Heating » Maintenance and faults

Published February 24, 2015 at 0:28 am

Any heating circuit operates at certain pressure and coolant temperature values, which are calculated at the design stage. However, during operation, situations are possible when the pressure drop in the heating system deviates from the standard level up or down and, as a rule, requires adjustment to ensure efficiency, and in some cases, safety.

Pressure drop in the heating system: functions, values,

What causes the pressure difference in water supply and heating systems? What is it for? How to regulate the difference? Due to what circumstances does the pressure drop in the heating system? In this article we will try to answer these questions.

First, let’s find out why the difference is created. Its main function is to ensure coolant circulation. Water will constantly move from a point with enormous pressure to a point where there is less pressure. The greater the difference, the greater the speed.

Useful: the limiting reason is the hydraulic resistance that increases with increasing flow velocity.

In addition, a difference is artificially created between the circulation connections of warm water supply into one thread (supply or return).

Circulation in this case performs two functions:

- Provides a consistently high temperature to heated towel rails , which in all modern buildings open one of the hot water supply risers connected in pairs.

- Guarantees a rapid flow of warm water to the mixer regardless of the time of day and water withdrawal through the riser. In dilapidated buildings without circulation connections, water has to be drained for a long time in the morning before it is heated.

Finally, the difference is created by modern water and heat consumption metering devices.

How and why? To answer this question, it is necessary to refer the reader to Bernoulli's law, according to which the static pressure of a flow is inversely proportional to the speed of its movement.

This gives us the opportunity to design a device that records water flow without the use of unreliable impellers:

- We pass the flow through the section transition.

- We record the pressure in the narrow part of the meter and in the main pipe.

Knowing the pressures and diameters, using electronics it is possible to calculate in real time the flow rate and speed of water flow; when using temperature sensors at the outlet and inlet of the heating circuit, it is easy to calculate the amount of heat remaining in the heating system. At the same time, based on the difference in flow rates on the supply and return pipelines, the consumption of warm water is calculated.

Deviations

Now let's look at the problems and their solutions.

Centralized water supply

- Who is to blame, and what to do if there is no pressure in the city water supply system?

This problem may be caused by:

- Insufficient productivity or insufficient pressure at the output of pumping stations installed without taking into account further development of the microdistrict;

The pumping station must cope with peaks in water consumption

- Malfunction of pumping stations;

Let us clarify: pressure booster pumps must be backed up in case one of them fails. However, installing a backup pump is only possible with sufficient funding, which often poses problems when there are large arrears for rent and utility bills.

- Overgrowing of steel and (to a lesser extent) cast iron main water pipelines with deposits and/or rust.

Over time, deposits reduce the clearance of steel pipes

None of these problems can be fixed by the homeowner himself. A simple instruction will help speed up the work of specialized organizations: every time you don’t have water during peak water consumption (usually in the morning and evening), call the emergency service and draw up a report indicating the current pressure in the cold water system at home.

- How to measure the current pressure on the cold water supply?

The water pressure gauge in the water supply system is usually located in the water meter unit.

Water meter with pressure gauge after the meter

If it is necessary to take measurements on the riser, a laboratory pressure gauge is screwed in instead of a plug or into the thread of the sump.

- What can you do yourself if there is no pressure in the water supply system of an apartment building?

Check that the valves on your cold water supply lines and riser are fully open. Visit the water meter and make sure that the valves or ball valves are not covered. If you have coarse filters on your liners, open them and wash the mesh.

A clogged filter can limit the flow of your water supply

Often the cause of a drop in pressure on the riser or supply line of the cold water supply system is debris accumulated in a narrow place in the water supply system - under the seat of the screw valve. To clean it, just unscrew the valve head (of course, after turning off the water) and remove scale, rust and sand with a screwdriver or any other suitable object.

Bottlenecks in an overgrown riser or bottling can be indicated by the characteristic hissing of water when drawing water. By cooperating with your neighbors, you can replace the riser from the bottling to the top floor, without waiting for the house to undergo major repairs.

Complete or partial replacement of risers will solve the problem of low pressure due to deposits in steel pipes

- How to reduce pressure in taps?

