When does the heating season start?

According to the law, the launch time for the central system occurs in the fall, from October 1 to October 15. The specific date is determined by local governments and given an order by the RSO or CHP. An early start to the heating season is possible when it is less than +8°C outside for five days in a row. The management company has drawn up a schedule for connecting houses, which they put into action immediately after starting heating. First of all, socially significant facilities are connected: hospitals, schools, kindergartens. Then the valves are opened on the remaining residential buildings one by one.

Parameters for turning on the heating

Heating is supplied in accordance with the standards prescribed in Decree No. 354 of 2011.

It contains information that heat is supplied to apartment buildings at an air temperature outside the window of +8°C, which persists for 5 days. If there are changes in temperature, the radiators will remain cold.

Heat meters

Let us remember once again that the heat supply network of an apartment building is equipped with thermal energy metering units, which record both the gigacalories consumed and the cubic capacity of water passed through the intra-house line.

In order not to be surprised by bills containing unrealistic amounts for heat when the degrees in the apartment are below normal, before the start of the heating season, check with the management company whether the meter is in working condition and whether the verification schedule has been violated.

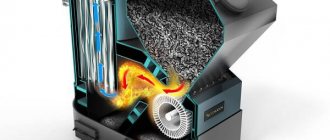

Many manufacturers of boiler equipment require that at the entrance to the boiler there be water at least a certain temperature, since cold return water has a bad effect on the boiler:

- boiler efficiency decreases,

- condensation on the heat exchanger increases, which leads to corrosion of the boiler,

- Due to the large temperature difference at the inlet and outlet of the heat exchanger, its metal expands differently - hence the stress and possible cracking of the boiler body.

The first method is ideal, but expensive.

Esbe

offers a ready-made module for mixing into the boiler return and controlling the loading of the heat accumulator (relevant for solid fuel boilers) - the LTC 100 device is an analogue of the popular Laddomat unit.

Phase 1. Beginning of the combustion process. The mixing device allows you to quickly increase the boiler temperature, thus starting water circulation only in the boiler circuit.

Phase 2: Start loading the storage tank. The thermostat, opening the connection from the storage tank, sets the temperature, which depends on the version of the product. High, guaranteed return temperature to the boiler, maintained through the entire combustion cycle

Phase 3: Storage tank during loading. Good control ensures efficient loading of the storage tank and correct stratification within it.

Phase 4: The storage tank is fully loaded. Even at the final stage of the combustion cycle, the high quality of regulation ensures good control of the return temperature to the boiler while simultaneously fully loading the storage tank

Phase 5: End of combustion process. By completely closing the top opening, the flow is directly directed into the storage tank, using the heat in the boiler

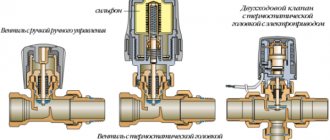

The second method is simpler, using a high quality three-way thermomixing valve.

For example valves from ESBE or VTC300. These valves vary depending on the power of the boiler used. VTC300 is used for boiler power up to 30 kW, VTC511 and VTC531 - for more powerful boilers from 30 to 150 kW

The valve is mounted on the bypass line between the boiler flow and return.

The built-in thermostat opens input “A” when the temperature at output “AB” is equal to the thermostat setting (50, 55, 60, 65, 70 or 75°C). Input “B” closes completely when the temperature at inlet “A” exceeds the nominal opening temperature by 10°C.

When the coolant temperature at the outlet of valve “AB” is less than 61°C, inlet “A” is closed, and hot water flows through inlet “B” from the boiler supply to the return. If the temperature of the coolant at the outlet “AB” exceeds 63°C, the bypass input “B” is closed and the coolant from the system return flows through inlet “A” into the boiler return. Bypass output “B” opens again when the temperature at outlet “AB” drops to 55°C

When a coolant with a temperature of less than 61°C passes through the “AB” outlet, the “A” input from the system return is closed, and the hot coolant from the bypass “B” is supplied to the “AB” output. When the temperature at the outlet “AB” reaches more than 63°C, inlet “A” opens and water from the return is mixed with water from bypass “B”. To equalize the bypass (so that the boiler does not constantly operate in a small circulation circle), a balancing valve must be installed in front of the “B” inlet on the bypass.

What is the difference between heating supply and return

Heating was invented to keep buildings warm and to ensure uniform heating of the room. At the same time, the design that provides heat should be convenient to operate and repair. A heating system is a set of parts and equipment used to heat a room. It consists:

- A source that creates heat.

- Pipe lines (supply and return).

- Heating elements.

Heat is distributed from the starting point of its creation to the heating block using a coolant. This could be: water, air, steam, antifreeze, etc. The most commonly used coolant fluids are water systems. They are practical, since all kinds of fuel are used to create heat, and they are also able to solve the problem of heating various buildings, because there are actually many heating schemes, varying in properties and cost. They also have high operational safety, productivity and optimal use of all equipment as a whole. But no matter how complex the heating systems may be, they are united by the same operating principle.

Briefly about return and flow in the heating system

The water heating system, using a supply from the boiler, supplies heated coolant to the radiators, which are located inside the building. This makes it possible to distribute heat throughout the house. Then the coolant, that is, water or antifreeze, having passed through all available radiators, loses its temperature and is supplied back for heating. The most simple heating structure consists of a heater, two lines, an expansion tank and a set of radiators. The conduit through which heated water from the heater moves to the batteries is called the supply. And the water conduit, which is located at the bottom of the radiators, where the water loses its original temperature and returns back, will be called return. Since water expands when heated, the system provides a special tank. It solves two problems: a supply of water to saturate the system; accepts excess water, which is obtained during expansion. Water, as a heat carrier, is directed from the boiler to the radiators and back. Its flow is ensured by a pump, or natural circulation.

Supply and return are present in one and two pipe heating systems. But in the first there is no clear distribution into the supply and return pipes, and the entire pipe line is conditionally divided in half. The column that leaves the boiler is called the supply, and the column that comes out from the last radiator is called the return. In a single-pipe line, heated water from the boiler flows sequentially from one battery to another, losing its temperature. Therefore, at the very end the batteries will be the coldest. This is the main and probably the only disadvantage of such a system.

But the single-pipe version will have more advantages: lower costs for purchasing materials are required compared to a 2-pipe; the diagram looks more attractive. It is easier to hide the pipe, and you can also lay pipes under doorways. The two-pipe system is more efficient - two fittings are installed in parallel into the system (supply and return).

