The automatic solid fuel boiler is designed to operate in long-term autonomous mode, so the unit can be used in a heating system. In the absence of gas communications, this option is optimal. To decide on the purchase of a device, you need to know the features of its operation.

The automatic solid fuel boiler operates in long-term mode.

What is an automatic TT boiler

The device is used to heat houses and industrial premises. Heat generation in them is continuous. The constant presence of a person in the room is not required, because The furnace is equipped with a storage facility for automatic feeding of wood materials. Such units are also called long-burning solid fuel boilers (TCDG).

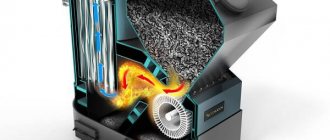

The device consists of 2 units: a stove and a container for collecting firewood, coal, etc. Fuel is loaded from storage into the combustion chamber mechanically. The bottom (hopper) is equipped with an iron screw cylinder or a tray plug. Rotating, they start the supply of fuel to the furnace through a pipe connecting the container to the combustion chamber.

When choosing a TKDG, you should consider how the room will be heated - wood or granulated raw materials. Not only the type of design (dimensions, weight), but also the energy efficiency of the installation (efficiency, heating price) depends on this.

pros

The advantages of TKDG are autonomous operation, economical fuel consumption, and environmentally friendly operation. When installing a boiler, a private owner relieves himself of the need to constantly monitor combustion processes (maintaining flame, temperature). Gradual (metered) loading of fuel significantly reduces the volume of burned materials per season. The amount of combustion products (ash, soot) is reduced. At the same time, the building is heated around the clock without temperature changes. The owner does not need to waste time on ignition.

An additional advantage of automatic boilers is their use in a home heating system. The dimensions of the units allow them to be placed in a utility room without redevelopment of the building and additional costs.

When installing the boiler, there is no need to control the combustion process.

Minuses

A solid fuel boiler with automatic fuel supply has one drawback. The red-hot structure heats the space and nearby objects. To comply with fire safety regulations, a major overhaul of the utility room (location) is required using non-combustible materials (stone, cement, ceramics).

The disadvantage of TKDG is its lower efficiency compared to heating stoves.

However, by purchasing a boiler with adjustable intensity, you can regulate the flow of raw materials and maintain the temperature.

Design features

There are 2 types of TT boilers.

Kinds:

- Small-sized models. They are stoves with a small capacity for fuel. The storage is built into the top or side of the unit, similar to a combine harvester.

- Large boilers. These are fireboxes combined with bunker-type storage. Most often this is a separate room equipped for a woodshed or storage area.

In the first case, long-term autonomous heating of the house is excluded. The fuel in the bunker is enough for 6-9 hours, depending on the type of wood materials. In the second case, fuel reserves are limited only by the storage volume (the boilers are completely autonomous).

Differences from semi-automatic

When using TT boilers, the outlet temperature can be adjusted. Automatic installations, unlike mechanical ones, allow you to control not only the speed of rotation of the cylinders and blades when taking fuel, but also adjust the frequency of its loading.

Automatic settings allow you to regulate the frequency of fuel loading.

TKDG is an autonomous equipment that excludes direct human participation in controlling combustion processes. The operation of the units can be fully automated, from ignition to temperature control, for example, in case of a long business trip.

TCDGs are capable of regulating the temperature of the coolant (in the heating system) and the environment (to protect against overheating). The optimal operating mode is configured using the remote control. If you integrate a GSM receiver into the module, the unit can be controlled using a smartphone.

Classic boilers

Standard type devices are designed to burn one type of raw material. Fuel is supplied to the furnace manually or automatically. The intensity of combustion and temperature will have to be controlled when using firewood. The raw materials are pre-cut and pricked. The process is automated by installing an electric knife in the compartment between the hopper and the combustion chamber. Peat and coal with 20% moisture content are crushed to the required fraction.

Briquettes and pellets from the store are ready for ignition, but they should be kept in a dry place.

When fuel is supplied, the storage becomes clogged with dust. This may damage the snack. To avoid breakdowns, already crushed fuel is poured into the storage. Coal must be sorted to prevent deformation of the chassis.

Combined

There are boiler models on sale that are suitable for burning wood, coal and pellets at the same time. This feature should be taken into account by residents of those areas where energy prices depend on the season. Thus, traditional firewood can be replaced with more affordable materials. In harsh climates, preference is given to cheap peat, coal, and pellets. Both firewood and crushed raw materials are suitable for heating houses in central and southern Russia.

