Why is the return hotter than the supply?

When heated, the liquid increases in volume, the excess enters the expansion tank. Since the heating system is completely filled with liquid, the hot coolant displaces the cold coolant, which returns to the boiler, where it is heated.

Interesting materials:

How long can stool be stored on Calprotectin? How long can flounder be stored in the refrigerator? How long can Nazivin drops be stored after opening? How long can crucian carp be stored in the freezer? How long can French fries be stored? How long can kefir be stored outside of the refrigerator? How long can bread be stored in the refrigerator? How long can bread be stored? How long can hops be stored? How long can Chinese tea be stored?

Return in the heating system - its purpose

The return in the heating system is the coolant that has passed through all the heating radiators, lost its primary temperature and is now cold and supplied to the boiler for the next heating. The coolant can move in both a two-pipe and an improved single-pipe heating system.

A single-pipe system implies a sequence of connections of heating radiators. That is, the supply pipe is connected to the first radiator, from which the next pipe goes to the second radiator, and so on.

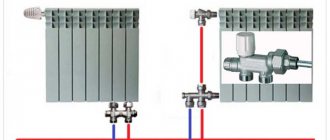

If a one-pipe heating system is improved, its design will be something like this: along the perimeter of the entire room there is one pipe into which the supply and return pipes of each radiator can be inserted. In this case, it is possible to install a control valve on each battery, with which you can very successfully regulate the air temperature in a given room.

The big advantage of this option is the minimal number of pipes in it. And the minus is the temperature difference between the first radiator from the boiler and the last. This problem can be eliminated with the help of a circulation pump, which will move all the water through the heating system much faster, and thus the coolant will not have time to reduce the temperature.

The two-pipe option represents the wiring of two pipes. One pipe is the supply of hot coolant, the second pipe is the return pipe in the heating system, through which already cooled water from the radiators enters the boiler. This system allows you to connect all radiators almost in parallel, which allows for flexible configuration of each radiator individually without affecting the operation of the others.

Consequences of cold return

Circuit for heating return

Sometimes, with an incorrectly designed design, the return flow in the heating system is cold. As practice shows, the fact that the room does not receive enough heat with a cold return is half the trouble. The fact is that at different supply and return temperatures, condensation may form on the walls of the boiler, which, when interacting with carbon dioxide released during fuel combustion, forms acid. It can also damage the boiler much ahead of time.

To avoid this, it is necessary to carefully consider the design of the heating system, special attention must be paid to such a nuance as the return temperature. Or include additional devices in the system, for example, a circulation pump or boiler, which will compensate for the loss of warm water.

Radiator connection options

Now we can more than confidently say that when designing a heating system, the supply and return must be perfectly thought out and configured. If the design is incorrect, more than 50% of the heat can be lost.

There are three options for inserting a radiator into the heating system:

- Diagonal.

- Lateral.

- Bottom.

The diagonal system gives the highest efficiency coefficient, and is therefore more practical and efficient.

The diagram shows a diagonal inset

How to regulate the temperature in the heating system?

In order to regulate the temperature of the radiator and reduce the difference between the supply and return temperatures, you can use a heating system temperature controller.

When installing this device, do not forget about the jumper, which must be located in front of the heating device. If it is absent, you will regulate the temperature of the batteries not only in your room, but throughout the riser. It is unlikely that the neighbors will be happy with such actions.

Read more: temperature controllers in the heating system.

The simplest and cheapest option for a regulator is to install three valves: on the supply, on the return and on the jumper. If you cover the valves on the radiator, the jumper must be open.

There is a huge abundance of different thermostats that can be used in apartment and private buildings. Among the wide variety, each consumer can choose a regulator that will suit him in terms of physical parameters and, of course, cost.

We hope that the article was useful to you. We will be grateful if you share it on social networks. The buttons for this are located a little lower. We wish you a nice day, come visit us again.

kvarremontnik.ru

Risers

The distribution of coolant through heating devices in a private house is possible horizontally and vertically (stand-up). In multi-apartment buildings in different areas, these schemes are side by side: if the bottling is always a horizontal layout, then the riser is a vertical layout.

What is useful to know about risers in an apartment building?

The heating system wiring is fully operational, but only with a huge (DN25) diameter of the connections.

Practical consequence: if you want to replace the interior wiring yourself, either use heating pipes of the same diameter, or throttle the jumper. The instructions are due to the fact that with a jumper diameter of 25 mm and connections with a nominal diameter of 15-20, the batteries will simply be cold.

Bottlings

Depending on their placement, there are two heating distribution schemes.

Lower

Bottom filling, or a heating system with bottom wiring, is used in most modern buildings. Both the feed and return bottling stations are located in the basement. The risers are connected in pairs by jumpers located in the apartment on the top floor or in the attic; at the top point of each jumper there is an air vent (Mayevsky tap).