This system is considered more optimal by experts. After all, its work revolves around supplying hot water through one pipe, and cooled water is discharged in the opposite direction through another pipe. In this case, the radiators are connected in parallel, which ensures uniform heating. Which of them establishes the approach must be individual, taking into account many different parameters.

There are only a few general tips to follow:

- The entire line must be completely filled with water; air is a hindrance; if the pipes are airy, the heating quality is poor.

- It is necessary to maintain a sufficiently high fluid circulation rate.

- The difference in supply and return temperatures should be about 30 degrees.

What is the difference between heating flow and return?

And so, let’s summarize the differences between supply and return in heating:

- Supply – coolant that flows through water pipes from a heat source. This could be an individual boiler or central heating of the house.

- Return water is water that, having passed through all the heating radiators, goes back to the heat source. Therefore, at the input of the system there is supply, and at the output there is return.

- It also differs in temperature. The feed is hotter than the return.

- Installation method. The water conduit that is attached to the top of the battery is the supply; the one that connects to the bottom is the return line.

Central heating

How does an elevator unit work?

At the elevator entrance there are valves that cut it off from the heating main. Along their flanges closest to the wall of the house, there is a division of areas of responsibility between homeowners and heat suppliers. The second pair of valves cuts off the elevator from the house.

The supply pipe is always at the top, the return pipe is always at the bottom. The heart of the elevator unit is the mixing unit, in which the nozzle is located. A stream of hotter water from the supply pipe flows into the water from the return pipe, drawing it into a repeated circulation cycle through the heating circuit.

By adjusting the diameter of the hole in the nozzle, you can change the temperature of the mixture entering the.

Strictly speaking, an elevator is not a room with pipes, but this unit. In it, supply water is mixed with return water.

What is the difference between the supply and return pipelines of the route?

In normal operation it is about 2-2.5 atmospheres. Typically, 6-7 kgf/cm2 enters the house on the supply side and 3.5-4.5 on the return side.

What is the difference in the heating system

The difference on the highway and the difference in the heating system are two completely different things. If the return pressure before and after the elevator does not differ, then instead of supply, a mixture is supplied to the house, the pressure of which exceeds the readings of the pressure gauge on the return by only 0.2-0.3 kgf/cm2. This corresponds to a height difference of 2-3 meters.

This difference is spent to overcome the hydraulic resistance of bottlings, risers and heating devices. Resistance is determined by the diameter of the channels through which water moves.

What diameter should be the risers, fillers and connections to radiators in an apartment building?

The exact values are determined by hydraulic calculation.

In most modern houses the following sections are used:

- Heating outlets are made from pipes DN50 - DN80.

- For risers, a pipe DN20 - DN25 is used.

- The connection to the radiator is made either equal to the diameter of the riser, or one step thinner.

The photo shows a more sensible solution. The diameter of the liner is not underestimated.

What to do if the return temperature is too low

In such cases:

- The nozzle is drilled out

. Its new diameter is agreed with the heat supplier. An increased diameter will not only raise the temperature of the mixture, it will also increase the drop. The circulation through the heating circuit will speed up. - In the event of a catastrophic lack of heat, the elevator is disassembled, the nozzle is removed, and the suction (pipe connecting the supply to the return) is turned off. The heating system receives water directly from the supply pipe. Temperature and pressure drop increase sharply.

What to do if the return temperature is too high

- The standard measure is to weld the nozzle and re-drill it, with a smaller diameter.

- When an urgent solution is needed without stopping the heating, the difference at the entrance to the elevator is reduced with the help of shut-off valves. This can be done with an inlet valve on the return line, controlling the process using a pressure gauge. This solution has three disadvantages:

- The pressure in the heating system will increase. After all, we limit the outflow of water; the lower pressure in the system will become closer to the supply pressure.

The wear of the cheeks and valve stem will accelerate sharply: they will be in a turbulent flow of hot water with suspensions.

- There is always the possibility of worn cheeks falling. If they completely shut off the water, the heating (primarily the access heating) will defrost within two to three hours.

Why do you need high pressure in the line?

Indeed, in private houses with autonomous heating systems, an excess pressure of only 1.5 atmospheres is used. And, of course, more pressure means much higher costs for stronger pipes and power supply for injection pumps.

The need for greater pressure is associated with the number of floors in apartment buildings. Yes, circulation requires a minimum drop; but the water needs to be raised to the level of the jumper between the risers. Each atmosphere of excess pressure corresponds to a water column of 10 meters.

Knowing the pressure in the line, it is not difficult to calculate the maximum height of a house that can be heated without the use of additional pumps. The calculation instructions are simple: 10 meters multiplied by the return pressure. A return pipeline pressure of 4.5 kgf/cm2 corresponds to a water column of 45 meters, which, with a height of one floor of 3 meters, will give us 15 floors.

By the way, hot water supply in apartment buildings is supplied from the same elevator - from the supply (at a water temperature of no higher than 90 C) or return. If there is a lack of pressure, the upper floors will remain without water.

Normative base

Ensuring optimal thermal conditions in a room is based on several regulatory documents. Here are the most important ones:

Attention! If you have any questions, you can chat for free with a lawyer at the bottom of the screen or call Moscow; Saint Petersburg; Free call for all of Russia

- Federal Law dated 07.12.11 No. 416-FZ in Art. 7 (Chapter No. 3) fixes the general provisions of the rules on the basis of which the thermal regime in buildings is regulated.

- Government Resolution No. 354, adopted on 05/06/11. The “Rules for the Provision of Utility Services” approved by him fix the standards for the supply of thermal energy to owners and users of residential real estate and premises in apartment buildings.

Attention Based on these documents, management companies are engaged in the acquisition of thermal energy and collecting fees from owners to pay for supplies. The provisions are disclosed in more detail in the agreement between the heat supplier and the management company, as well as in the internal instructions of the management company

However, they cannot contradict basic regulatory documents approved at the federal level.

Changes in heating design

Replacement of existing heating devices in an apartment is carried out with the obligatory approval of the management company. Unauthorized changes in the elements of warming radiation can disrupt the thermal and hydraulic balance of the structure.