Combination boilers are suitable for burning wood and coal.

A universal type of automated boilers is most often used in heating systems of houses. During the day, wood or coal is burned, and at night the installation is set to power supply (in order to save money). Combination boilers are also recommended for purchase when there are large seasonal temperature changes.

The use of firewood, coal or pellets has different effects on the efficiency of the equipment. So, in the summer, the premises can be heated with compressed sawdust, in the off-season - with peat, and in cold weather - with birch firewood, for example. To do this, the boiler design includes several bunker compartments and an additional burner, a heat exchanger (accumulator) for connection to the heating system.

Pellet

In boilers of this type, compressed granules from sawdust and shavings are used. Instead of pellet cassettes, wood chips and agricultural waste (husks, straw) are filled into the storage facility. The screw part processes a tank of fuel in 3-7 days. Despite the long autonomy of operation, the efficiency of the boilers is low (50-90%) and largely depends on the quality of the pellets. They must be dry, tightly compressed and contain at least 50% solid wood chips.

Pyrolysis

Boilers of this type generate energy due to the thermal decomposition of fuel. It is not the raw material itself that burns in the furnace, but the gas produced as a result of the pyrolysis process. The TKDG design is equipped with a built-in heat exchanger. Battery life increases to 1 month. Any solid fuel is suitable as fuel, but taking into account the manufacturer and model. In pyrolysis installations, you can configure auto-ignition and remote control.

Pyrolysis boilers use the energy of fuel decomposition.

How does an automatic TT boiler work?

The operating principle of TKDG is the same as that of a stove (fireplace). Fuel is supplied to the combustion chamber. During the combustion process, decomposition products are collected in the ash pan. Gases exit through the chimney (to the street).

The operation of an automatic boiler directly depends on the storage facility where the wood materials are stored. When purchasing, first of all, take into account its volume and method of loading raw materials. High-quality fuel with a fraction of 5-25 mm is used for bunkers with auger feed. There are no special requirements for raw materials for rotating drum storage facilities. Peat or coal is split and thrown inside.

Standard options

During fuel combustion, the TKDG generates heat. The energy is supplied through the pipes to the battery, which distributes liquid (water, antifreeze) throughout the radiator system.

The degree of heating of the pipes is regulated by the heat exchanger, and the combustion temperature and frequency of fuel supply are controlled by the TKDG itself.

Coal boilers

The operation of the installation is based on energy exchange: the coolant attached to a container with coal heats the radiator pipes. By circulating the liquid in a circle, the battery system heats up. The boiler controls the temperature in the specified mode.

Coal boilers are based on energy exchange.

The correct fuel fraction ensures uninterrupted operation of the TKDG. An automatic coal boiler selects the heating mode taking into account the settings and amount of fuel. If a log or piece of peat does not pass into the combustion chamber, the operation of the unit will end. Fuel is poured into coal and pellet TKDGs 1-2 times a week, into wood-burning ones - daily.

Principle of operation

The coolant that fills the water jacket is heated by the energy of the burned fuel. Circulation pumps supply hot working fluid through an insulated underground pipeline into the house, where it is distributed to radiators. The cooled water returns to the boiler mediastinum for reheating.

As the fuel burns out, additional loading is carried out and the ash pan is cleaned.

Types of fuel bunker

Loading devices for long-burning boilers are of 2 types: built-in and mechanized storage. The equipment of the unit affects the autonomy of operation and the very possibility of placing the installation. The area of individual bunker storage facilities in private homes can reach 20-50 m².

Built-in

Combine boilers are equipped with storage capacity of up to 1 m³. The container is mounted above the firebox or on the side of it. When choosing built-in bins, their height is taken into account. Fuel loading into an empty compartment must be carried out without interference. The higher the container, the more difficult it is to pour pellets and coal into it.

The advantage of built-in storage is its small size. Disadvantage: low autonomy.

Mechanized

Boilers with sleeve loading require separate storage of fuel in special tanks. They can be hanging canvases, free-standing boxes, frame pallets or entire utility rooms. The length of the hose providing the supply of raw materials should not exceed 10 m. During transportation, solid fuel crumbles, forming a lot of dust. This reduces the efficiency of the boiler.

A mechanized bunker involves storing fuel.

The advantage of mechanized storage is its capacity. The only drawback is the need for constant monitoring of the load (electrical wiring, sleeve attachments).

