Any manufacturer of gas heating equipment tries to limit consumer access to the design of the device as much as possible. In this way, the number of possible accidents is reduced. Professional gas boiler repair requires experience. The customer service department is reluctant to share information - this is their main source of income. Therefore, there is not much information about the causes of malfunctions.

However, it is possible to repair gas boilers on your own, but provided that you have an understanding of the problem that has arisen and experience working with your own hands.

Is it possible or impossible to repair a gas boiler without a specialist?

A typical gas boiler consists of many elements, which can mainly be combined into 3 groups:

- Burner.

- Security blocks.

- A heat exchange unit equipped with several additional devices, which include a fan, circulation pump and many others.

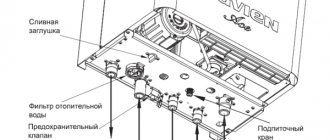

A simplified structure of this mechanism can be represented as follows.

If you detail the picture, you can find about 2 dozen different elements in the device.

The main danger during repairs is a possible gas leak. This can happen due to improper repair, dismantling or installation of equipment related to the fuel supply.

Therefore, it is better to entrust the repair of these parts of the structure to a specialist. Also, you should not troubleshoot electronic equipment in gas boilers yourself. Automation is a specific device, therefore, without the appropriate qualifications, it is almost impossible to correctly carry out restoration work and repair such equipment yourself.

What can you repair yourself?

All other elements can be repaired yourself, for example:

- The heat exchanger is washed manually (to do this, the unit is dismantled, after which it must be correctly put back in place). You can perform this work without dismantling - using pumps.

- Chimney cleaning will be needed in cases where there is a problem with draft (mechanical or chemical removal of blockages is carried out).

- Repair of the boost fan by lubricating its bearings with technical oil.

In fact, you can repair a gas boiler yourself only in cases where there are mechanical damages or blockages that can be easily identified visually (or by smell).

Other breakdowns are considered more serious, so they are repaired with the help of a specialist, and not with your own hands.

The main causes of gas boiler failure

Before you figure out how to repair a gas boiler with your own hands, it is useful to understand why exactly malfunctions occur. Correct understanding of the reasons will help to avoid the problem in the future. Practice shows that 4 harmful factors most often affect:

- Power surges - this problem is especially relevant in remote towns and villages. Modern equipment is necessarily equipped with stabilizers, as well as energy storage devices, which ensure the device operates for a short time even after the source is turned off. Therefore, if there are no such devices, you should purchase them in advance.

- Poor quality water - this problem arises in cases where the equipment is used not only for heating, but also to produce hot water for domestic purposes (double-circuit gas boiler). It is not the water itself that harms the equipment, but the presence of salts in it, which increase hardness. If the concentration of these insoluble substances is quite high, this can lead to wear and tear of the equipment in just 1-2 seasons. Therefore, it is necessary to take care of installing filters that purify water.

- Installation errors can lead to quite serious consequences, including irreparable breakdowns and failure of all equipment. Therefore, you can trust this work only to qualified specialists.

- frosty winters can also play a role . Typically, during such a period, neighbors turn on the equipment at full power, and it operates in this mode for a long time. As a result, the pressure in the gas pipeline system drops noticeably, and the boilers begin to work largely in vain. At this point, you can use equipment that runs on another fuel (for example, diesel). It makes sense to purchase it if the region has long, harsh winters.

Running self-test

The Navien boiler self-diagnosis system operates constantly and does not require a separate startup.

The probability of a failure of one or another node exists at any time, so the sensors send signals about the status of certain elements 24/7, never stopping.

If the sensor stops working for any reason, the corresponding error code immediately lights up on the display. This is an important function that helps maintain performance and timely troubleshooting .

Table of common breakdowns

The most common gas boiler breakdowns are described in the table.

| problem | possible reasons | what to do |

| small burner flame | air entering the gas pipeline or nozzles becoming clogged | call a technician |

| the burner goes out quickly | malfunction of the ionization electrode | |

| the flame comes off, the nozzle makes an unusual noise | the draft is too strong (the chimney pipe is high) or the pressure in the system is not adjusted | reduce cravings |

| the boiler does not turn on | different | you can turn the plug to change contacts and turn it on again |

| disruption of automation and electronic equipment | different: difficult to eliminate on your own | call a technician |

| incorrect operation, voltage drop | power fluctuations | install stabilizer |

| scale blockage | hard water | clean and install filter |

| overheat | heat exchanger clogged with soot | clean the mechanism manually |

A video review of possible flame problems and their causes can be seen here.