When the heating season begins, changes in temperature conditions in other apartments and areas will be recorded. A technical inspection of the premises will reveal unauthorized changes in the types of heating devices, their quantity and size. The chain is inevitable: conflict - court - fine.

Therefore, the situation is resolved like this:

- if non-old ones are replaced with new radiators of the same size, then this is done without additional approvals; the only thing you need to contact the management company for is to turn off the riser during repairs;

- if new products differ significantly from those installed during construction, then it is useful to interact with the management company.

How is it calculated?

A control method is selected, then a calculation is made

The calculated winter and reverse order of water supply, the amount of outside air, and the order at the break point of the diagram are taken into account. There are two diagrams: one of them considers only heating, the second considers heating with hot water consumption

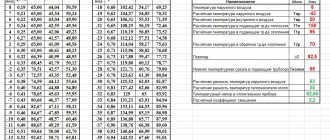

For an example of calculation, we will use the methodological development of Roskommunenergo.

The input data for the heat generating station will be:

- Tnv – the value of outside air.

- TV - indoor air.

- T1 – coolant from the source.

- T2 – reverse flow of water.

- T3 – entrance to the building.

We will look at several heat supply options with values of 150, 130 and 115 degrees.

At the same time, at the exit they will have 70°C.

The results obtained are compiled into a single table for subsequent construction of the curve:

So, we have three different schemes that can be used as a basis. It would be more correct to calculate the diagram individually for each system. Here we examined the recommended values, without taking into account the climatic features of the region and the characteristics of the building.

To reduce energy consumption, it is enough to select a low temperature setting of 70 degrees and uniform heat distribution throughout the heating circuit will be ensured. The boiler should be taken with a power reserve so that the system load does not affect the quality operation of the unit.

Consumer choice: cast iron or aluminum

The aesthetics of cast iron radiators is the talk of the town. They require periodic painting, since the rules require that the working surface have a smooth surface and allow dust and dirt to be easily removed.

A dirty coating forms on the rough inner surface of the sections, which reduces the heat transfer of the device. But the technical parameters of cast iron products are excellent:

- are slightly susceptible to water corrosion and can be used for more than 45 years;

- have high thermal power per section, therefore they are compact;

- are inert in heat transfer, so they smooth out temperature changes in the room well.

Another type of radiator is made of aluminum. Lightweight, factory-painted design, does not require painting, and is easy to maintain.

But there is a drawback that overshadows the advantages - corrosion in an aquatic environment. Of course, the inner surface of the heater is insulated with plastic to avoid contact of aluminum with water. But the film may be damaged, then a chemical reaction will begin with the release of hydrogen, and when excess gas pressure is created, the aluminum device may burst.

The temperature standards for heating radiators are subject to the same rules as batteries: it is not so much the heating of a metal object that is important, but the heating of the air in the room.

In order for the air to warm up well, there must be sufficient heat removal from the working surface of the heating structure. Therefore, it is strictly not recommended to increase the aesthetics of the room with shields in front of the heating device.

Hot water priority

In the hot water priority mode, we observe a clear sequence of actions and cyclic switching on for heating. If you want to turn on one of the hot water taps, the boiler will forget about heating and begin to heat the water. This is called hot water priority.

The heating works around the clock, the boiler knows when to turn on and off, maintaining the required temperature in the house. The need for hot water is much less frequent than the need to heat a house. When you turn on the water, the house is “already warm,” but the water is “still hot.” Therefore, priority for heating hot water is higher than for heating.

In most modern gas boilers, the water temperature can be adjusted separately in the range from 35 ºC to 55 ºC. The procedure is similar to the heating procedure. Set the appropriate temperature and use hot water.

Parameters of distributing elements

One of the details of warming a home is the riser through which the coolant enters the battery or radiator from the Coolant temperature standards in the heating system require heating in the riser in winter in the range of 70-90 °C. In fact, the degrees depend on the output parameters of the thermal power plant or boiler house. In the summer, when hot water is needed only for washing and showering, the range moves to 40-60 °C.

Observant people may notice that the heating elements in the neighboring apartment are hotter or colder than in his own.

The reason for the temperature difference in the heating riser lies in the method of hot water distribution.

In a single-pipe design, the coolant can be distributed:

- above; then the temperature on the upper floors is higher than on the lower ones;

- from below, then the picture changes to the opposite - it is hotter from below.

In a two-pipe system, the degree is the same throughout, theoretically 90 °C in the forward direction and 70 °C in the reverse direction.

Heating pipe temperature table

The heating temperature, including return pipes, directly depends on the readings of street thermometers. The colder the air outside and the higher the wind speed, the higher the cost of heat.

A standard table has been developed that reflects the temperature values at the inlet, supply and outlet of the coolant in the heating system. The indicators presented in the table provide comfortable conditions for a person in a living space:

| Pace. external, °С | +8 | +5 | +1 | -1 | -2 | -5 | -10 | -15 | -20 | -25 | -30 | -35 | |

| Pace. at the entrance | 42 | 47 | 53 | 55 | 56 | 58 | 62 | 69 | 76 | 83 | 90 | 97 | 104 |

| Pace. radiators | 40 | 44 | 50 | 51 | 52 | 54 | 57 | 64 | 70 | 76 | 82 | 88 | 94 |

| Pace. return lines | 34 | 37 | 41 | 42 | 43 | 44 | 46 | 50 | 54 | 58 | 62 | 67 | 69 |

Important! the difference between the supply and return temperatures depends on the direction of movement of the coolant. If the wiring is from above, the differences are no more than 20°C, if from below - 30°C

Minimum temperatures

First, you should pay attention to this point: there is not a single document that would determine the standards for heating batteries. There are documents that regulate the temperature of the coolant and the temperature in the apartment

Why is this so? This can be explained by the different thermal conductivity of the materials used to produce heating batteries, as well as the design features of different models.

Cast iron, steel, copper and aluminum (they are most often used to make radiators) have different thermal conductivities. This means that batteries made from these materials heat up and release heat differently. That is, provided that the coolant temperature at the inlet is 100 °C, the cast iron radiator will not heat up to such a temperature. A copper device can (among the above 4 materials, copper conducts heat the best).

It would be possible to set heating standards for radiators for a specific type of material. However, the situation is complicated by manufacturers who use various tricks when developing radiator shapes. as well as improving the heat transfer of an individual product. Therefore, it is very difficult to develop universal temperature standards for water batteries.