And in this case, it all depends on what kind of problem you want to solve:

- If you are concerned that water consumption increases as the pressure increases, teach family members not to open the taps completely or, if this is problematic, install needle throttles on the connections to each mixer to forcefully limit the flow rate;

1/2" Needle Throttle Valve

- If you are afraid that the water supply system itself may be damaged by high pressure, a pressure reduction will be provided by a reducer installed at the inlet;

Reducer at the water supply inlet

- If increased pressure is dangerous for individual plumbing fixtures, filters or household appliances, the same reducers are installed on their connections.

Piston gear design

Autonomous water supply

- How to ensure increased pressure in the water supply system of a private home?

It all depends on the symptoms of the problem you have:

- If you observe short-term drops in pressure during active water withdrawal through several taps, a capacious hydraulic accumulator connected to any point in the water supply will save the situation. Within the limits of its effective capacity, it compensates for the excess flow over the water flow rate. Do not forget to install a check valve at the water supply inlet, which will prevent water from the membrane tank from draining back into the water supply main;

In the photo - a hydraulic accumulator in the water supply system

- How to increase stable low pressure? This can only be achieved by installing a water storage tank and a pumping station. A container installed in a basement or other room with a year-round positive temperature creates a supply of water during peak consumption; a pumping station with a hydraulic accumulator provides acceptable pressure in the water supply.

How to create additional pressure? Supplying water with a pump from a storage tank

- How to reduce the pressure drop in the water supply system of a private house between the moments when the pump is turned on and off?

By adjusting the pressure switch for the water supply system - by reducing the pressure at which the pump turns off, or by increasing the threshold for turning it on. In the second case, do not forget to raise the pumping pressure of the hydraulic accumulator to the appropriate value. Please note that this will cause the pump to start more often, which will significantly reduce its service life.

Reliable and silent pressure switches for DAB water supply systems allow you to adjust the pump on and off pressure in the range of 10-90 meters

Creating a drop

How is pressure difference created?

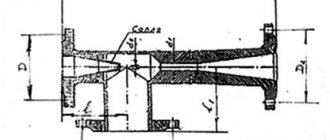

The main element of the heating system of an apartment building is the elevator unit. Its heart is the elevator itself - a nondescript cast-iron tube with three nozzles and flanges. Before explaining the principle of operation of the elevator, it is worth mentioning one of the troubles of central heating.

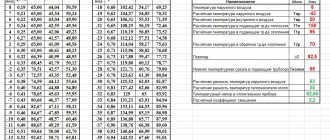

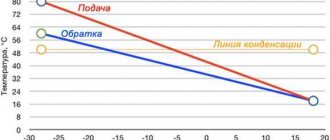

There is such a thing as a temperature graph - a table of the dependence of the temperatures of supply and return highways on weather conditions. Let's give a small excerpt from it.

Deviations from the schedule, large or small, are equally undesirable. In the first case, it will be cold in the apartments, in the second, energy costs at a thermal power plant or boiler house are rapidly growing.

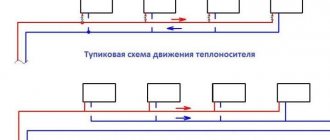

Along with this, as is easy to notice, the spread between the return pipeline and the supply is large. With circulation slow enough for such a temperature delta, the temperature of the heating devices will be unevenly distributed. Residents of apartments whose radiators are connected to the supply risers will suffer from the heat, and those with radiators on the return line will freeze.

The elevator supplies partial recirculation of the coolant from the return pipeline. Injecting a rapid stream of warm water through the nozzle, in full accordance with Bernoulli's law, it forms a rapid flow with low static pressure, which draws in an additional mass of water through the suction.

The temperature of the mixture is noticeably lower than that of the supply and slightly higher than that of the return pipeline. The circulation speed is high, and the temperature difference between the batteries is minimal.

Support washer

This simple device is a steel disk no less than a millimeter thick with a hole drilled in it. It is placed on the flange of the elevator unit between the circulation taps. Washers are placed on both the supply and return pipelines.

It is fundamentally important: for normal operation of the elevator unit, the diameter of the holes in the retaining washers must be larger than the diameter of the nozzle. In most cases, the difference is 1-2 millimeters.

Circulation pump

In autonomous heating systems, the pressure is created by one or several (according to the number of free circuits) circulation pumps. The most common devices - with a wet rotor - are a design with a non-specialized shaft for the rotor and impeller of the electric motor. The coolant performs the functions of lubricating and cooling the bearings.

