A correctly selected and installed chimney for a geyser not only ensures its reliable operation, but also does not allow combustion products to enter the interior of the house. Therefore, special attention should be paid to this issue, because cases of waste from improper operation of instantaneous water heaters are not so uncommon.

The following material will help you figure out how to choose a gas chimney for different types of water heaters and install it yourself in accordance with the rules.

Types of geysers

According to the principle of operation, geysers are divided into two main types:

- equipped with an open chamber in which fuel combustion occurs;

- columns with a closed combustion chamber.

In the first case, the heating device operates due to natural draft and requires the installation of an exhaust hood and a smoke exhaust duct. The main advantage of such a geyser is that it costs less than a closed type device, and is also more reliable in operation.

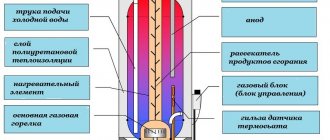

In turn, closed-type water heating devices (operating on gas) do not require the installation of a smoke duct. Closed gas water heaters are also called turbine water heaters, since the thrust in them is pumped through a turbine . Removal of combustion products in such structures occurs due to a turbine and a coaxial pipe. The cost of such products is higher than for speakers with an open chamber, and they are also volatile.

Such heating devices are classified according to the following parameters:

- power indicator;

- ignition option.

Closed-type columns do not require laying a special smoke channel; a coaxial chimney is sufficient for them

The choice of a gas water heater depends on the operational features in a particular case, as well as on the financial capabilities of the owners of the house or apartment.

Additional ventilation

Ventilation in a kitchen with a gas water heater should have not only an exhaust hood, but also an additional forced or natural ventilation channel. Before installing a speaker in a certain room, it is necessary to check the quality of natural supply and exhaust ventilation. To do this, you need to take a piece of paper and bring it to the grille that covers the ventilation duct:

- if paper is sucked into the hole, then the ventilation is good;

- if the leaf remains motionless, then there is no traction;

- It happens that the paper is sometimes blown in the opposite direction - this indicates the presence of reverse draft.

If there is no natural ventilation, you will have to purchase supply and exhaust devices with a fan and install them in a wall or window. Such a device will provide high-quality air exchange and eliminate the possibility of the formation of carbon monoxide concentrations.

The recommendations stipulate whether it is possible to use brick, steel and corrugated chimneys for geysers, what diameter the pipes should be, fire breaks and much more.

Types of chimneys for geysers

The chimney for a geyser can be made of various materials. Let's look at the main materials from which smoke exhaust pipes are made:

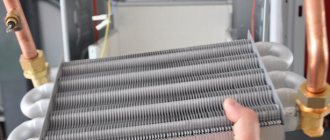

Flexible chimneys made of corrugated pipes. Individual elements of such chimneys are made of aluminum foil. To impart rigidity, the corrugated structure is equipped with a special spiral, which is made of steel wire. The main advantage of such pipes is their simple installation.

Note! If necessary, corrugated pipes can be bent at any angle, and their length can also be changed.

Aluminum chimneys. Aluminum chimney pipes have the following advantages: light weight, ease of installation. And also the use of such chimneys allows you to avoid the formation of condensation inside the chimney during operation of heating equipment. Among the disadvantages of aluminum chimneys, one main one can be identified - the need for thermal insulation.

Exhaust systems made of galvanized steel. Galvanized steel has high strength characteristics and useful anti-corrosion properties. Like pipes made of aluminum, these products also require thermal insulation.

Steel chimneys of various types are suitable for geysers, including those with double walls

Chimneys made of sandwich pipes. A sandwich pipe is a product that consists of two pipes (one of them is located in the other) and a layer of heat-insulating material between them. Experts recommend installing chimneys from sandwich pipes in cases where communications need to be laid through ceilings or roofing.

Connection

The process of installing a geyser with a chimney can be divided into several stages. Let's consider the simplest option for installing a chimney, using a corrugated pipe:

- Installation of a geyser begins with choosing the location of the equipment, so that it is convenient to install the hood;

- Then a hole is made in the ceiling and roof;

- A piece of asbestos pipe one and a half or two meters long is inserted into the prepared hole;

- A pipe sticking out of the ceiling can be disguised with a special decorative rosette;

- Next, using dowels and self-tapping screws, a gas water heater is installed;

- When the column is fixed to the wall, take a piece of corrugated pipe, one end is put on the outlet pipe of the column, and the other end is inserted into the chimney socket (if an enameled steel pipe is used to install the chimney, then a tee is used to connect the chimney to the gas column);

- To supply gas to the equipment, a tee is cut into the gas pipe, a gas tap is installed, and a flexible line is connected to the column with a fitting with a union nut;

- In the same way, a tee is cut into the water supply system, a water tap is installed and the water supply pipe is connected to the column (salt and magnetic filters must be installed);

- All that remains is to connect the column to the hot water supply system. Read the instructions on how to make an insulated chimney on this page.