It is also worth adding that batteries with 5 and 11 sections heated to the same temperature create different heat flows. Therefore, the room will warm up differently. Of course, this is said to understand the idea. In practice, when planning a water heating system, the optimal dimensions and required power of the heating battery for each room are always calculated. Therefore, if the entire heating system operates correctly, the battery, which has a sensor and thermostat, will give off the required amount of heat.

From the above it follows that it is best to measure the temperature of the coolant and check whether the resulting indicator corresponds to the norm. This can be done in different ways. Some of them include measuring the temperature of the radiator, and using correction values depending on the material used to make the heating device.

The minimum temperature of the coolant is +30 °C (this is according to the Decree of the State Construction Committee dated September 27, 2003 No. 170). Such water must circulate through a system in which the coolant moves in a “bottom-down” pattern when the outside temperature is +10 °C.

If it is 0 °C outside the window, go to radiators with a sensor. as well as a device for adjusting the heating, water must flow no colder than +57 ° C. It is clear that the battery can heat up almost to this temperature. The above-mentioned document has a whole table that indicates the normal temperature of the coolant at the inlet and outlet depending on the weather and the method of supplying heated water.

With forced circulation

This system is divided into two types:

The difference between them is quite big. The layout of the pipes, their number, and the sets of shut-off, control and control valves differ.

According to SNiP 41-01-2003 (“Heating, ventilation and air conditioning”), the maximum coolant temperature in these heating systems is:

- two-pipe heating system - up to 95°C;

- single-pipe - up to 115°C;

The optimal temperature is from 85°C to 90°C (due to the fact that at 100°C, water already boils. When this value is reached, special measures must be used to stop boiling).

The amount of heat emitted by the radiator depends on the installation location and the method of connecting the pipes. Thermal output can be reduced by 32% due to poor pipe placement.

The best option is a diagonal connection, when hot water comes from the top and return flow from the bottom of the opposite side. This is how radiators are tested during testing.

The worst thing is when hot water comes from below, and cold water comes from above on the same side.

Heating standards for apartment buildings heated centrally

These norms are the most “ancient”.

They were calculated at a time when they did not save on fuel for heating the coolant, the batteries were hot. But houses were built mainly from materials that were “cold” in terms of heat-saving qualities, that is, from concrete panels. Times have changed, but the norms remain the same. According to the current GOST R 52617-2000, the air temperature in residential premises should not be lower than 18°C (for corner rooms - at least 20°C). At the same time, the organization that supplies thermal energy has the right to reduce the air temperature at night (0-5 hours) by no more than 3°C. Heating standards are set separately for different rooms of the apartment: for example, in the bathroom it should be at least 25°C, and in the corridor - at least 16°C.

Society has been fighting for a long time, and at times not unsuccessfully, to change the procedure for determining heating standards, tying them not to the air temperature in the premises, but to the average temperature of the coolant. This indicator is much more objective for consumers, although it is unprofitable for the heat energy supplier. Judge for yourself: the temperature in residential premises often depends not only on the operating system, but on the nature of a person’s life activity and living conditions.

For example, the thermal conductivity of brick is much lower than that of concrete, so in a brick house at the same temperature you will have to spend less thermal energy. In rooms such as the kitchen, the process of cooking food does not generate much less heat than from radiators.

Much also depends on the design features of the heating devices themselves. For example, panel heating systems will have a higher heat transfer rate than cast iron radiators at the same air temperature. Thus, heating standards tied to air temperature are not entirely fair. This method takes into account the outside air temperature below 8°C. If such a value is recorded for three days in a row, the heat generating organization must unconditionally supply heat to consumers.

For the middle zone, the calculated values of the coolant temperature depending on the external air temperature have the following values (for the convenience of using these values using household thermometers, temperature indicators are rounded):

Outside air temperature, °C

Temperature of network water in the supply pipeline, °C

Using the table above, you can easily determine the water temperature in a panel heating system (or any other) by using a regular thermometer at the time of draining part of the coolant from the system. For the forward branch, use the data in columns 5 and 6, and for the return branch, use the data in column 7. Note that the first three columns establish the release temperature of the water, that is, without taking into account losses in the transmission main pipelines.

If the actual coolant temperature does not correspond to the standard temperature, this is the basis for a proportional reduction in the payment for the central heating services provided.

There is also an option to install heat meters, but it only works when all apartments in the building are served by a centralized heating system. In addition, such meters are subject to annual mandatory inspection.

Parameter control methods

System regulation Heating can be adjusted. Methods:

- quantitative;

The parameters are changed by increasing or decreasing the amount of coolant supplied. Pumps increase the pressure in the system, valves reduce the speed of the carrier.

- qualitative;

With quality, the parameters of the coolant change, additives are added that change the characteristic indicators.

- mixed.

Uses both methods.

Method for reducing heat loss

The first, main condition for reducing heat loss is good thermal insulation.

The system needs to be optimized. Adjust a comfortable temperature inside living rooms, follow the recommendations for temperature conditions in utility and non-residential premises.

Comfort in home

Staircase heating

Since we are talking about an apartment building, we should mention the staircases. The coolant temperature standards in the heating system state: the degree measure at the sites should not fall below 12 °C.

Of course, the discipline of residents requires closing the entrance doors tightly, not leaving the transoms of the staircase windows open, keeping the glass intact and promptly reporting any problems to the management company. If the management company does not take timely measures to insulate points of probable heat loss and maintain temperature conditions in the house, an application for recalculation of the cost of services will help.

Good values in a personal heating system

Individual heating helps to avoid most of the problems that arise with a centralized network, and the comfortable temperature of the coolant can change according to the season. In the case of autonomous heating, the concept of norms includes the heat output of the heating device per unit area of the room where the device is located. The heat regime in this situation is ensured by the design characteristics of the radiators.

The main thing is to ensure that the coolant in the network does not cool below 70 °C. A value of 80 °C is considered good. With a gas water heater, it is easier to control heating, since manufacturers limit the possibility of heating the coolant to 90 °C. By using sensors to regulate the gas supply, the heating of the coolant can be adjusted.

It is a little more difficult with solid fuel devices; they do not regulate the heating of the liquid, and can easily turn it into steam. And in such a situation it is unrealistic to reduce the heat from coal or wood by turning the knob. Control of heating of the coolant is quite relative with high errors and is done using rotary thermostats and mechanical dampers.