What is the pressure difference between different parts of the heating system?

- Between the supply and return lines of the heating main, it forms approximately 20 - 30 meters, or 2 - 3 kgf/cm2.

Reference: excess pressure of one atmosphere raises the water column to a height of 10 meters.

- The difference between the mixture at the end of the elevator and the return pipeline is only 2 meters, or 0.2 kgf/cm2.

- The difference on the retaining washer between the circulation taps of the elevator unit rarely exceeds 1 meter.

- The pressure created by a circulation pump with a wet rotor in most cases varies from 2 to 6 meters (0.2 - 0.6 kgf/cm2).

Values

What is the pressure difference between different parts of the heating system?

- Between the supply and return lines of the heating main, it forms approximately 20 - 30 meters, or 2 - 3 kgf/cm2.

Reference: excess pressure of one atmosphere raises the water column to a height of 10 meters.

- The difference between the mixture at the end of the elevator and the return pipeline is only 2 meters, or 0.2 kgf/cm2.

- The difference on the retaining washer between the circulation taps of the elevator unit rarely exceeds 1 meter.

- The pressure created by a circulation pump with a wet rotor in most cases varies from 2 to 6 meters (0.2 - 0.6 kgf/cm2).

Adjustment

How to adjust the pressure in the elevator unit?

Support washer

To be correct, when using a retaining washer, it is not necessary to adjust the pressure, but to periodically replace the washer with a similar one due to abrasive wear of the narrow metal sheet in process water. How to replace the washer with your own hands?

The instructions are generally quite simple:

- All valves or valves in the elevator are closed.

- One vent on the return and supply is opened to drain the unit.

- The bolts on the flange are loosened.

- Instead of the old washer, a new one is installed, equipped with a pair of gaskets - one on each side.

Tip: in the absence of paronitis, washers are cut from a dilapidated car inner tube. Don't forget to cut an eyelet that will allow the washer to fit into the flange groove.

- The bolts are tightened in pairs, crosswise. Once the gaskets are pressed, the nuts are tightened until they stop, no more than half a turn at a time. If you rush, uneven compression will certainly lead to the gasket being torn off by pressure from one side of the flange.

Heating system

The difference between the mixture and the return flow is normally regulated only by replacing, welding or drilling out the nozzle. But from time to time it becomes necessary to remove the difference without stopping the heating (in most cases, with important deviations from the temperature schedule during the peak of cold weather).

This is done by adjusting the inlet valve on the return pipeline; Thus, we remove the difference between the forward and reverse threads and between the mixture and the return.

- We measure the supply pressure at the end of the inlet valve.

- Switch the hot water supply to the supply thread.

- We screw the pressure gauge into the vent on the return line.

- We completely close the input check valve and then slowly open it until the difference decreases from the initial one by 0.2 kgf/cm2. Manipulation with subsequent opening and closing of the valve is necessary so that its cheeks descend as much as possible on the stem. If the valve is closed, the cheeks may sag in the future; the price of ridiculous time savings is at least defrosted access heating.

- The return temperature is monitored at daily intervals. If it is necessary to lower it further, the difference is removed 0.2 atmospheres at a time.

How to deal with pressure changes

A drop or increase in pressure leads to a decrease or increase in the temperature in the room, which causes a deterioration in people’s well-being, changes in air humidity, and the appearance of fungus and mold.

There are the following methods for maintaining optimal operating parameters of the heating system:

- Detection and elimination of leaks. You can find them by visually inspecting the entire harness and batteries. Elimination is carried out independently by applying clamps or by specialists. If the breakthrough occurred inside the wall, then it is advisable to make a bypass channel so as not to spoil the finish.

- Blockages, scale and plaque are removed mechanically. The pipes are cleaned with a brush or a special liquid is poured into them. In apartments with autonomous heating, it is advisable to use water softening additives.

- Adjust the pressure in each radiator. For this purpose, pressure gauges and regulators are installed on them. This equalizes the pressure on each battery, regardless of the level at which it is installed.

How to raise blood pressure

There are several ways to do this. In some cases, professional help may be required.

This goal is achieved in the following ways:

- Installation of an auxiliary pump. This approach is chosen for a multi-storey private house. A unit with a minimum noise level is selected so as not to disturb the comfort of residents.