Basic error codes and their interpretation

Let's look at what error codes may appear on the unit display:

| Error code | Fault type |

| E01-02 | Lack of coolant in the system (flow sensor malfunction) |

| E03 | No flame |

| E04 | False evidence of the presence of a flame (spark breakdown to the sensor) |

| E05 | Exhaust temperature sensor break |

| E06 | Exhaust temperature sensor short circuit |

| E07 | Broken DHW temperature sensor |

| E08 | Short circuit of DHW temperature sensor |

| E09 | Fan failure |

| E10 | Malfunction of the smoke removal system |

| E13 | Short circuit of the OM flow sensor |

| E15 | Malfunction or failure of the control board |

| E16 | Exceeding the permissible boiler heating temperature |

| E18 | Smoke sensor overheating |

| E27 | Short circuit or break in the air pressure sensor |

The appearance of most errors is accompanied by a shutdown of the boiler, which is dangerous in winter, so you should respond to them as quickly as possible.

How to repair a boiler yourself: step-by-step instructions

Once a specific breakdown has been accurately diagnosed, you can begin to fix it. Of course, if you are sure that this is a feasible task that does not require special skills and equipment.

Preparatory stage

- First of all, you need to disconnect the device from the power supply and also turn off the gas valve tightly. Even if the repair is not related to elements in direct contact with fuel, this condition is mandatory.

- If it is difficult to estimate the time of restoration work, and it could theoretically take several hours, you should completely drain the water from the heating system or pour in an antifreeze solution (if it is not there). The fact is that during the repair the air temperature in the room may drop to negative values, and the water will freeze.

- Safety precautions: along with turning off the gas valve and de-energizing the system, you should also remember that before repairs, the working surface must cool to an acceptable level. Otherwise, touching it may cause burns.

Cleaning the heat exchanger

If the boiler overheats, this may indicate 2 reasons:

- The automation that controls the operation of the device is faulty.

- The heat exchanger is clogged (soot deposits).

Automation can be repaired only with the help of special equipment, which in most cases is not available in the house. But it is quite possible to clean the heat exchanger yourself.

The sequence of actions is as follows:

- Turn off the boiler and allow it to cool.

- The taps are turned off.

- Remove the front cover.

- Dump the remaining water (open a hot water tap or a valve inside the mechanism to drain water from the heating system).

- Remove the heat exchanger.

- The heat exchanger is cleaned first mechanically, then in a solution of vinegar and citric acid, taken in equal quantities (you can use a tablespoon per liter of water). Instead of a solution, you can also use special formulations purchased in the store.

- The heat exchanger is kept in this mixture for 1-2 hours until completely cleaned.

- Then rinse with running water and wipe dry.

- Put the heat exchanger back, close the lid, and fasten all the parts.

Chimney cleaning

Reduced draft and overheating of a gas boiler can certainly be associated with a clogged chimney. It is in this part of the system that the largest amount of soot accumulates. However, dirt accumulation is quite rare since the gas does not produce a large amount of waste.

Types of sealants

In today's everyday life, a large number of products with sealing properties are used.

Based on their chemical composition, sealants are divided into the following main types:

- acrylic - unstable, do not tolerate temperature changes;

- polyurethane - elastic, have high adhesion to metals, resistant to corrosion and temperature;

- silicone - the most common type of universal sealants, retain elasticity and moisture resistance over a wide temperature range, and are durable.

When sealing leaks in metal elements of a heating system with silicone sealant, it is permissible to use only its neutral variety, but not the acidic one, since the acetic acid contained in the acidic sealant will cause active corrosion of the metal.