Coordination of coolant and boiler temperatures

Regulators help set the temperature of the coolant and boiler. These are devices that form automated control and adjustment of supply and return temperatures.

The return temperature depends on the amount of liquid passing through it. Regulators cover the liquid supply and increase the difference between supply and return to the level that is necessary, and the necessary indicators are placed on the meter.

If it is necessary to expand the flow, an increase pump can be added to the network, which is controlled by a regulator. To reduce the heating of the supply, a “cold start” is used: that part of the liquid that has passed through the network is again transported from the return to the inlet.

The regulator redistributes the supply and return flows based on the data collected by the meter, and ensures the strict temperature standards of the heating network.

Return in the heating system - its purpose

The return in the heating system is the coolant that has passed through all the heating radiators, lost its primary temperature and is now cold and supplied to the boiler for the next heating. The coolant can move in both a two-pipe and an improved single-pipe heating system.

A single-pipe heating system implies a sequence of connections of heating radiators. That is, the supply pipe is connected to the first radiator, from which the next pipe goes to the second radiator, and so on.

If a one-pipe heating system is improved, its design will be something like this: along the perimeter of the entire room there is one pipe into which the supply and return pipes of each radiator can be inserted. In this case, it is possible to install a control valve on each battery, with which you can very successfully regulate the air temperature in a given room.

The big advantage of such a heating system is the minimal number of pipes in it. And the minus is the temperature difference between the first radiator from the boiler and the last. This problem can be eliminated with the help of a circulation pump, which will move all the water through the heating system much faster, and thus the coolant will not have time to reduce the temperature.

A two-pipe heating system consists of two pipes. One pipe is the supply of hot coolant, the second pipe is the return pipe in the heating system, through which already cooled water from the radiators enters the boiler. This system allows you to connect all radiators almost in parallel, which allows for flexible configuration of each radiator individually without affecting the operation of the others.

Consequences of cold return

Circuit for heating return

Sometimes, with an incorrectly designed design, the return flow in the heating system is cold. As practice shows, the fact that the room does not receive enough heat with a cold return is half the trouble. The fact is that at different supply and return temperatures, condensation may form on the walls of the boiler, which, when interacting with carbon dioxide released during fuel combustion, forms acid. It can also damage the boiler much ahead of time.

To avoid this, it is necessary to carefully consider the design of the heating system; special attention must be paid to such a nuance as the return temperature in the heating system. Or include additional devices in the system, for example, a circulation pump or boiler, which will compensate for the loss of warm water

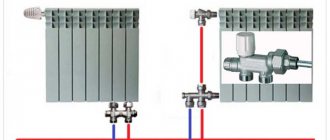

Radiator connection options

Now we can more than confidently say that when designing a heating system, the supply and return must be perfectly thought out and configured. If the heating system is not designed correctly, more than 50% of the heat can be lost.

There are three options for inserting a radiator into the heating system:

The diagonal system gives the highest efficiency coefficient, and is therefore more practical and efficient.

The diagram shows a diagonal inset

How to regulate the temperature in the heating system?

In order to regulate the temperature of the radiator and reduce the difference between the supply and return temperatures, you can use a heating system temperature controller.

When installing this device, do not forget about the jumper, which must be located in front of the heating device. If it is absent, you will regulate the temperature of the batteries not only in your room, but throughout the riser. It is unlikely that the neighbors will be happy with such actions.

The simplest and cheapest option for a regulator is to install three valves: on the supply, on the return and on the jumper. If you cover the valves on the radiator, the jumper must be open.

There is a huge abundance of different thermostats that can be used in apartment and private buildings. Among the wide variety, each consumer can choose a regulator that will suit him in terms of physical parameters and, of course, cost.

How to make radiators hot, looking for solutions

If you find that the return is too cold, you should take a number of steps to find the causes and troubleshoot problems. First of all, you need to check that the connection is correct. If the connection is not made correctly, the down pipe will be hot when it should be slightly warm. The pipes should be connected according to the diagram.

To avoid air pockets that impede the flow of coolant, it is necessary to provide for the installation of a Mayevsky valve or bleeder for air removal. Before bleeding the air, you need to turn off the supply, open the tap and let out the air. Then the tap is turned off and the heating valves open.

Often the cause of cold return is the control valve: the cross-section is narrowed. In this case, the tap must be dismantled and the cross-section increased using a special tool. But it is better to buy a new faucet and replace it.

The reason may be clogged pipes. You need to check them for passability, remove dirt and deposits, and clean them well. If passability cannot be restored, the clogged areas should be replaced with new ones.

If the coolant flow rate is insufficient, you need to check whether there is a circulation pump and whether it meets the power requirements. If it is missing, it is advisable to install it, and if there is a lack of power, replace or upgrade it.

Knowing the reasons why heating may not work efficiently, you can independently identify and eliminate malfunctions. Comfort in the house during the cold season depends on the quality of heating. If you carry out the installation work yourself, you can save on hiring third-party labor.

When autumn confidently strides across the country, snow is flying above the Arctic Circle, and in the Urals night temperatures stay below 8 degrees, then the word form “heating season” sounds appropriate. People remember past winters and try to understand the normal temperature of the coolant in the heating system.

Prudent owners of individual buildings carefully inspect the valves and nozzles of boilers. By October 1, residents of an apartment building are waiting like Santa Claus for a plumber from the management company. The Lord of valves and valves brings warmth, and with it joy, fun and confidence in the future.

Heating battery return is cold - device, causes, solutions

Heating systems differ in the way pipes are laid. They can be laid in one-pipe or two-pipe ways. The most popular is the single-pipe wiring diagram. Most often it is installed in multi-storey buildings. It has the following advantages:

Cold return is a serious problem that must be eliminated. It entails many unpleasant consequences: the temperature in the room does not reach the desired level, the efficiency of radiators decreases, and there is no way to correct the situation with additional devices. As a result, the heating system does not work as it should.

Theory of linguistics

The name “battery” is a common one, meaning a number of identical objects. In relation to home heating, this is a series of heating sections.

Temperature standards for heating radiators allow heating no higher than 90 °C. According to the rules, parts heated above 75 °C are protected. This does not mean that they need to be covered with plywood or bricked. Usually a lattice fence is installed that does not impede air circulation.

Cast iron, aluminum and bimetallic devices are common.

