small, which makes it possible to organize natural circulation of the coolant. The principle is based on the fact that coolant with different temperatures has different densities, and therefore mass. Example: 1 m3 of water at t = 40 °C weighs 992 kg; after the temperature rises to 60 °C, the mass of 1 m3 drops to 983 kg.

It would seem that the difference is insignificant. Nevertheless, it allows the cooled coolant at a low temperature to displace lighter hot water from the boiler. Natural (convective) circulation occurs in pipelines, and such systems are called gravity or gravitational, because movement in them occurs due to gravity. Therefore, the coolant flow rate in the mains and radiators is low, only 0.1–0.3 m/s. But such schemes are completely energy independent, provided that boilers for an open heating system that do not require electricity work together with them.

Note. In gravity systems, lines are made with increased slopes and pipe diameters.

In order to increase the speed of water flow through the pipes and reduce the heating time of the premises, a pump is built into the main line coming from the boiler. It forces the coolant to move at a speed of 0.3-0.7 m/s, which is why heat transfer occurs more intensely and all branches heat up more evenly. Thanks to the presence of a pump, the distance between the heat source and the batteries can be increased both in length and height.

Installing a pump unit allows you to create a slight excess pressure in the heating system, allowing the coolant to flow well into the radiators. This definitely increases the efficiency of the system as a whole, although it makes it dependent on the availability of electricity.

Note. To ensure that the heating of a private house does not stop when the electricity is cut off, it is customary to install the circulation pump on a parallel bypass line.

Heat exchanger fouled by soot

During long-term operation of the boiler, combustion products are deposited on the surface of a plate, bithermal or fire-tube heat exchanger. Due to the layer of soot, the fire ceases to be in direct contact with the walls of the combustion chamber, heat transfer from the source decreases, the boiler does not heat up as efficiently and does not reach the desired temperature.

To solve this problem, you need to clean the heat exchanger. Considering that soot settles on the walls along with resin, tar and ash, cleaning the combustion chamber after it has completely cooled is not so easy. For quick and effective cleaning, you can contact specialists. Professionals use special equipment to remove soot:

- the “Streamer” complex (electric discharge method) is an effective procedure that allows you to remove a fairly thick layer of combustion products without damaging the heat exchanger;

- use of a high-pressure pump (hydrodynamic method) - quick removal of small deposits, the combustion chamber does not even need to be removed;

- booster for chemical washing. This method is effective if the heat exchanger is very dirty, and the deposit of soot and tar is old and cannot be removed in any other way. The disadvantage of this option is the risk of reducing the service life of the combustion chamber.

All these methods involve additional expenses. To remove combustion products yourself, you can use one of the common methods offered by experienced professionals. For example, heat the surface of the chamber using a hair dryer and use a regular spatula to remove soot.

Coarse filter

As mentioned above, one of the reasons that there is no coolant circulation may be the accumulation of debris in the pipeline. To completely avoid this, again, we don’t save on pennies, but install a coarse filter in front of each device:

Using a filter, catching dirt is easier than correcting the consequences of clogged pipelines or boiler heat exchangers.

Conclusion! We place coarse filters in front of each heating system device (pump, boiler, etc.) and in front of each plumbing fixture. We do NOT save pennies to “buy” problems. There are arrows stamped on the filter housing indicating the direction of movement of the coolant or water in the water supply...

The filter needs to be cleaned regularly. And this is very simple to do: close the valves before and after the filter - unscrew the plug (1) on the filter - remove and rinse the mesh under the tap - put it in place and tighten the plug. All. Not like changing pipes

These are the simple “body movements” you need to perform in order to never complain that there is no circulation in the heating system. Good luck.

no circulation in the heating system

The return in the heating system is the coolant that has passed through all the heating radiators, lost its primary temperature and is now cold and supplied to the boiler for the next heating. The coolant can move in both a two-pipe and an improved single-pipe heating system.

A single-pipe system implies a sequence of connections of heating radiators. That is, the supply pipe is connected to the first radiator, from which the next pipe goes to the second radiator, and so on.

If a one-pipe heating system is improved, its design will be something like this: along the perimeter of the entire room there is one pipe into which the supply and return pipes of each radiator can be inserted. In this case, it is possible to install a control valve on each battery, with which you can very successfully regulate the air temperature in a given room.

The big advantage of this option is the minimal number of pipes in it. And the minus is the temperature difference between the first radiator from the boiler and the last. This problem can be eliminated with the help of a circulation pump, which will move all the water through the heating system much faster, and thus the coolant will not have time to reduce the temperature.

The two-pipe option represents the wiring of two pipes. One pipe is the supply of hot coolant, the second pipe is the return pipe in the heating system, through which already cooled water from the radiators enters the boiler. This system allows you to connect all radiators almost in parallel, which allows for flexible configuration of each radiator individually without affecting the operation of the others.

Flow extender

A typical problem for a two-pipe system. Is it possible to make any number of sections? It is possible, but the very last sections of the battery will not warm up. Cause? Water, like a person, looks for “where it’s easier” and follows the shortest path. In order to “teach order” to the lazy one - water, a flow extender is required. Factory-made, or made independently from a piece of pipe. By directing the fluid to the middle of the structure, it will force the flow to circulate correctly, reaching the farthest ends of the heat exchanger.

Interesting fact: the same problem can be solved by connecting the heating device “diagonally”. But this is rarely used, due to the lack of aesthetics of this solution on ready-made systems.

Basic malfunctions of heating systems and their elimination

Air jams

Air pockets occur in radiators and pipes and interfere with the normal circulation of water in the heating system. They appear for various reasons:

- violation of the technology for filling the system with water after the summer period;

- non-compliance with water deaeration regime;

- performing repairs with disassembling pipelines;

- failure to observe slopes when installing the heating system;

- air leakage through leaky joints.

To remove air from the system, use a Mayevsky valve installed on the radiator. You should open it, wait until the air comes out, the hissing stops, and the water begins to pour out calmly without bubbles. After this, the valve is closed. Don't forget to provide a container or towel to drain the water.

Old cast iron batteries do not have Mayevsky taps. The air is released without completely unscrewing the plugs at the ends of the radiators. It is better to entrust this operation to plumbers - if you unscrew the plug completely, you can flood the apartment.

The heating system is a complex structure consisting of several elements combined into one circuit and put into operation through a chain reaction.

But it happens that the system fails and the water in the batteries becomes cold. The reason for this may be problems with the return line.

Heating systems with forced circulation

A standard forced circulation heating system operates using the same connection methods. The difference is that due to the large extent of this system or the lack of natural conditions to create an inclination of the pipes, it is necessary to include a pump in the system. The circulation pump is mounted to the main pipe - this helps to increase the service life of the heating system. Using a pump helps not only increase heating efficiency, but also reduce the number of lines. A forced circulation system has the ability to heat not just several rooms, but even a house with several floors.

Heating systems with forced circulation

In order to produce high-quality operation of this type of system, a continuous power supply is required. Installation of a circulation pump in the heating system is required in order to create forced circulation of water in a closed loop. In this type of system, the pump is the central component among the equipment. It should be noted that the circulation pump may not have significant performance: its power is only needed to direct the liquid into the supply pipe. The same pressure pushes the water in the opposite direction, since the system is closed.

The circulation pump is necessary to ensure uninterrupted operation of the heating system, therefore it must fully comply with the system into which it is installed. Due to its functionality, this type of pump can be widely used in a wide variety of pipelines.