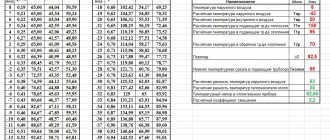

Any riser is a bridge between bottlings. The inevitable imbalance between the risers closest to the elevator unit and those farthest from it is compensated by the difference in the permeability and size of the pipes. Let us present the usual values of remote control for a heating circuit serving the entrance to a modern ten-story building.

| Plot | DU pipes |

| Spills near the elevator unit | 50 |

| Spills at end risers | 40 |

| Risers | 20-25 |

What specific advantages does bottom routing of heating pipes provide?

But: often basements are used for storage or utility rooms of stores. In this case, you yourself realize that there is no need to talk about any advantage: you will have to dump the risers through a hose into the sewer.

The main drawback of the lower wiring of heating systems is the complexity of starting them after the reset is completed. In order for circulation to begin through all risers, it is necessary to bleed off the air space. At the same time, not all residents of the upper apartments can do this; we should not forget about the empty premises.

Upper

Top filling, or heating with a top supply distribution, is completely and predictably different in that the filling supply thread is placed in the attic. The return remains in the basement. Any riser is a separate element, free from other risers.

In the attic, in addition to bottling the supply, in this case there are:

This heating system wiring scheme was widely used until approximately the 80s of the last century.

How does it look against the background of the bottom bottling?

It’s curious: a whole house heating system with an upper supply distribution is reset and started much more easily, especially if the discharge from the heating expansion tank is routed to the elevator unit. Alas: dumping a house is associated with the loss of a huge amount of coolant, which is undesirable from the standpoint of saving thermal energy.

Types of heating wiring: diagrams, methods and selection of a suitable system

The main types of wiring for water heating system risers are single-pipe and two-pipe schemes, each of which has its own characteristics.

Single pipe heating system. Click on photo to enlarge.

With this organization of water heating, all batteries are connected in series, that is, from the boiler the pipe goes to the first heating element, from it to the second, then to the third, etc. There is another option for single-pipe systems: from the boiler there is one solid riser of large diameter, and sections of pipes of smaller diameter are connected to it in the necessary places - supply and “return” from each radiator. Here it becomes possible to install a thermal valve in front of each battery, which allows you to shut off the supply of hot coolant when the temperature in the room reaches a certain level.

A single-pipe heating main is a simple device and has a minimum number of pipes, which means that the costs of organizing such heating will be low. A significant drawback of this scheme is that there is a large difference in the heating of the radiator near and far from the boiler, and this parameter is almost impossible to regulate.

In addition, if the system involves the movement of coolant naturally, that is, under the influence of a slope, it is not possible to create an extended pipeline. If you include a powerful electric pump in the heating circuit, the heating main can be made as long as desired.

Two-pipe heating system. Click on photo to enlarge.

Two-pipe wiring of heating systems involves the presence of two pipes: one is supplied with hot coolant to the heating elements, and the other is cooled back into the boiler. The batteries are located in parallel, which makes it possible to regulate the heat transfer of each element separately, without affecting the functioning of others.

Within the framework of a two-pipe scheme, the following types of wiring of central water heating systems are distinguished: mains with spaced risers and mains with nearby risers.

The first type of wiring is a larger diameter pipe (supply) in the attic, and from there risers of smaller diameter are laid to each of the radiators in the system. The cooled coolant is discharged through a common “return” riser, which is mounted under the radiators, that is, at floor level. The general supply riser located in the attic must be carefully insulated to ensure maximum efficiency of the heating system.

When distributing with spaced pipes, if a pump is not used, it is important to observe the slopes: the supply should be mounted at a slight (up to 10 cm per 20 linear meters) slope from the boiler, and the “return”, on the contrary, at a slope towards the boiler.

Wiring with nearby pipes involves installing direct and return risers under the batteries. The hot coolant will rise up and warm up the radiator, and the cooled coolant will fall down and flow into the return pipe.

There are also mixed wiring schemes, for example, the coolant is supplied to the heating elements sequentially, and the cooled water is discharged into a common return riser. Another case is collector wiring, that is, the presence of its own circuit, powered by a common supply, on each floor of a multi-story building.

In general, the choice of heating system wiring method is determined by many factors, among which the most important are the power of the boiler, the number of radiators and the number of sections in each of them, the number of floors of the building, etc.

The issue with the number of pipes in the heating system has been resolved. Let's move on to an overview of the main methods of connecting radiators to supply and return risers.

Lateral one-way connection

Such an organization of heating systems involves connecting the supply and “return” to the heating element on one side: the direct riser is connected from above, and the return riser is connected from below. This is the recommended order, otherwise heat loss may increase by 7%, since the battery sections will heat up unevenly. The lateral one-sided design is suitable for radiators with more than 15 sections, as well as for multi-storey buildings with parallel connection of heating elements.

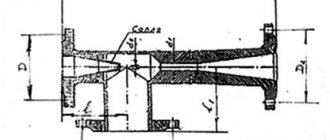

Diagonal connection

This method is recommended for heating systems with long radiators. The difference with a lateral one-way connection is that the risers are connected to the battery from different sides, for example, the direct riser is connected to the leftmost section at the top, and the reverse riser is connected to the rightmost section at the bottom.