Optimal values in an individual heating system

Autonomous heating helps to avoid many problems that arise with a centralized network, and the optimal temperature of the coolant can be adjusted according to the season.

In the case of individual heating, the concept of standards includes the heat transfer of a heating device per unit area of the room where this device is located. The thermal regime in this situation is ensured by the design features of the heating devices. It is important to ensure that the coolant in the network does not cool below 70 °C. 80 °C is considered optimal

With a gas boiler, it is easier to control heating, because manufacturers limit the ability to heat the coolant to 90 °C. Using sensors to regulate the gas supply, the heating of the coolant can be adjusted.

It is a little more difficult with solid fuel devices; they do not regulate the heating of the liquid, and can easily turn it into steam. And it is impossible to reduce the heat from coal or wood by turning the knob in such a situation. Control of heating of the coolant is quite conditional with high errors and is carried out by rotary thermostats and mechanical dampers.

Electric boilers allow you to smoothly regulate the heating of the coolant from 30 to 90 °C. They are equipped with an excellent overheat protection system.

The Gigacalorie Path

Megacities sparkle with high-rise buildings. A cloud of renovation hangs over the capital. The outback prays to five-story buildings. Until demolished, the house operates a calorie supply system.

Heating of an economy class apartment building is carried out through a centralized heat supply system. The pipes enter the basement of the building. The supply of coolant is regulated by inlet valves, after which the water enters the mud traps, and from there it is distributed through the risers, and from them it is supplied to the radiators and radiators that heat the home.

The number of valves correlates with the number of risers. When performing repair work in a single apartment, it is possible to turn off one vertical line, rather than the entire house.

The waste liquid is partially discharged through the return pipe, and partially supplied to the hot water supply network.

Calculation of the optimal temperature of the heating device

The most important thing is that the most comfortable temperature for human existence is +37°C. When choosing a radiator, you need to calculate whether the thermal power of the device is enough to heat the room

There is a special formula for this:

When choosing a radiator, you need to calculate whether the thermal power of the device is enough to heat the room. There is a special formula for this:

S*h*41:42,

- where S is the area of the room;

- h – room height;

- 41 – minimum power per 1 cubic m S;

- 42 – nominal thermal conductivity of one section according to the passport.

When you use a radiator to maintain the desired temperature in a room, you have two options: you can use small radiators and increase the water temperature in them (high temperature heating) or install a large radiator, but the surface temperature will not be as high (low temperature heating) .

With high temperature heating, radiators are very hot and can cause burns if you touch them. In addition, at a high temperature of the radiator, the decomposition of dust settled on it may begin, which will then be inhaled by people.

When using low temperature heating, the appliances are slightly warm, but the room is still warm. In addition, this method is more economical and safe.

Cast iron radiators

The average heat output of a separate section of a radiator made of this material ranges from 130 to 170 W, due to the thick walls and large mass of the device. Therefore, it takes a lot of time to warm up the room. Although this also has the opposite advantage - high inertia ensures long-term retention of heat in the radiator after the boiler is turned off.

Calculation of heating operating temperature conditions

When calculating heat supply, it is necessary to take into account the properties of all components. This is especially true for radiators. What is the optimal temperature for heating radiators - +70°C or +95°C? It all depends on the thermal calculation, which is performed at the design stage.

An example of drawing up a heating temperature schedule

First, it is necessary to determine the heat losses in the building. Based on the data obtained, a boiler with the appropriate power is selected. Then comes the most difficult design stage - determining the parameters of the heat supply batteries.

They must have a certain level of heat transfer, which will affect the temperature chart of the water in the heating system. Manufacturers indicate this parameter, but only for a certain operating mode of the system.

If to maintain a comfortable level of air heating in a room you need to spend 2 kW of thermal energy, then the radiators must have a no less heat transfer rate.

To determine this, you need to know the following quantities:

- The maximum permissible water temperature in the heating system is t1. It depends on the power of the boiler, the temperature limit on the pipes (especially polymer ones);

- The optimal temperature that should be in the heating return pipes is t This is determined by the type of pipeline layout (one-pipe or two-pipe) and the total length of the system;

- The required degree of heating of the air in the room is t.

Having these data, you can calculate the temperature difference of the battery using the following formula:

Next, to determine the power of the radiator, use the following formula:

Where k is the heat transfer coefficient of the heating device. This parameter must be indicated in the passport; F – radiator area; Tnap – thermal pressure.

By varying various indicators of the maximum and minimum water temperatures in the heating system, you can determine the optimal operating mode of the system

It is important to correctly initially calculate the required power of the heating device. Most often, the low temperature indicator in heating radiators is associated with heating design errors

Experts recommend adding a small margin to the obtained radiator power value - about 5%. This will be needed if the outside temperature drops critically in winter.

Most manufacturers indicate the heat output of radiators according to accepted standards EN 442 for mode 75/65/20. This corresponds to the normal heating temperature in the apartment.

What does temperature depend on?

There are several other factors that influence indoor temperature:

- If the air temperature outside is low, it will be lower indoors;

- Wind speed also has an impact on temperature. The stronger the wind loads, the greater the heat loss will be through windows and entrance doors;

- Tightness of sealing joints in the walls of the house. For example, metal-plastic windows and insulation of facade walls can significantly affect the temperature inside the home.

Everything described above is undoubtedly important. But the main factor that greatly influences the temperature in the rooms is the temperature of the heating radiators themselves.

Typically, heating batteries powered from a central system have a temperature of 70 - 90°C.

It is known that the required temperature inside the room cannot be achieved by this factor alone, taking into account the fact that different rooms should have different temperature conditions due to their different purposes.

The temperature inside the room is also influenced by how intense the movement of people inside it is. Temperatures will be higher where people move the least.

This is the basis of heat distribution. As evidence, in sports facilities where people are constantly moving, the temperature is maintained at 18°C, since maintaining a higher temperature is not advisable.

Factors influencing the temperature of radiators:

It is naturally clear to everyone that, regardless of whether it is a convector or a radiator, heat transfer will directly depend on the temperature outside. At zero street temperature, the heat transfer rate of radiators should vary within 40-45 °C supply and 30-35 °C return. For convectors, these characteristics are as follows: 41-49 °C supply and 36-40 °C return.