Heat-resistant sealant for heating pipes is used for metal and polymer materials. This product properly fulfills its purpose - to prevent the penetration of moisture from damaged elements of the heating system. The sealing substance, which is a viscous mass, hardens quite quickly at the site of application and subsequently withstands high temperatures.

To seal threaded connections in modern heating networks, anaerobic adhesive sealant is used instead of flax tow and FUM tape. The environmental friendliness of such a sealant allows it to be used not only in heating systems, but also in plumbing systems.

Sealant for heating boilers is used to eliminate gaps in places where heat resistance of the material up to 1500°C is required.

Using this product, it is possible to seal cracks in heat exchangers and chimneys of boilers and furnaces. After hardening in the seams between surfaces of different materials (metal, brick, concrete), the substance retains its tightness.

Do-it-yourself repair of double-circuit boilers

Double-circuit boilers should be repaired especially often, since they work in intensive mode, heating rooms and storing hot water for domestic needs.

NOTE

During the repair of gas boilers, structures will almost always need to be dismantled. You need to carry it out carefully, remembering the connection sequence, so that later you can correctly assemble all the elements of the system.

Repair of a wall-mounted gas boiler (cleaning and flushing the heat exchanger with special means) is clearly shown here:

Organization of access to the control system

Attention!

Switch off the power supply to the boiler at the external switch before performing the following operations.

Checking the status of fuses

- Remove the back cover on the control panel

(Fig. 1.54);

- Remove the fuses (Fig. 1.55).

Removing the timer

- Disconnect the electrical connector “P1” from the timer (Fig. 1.56);

- Unscrew the screws “Q1” (Fig. 1.57);

- Remove the timer from the control panel (Fig. 1.58).

Removing the control board

- Disconnect the boiler from the power supply

- Remove the back cover of the control panel

- Disconnect all electrical connectors on the control board

- Unscrew the screws “R1” (Fig. 1.59);

- Detach the front decorative panel from the base of the control panel

- Unscrew the “S1” screws and remove the control board (Fig. 1.60).

Malfunctions of gas boilers: prevention

Obviously, a preventative measure is always better than repairing a breakdown that has already occurred. Therefore, it is important to know about those ways to prevent malfunctions of gas boilers that will help you avoid trouble and practically guarantee that the problem will not be taken by surprise.

First of all, you should refer to the instructions from the manufacturer, which detail the rules for operating the mechanism. As a rule, they are almost the same for different models.

Cleaning the heat exchanger

This is the most vulnerable place in the boiler, since a large amount of soot periodically accumulates in it. The heat exchanger is in most cases made of stainless steel, less often - of copper. It must be cleaned at least once every 3-4 years.

This is done with a metal brush. And if the mechanism is made of copper, use a metal sponge, which is used for washing dishes. It is advisable to monitor its condition annually for contamination, especially after a cold winter, when fuel consumption increases significantly.

Pressure check

Carried out periodically, several times a year. The optimal range for each model may vary slightly, but is usually between 1.0 and 2.0 bar (if the mechanism is cold). If the indicator drops regularly, it is preferable to immediately contact a service company.

Checking the water level

This is a very important requirement. After all, if the volume of moisture is less than standard, this can lead to fairly rapid wear of the mechanisms. The level is monitored annually, especially often after repair work, when moisture can evaporate faster than usual.

In this case, every summer, before the start of the next heating season, all liquid should be removed, and parts and components should be carefully inspected for the presence of scale, dirt, damage and other malfunctions.

Proper boiler care

Includes the usual safety measures:

- Do not direct water jets at the equipment, i.e. It can only be washed with a cloth (by hand).

- Jets of air and steam, especially hot ones, are not allowed to enter. Therefore, it is better not to place equipment in the kitchen.

- It is also prohibited to place any objects on the surface of the unit.

- Impacts, mechanical impacts, radiation, etc. are not allowed.

- If there is a long period of downtime (1 or several seasons), the equipment is prepared for it in advance. For example, you need to take care of protection against freezing, which is described in detail in the instructions for the gas boiler.

Thus, in some cases it is indeed possible to repair a gas boiler with your own hands.

But if the breakdowns are quite serious, or the malfunctions of gas boilers are not completely clear, there is only one way out - to invite a specialist from a service company.