Options for installing a gas chimney in the figure.

When installing a chimney for a gas water heater, you should adhere to some rules:

- do not use more than three taps;

- the constituent elements of the chimney must be rigidly fixed and not bend;

- cross sections should not have narrowings;

- an inspection grille and a condensate collector are installed at the bottom of the chimney;

- the chimney should not have joints in the ceiling;

- the internal surface of the chimney should have as little roughness as possible.

Coaxial chimney for a gas-powered column

Today, the coaxial chimney is the most modern solution for installing heating communications. Such smoke removal devices are used in systems that are characterized by having a closed chamber for gas processing.

From a constructive point of view, a coaxial chimney is a central pipe located in a second pipe. The internal pipe in this design performs the function of removing combustion products from the heating device outside the residential building. And the air necessary for the operation of the heating device comes from the street and is delivered to the closed chamber through the free space located between two pipes.

This chimney design has a number of advantages:

- reducing the length of the chimney pipe;

- increasing the coefficient of performance (efficiency) of a geyser;

- lack of oxygen consumption in the room where the heating equipment is located.

A coaxial type chimney is the most modern solution for a gas heating system today

Thus, due to the fact that a geyser with a coaxial pipe takes air outside the room, there is no need to organize a complex ventilation system. During installation of this equipment, care must be taken to ensure that the cross-sectional area of the coaxial pipe is not smaller than that of the outlet pipe of the gas heating device.

Step-by-step instructions for constructing a smoke exhaust system

When commissioning the equipment, room ventilation must be taken into account. In the absence of air exchange, forced turbo exhaust must be installed. Without it, putting a gas boiler into operation is impossible. We will look at how to install a hood for a gas boiler in a private house using the example of a coaxial chimney. The length of the pipe from the boiler room to the street for this type of hood cannot be more than two meters.

- When starting work, make sure that the installation of the gas boiler complies with the rules and regulations approved by inspection organizations in order to avoid reworking the entire power unit.

- Select the appropriate material for the hood, taking into account the parameters of the gas outlet: gas boiler inlet = pipe diameter.

- Calculating the power of the fans and their number, taking into account how long the hood is, the number of bends in its structure, and the position in space relative to the horizon, at what height the exhaust pipe is located in the room.

- Do not forget about the features of budget equipment indicated in the technical passport.

- All materials used in the work must be fireproof and not susceptible to corrosion.

- After making sure that all parts are intact, we proceed to assembly. We connect the chimney elbow to the gas boiler pipe using a tee.

- To extend the coaxial pipe and connect all its parts, special crimp clamps and fire-resistant sealants are used.

- Turbo exhaust is used if there are more than two elbows in the pipeline geometry. This helps maintain the efficiency of the gas boiler . The fan and all sensors are installed after installing the supply pipe.

- Installing a coaxial pipe outside a building is no different from installing a conventional sandwich chimney.

Outside the building

Having laid the line for the exhaust device in the house, the design of the hood for the gas boiler goes outside.

- As soon as the pipe has been brought outside through a hole in the wall, it must be closed with special metal plates. The remaining space between the pipe and the wall is filled with mineral wool.

- Now we install the tee. The lower hole is closed with a plug with an inspection for cleaning the pipe.

- We increase the chimney to the required length by connecting the parts using a special sealant and clamps with gaskets. As the pipe grows, we attach it to special brackets.

- We install a protective cone at the top of the chimney and additionally attach it to guy wires in those places.

- If the chimney structure was not coated with special paint at the factory, this can be done at home. This is done to protect the metal from environmental influences.

When ordering an outdoor chimney system, it is important to consider where the forced exhaust starts from the gas boiler or from the room where the turbo elements are installed.

Inside the house

Inside the house, the installation of a coaxial chimney was described in detail, with comments, above. The only step you have left to do is to connect two pipes, street and indoor, using the extension method. For additional insulation, it is recommended to use special metal tape.

I would like to note an important advantage of a coaxial chimney - the absence of additional holes in the roof or wall of your home.