The dimensions of the bunker are responsible for the functionality and practicality of the boiler. The shape of the storage is selected taking into account the use of free space or volume. The design is purchased to order, taking into account fuel consumption. For example, 1 t of pellets is placed in a container with a volume of 2 m³. This amount is enough for 40 days. At standard fuel consumption (25 kg per day), one side of the tank should be at least 40 cm.

Video description

How to make automation for a boiler using improvised means.

For this purpose, solid fuel boilers can be equipped with the following devices:

- The electronic control board must know the exact thrust level at every moment. For this purpose, a special sensor is installed.

- If the draft is not enough for proper combustion, a fan can be used to adjust the air supply to the chamber where the fuel is located.

- Sensors are used that transmit information about the water level in the jacket.

- The pressure level is recorded.

- A circulation pump that supplies the right amount of air to maintain the desired combustion intensity.

- If the coolant for the heating system is heated, then sensors for its temperature and fuel consumption can be installed.

- The control board can receive information about the loading of the container with firewood, pallets or coal. In accordance with them, the next portion can be served.

The electronic control board receives the necessary information about the operation of the device, processes it and gives the necessary commands. It ensures the execution of the operating mode specified by the owner.

Automation kit for boiler Source gradusplus.com

Automatic fuel delivery options

Loading of flammable materials into the chamber is carried out using 2 main mechanisms: screw and pneumatic. The feed hoses are powered by electricity. All solid fuel boilers are volatile.

Pneumatic conveyor

TKDG with a compressor are practical. The length of the flexible hose can exceed 10 m with sufficient engine power, which allows you to set up a bunker in an outdoor hangar. The pneumatic conveyor operates on the principle of a pump. After turning on the installation, pressure is created in the air pipe, and fuel is poured into the combustion chamber. The operation must be performed once a day (week) as fuel is consumed.

The main disadvantage of pneumatic boilers is their high electricity consumption.

Advantages – range, price, ease of installation.

Using augers

In TKDG with cylindrical screws, fuel is loaded continuously (according to the programmed program). The auger is located at the bottom of the bunker, which allows you to gradually process the entire stock of raw materials in the tank. After turning on the installation, the propeller, the blades of which are filled with fuel, begins to rotate, moving the mass into the firebox.

Using augers, fuel is loaded continuously.

The main disadvantages of screw boilers are the constant load on the electrical network and noise during operation. Advantages - durability, possibility of installation in technically combined utility rooms for conveyor loading.

What fuel to use for a long-burning boiler

The choice of combustible materials must be rationally justified, taking into account practical benefits. When purchasing TKDG, take into account the following points:

- Pellets are the most powerful source of energy in TT boilers. The raw materials are environmentally friendly and do not require processing. The price is comparable to the cost of firewood.

- Coal and peat are the cheapest energy sources. They leave a lot of soot behind during the combustion process. Raw materials require grinding to the desired fraction, a special ignition technique that prevents smoldering. In terms of heat production, the materials are inferior to firewood.

- Wood is a traditional source of energy, environmentally friendly and inexpensive. Firewood produces a lot of ash and requires preliminary preparation to fit the size of the firebox.

These parameters should be taken into account when choosing a boiler for heating or heating.

Prices: summary table

| Model | power, kWt | Efficiency, % | price, rub. |

| Teplodar Cooper Praktik 14 | 14 | 80 | 20 000-27 000 |

| Protherm “Beaver” 20 DLO | 19 | 91 | 79 000-83 000 |

| Viadrus Hercules U22 D4 | 24 | 80 | 59 000-90 000 |

| Kentatsu ELEGANT-03 17 | 17 | 85 | 32 000-36 900 |

| Buderus Logano S171-22W | 22 | 89 | 179 000-198 000 |

| STROPUVA S20 | 20 | 85 | 89 000-110 000 |

The summary table reflects the approach of our manufacturers to the production of wood-burning boilers for heating. The price and declared characteristics in the first position may well suit a villager and not tempt him to experiment with homemade boilers. In our open spaces, such a low-budget boiler is preferable at long distances from service centers.

Requirements for installing an automatic TT boiler

TKDG is operated taking into account fire safety rules and technical installation standards.

Requirements:

- Availability of a ventilation shaft (2 pipes for oxygen access and gas exhaust). The diameter of the holes is at least 10 cm.