Only in this way is maximum heat transfer achieved, and heat loss is reduced to 2%. If you install pipes in the reverse order (supply from below, return from above), the efficiency of heating the room will decrease by 10%.

Bottom connection

This layout outperforms others because of its aesthetic appeal: only the radiator is visible, and all the pipes are hidden under it or even “hidden” under the floor. However, heat loss in this case can increase up to 15%, since the battery sections will heat up unevenly.

Tichelman connection

Tichelman connection. Click on photo to enlarge.

This type of wiring is used when organizing heating systems in large buildings: hangars, warehouses, high-rise buildings, etc. This scheme contains a standard set of elements. The difference is that when installing risers in different sections of the highway, pipes of different diameters are used. These are called constriction devices.

For example, if the straight riser coming from the boiler has a diameter of 50 mm, then after a 20 mm outlet to the first heating element, the supply diameter is reduced to 40 mm. A 32 mm riser is installed after the second radiator, and a 25 mm riser is installed after the third. This arrangement of hot coolant supply allows energy to be distributed approximately equally between all batteries.

The return riser is assembled in a mirror way: a pipe of the smallest diameter goes from the first radiator, and a 50-mm pipe goes from the last one to the boiler.

How does the choice of heating distribution system depend on the building design?

If the house is one-story and its roof is high enough, it is advisable to use a heating scheme with vertical supply branches. In this case, you can turn the attic into a living space - convert it into a heated attic.

If the house has a deep basement and a flat roof, it is recommended to use horizontal wiring with the boiler placed in the basement.

If the house has two or more floors, the type of wiring in any case will be two-pipe with vertical risers, regardless of which method of laying pipes you choose: upper or lower.

Recommendations for optimizing the operation of water heating

A natural circulation system will begin to function much more efficiently if a powerful electric pump is introduced into it. This way you can achieve good heating even of radiators far from the boiler. In addition, installing a pump allows the use of risers of smaller diameter. The only thing that needs to be treated with utmost attention is the power reserve of the pump.

Scheme of water heating at home. Click on photo to enlarge.

The circulation pump accelerates the circulation of water in the system, so the latter works more efficiently, which means fuel costs (electricity, gas or solid energy resources) are significantly reduced.

Modern boilers do not require filling the system with a large volume of water, so they are constantly in operating mode. On the contrary, the use of solid fuel stoves, when the combustion is carried out 1-2 times a day, will be effective only in combination with large-diameter pipes and an appropriate volume of coolant.

Plastic or metal-plastic ones should be preferred to metal risers. Metal has greater thermal conductivity than plastic, which is why batteries are made of metal. During circulation through metal pipes, the coolant loses much more energy than when moving through plastic risers. Thus, replacing metal risers with plastic ones will help solve the problem of excessive heat loss.

ultra-term.ru

Features of the heating system of apartment buildings

When installing heating in multi-storey buildings, it is imperative to comply with the requirements established by regulatory documentation, which include SNiP and GOST. These documents indicate that the heating structure must ensure a constant temperature in the apartments within 20-22 degrees, and humidity must vary from 30 to 45 percent.

Despite the existence of standards, many houses, especially older ones, do not meet these indicators. If this is the case, then first of all you need to install thermal insulation and change heating devices, and only then contact the heat supply company. The heating of a three-story house, the diagram of which is shown in the photo, can be cited as an example of a good heating scheme.

To achieve the required parameters, a complex design is used, requiring high-quality equipment. When creating a project for the heating system of an apartment building, specialists use all their knowledge to achieve uniform heat distribution in all sections of the heating main and create comparable pressure on each tier of the building. One of the integral elements of the operation of such a design is operation on a superheated coolant, which provides for the heating scheme of a three-story building or other high-rise buildings.

How it works? The water comes directly from the thermal power plant and is heated to 130-150 degrees. In addition, the pressure is increased to 6-10 atmospheres, so the formation of steam is impossible - high pressure will drive water through all floors of the house without loss. The temperature of the liquid in the return pipeline in this case can reach 60-70 degrees. Of course, at different times of the year the temperature regime may change, since it is directly related to the ambient temperature.

Types of radiator connections

The main methods of connecting heating system devices are several types:

Side connection

Lateral radiator connection.

Connection from the end of the device - supply and return are located on one side of the radiator. This is the most common and effective connection method; it allows you to remove the maximum amount of heat and use the entire heat transfer of the radiator. As a rule, the supply is at the top and the return is at the bottom. When using a special headset, it is possible to connect from bottom to bottom, this allows you to hide the pipelines as much as possible, but reduces the heat transfer of the radiator by 20 - 30%.

Diagonal connection

Diagonal radiator connection.

Connection diagonally to the radiator - the supply is on one side of the device from the top, the return is on the other side from the bottom. This type of connection is used in cases where the length of a sectional radiator exceeds 12 sections, and a panel radiator is 1200 mm. When installing long radiators with side connections, there is uneven heating of the radiator surface in the part furthest from the pipelines. To ensure that the radiator heats up evenly, a diagonal connection is used.