Basic requirements for a geyser chimney

A chimney is a communication that performs a very important function, namely: the removal of combustion products from the heating device outside the house. Any errors during the selection or installation of this equipment can cause emergency situations, so experts recommend carefully studying the basic requirements for chimney pipes. Let's look at them:

- the design that removes combustion products must have high sealing performance. Otherwise, there is a risk of gas leakage;

- The chimney must be installed from reliable materials. The pipe material must be resistant to destructive corrosive influences, as well as high temperatures;

Important! Any smoke exhaust structure, regardless of the material of manufacture, must comply with the building codes set out in SNiP.

- It is imperative to follow the installation rules related to fixing the chimney (any sagging is unacceptable);

- the traction indicator should be the same along the entire length of the communication. To achieve these goals, it is recommended to use pipes that have a round cross-section. This is due to the fact that round pipes have a high throughput;

- the cross-sectional indicator of the inlet determines the diameter of the entire communication;

- The installation of the smoke exhaust duct must be carried out in a vertical plane. The permissible deviation for vertical installation of this communication is 30° relative to the axis;

- laying a pipe through the wall (for connecting a heating device) is allowed to be carried out with a deviation of 90°;

- The smoke exhaust system must be equipped with an inspection window. This is necessary in order to protect gas processing equipment from condensation.

The chimney with outlet to the roof must be positioned strictly vertically

The choice of the required cross-section of the chimney pipe depends, as a rule, on the specific case and is carried out taking into account the power of the heating device. The most common pipe cross-sections used to remove combustion products are 110 mm and 130 mm.

Features of installing a chimney in an apartment and private house

The installation of a smoke exhaust duct in an apartment is directly related to the presence of a stationary duct for smoke removal. As a rule, such ducts run through the walls and form the ventilation system of a multi-story building. Installation of a heating system in an apartment requires a chimney supply from a gas water heater to such a channel. In the absence of stationary ventilation, it is recommended to install coaxial smoke exhaust.

There are other nuances of installing chimneys for a gas water heater in an apartment that are worth paying attention to:

- the communication design, which is necessary to remove combustion products, must comply with SNiP standards. The chimney should not have narrowings or be pinched, as this may cause smoke in residential premises ;

- smoke exhaust pipes must have a smooth inner surface that facilitates throughput;

- As a rule, the installation of a chimney in an apartment is carried out in a vertical plane;

- the permissible number of bends in vertical communications is no more than 3;

- the channel must be well sealed.

It is not recommended to use aluminum corrugated pipes for indoor installation of chimneys. This is due to the fact that such pipes fail very quickly (burn out). The most suitable option for an apartment is considered to be galvanized steel communications.

Installing a chimney in a private house is a more complex undertaking. First of all, it should be noted that exactly when this communication will be installed plays a big role. If the installation of a smoke exhaust duct will be carried out during the construction phase of the building, it is recommended to arrange a brick shaft in a vertical plane and place a galvanized steel pipe inside it.

Important! The heating system and the gas water heater must have different shafts to remove combustion products.

If a private house has already been built, a galvanized pipe for a geyser equipped with the necessary thermal insulation is best suited. There are two options for installing a smoke exhaust duct in a private house:

The chimney must be mounted so that, if necessary, it can be easily reached. And the end of the chimney structure must be located above the roof at a distance of at least 0.5 m. The main thing to remember is compliance with building codes and regulations when installing a chimney structure - the main requirement, following which you can avoid many troubles in the future.

Corrugated aluminum chimney

More details Aluminum corrugation for geyser. To remove burnt gas from a geyser into the ventilation shaft. Easy installation | Size | Wholesale | Retail price |

| Aluminum corrugation Ø110 | 320 | 340 rub. | |

| Aluminum corrugation Ø130 | 350 | 370 rub. |

Exhaust pipes are installed on the gas water heater in an apartment or house, and are designed to exhaust burnt gas into the ventilation shaft. The air duct pipes for the geyser are made of steel and covered with a high-quality protective coating of white heat-resistant enamel.

Enameled white air ducts of a geyser are highly safe, aesthetically pleasing and resistant to the destructive effects of hot gas and the resulting carbonic acid. White enamel applied to the chimneys of a geyser easily withstands elevated temperatures and protects the outside of the pipe from corrosion. White air ducts "Whitesteel" have the following advantages:

- Special sealed Z-shaped seam

- Easily cut to size with a hacksaw or grinder

- Chemical resistant - resistant to condensate and carbonic acid

- Covered with white heat-resistant enamel to match the color of the geyser

- Recommended for installation by the gas service of St. Petersburg

High strength steel 0.6mm, which reduces to zero the possibility of damaging the chimney of a geyser and ensures durability

High quality workmanship. Bends and other elements are made as compact as possible to look aesthetically pleasing in your kitchen or bathroom and take up as little space as possible. Elements are decoratively thought out and measured according to air resistance indicators

VentDom is a manufacturer of chimneys for geysers "Whitesteel" in St. Petersburg, carrying out retail and wholesale sales. In most apartments, modern enameled exhaust pipes are installed; they look beautiful and do not spoil the appearance of the room; they are much more reliable and safer than corrugated pipes. Modular chimney pipes for geysers are used to remove hot air from geysers.