When the thermometer drops to -20 °C, these characteristics will be as follows: for radiators - supply 67-77 °C, return 53-55 °C, for convectors - supply 68-79 °C and return 55-57 °C. But when the thermometer reaches -40 °C, both radiators and convectors will have the same characteristics: supply 95-105 °C, return temperature 70 °C.

Ways to reduce heat loss

The above information will help to be used to correctly calculate the coolant temperature norm and tell you how to determine situations when you need to use a regulator.

But it is important to remember that the temperature in the room is affected not only by the temperature of the coolant, street air and wind strength. The degree of insulation of the facade, doors and windows in the house should also be taken into account

To reduce heat loss from your home, you need to worry about its maximum thermal insulation. Insulated walls, sealed doors, and metal-plastic windows will help reduce heat loss. This will also reduce heating costs.

First, let's look at a simple diagram:

In the diagram we see a boiler, two pipes, an expansion tank and a group of heating radiators. The red pipe through which hot water flows from the boiler to the radiators is called DIRECT. And the lower (blue) pipe through which colder water returns is called REVERSE. Knowing that when heated, all bodies expand (including water), an expansion tank is built into our system. It performs two functions at once: it is a reserve of water to replenish the system and excess water goes into it during expansion from heating. Water in this system is a coolant and therefore must circulate from the boiler to the radiators and back. Either a pump or, under certain conditions, the force of earth's gravity can force it to circulate. If everything is clear with the pump, then with gravity many may have difficulties and questions. We have dedicated a separate topic to them. For a deeper understanding of the process, let's look at the numbers. For example, the heat loss of a house is 10 kW. The operating mode of the heating system is stable, that is, the system neither warms up nor cools down. The temperature in the house does not rise or fall. This means that 10 kW is generated by the boiler and 10 kW is dissipated by the radiators. From a school physics course we know that to heat 1 kg of water by 1 degree we will need 4.19 kJ of heat. If we heat 1 kg of water by 1 degree every second, then we will need power

G=Q/(4.19*dT)=10/(4.19*10)=0.24 kg/sec.

Can water in a well freeze? No, the water will not freeze, because... In both sandy and artesian wells, the water is below the freezing point of the soil. Is it possible to install a pipe with a diameter greater than 133 mm in a sand well in a water supply system (I have a pump for a large pipe)? When installing a sand well, it does not make sense to install a pipe with a larger diameter, because Sand well productivity is low. The Malysh pump is specially designed for such wells. Can a steel pipe in a water supply well rust? Quite slowly. Since when constructing a country water supply well it is sealed, there is no oxygen access to the well and the oxidation process is very slow. What are the pipe diameters for an individual well? What is the productivity of a well at different pipe diameters? Pipe diameters for constructing a water well: 114 - 133 (mm) - well productivity 1 - 3 cubic meters per hour; 127 - 159 (mm) - well productivity 1 - 5 cubic meters ./hour; 168 (mm) - well productivity 3 - 10 cubic meters/hour; REMEMBER! It is necessary that...

Type

Factors influencing blood pressure

Measuring instruments in the elevator unit room note any disruption in the supply or drainage of water from the building.

Increased pressure in the heating radiators of an apartment building can be created by the following factors:

- the temperature of the hot resource is too high compared to the established norm;

- the diameter of the pipe distribution was reduced due to unauthorized reconstruction by residents of the apartment heating scheme;

- formation of air jams in the end radiators of floors;

- the use of centrifugal pumps of greater power than provided for in the plan;

- part of the system is not working or is blocked.

A decrease in agent pressure also indicates a problem with the heating circuit.

When the pressure drops, you need to pay attention to the following possible aspects:

- emergency situations when supply pipelines rupture;

- malfunction or unsatisfactory operation of the circulation pump;

- failure of the safety unit;

- rupture of the expansion tank resonator.

Silting or clogging of the filter in front of the elevator unit also contributes to a drop in pressure.

A leak

The leakage of water from the heating circuit is the most common factor in reducing the pressure of the coolant. Most often, ruptures occur at the junction of pipes with the boiler and heating equipment.

A break is also possible in other arbitrary places if the owner of the apartment or house did not conduct a visual inspection before the start of the season, or installed defective elements.

A hot agent leak can occur in several ways:

- Through a rupture in the diffuser of the expansion tank. Such an accident cannot be visually determined due to the presence of water inside the container. To check, you need to press your finger on the valve that pumps air into the tank. When water leaks out of the spool, we can talk about a membrane crack.

- When the resource boils in the heat exchanger, through the relief valve.

- Microcracks, corroded areas of measuring instruments, and loose connections can also contribute to a drop in pressure and leakage of water.

The surest way to determine a possible leak is to turn off the circulation pump. The static pressure indicator will differ from the calculated characteristics.

Air outlet

After filling the artificial heating system with water, its pressure decreases when air leaves the circuit. Pre-boiler preparation - deaeration of water with chemical reagents - will help to avoid this problem.

The latter reduce the amount of carbon dioxide and oxygen in the coolant to the calculated level. The heating circuit is filled with a slow supply from below - through the relief valve, with cold water.

Aluminum radiators

Installing lightweight batteries - aluminum, leads to the reaction of oxygen with the metal, thereby forming an oxidizing film. The released hydrogen leaves through an automatic air vent.

A similar process is often observed in newly installed aluminum batteries, and the reaction stops after the film covers the entire internal surface of the radiator

Therefore, when installing new heating equipment, you should pay attention to the fact that the pressure in the central heating may drop and the volume of the thermal agent will have to be supplemented

Types of heating schemes

For buildings with several floors, a single-pipe direct distribution system is sometimes used. It does not have a clear division of pipes into the supply of liquid to the heating devices and the return, thanks to which the complete circuit is figuratively divided into two identical parts. The riser coming out of the boiler is called the supply, and the pipes coming out of the last heating device are called the return. The advantages of this scheme:

- saving time and financial costs;

- convenience and simplicity of installation work;

- beautiful view;

- the absence of a return riser and the methodical placement of heating devices (the coolant is supplied to the 1st, after the 2nd, 3rd and so on ).

For a single pipe system, a vertical wiring design with a vertical circuit and heat supply from above is popular.

With a two-pipe wiring system, we mean the installation of two closed, parallel-connected circuits, one of them provides the function of supplying the heat carrier to the device for heating the room (heat exchanger), the second - the function of its removal (return).