- Equipment of the podium for the boiler. Material – steel sheet with a thickness of at least 3 mm or a cement foundation. Coverage area – at least 7 m².

- Use of non-combustible materials for finishing walls, ceilings, floors. Thermal protection of seams in places where the chimney is attached to the roof is mandatory.

- The installation distance to the walls is at least 50 cm. End-to-end corner installation is prohibited. The minimum perimeter of the box for the ventilation shaft is 20x20 cm.

- Installation of an expansion tank to discharge excess coolant (in the attic). In its absence, the heating system pipes will rupture and the boiler will explode.

An automatic TT boiler must have a ventilation shaft.

Before installing the TKDG, you need to call a specialist to your home who will suggest the best option for placing the unit.

Advantages and disadvantages

The air heating system has a number of advantages:

- Low cost. Instead of expensive pipes and radiators, air ducts are used, which you can make yourself from plywood.

- Simple design. No pump, expansion tank, pressure gauge, safety valve, or air vent are needed. Cheap dampers are used instead of expensive fittings.

- Security. The coolant does not freeze, does not boil, does not cause corrosion of metal elements, and air pockets do not form in it.

The disadvantage is that, due to their large size, the boxes cannot be laid in a finished house without compromising the aesthetics of the interior design. The air system is designed together with the house, laying channels in the walls, between the floor joists and behind the suspended ceiling.

Boiler accessories

For greater heat transfer from TCDG, air flows and liquid are brought to the desired temperature or state. This allows you to extend the life of the unit and reduce energy consumption.

Auxiliary equipment:

- Fuel supply system (grabs, conveyors).

- Draft cleaning mechanisms (smoke exhausters, fans, flues, air ducts).

- Ash and slag removal structures (crushers, bunkers, conveyors, ash collectors).

- Pumping equipment (for feeding coolant, filling the water circuit, etc.).

- Separation devices for water treatment (filters, deaeration unit).

- Automation systems (measuring instruments, sensors, electronics).

The latter allow you to program ignition, set up automatic collection of ash into a container, connect a battery, control the installation remotely, and select temperature modes.

Can I do it myself at home?

Outdoor boilers are massive and bulky devices. Their weight can reach a ton, and the volume of coolant contained by the water circuit is 400-700 liters. These units are made of special materials that can withstand prolonged high-temperature exposure, with minimal deformation.

High-density basalt fillers are used for thermal insulation of outdoor wood-burning boilers. In a home workshop, it is problematic to produce a device of such mass and dimensions. But despite this, with the proper level of mechanization and possession of the necessary skills, you can make a small outdoor boiler yourself.

Many manufacturers provide a lifetime warranty on their devices. This indicates the highest quality of materials used in the construction and the professional level of the workers.

Choosing a boiler with automatic fuel supply

The operational characteristics of the units help to narrow down the search for the right model. If you have a limited budget, it is advisable to choose boilers taking into account the following parameters.

Dimensions

The dimensions of the TKDG must correspond to the area of the room in which the boiler room is planned to be installed. The dimensions of the unit affect the autonomy of operation. The larger the bunker can be mounted next to the firebox, the more practical the installation will be. The volume of the combustion chamber for solid fuel must be at least 80 liters (8-12 hours of operation at a power of 20 kW). The larger the firebox, the higher the efficiency of the boiler.

The dimensions of the boiler depend on the area of the room.

Heat exchanger material

As a result of temperature changes (when the device is turned off), the walls of the coolant compress and expand. The degree of metal deformation and the service life of the boiler depend on the alloy used.

Steel structures can last up to 15 years. The metal is durable, heats up quickly, and withstands temperature changes better. The weak point of steel heat exchangers is the welding seams and the place where the chimney is attached. Poor installation causes frequent breakdowns.

Cast iron structures last up to 20-25 years. The alloy is durable, but can burst due to sudden temperature changes. The material warms up slowly, but is excellent for organizing uninterrupted boiler rooms, because... not susceptible to corrosion. A cast iron heat exchanger can be used without water filtration. Alloy boilers are demanding on the return flow fluid temperature. Therefore, water circulation in the system is started after it has been preheated.

Boiler power

The amount of heat generated depends on this parameter. Boilers operate in several modes. The choice of unit is made taking into account the power range (from minimum to maximum), which affects the amount of electricity consumed. If the boiler operates in 5-30 kW modes, then with one load of fuel (4-12 hours) it will be possible to generate at least 20-60 kW. The network power of the unit is selected taking into account the power supply circuit of the house. In some cases, it will be necessary to replace the meters and run a separate wiring cable to the boiler room.