White chimneys are recommended for installation on geysers of all manufacturers: Neva, Neva Lux, Electrolux, Bosch, Zanussi, Roda, Gorenje, Ariston, Termet, Baxi, EDISSON, Mora Top, Ladogaz, Elsotherm (tested for compatibility with each brand).

Structurally, chimneys are modular elements that are connected to each other in series, similar to a constructor. Due to the modular assembly principle, you can independently install the chimney of a gas water heater with your own hands while meeting the necessary safety requirements. During installation, the pipes are laid from the outlet of the column to the wall flange fixed to the opening of the common house ventilation shaft. Additional sealing of chimney seams is not required. To pass through or close to a suspended ceiling (film), a heat-insulating mineral wool cylinder is used, which is placed over the pipes.

Corrugated flexible chimneys are prohibited for installation on a gas water heater according to SNiP and are allowed for installation only on an exhaust hood. It is also prohibited to combine the hood from the stove and the gas water heater into one hole in the common shaft. According to the design, such houses have 2 separate shafts; the building manager or neighbors living on the same riser as you can help you find it. If the second shaft could not be found, the gas water heater is connected to the ventilation duct, and the hood starts in recirculation mode.

How to choose a pipe for a geyser?

One of the most common devices that can provide uninterrupted hot water supply to a home is a gas water heater. It does an excellent job of heating any volume of water in the shortest possible time. At the same time, modern modifications allow you to clearly set the required temperature and automatically turn on and off in accordance with the operating mode of the water point.

Gas-powered instantaneous water heaters are quite economical and safe to use. The only inconvenience is the need to organize high-quality removal of combustion products. This problem can be solved once and for all only with the help of proper installation of an exhaust pipe for a geyser. When choosing the parameters and configuration of the smoke exhaust system, you must be guided by the manufacturer’s instructions and current regulatory documents.

Regulatory requirements

According to the table of definitions NPB 252-98, the exhaust pipe for a gas water heater is the connecting pipe for the smoke exhaust pipe of the device and the smoke duct. Accordingly, it transports gas combustion products and must meet the requirements for chimneys. Failure to comply with them can lead to gas pollution in the room and carbon monoxide poisoning.

All requirements for chimneys are set out in the following regulatory documents:

- NPB 252–98;

- Rules for the production of pipe and furnace works VDPO;

- SP 42-101-2003, Appendix G

- SP 60.13330.2012, which is an updated version of SNiP 41-01-2003 (replacing SNiP 2.04.05–91).

The main provisions that directly relate to smoke removal from household gas water heaters boil down to the following points:

- The cross-sectional area of the exhaust pipe is taken to be no less than the cross-section of the outlet pipe of the unit;

- It is necessary to ensure complete tightness of the chimney, its resistance to corrosion and high temperatures up to 200 °C;

- Laying connecting pipes through living rooms is prohibited;

- The vertical section of the exhaust pipe at the outlet of the column must be 500 mm high, in some cases it can be reduced to 250 mm;

- Connecting pipes should be up to 3 m long in new buildings and up to 6 m in existing ones;

- It is allowed to use no more than 3 turns with a bend radius no less than the diameter;

- The exhaust pipe is installed at a distance from the ceiling or wall made of non-combustible materials of at least 5 cm, if they are combustible or difficult to burn, then at least 25 cm. The distance can be reduced to 10 cm by taking protective measures in accordance with SP 42-101-2003;

- If the connecting pipe for a gas water heater passes through an unheated room, then thermal insulation must be used;

- The exhaust pipe must be laid with a slope of 0.01 or more towards the appliance.

Important! Removal of combustion products is possible only through smoke ducts or specially installed chimneys; the use of ventilation ducts is strictly prohibited.

Smoke ducts are installed in walls made of non-combustible materials and are insulated, if necessary, to prevent condensation. If there are no suitable walls or the building in use does not have channels for removing combustion products, then install a top-type or root-type chimney.