- Disabling unused heat exchangers. There are rooms in houses that are empty and do not need heating. If they are blocked, the pumping system will provide the required pressure for the remaining rooms.

- By setting the pressure separately for each radiator. This is how hot water is distributed depending on the needs of property owners.

In all cases, it is advisable to install air bleed valves on each riser.

Leak test

This event is carried out after the installation of the pipeline, its repair, modernization and before the start of each heating season. During a test run, a pressure is created in the system that is at least 1.5 times the calculated dynamic pressure.

Checking the tightness of the line is carried out in the following sequence:

- Visual inspection. The piping, batteries, fittings and boiler are inspected. Signs of a leak include streak marks and rust.

- Cold stage. Water is supplied, air is released, and the pressure rises to the minimum operating value. The system is maintained in this state for at least 30 minutes.

- Hot stage. This is done after connecting the pipeline to the boiler. Maximum pressure is created in the main line, the coolant is heated to the maximum value.

Leak testing must be carried out under constant supervision. If the event was successful, the system can be put into operation.

What pressure should be in a closed heating system

The operation of water heating networks is characterized by two main parameters - temperature and coolant flow. But there is a third value that often attracts the attention of residents of apartment buildings and private buildings - the pressure in the heating system. The main question is what it should be like for the normal functioning of all heating devices - radiators, heated floors, and so on. Since there is no clear answer, we decided to explain the essence of the problem within the framework of this publication.

Increased pressure

If the maximum pressure in the heating system is exceeded, the reason for this is slowing down or stopping the movement of water in the heating circuit. This can lead to:

- contamination of mud traps and filters;

- the occurrence of an air lock;

- replenishment of the coolant due to an automatic failure or incorrectly adjusted valves located on the supply and return (read: “Automatic recharge of the heating system - diagram of the assembly and recharge valve”);

- a feature of the regulator or its incorrect setting.

Unstable pressure is especially common in recently installed heating systems due to the removal of air. This is considered normal if, after bringing the water volume and pressure to operating levels, no deviations are observed for several weeks. Otherwise, most likely, pressure instability is associated with incorrect hydraulic calculations, including insufficient volume of the expansion tank. That is why, when installing a heating system, it is important to correctly perform all the calculations - in the future this will eliminate various problems with its functioning.

Introductory information on the topic

First of all, we propose to consider why excess pressure (above atmospheric pressure) is created in pipelines and how it is measured. Let's start from the end: the amount of water pressure in a closed heating system is usually displayed in the following units:

- 1 Bar = 10 m water column;

- 1 MPa equals 10 Bar or 100 m of water. Art.;

- 1 kgf/cm² – the same as 1 technical atmosphere (Atm.) = 0.98 Bar.

For reference. Kilogram-force per cm² is a measurement often used during Soviet times. At the moment, pressure is usually measured in more convenient metric units - MPa or Bar.

Simplified heating scheme for a 3-story mansion

Next, imagine a three-story cottage with a ceiling height of 3 m, which needs to be heated in winter. To do this, batteries are installed on both floors, connected to a common riser coming from the boiler, as shown in the diagram. The actual pressure in the resulting closed heating system will consist of three components:

- A column of water in a pipeline presses with a force equal to its height. In our example, this is 6 m or 0.6 Bar (0.06 MPa).

- The pressure created by the circulation pump. It forces the coolant to move at the required speed and overcome the resistance of three forces: gravity, friction of the liquid against the walls of the pipes and obstacles in the form of reinforcement and fittings (restrictions, tees, turns, etc.).

- Additional pressure arising from thermal expansion of the liquid. Practice shows that cold water with a temperature of 10 °C after heating to 100 °C adds about 5% of its original volume.

Note. The static pressure of the liquid column varies depending on the measurement location. When the pump is turned off, the pressure gauge at the bottom point of the system will show the maximum value - 0.6 Bar, and at the top - zero.

Thermal expansion of liquid

A very important point. In order to supply the required amount of heat to the premises, it is necessary to ensure the required water temperature and its flow rate - two main parameters for the operation of water heating. The resulting pressure is only a consequence of the system’s operation, and not the cause. Theoretically, it can be anything as long as the radiators and boiler installation can withstand it.