Heating devices are connected in several ways:

- Lower (or saddle, crescent-shaped). Takes into account the connection of the supply and return to the lower connecting holes of the heating device. An air vent and a plug are installed on the upper holes. Used for systems in which pipes are hidden under the floor or baseboard. Suitable for multi-section heating devices; with a small number of sections, heat loss reaches up to 15%.

- The lateral method is popular. The pipes are connected to the heat exchanger on one side: the heat carrier supply is through the top, the return line is through the bottom. Not suitable for devices with a large number of sections.

Photo 2. Heating circuit with two pipes with a side connection type. The supply and return temperatures are indicated.

- The diagonal (or lateral cross ) method involves supplying hot water from above, connecting the return line from below and on the other side. Suitable for heating devices with at least 14 sections.

- The third option for organizing a heating circuit is considered a hybrid method, which is based on the simultaneous use of one-pipe and two-pipe systems. For example, the collector circuit involves supplying a heat carrier through a single riser; subsequent on-site wiring is carried out according to an individual plan.

Working principle on how to increase productivity

A single circuit does not provide equal heating of the radiators; heat transfer decreases as it moves away from the boiler (the latter heating devices receive coolant cooler than the first ones). The disadvantage of such a system is the high pressure values of the coolant.

Reference. The productivity of a single pipe system increases if there is a bypass or circulation pumps formed on each floor.

Advantages of the two-pipe heat supply option:

- heating the required number of devices in the same way, regardless of their distance to the heat source;

- adjusting the temperature regime, carrying out repair activities on an individual device does not affect the operation of others.

Minuses:

- complexity of the wiring diagram;

- complexity of installation and connection.

The most productive system of two pipes, which is also often selected for heating luxury housing, is considered an excellent choice for private construction

The process of installing a two-pipe type system is best carried out with the installation of a circulation pump, which makes it possible to use pipes of smaller diameter.

After it, in order to protect the recirculation circuit from squeezing, a check valve is installed.

When installing a system without a bypass, the rule is followed : supply is possible if there is a slope from or to the boiler. A coolant with a higher temperature enters the heating device through the inlet (Slope from the boiler to the device for heating the room) and heats it, and then exits through the return (Slope from the heating device to the boiler), but with a lower temperature. Qualified craftsmen often resort to replacing the recirculation pump ring with a system of 3 or 4-way mixing devices.

Main! With gravitational circulation, the entire pipe line from the riser to the heating devices does not have to be long.

Specifics

Long-term operation of boiler room equipment is possible with a properly designed pipe branching system, which provides some kind of temperature difference between the pipes supplying and discharging the coolant.

Attention! The presence of a fundamental difference in temperature values is considered the basis for the formation of abundant condensation on the firebox.

Drops of water, especially in combination with carbon monoxide formed during fire (in the case of equipment operating on solid fuel), quickly corrode the walls of the chamber, the impermeability of the main element is broken, and the boiler fails.

An acceptable solution in this situation is to connect an additional water heating device - an electric water heater. It is placed next to the boiler in a special way so that the coolant, having passed through all the devices of the system, enters it and then into the boiler.

Photo 3. Heating system with a storage water heater to heat the water. The device is placed next to a gas water heater.

Why is a valve needed?

The correct design of a heating system is developed taking into account the difference in temperature values in the coolant supply and return pipes.

Often, instead of installing a boiler, another protection option is used that ensures long-term operation of solid fuel boiler equipment.

It helps to connect a bypass , which is a specially embedded pipe that allows the cooled coolant to change the direction of movement around the boiler.

The bypass ensures circulation of the coolant through the so-called small circuit. When forming this circuit, a thermostatic or three-way valve is installed at the junction of the bypass and return .

The hot one went

According to sanitary rules, the temperature of hot water at the points of analysis should be in the range of 60-75 ° C.

In the hot water supply network, the coolant is supplied from the pipe:

- in winter - with the reverse, so as not to scald users with boiling water;

- in summer - from a straight line, since in summer the carrier is heated no higher than 75 ° C.

A temperature schedule is drawn up for the heating season. The average daily return water temperature should not exceed the schedule by more than 5% at night and 3% during the day.

Why doesn't the return work work?

There are many problems associated with return flow in a heating system.

Squeezes feed

The water temperature in the return pipeline is determined by the design of the heating system and corresponds to the value in the temperature chart approved by the service organization.

Often apartment residents are faced with a problem when the return flow squeezes the supply.

A common reason is the transition of hot coolant from the supply line to the return circuit through various parts (for example, jumpers) of the hot water supply pipeline or ventilation. With an automatic control device, as a rule, it is enough to configure it correctly.

The coolant does not drain well

If the circulation of fluid in the heating circuit is disrupted, the water in the return pipes does not drain well. Initially, check that the power of the circulation pump meets the requirements. The reason may be hidden in a banal pipeline leak . The situation with poor circulation is typical for apartment buildings located on the final section of a heating main with insufficient pressure drop .

The return is cold, the pipes are clogged

Low return temperature is a serious problem that prevents indoor comfort. Causes of cold return:

- incorrect heating wiring;

- air bubble in the system or riser;

- insufficient water flow through the network;

- low temperature in underwater pipes;

- increased volumes of heat loss ;

- inefficiency of pumping equipment , result: poor circulation and insufficient temperature difference between heat supply and return;

- low pressure;

- clogged pipes and radiators.

The use of Mayevsky cranes makes it possible to eliminate air pockets that impede the movement of the coolant.

Photo 4. Mayevsky tap installed on a heating radiator. Using it you can bleed excess air from the system.

It is important to bleed air correctly:

- shut-off valves to stop the heat supply;

- open the Mayevsky tap, bleed the coolant with air;

- restore the movement of heat by opening the lock.

The narrow passage of the control valve often explains the low return temperature, this is a reason to replace it with a new one.

Periodically check the pipeline for clogging, which interferes with the movement of the coolant. Dirt and deposits are removed . If pipe patency cannot be restored, the section is replaced with a new pipeline.

Attention! The exact cause determined after checking the entire heating system.

This article lists the main malfunctions that can happen to the heating system of a private home, as well as ways to eliminate them. Troubleshooting heating systems can be divided into two types. Do-it-yourself heating system repairs can be done in the heating system wiring: radiators and fittings. All problems that arise in the boiler room and equipment require special knowledge and experience, so heating system repairs related to equipment to specialists.