Each fuel-burning device must have a separate smoke duct or pipe. In some cases, it is allowed to remove exhaust gases from the column and boiler into one chimney with an increase in the cross-section of the pipe. In this case, the combustion products must be introduced into the channel at different levels at a distance of at least 0.75 m or at the same level using a cut with a height of 0.75 m and a thickness of 0.12 m.

The chimney must be strictly vertical and have at the base a removable pipe or pocket 250 mm deep with a door for cleaning soot. If it is necessary to bypass existing obstacles, a deviation of up to 30° from the vertical is allowed, while the cross-sectional area is maintained, and the offset should not exceed 1 m.

Note: the round or rectangular hole under the entrance to the smoke channel is intended for cleaning soot and must always be accessible for maintenance. When doing general cleaning in the kitchen, do not forget to open the door and clean out soot, leaves and other debris.

The height of the chimney is a key factor in creating good draft. It is this that is decisive in the issue of high-quality removal of combustion products. The height of the chimney must be determined in accordance with the diagram given in SP 42-101-2003 (Appendix D).

If there are taller buildings or trees nearby, then it is necessary to additionally check the height of the wind pressure zone and, if necessary, increase the height of the chimney. In any case, the elevation above the adjacent part of the roof must be at least 50 cm, and with a combined (flat) roof - at least 200 cm.

Note: in rooms with hermetically sealed windows, the gas water heater may periodically turn off due to insufficient air flow. The automation stops the operation of the water heater to prevent reverse draft, which may occur due to rarefaction of air in the room. To eliminate the problem, it is enough to keep the kitchen window in micro-ventilation mode while the column is running.

Expert advice

Before purchasing the necessary materials for arranging an external chimney, the power of the equipment is determined. It affects the diameter of the pipes. You can also use these expert tips:

- if the heating equipment is equipped with forced draft, then it is not necessary to increase the vertical section of the structure; it is enough to remove the horizontal pipe;

- a horizontal section that is too long helps slow down the smoke flow (the value should not exceed 1-1.5 m);

Rules for installing chimney pipes Source krovgid.com

Inspection openings are installed not only on the outer part of the structure, but also on the internal horizontal element.

Selection of pipeline material

When going to purchase an exhaust pipe, you need to carefully study the installation conditions, know the model of the gas water heater, the diameter of the smoke exhaust pipe and the required lengths of the pipeline sections. It is advisable to stock up on a diagram of the location of the water heater indicating all the distances; this will help you better navigate when choosing the necessary elements and, if necessary, obtain specialist advice.

According to SP 60.13330.2012, connecting and chimney pipes must be made of non-combustible materials with an equivalent internal surface roughness of no more than 1.0 mm. In addition, they must be tight with tightness class B and prevent air leaks at the connections and in places adjacent to the smoke duct. The use of materials such as ceramics and stainless steel is recommended.

SP 42-101-2003 allows the use of roofing or galvanized steel with a thickness of 1 mm or more, flexible metal corrugated pipes and standardized elements supplied with the unit.

It is very important that the material of the exhaust pipe is resistant to corrosion, since condensation can destroy it quite quickly. The smoother the inner surface, the less soot will accumulate on it. The roughness of the outer surface is not standardized, but from the point of view of ease of cleaning, a smoother material for the connecting pipe will be more practical.

However, corrugated pipes are quite popular for connecting a gas water heater to a smoke duct. They are easy to work with and very convenient in tight spaces. Their use allows you to successfully avoid obstacles and carry out hidden installation, hiding equipment in cabinets and covering the pipeline with removable panels.

Galvanized steel 1 mm thick is an acceptable material, but there is an opinion that when heated strongly, galvanizing can release harmful substances. Accordingly, its use is undesirable for models with high flue gas temperatures.

Exhaust pipes made of steel coated with heat-resistant enamel have proven themselves quite well. White shiny pipes look quite nice in the kitchen and can fit into almost any interior.

The ideal material in terms of durability, aesthetics and compliance with all requirements is stainless steel. It is not at risk of corrosion, burnout, dust accumulation, or accidental damage. Quite naturally it turns out to be the most expensive.

Installation procedure

Installation of an exhaust pipe for a geyser made of any material begins with taking measurements and preparing all the necessary elements. In the case of corrugation, the work procedure is very simple. It is enough to take a pipeline of the required length, put it on the smoke exhaust pipe of the water heater and clamp it with a clamp. The free end is inserted into a decorative ring and fixed in the opening of the smoke channel. The main thing here is to ensure that the diameter of the corrugated pipe matches the size of the outlet hole of the column.