This gives rise to the concept of what operating pressure is in a heating system: this is the maximum permissible value specified in the technical documentation of the equipment - boiler or batteries. Regulatory documents require that in private homes it should not exceed 0.3 MPa, although some cheap units are not able to withstand even 0.2 MPa.

Optimal value for a private house or cottage

Any boiler operates at certain system settings, in particular, it is necessary to correctly calculate the water pressure. This value is influenced by the number of floors of the building, the type of system, the number of radiators and the total length of the pipes. Usually for a private house the pressure level is 1.5-2 atm, but for a five-story apartment building this value is 2-4 atm, and for a ten-story building it is 5-7 atm. For higher buildings, the pressure level is 7-10 atm, the maximum value is achieved in heating mains, here it is 12 atm.

For radiators that operate at different heights and at quite a decent distance from the boiler, constant pressure adjustment is required. In this case, special regulators are used to reduce it, and pumps to increase it. But the regulator must always be in good working order, otherwise sharp fluctuations and drops in coolant temperature will be observed in certain areas. The system must be adjusted so that the shut-off valves are never completely closed.

Why raise the pressure?

The pressure in the supply line is higher than in the return line. This difference characterizes the heating efficiency as follows:

- A small difference between the supply and return makes it clear that the coolant successfully overcomes all resistance and transfers the calculated amount of energy to the premises.

- An increased pressure drop indicates increased section resistance, decreased flow velocity and excessive cooling. That is, there is insufficient water flow and heat transfer to the rooms.

For reference. According to the standards, the optimal pressure difference in the supply and return pipelines should be in the range of 0.05–0.1 Bar, maximum 0.2 Bar. If the readings of 2 pressure gauges installed on the line differ more, then the system is not designed correctly or needs repair (flushing).

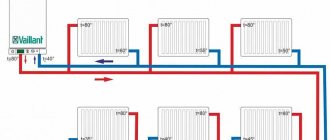

To avoid high drops on long heat supply branches with a large number of batteries equipped with thermostatic valves, an automatic flow regulator is installed at the beginning of the line, as shown in the diagram.

So, excess pressure in a closed heating network is created for the following reasons:

- to ensure forced movement of the coolant at the required speed and flow rate;

- to monitor the condition of the system using a pressure gauge and recharge or repair it in time;

- Coolant under pressure heats up faster, and in the event of emergency overheating, it boils at a higher temperature.

We are interested in the second item on the list - the pressure gauge readings as a characteristic of the serviceability and performance of the heating system. They are of interest to homeowners and apartment owners who independently maintain home communications and equipment.

Pressure in pipes of apartment buildings

From the contents of the previous sections, it becomes clear that the amount of heating in the central heating pipelines of high-rise buildings depends on the floor on which the apartment is located. The situation is as follows: if residents of the first two floors can roughly navigate using a pressure gauge installed in the basement heating unit, then the real pressure in the remaining dwellings remains unknown, since it drops with every meter of water rise.

Note. In new buildings with apartment-by-apartment heating distribution from a common riser, where floor-to-floor heating units are equipped, it is possible to control the coolant pressure at the entrance to each apartment.

Moreover, knowing the amount of pressure in a centralized network is of no practical use, since the owner cannot influence it. Although some people argue this way: if the pressure in the line has dropped, it means that less heat is supplied, which is a mistake. A simple example: turn off the return tap in the basement and you will see a jump in the pressure gauge needle, but the movement of water will stop and the supply of thermal energy will stop.

This is what the heating point looks like at the entrance

Now specifically about the numbers. The diameters of the heating supply networks and the power of the supply pumps from the boiler room are calculated so as to ensure the rise of the required amount of coolant up to the top floor. This means that at the entrance to a multi-storey building the working pressure in the heating system will be:

- in old five-story buildings, where cast iron radiators are still found to this day, no more than 7 bar;

- in nine-story Soviet-built buildings, the minimum value is 5 Bar, and the maximum depends on the proximity of the boiler room to the pumps, but not higher than 10 Bar;

- in high-rise buildings - no more than 15 bar.

Causes of pressure changes

There are several prerequisites for the occurrence of this phenomenon. Changes occur in highways installed in private houses and multi-storey buildings.

The reasons for the decrease and critical increase in pressure in the pipeline may be the following:

- Line blockage. Over time, limescale deposits form on its inner walls. Steel structures change their parameters due to corrosion. Often pieces of gaskets, debris and tow get into the pipeline.