The boiler power affects the electricity consumed.

Safety

Fire safety parameters of boilers are confirmed by international quality certificates.

The equipment supports operation:

- In the event of a power outage (emergency circuit in the TKDG harness, uninterruptible power supply battery).

- In the event of a breakdown of the boost fan (overheating protection valve).

- When the feed pump is jammed (forced circulation of liquid in the heat exchanger).

- In case of boiling of the coolant (thermostat), increase in pressure in the tank (water and gas discharge valve).

- When liquid circulation in the circuits stops (TT boiler safety group, separate heat exchanger).

This is not enough for a demanding buyer. For safe operation, the solid fuel boiler is equipped with a control module. Program settings allow you to use frost protection (in winter), automatic temperature and ventilation modes, self-regulating ignition (pyrolysis boilers).

Noise level during operation

Boiler units are noisier than gas heaters. Massive installations with hose fuel supply from the bunker create additional inconvenience (sounds of the pneumatic pump, engine, feed mechanisms).

There are several solutions to the problem:

- soundproofing the room;

- purchase of a boiler with a changeable supply mode;

- inclusion of an electric heating element in the heating system, which will heat the house at night.

An automatic solid fuel boiler is noisy.

Small-sized TT-boilers using pellets are comparable in noise level to stoves.

Fuel used

Raw materials for ignition are selected taking into account prices in the region of residence. Special attention is paid to the fuel moisture indicator, which affects energy production. Fuel efficiency decreases by 20-30% when using damp firewood. The optimal fuel humidity is 25-30%, like pellets. In this case, the heat generation reaches its maximum, but the amount of carbon deposits also increases (cleaning is needed). The manufacturer indicates the boiler power taking into account the use of non-raw fuel. The efficiency of the unit largely depends on the quality of the fuel.

Autoignition

The delayed heating start function is provided only in pyrolysis boilers, which are several times more expensive compared to classic models. Auto-ignition is an unnecessary option for home use. Fuel is loaded continuously, the fireplace burns constantly.

Manufacturers have provided the possibility of delayed heating for consumers who heat their homes at night, in the off-season, or simply want to spend the weekend in a warm home.

When choosing an automatic ignition, take into account the type of mechanism that lights the flame (timer, temperature sensor, GSM module).

Cost-effectiveness and energy dependence

The heat transfer of wood, coal and pellets differs from each other. To get the same power from one bookmark, peat and sawdust, for example, need to burn for different amounts of time. The heat transfer of materials will differ, which will affect costs in monetary terms. 1 ton of pellets can replace a trailer of firewood in terms of calorific value. At the same time, the consumption of materials per unit of time differs. Taking this feature into account, the most efficient energy carrier is selected.

The consumption of different materials for the boiler is different.

Any TKDG or its module combined with a boiler room operates only from the mains. Setting up a non-volatile unit is expensive, because... You will need several powerful batteries and additional equipment for supplying current.

However, in emergency situations, backup power to the boiler will not hurt. The battery should be selected taking into account the battery life.

Efficiency

The indicator determines the rated power (heat transfer) of the unit and is 80-90% with proper operation. Because the boiler can be used constantly or periodically; low efficiency each time the system is started will hit the pocket, increasing fuel and electricity consumption.

Remote control

GSM controllers program boiler operating modes and notify the owner when critical (pre-emergency) values of several indicators are reached at once. For operational management purposes, the buyer should pay attention to the number of available SIM cards (providers), a set of commands, and the ability to analyze statistics online through a browser.

Installation procedure

The purchase of a solid fuel boiler equipped with everything necessary is available. But usually it needs to be installed. You can do this yourself. To complete this procedure, you must take the following steps:

- First install the fan. It can be placed where there is an ash pan door or one designed for air supply. Some models of solid fuel boilers already have space for installing a fan. If this is not the case, you will need to drill holes for the corresponding bolts yourself. In this case, the fan must be installed on a special heat-resistant gasket.

- Next, you need to directly connect the automation to the boiler. Typically, the installation location of the controller is provided in the upper part of the boiler body. It is important to make sure that the place where the electronic board is attached will not overheat. Otherwise, the increase in temperature may cause system malfunction.

- The necessary sensors are installed. Submersible ones can be used to control the coolant. Special sleeves are provided for them.