For all other materials, you need to prepare the required number of straight and rotary elements that will be inserted into each other, forming the desired chimney configuration according to the principle of a designer. Rotation angles are standard or made individually for specific sizes.

During assembly, ensure maximum tightness of connections. The entry of one element into another must be at least half the diameter. For better sealing, heat-resistant sealant is used. The joints are fastened with clamps and are located outside the ceilings and are freely accessible.

Due to the limitation on the number of permissible turns, the number of possible chimney configurations is quite limited. There are three main options depending on the location of the exhaust vent. Two more can be obtained by mirroring the previous ones.

All requirements and recommendations stated above apply to devices with an open combustion chamber. The standards also allow the removal of combustion products through an external wall without a vertical smoke duct from geysers with a closed combustion chamber and forced release of exhaust gases. In this case, installation is carried out according to the manufacturer's instructions in compliance with the standard distances and lengths of the coaxial chimney specified in SP 42-101-2003.

Why do you need a hood for a geyser, what are the requirements for it and how to calculate it correctly?

Hello, my dear interlocutor.

More than one and a half million people die from carbon monoxide poisoning every year. And in most cases this happens due to faulty geysers or poorly cleaned air ducts.

Do you know what is most dangerous? The gas in cookers is specially “flavoured”. Therefore, our sense of smell can sense a methane leak. With gas in the column, the story is a little different. With poor ventilation, combustion occurs with a lack of oxygen, resulting in the formation of dangerous carbon monoxide, after inhaling which a person loses consciousness and falls asleep. Unfortunately forever.

Therefore, a hood for a geyser is a must-have device. We’ll find out how it works and how to install it correctly from today’s article.

What is it and what is it for?

Geysers are devices where water flowing through pipes is heated with an open flame. When natural gas burns, toxic substances are formed that are dangerous to human life.

They must be removed from the room in which the equipment is located. To do this, a chimney pipe is installed that removes waste substances to the outside. In addition, due to the pressure difference, clean air is drawn into the firebox, necessary for continuous combustion.

Why does a gas water heater need a hood?

A geyser is a convenient device that allows you to provide residents of your home with hot water at any time of the year. Modern devices are equipped with temperature regulators, sensors for the operation of the water point and other convenient functions. But even the most modern unit will not protect against carbon monoxide if the chimneys in the house are not cleaned.

In addition, household gas is explosive, and if leaked, in a certain proportion with oxygen, it can provoke a disaster.

A hood will help solve the issue of removing combustion products and providing sufficiently high draft. It should be installed strictly in accordance with the requirements of regulatory documents.

The chimney of the column should not be confused with devices for other kitchen appliances that run on gas.

We will consider the advantages of built-in coal hoods for kitchen stoves in one of the following articles.

Make it yourself or order it

You should only take on making chimneys yourself if you have good knowledge of the theory in this industry, a set of professional tools and the ability to use them. The slightest miscalculation can lead to fatal consequences.

It is much easier and faster to order a finished product and entrust its installation to specialists. But, this service will cost much more than doing it yourself. It is worth carefully weighing your options before making a decision. Studying the regulatory documentation on this topic will help with this.

Requirements for chimneys for geysers (SNIP)

Requirements for chimneys are set out in the following documents:

- SNiP 41-01-2003 in a new edition (SP 60.13330.2012);

- NPB 252-98 (fire safety standards);

- SP 42-101-2003;

- VDPO (rules for the production of pipe and furnace works).

The main provisions regarding the direct removal of smoke from household water heaters are collected in the following paragraphs:

- The cross-sectional area of the chimney pipe must be greater than or equal to the cross-section of the outlet pipe of the column;

- Laying gas pipes through living rooms is prohibited;

- The chimney system must be completely sealed, resistant to corrosion and temperatures up to 200°C;

- The vertical section of the chimney at the outlet of the column should not be shorter than 500mm. Only in some cases this figure is reduced to 250mm;

- The length of connecting pipes should not be more than 3 m in designed houses and no more than 6 m in existing ones;

- The design allows for no more than 3 turns with a radius of at least the pipe diameter;

- If the wall of the building is made of non-combustible materials, the distance from it to the exhaust pipe must be at least 5 cm, if the wall material is flammable - at least 25 cm. If the fire protection requirements of SP 42-101-2003 are met, the distance can be reduced to 10 cm;

- If the connecting pipe passes through an unheated room, it must be protected with thermal insulation;

- The slope of the exhaust pipe towards the column must be more than 0.01;

- You cannot use one hood for a gas water heater and a gas stove;

- The ceiling height in the room with a water heater and chimney should not be less than 2 m. Area – at least 7.5 m for one device, at least 13.5 for 2 devices.