- Pumping equipment malfunction. We are talking about a failure of automation or a sudden change in voltage in the network. The injection system may fail completely, which leads to a complete lack of pressure and cessation of coolant circulation.

- Leaks and breakthroughs. Water leaks, dynamic and static pressure decreases, the system, if not equipped with a check valve, loses coolant and fills with air.

As practice shows, deterioration in water circulation through the pipeline occurs due to a subjective factor.

In multi-storey buildings, some co-owners screw down the supply taps in order to save on utility bills.

Pressure indicators in a private home and the reasons for its drop

In closed heating systems of country houses and cottages, it is customary to withstand the following pressure values:

- immediately after filling the heating network with water and releasing air, the pressure gauge should show 1 Bar;

- after warming up to operating temperature, the minimum pressure in the pipes is 1.5 Bar;

- during operation in different modes, indicators can vary within 1.5-2 Bar.

Important point. It is not for nothing that we indicated what pressure should be provided with a cold heating system. The fact is that the vast majority of imported gas boilers equipped with modern automation are designed to start at a minimum pressure of 0.8-1 Bar and in its absence simply will not turn on.

How to properly remove air from heating lines and create the required pressure is described in a separate instruction. Here we will list the reasons why, after successful commissioning, pressure indicators may decrease, even to the point of automatic shutdown of the wall-mounted boiler:

- Residual air escapes from the pipeline network, heated floors and heating equipment ducts. Its place is taken by water, which is recorded by the pressure gauge falling to 1-1.3 Bar.

- Due to a leak in the spool, the air chamber of the expansion tank was emptied. The membrane is pulled in the opposite direction and the container is filled with water. After heating, the pressure in the system rises to a critical level, causing the coolant to be discharged through the safety valve and the pressure again drops to a minimum.

- The same thing, only after the expansion tank membrane breaks.

- Minor leaks at the joints of pipeline fittings, fittings or pipes themselves as a result of damage. An example is the heating circuits of underfloor heating, where leaks can remain unnoticed for a long time.

- The coil of the indirect heating boiler or buffer tank is leaking. Then pressure surges are observed depending on the operation of the water supply: the taps are open - the pressure gauge readings fall, closed - they rise (the water supply is pressed through a crack in the heat exchanger).

The master will tell you more about the causes of pressure drops and how to eliminate them in his video:

Pressure drop

If the pressure in the system drops, then most likely there is a coolant leak. The most vulnerable places are joints, seams and joints. To check, turn off the pump and observe changes in static pressure. If the pressure continues to decrease, you need to find the damaged area. For this purpose, experts recommend disconnecting different sections of the circuit, and after determining the location of the damage, replacing or repairing these elements.

If the pressure remains stable, a decrease in pressure may be due to a malfunction of the heating equipment or pump. A short-term drop in pressure sometimes occurs due to the operating characteristics of the regulator, which periodically releases part of the water from the supply to the return. If the radiators heat up to the required temperature, and evenly, then the pressure drop is due to the regulator. Also, reasons for low blood pressure may be:

- decrease in water temperature;

- removal of air through vents, due to which the volume in the coolant system decreases.

Operating pressure in the heating system

Working pressure is considered to be the pressure whose value ensures optimal operation of all heating equipment (including the heating source, pump, expansion tank). In this case, it is taken equal to the sum of pressures:

- static - created by a column of water in the system (in calculations the ratio is taken: 1 atmosphere (0.1 MPa) per 10 meters);

- dynamic - due to the operation of the circulation pump and the convective movement of the coolant when it is heated.

It is clear that in different heating schemes the operating pressure will differ. So, if natural circulation of the coolant is provided for heating the house (applicable for individual low-rise construction), its value will exceed the static value by only a small amount. In forced schemes, it is taken as maximum permissible to ensure higher efficiency.

It should be borne in mind that the operating pressure limits are determined by the characteristics of the heating system elements. For example, when using cast iron radiators, it should not exceed 0.6 MPa.

Numerically, the working pressure is:

- for one-story buildings with an open layout and natural circulation of water – 0.1 MPa (1 atmosphere) for every 10 m of liquid column;

- for low-rise buildings with a closed layout - 0.2-0.4 MPa;

- for multi-storey buildings - up to 1 MPa.