- All elements must be installed in accordance with the connection diagram. It is usually included in the documentation provided when purchasing the control system.

After the connection is completed, it is necessary to configure the equipment.

Operating principle of a solid fuel boiler Source househill.ru

How to calculate boiler power

SNiP 2.04.01-85 – technical guide for installing TT boilers. According to a simplified scheme, the heating power is calculated at a rate of 1 kW per 10 m² (with ceilings up to 3 m, brick walls laid in 2 rows). The total area is divided by 10 and the required power is obtained. Additionally, the degree of insulation of the house, heat loss, inaccuracies taking into account the complex layout, and the presence of hot water circuits are taken into account. The margin for each parameter should be 10-20%.

Heating power is calculated using the technical manual.

When the power is overloaded, the boiler becomes underloaded. It can be eliminated by connecting additional equipment.

If there is a lack of power, the rooms will not warm up, and the system will need to be redone.

The best solid fuel boilers with automatic fuel supply

When considering purchasing a solid fuel boiler for heating a private home, which one is better to choose?

The range of boilers and bunkers allows you to equip boiler rooms to suit your needs.

Metal-Fach SMART Auto ECO 20

Efficiency – 90%. Remote control with automatic security group. Heated with sorted coal and wood. Storage reserve – 5 days. Power is 6-20 kW.

Galmet Duo 17

Efficiency – 86%. Remote control with overheating protection, handheld programmer. Heated with coal, briquettes and wood. Storage reserve – 12 days. Power – 3-17 kW.

Galmet Duo 17 has an efficiency of 86%.

Zota Pellet 100A

Efficiency – 90%. Remote and manual control. Options - automatic ignition, ash removal, heat exchanger cleaning. Heated with pellets and wood. Bunker reserve – 10 days. Power – 5-100 kW. The unit is connected to a room thermostat.

Zota Optima 20

Efficiency – 85%. GSM control. Options: weather-compensated automatic. Can be heated with any fuel in manual mode. The reserve for one load is 1-2 days. Power – 5-20 kW. A heating element connection is provided.

ACV Tkan 100

Efficiency – 85%. Sensor system, manual control. Options - automatic ignition, ash removal, heat exchanger cleaning, overheating control. Can be heated with any fuel. Bunker reserve – up to 7 days. Power – 5-100 kW.

ACV Tkan 100 is a model with automatic ignition.

Wattek Pyrotek 36

Efficiency – 90%, power – 5-36 kW (pyrolysis). Sensor system, automatic control. Heated with wood and briquettes. Storage reserve – 1-3 days. Connection of a boiler and heat accumulator is provided.

Pereko KSP Duo 18

Efficiency – 95%. Sensor system, electronic control with safety group. It is heated with eco-peas, pellets, firewood, and brown coal. There is a chamber for burning wood. Storage reserve – up to 2 days. Power – 5-18 kW. Only heating equipment can be connected.

Heiztechnik Q Eko Lux 15

Efficiency – 88%. Sensor system. Options – remote control, burner auto-cleaning. Heated with coal and pellets. The reserve for one load is 2-4 days. Power – 5-15 kW. Connection of additional equipment is provided.

Boiler reviews

Alexander, 37 years old, Syzran

I bought Metal-Fach SMART OPTIMA 19 for boiler heating. I use firewood. One load is enough for 12 hours. The case is durable, steel. Mechanical control. Serves for 5 years without breakdowns.

David, 40 years old, Nakhodka

I use ZOTA Topol-M 30. A powerful unit that can withstand the connection of a heat accumulator. Compact, easy to clean. Large combustion chamber for 10 hours. The unit requires high-quality installation and proper piping. The disadvantage is the lack of a draft thermostat. I had to install it myself.

Sergey, 45 years old, Tula

Protherm Beaver 30DLO with a cast iron heat exchanger has a safety group with many sensors. The design is on par, but these characteristics turned out to be unnecessary during operation. Firewood burns out in 2 hours, you need to chop it finely. Efficiency is high. After 4 months, the cast iron section of the heat exchanger burst. The device is intended only for antifreeze approved by the manufacturer. Replacement of goods was refused. The second purchase was thought out to the smallest detail. For a 2-story house I took a Turkish Totem with a side bunker. A simple, silent unit.

TKDG is used instead of gas boilers for heating and space heating. Purchasing a unit is advisable if the storage capacity ensures long-term autonomy. The less often it is filled, the more convenient the operation of the boiler.