Video description

This video clearly shows an example of violation of the rules for installing a sandwich chimney:

- The position of the pipe is not observed. It is installed strictly vertically. When insulating main walls with foam plastic or mineral wool, long dowels are used to secure the chimney.

- There is no ebb on the side roof slope. In this case, precipitation can get on the insulation and impair its functions.

- Insufficient overall vertical height. This error leads to poor traction.

Problems arise when using low-quality insulating material. Cheap insulation shrinks over time, so there is a possibility of local overheating of some parts of the chimney.

Calculation of hood parameters

Before starting work on installing a chimney for a geyser in an apartment or private house, it is necessary to calculate the parameters of the exhaust channel. These parameters determine the required amount of air removed from the room.

When calculating, the following indicators should be taken into account:

- power of heating devices;

- volume of exhaust gases;

- difference in temperatures of outside air and combustion products;

- the height of the chimney pipe (for gas installations at least 2 m).

There are many types of pipelines for geysers, of different diameters, shapes, and lengths. Standard chimney diameters are 110-130 mm. For dispenser power up to 19 kW, a pipe with a diameter of 11 cm is used, above – 13 cm.

What kind of corrugation is used for chimneys

Combustion products in an apartment building are discharged into the ventilation duct, in a private apartment - to the street. Depending on where the gases are discharged, the pipes are divided as follows:

- Coaxial - the pipe exits through the wall or roof of the house to the street;

It is a structure of two pipes, the larger of which is put on the smaller one. Oxygen from the street is supplied to the fire through the free space between the pipes.

- Chimney - with connection to the ventilation duct.

Chimney pipes, in turn, can be smooth steel or corrugated.

- Smooth steel pipelines. Covered with white heat-resistant enamel or galvanized. Maximum length -1.5m. Made from sheet steel with a minimum thickness of 0.6mm. Due to temperature differences, condensation forms in the pipes and freezes in winter. Therefore, the structure must be carefully insulated.

- Flexible corrugated air ducts. Corrugated pipes are the best choice for removing waste gases from the column. They are convenient, reliable, and inexpensive. Due to their low weight and flexibility, they are easy to install.

The standard diameter of corrugated pipes is 11 and 13 cm. Maximum length – up to 3m. If you need to mount a longer section, the parts are connected with metallized tape. It can also be used when repairing corrugation.

When choosing a pipe for exhaust, it is necessary to take into account the temperature of the exhaust gases. Usually in the column it reaches 200-300°C, so the operating temperature of the corrugation should be at least 350°C.

Corrugated chimneys are made from stainless steel or aluminum.

In the case of gases venting through the wall, a special hole is prepared in it with an installed passage pipe, isolating the wall and the pipe from each other.

Let's look at the features of each material.

Stainless steel chimney:

- Withstands heating up to 900°C.

- Stainless steel is a durable and corrosion-resistant material;

- The corrugation bends in any direction and does not require additional fittings.

- The multilayer structure made of aluminum foil and reinforcing wire is not inferior in flexibility to stainless corrugation;

- The temperature of the exhaust gases should not exceed 400° C;

- Aluminum is lighter than stainless steel and has better stretchability;

- These products are inferior to their stainless steel counterparts in strength.

The use of aluminum pipes is not prohibited, but, as practice shows, inspectors in most cases require replacing aluminum with another material.

In any case, you should purchase only certified products.

Kinds

A coaxial chimney for a gas water heater is structurally composed of two pipes of different diameters, with a smaller diameter pipe (designed to remove combustion products) located inside a larger diameter pipe (designed to provide additional ventilation).

The enameled chimney for a geyser is made of high quality steel with a thickness of 0.6 mm and is coated with heat-resistant enamel to increase its strength characteristics. Additional insulation of the chimney system is required during winter use. Review of technical characteristics and elements of stainless steel chimneys here: https://mykaminz.ru/dymoxod/vidy/nerzhavejka/obzor-texnicheskixe-xarakteristik-i-elementov-dymoxodov-iz-nerzhaveyushhej-stali.html.

The corrugated chimney for a geyser is made of laminated multilayer aluminum foil, and between the layers of aluminum there is an additional reinforcing frame made of steel wire.

Chimneys for geysers made of stainless steel, as a rule, are double-circuit pipes, and mineral wool is used as an intermediate thermal insulation layer.