What does pressure in pipes affect?

Not everyone realizes how important it is to maintain the required pressure in the pipeline through which the coolant moves.

The pressure created in the system determines the following indicators:

- Room temperature. If the liquid moves slowly along the line, it does not enter the heat exchangers. In addition, before reaching the turning section of the circuit, it has time to cool down significantly.

- Presence of air pockets. If the pressure is insufficient, air bubbles form, preventing circulation. As a result, the flow of water throughout the riser stops.

- Pipeline integrity. With excessive pressure, gaskets rupture, threads on fittings break and batteries are destroyed. Watching the video will help you visualize the consequences of violating the heating technology of buildings and structures.

When the coolant flow rate decreases, energy consumption for heating increases, which leads to an increase in material costs.

Control of operating pressure in heating circuits

For normal, trouble-free operation of the heating system, it is necessary to regularly monitor the temperature and pressure of the coolant.

To check the latter, deformation pressure gauges with a Bourdon tube are usually used. To measure small pressures, their varieties can be used - diaphragm devices.

It must be remembered that after water hammer such models need to be verified, because they will show inflated values in subsequent control measurements.

Figure 1 – Strain gauge with Bourdon tube

In systems where automatic control and regulation of pressure are provided, various types of sensors are additionally used (for example, electric contact).

The placement of pressure gauges (insertion points) are determined by regulations: devices must be installed in the most important areas of the system:

- at the inlet and outlet of the heating source;

- before and after the pump, filters, mud traps, pressure regulators (if any);

- at the exit of the main line from the thermal power plant or boiler house and at its entry into the building (with a centralized scheme).

You should not neglect these recommendations even when designing a small heating circuit using a low-power boiler, because This not only ensures the safety of the system, but also its efficiency due to optimal water and fuel consumption.

Figure 2 – Section of the heating circuit with installed pressure gauges

To make it possible to zero, purge and replace devices without stopping the system, it is recommended to connect them through three-way valves.

Pressure drop and its importance for the functioning of the heating system

For optimal functioning of any heating circuit, a stable and defined pressure drop is required, i.e. the difference between its values at the coolant supply and return. As a rule, it should be 0.1-0.2 MPa.

If this indicator is less, this indicates a disruption in the movement of the coolant through the pipelines, as a result of which water passes through the radiators without heating them to the required degree.

If the difference exceeds the above value, we can talk about “stagnation” of the system, one of the reasons for which is airing.

Why are changes dangerous?

With low pressure, radiators on upper floors or distant rooms do not warm up well.

Low and high pressure lead to malfunctions in the entire heating system or breakdowns that require expensive repairs.

When the indicators are reduced, the automation (for modern models) stops the energy supply and the boiler turns off. If heating is stopped for a long time during the frosty season, the pipes, radiators, and boiler heat exchanger will be destroyed.

In addition, if the rate is low, the pressure may not be enough to effectively pump coolant throughout the system. The upper floors and radiators furthest from the riser pipes will remain without heat.

An important indicator for the operation of a warm water floor. The maximum length of the circuit reaches 100–120 m, which creates resistance to the movement of the coolant. If the pressure is insufficient, the circuit will stop heating.

With increased pressure, water begins to leak through the threaded connections of pipes and radiators. Possible destruction of structural parts.

Equal pressure in supply and return

#1 Equal pressure in supply and return

Post » 17 Jan 2013, 13:54

#2 Equal pressure in supply and return

Post » 17 Jan 2013, 16:52

#3 Equal pressure in supply and return

Post » 17 Jan 2013, 17:43

#4 Equal pressure in supply and return

Post » 18 Jan 2013, 08:59

#5 Equal pressure in supply and return

Message » 18 Jan 2013, 14:15

#6 Equal pressure in supply and return

Post » 18 Jan 2013, 14:21

#7 Equal pressure in supply and return

Post » Jan 18, 2013, 8:39 pm

there is also a pressure difference in Pascals! With a pressure gauge that measures millions of pascals, you won’t see the difference (Even though it’s definitely there!)

if you specifically wanted to do a mischief, then there are a lot of options, I’m at a loss

The pump will definitely not help you, don’t install it under any circumstances,

you need to remove the radiators, drain the risers for a short time, look at the inserts, maybe the plumbers forgot their gloves, or something else.