In the case of a chimney for a gas water heater through a wall, a special hole is prepared and a passage pipe is installed to isolate the chimney pipe from the wall of the house.

When installing a chimney for a gas water heater in an apartment, keep in mind that you cannot connect one chimney to both a gas stove and a gas water heater, since the chimney system may not be able to cope with the removal of a significant volume of flue gases.

When installing a chimney for a gas water heater in a private house, keep in mind that the vertical section of the pipe, from the smoke outlet of the gas water heater to the horizontal section of the pipe, must be at least half a meter. When installing a chimney system, no more than three turns are allowed, and the radius of curvature must be no less than the cross-section of the pipe. Read an overview of types of chimney dampers.

Average prices per set

The average cost of the kit primarily depends on the length of the chimney and the diameter of the selected pipe.

When purchasing, please note that aluminum corrugation stretches from the original length of 0.65cm to 3m. Stainless steel products have little stretch. Average cost of products:

- Aluminum - 200 rub/m;

- Stainless steel sleeve – 650 rub/m.

In addition, you should purchase special metal tape, sealants and the necessary fittings.

The average cost of a complete set made of aluminum is 500 rubles, from stainless steel - 1000 rubles.

How to install

The installation of gas equipment should be carried out by a specialist. If you decide to install the pipe yourself, be sure to read all the safety requirements.

- We accurately measure the distance required to install the chimney and apply markings to the wall;

- Purchases clamps for fastening, pipes, an adapter from the column, units for laying pipes through ceilings, a nozzle for covering the street chimney;

- We determine where the pipe will go - into the ventilation duct shaft, or to the street, and prepare the appropriate technological holes;

- We begin the installation of the lower part of the chimney - connect it to the column;

- We connect a pipe with a valve to increase traction;

- We fasten the remaining parts of the chimney with clamps installed every 1.6 m;

- All locations of passages through the floors and roof must be isolated with plugs to prevent fires;

- If the room does not have an exhaust duct inside the wall, it is recommended to use an attachment or root pipe for a gas water heater;

- If steel pipes are attached, it is necessary to provide L-shaped adapters for the ventilation duct and exhaust hood;

- All joints are connected using heat-resistant sealants;

Advice from a professional: To install a hood in a private house, it is better to use coaxial pipes or double sandwich pipes with insulation. In an apartment building, you should not install a chimney yourself at all.

Maintenance and cleaning

According to SNiP requirements, exhaust ducts must be inspected and serviced twice a year.

The following points are checked:

- clogging;

- soot thickness;

- integrity of the walls;

- state of traction.

If deviations from the norm are detected, the chimney is partially disassembled, cleaned, repaired or damaged areas are replaced.

Common mistakes

Errors when installing ventilation elements can lead to disruption of the proper operation of the structure and loss of operational safety. The most common are the following:

- Combination of hoods for a water heater and a gas stove, or for a gas boiler. In this case, reverse draft may occur in the ventilation shaft and carbon monoxide will return to the room;

- Do not connect two speakers to one chimney;

- The next mistake concerns the installation of a geyser - it is often placed in the bathroom, this cannot be done. All gas appliances must be installed in rooms with a window;

- Self-taught craftsmen often confuse the ventilation duct with the riser supplying water to the column. The consequences of such an error will be the replacement of all gas equipment, not only for you, but also for your neighbors below. Gas services remove liquid. They will turn off the gas and issue a hefty fine;

Installation work

Pros of a qualified installation:

- High-quality and safe smoke removal;

- Increasing the efficiency of equipment operation;

- Protection against accident and leakage.

- A section of pipe is being installed into the wall. After that, the structure is connected to the column and connected to a section of pipe for output to the street. All cracks and connections are sealed with sealant;

- A smoke exhaust duct is installed on the outer wall. All connections are secured with clamps;

- To ensure that the device is level and stable, it is additionally secured with spider fasteners at a distance of two meters. It is important that there are no deflections in the system;

- To prevent clogging of the system, a protective umbrella is placed on top;

- It is necessary to organize a window below to inspect the condition of the chimney.

As soon as the work is completed, it is necessary to check the traction force. To do this, you need to bring a burning match to the ventilation or chimney opening. If the flame deviates, it means there is draft.

Why doesn't the system stop working?

Problems that may appear in the operation of the chimney and why they appear:

- Burnout: poor installation, use of low quality materials;

- Soot fire: poor operation of equipment, failure to follow instructions;

- A considerable amount of condensate: insufficient insulation of the system.

In the organization and installation of gas equipment, everything must be clear. You can turn to professionals - now you know how to check their work.