The quality of heating of the entire house depends on the serviceability of the gas boiler, which is especially important in the cold season. Even the slightest breakdown can cause the equipment owner to have a panic attack, since repairing it can be too expensive. Agree, it is not always necessary to call a specialist, because you can independently figure out the reasons for the malfunction of the Conord gas boiler and repair the equipment yourself.

Despite the already established tendency to always blame the manufacturer, often gas boiler breakdowns have absolutely nothing to do with production features. They often arise due to a malfunction in the equipment settings, unstable pressure or voltage in the network.

Further in the article we will tell you what breakdowns of the Conord boiler occur most often, and how to independently restore its operation after another failure. In some cases, repairs may not be necessary because all you need to do to fix the problem is simply set the correct settings.

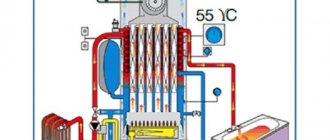

The principle of operation of a gas burner

There are several different types of gas burners, but they operate on the same principle.

The burner is a hollow metal tube with several holes (nozzles). Gas is supplied into it, which burns in air forced into the combustion chamber.

As a result, a mixture of combustion products is formed (carbon monoxide, carbon dioxide, water vapor, soot - pure carbon), which is discharged outside. The gas is distributed evenly thanks to a system of nozzles, and the air is forced through natural draft (in industrial furnaces the draft is forced).

It can be represented schematically like this.

Operating principle of a gas burner (diagram)

And in a real gas boiler the burner looks like this.

Thus, if a gas boiler does not light up, this means that any of the combustion conditions are not met:

- Gas is not supplied.

- There is no draft (no air supply).

- Combustion products are not removed (as a result, they accumulate and do not allow the flame to flare up, which is why it goes out immediately after ignition).

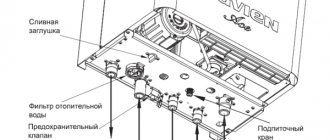

How to clean its modules

We have previously published detailed instructions for cleaning gas boilers. In order not to repeat ourselves, we list only the elements that need to be cleaned in the case of Signal gas boilers:

- Heat exchanger. To clean it, you need to remove the top or side panel of the case, depending on the model. Cleaning is done with a metal brush, sandpaper and other convenient means.

- Main burner. It can be removed without disassembling the boiler by unscrewing the screws at the bottom of the front panel. The main burners rarely become dirty; use a cloth for cleaning; for more severe contamination, use metal brushes.

- Igniter, thermocouple and other automation contacts. The igniter is located above the burner, in the center (see the instructions for the exact location). This must be done carefully, using sandpaper or a soft brush, without leaving scratches or deforming the parts.

The main causes of problems with a gas boiler

You can begin to repair equipment only after the cause of the malfunction has been accurately determined. Then you can determine whether it is possible to fix it yourself or whether you will have to call a specialist.

External causes of boiler malfunction

The reasons for the extinguishing of the boiler burner can be caused by external factors:

- deterioration of the natural draft of the chimney or its overturning;

- decrease in gas pressure in the main;

- gas meter malfunction;

- gas filter clogged;

- power outage;

- lack of supply air;

- a draft in the house, creating a short-term excess of supply air;

- heating system problems.

Very rarely, sharp gusts of wind can upset the draft in vertical external chimneys or exhaust shafts built into the thickness of the wall, which is why the gas boiler can go out.

Problems inside the boiler

Modern gas boilers are equipped with a minimum set of automatic safety systems that shut off the gas supply for the following reasons:

- Gas pressure drop in the line.

- Insufficient draft created by the chimney.

- Burner damping due to external influence.

An expanded set of automation allows you to control the temperature of the coolant, regulate the intensity of combustion, and so on. The more complex the device, the more elements it contains that are susceptible to malfunctions. Because of them, the fuel supply is blocked and you should look for the reason why the gas boiler does not ignite.

Here is a list of possible malfunctions:

- The burner ignites, but goes out after a few seconds. The cause may be contamination of the photocell of the flame control sensor with soot. You need to clean the element and try to ignite again.

- Failure of the draft sensor blocks the flow of gas to the burner. You can try to clean the sensor, if this does not help, then replace it.

- A failed thermocouple that controls the safety valve will prevent the burner from working when the control wheel is released during ignition. The faulty element must be replaced.

- The gas supply is also blocked if the coolant pressure sensor is faulty. As a temporary solution, its contacts can be enabled directly, but then a new element can be installed later.

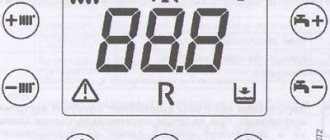

- A “dead” display may indicate that the controller fuse has blown; replacing it will help. The same effect occurs when the phasing of the electrical network is incorrect; it can be treated simply: you need to pull the plug out of the socket and insert it back, turning it upside down.

The product passport or operating instructions will help determine why the boiler goes out and where to look for the fault. They decipher the error codes that appear on the display of the heating installation in each case of incorrect operation.

Popular breakdowns and their elimination

The lower the serial number of the error, the more often it occurs when operating the Beretta boiler.

Let's look at the most common errors and possible ways to eliminate them:

- A01. Blockage due to lack of flame. There are several possible reasons - problems with the gas supply in the main line, the gas supply valve to the boiler is closed, the burner nozzles are severely clogged. Find out if there is gas in the line, clean the burner and nozzles.

- A02. Overheating of the heat exchanger indicates a lack of water. Check the operation of the circulation pump and the coolant pressure, add fluid to the system.

- A03. High pressure in the chimney indicates blockage of the outlet with ice, frost, and soot accumulation. Possible weather conditions - strong gusty winds.

- A 04. A drop in coolant pressure may be caused by a lack of liquid. Check the system for leaks and repair if found.

- A05. Problems with the DHW line thermistor can be eliminated by replacing the sensor.

- A06. A failed heating circuit thermistor must be replaced immediately.

- E33. It is necessary to swap the electrodes in the power plug. Beretta boilers are phase-dependent and do not work if the phase wire is incorrectly connected.

- E46. Exceeding the permissible temperature of the coolant indicates problems in the circulation of the liquid. You should check the operating mode of the circulation pump.

- The bell symbol (bell, p) is flashing. This is a signal from the chimney pressure sensor, indicating that there is an obstacle to the exit of smoke, or the formation of ice or frost at the pipe outlet.

IMPORTANT! The Beretta boiler error is reset by pressing the shutdown button and turning the boiler back on after 5-6 seconds.

What you can do yourself

The sequence of first actions is the same in all cases:

- The boiler is disconnected from the power supply, and the gas tap is completely closed.

- A visual inspection is carried out to check for possible blockages and mechanical damage.

- If the combustion chamber is open, you can simply light a match or lighter and hold the flame near the holes through which air is supplied to the burner. If the draft is not clogged, the tongue will immediately deflect towards the holes, and the flame will burn evenly. If the flame deflects weakly, then there are large blockages.

- You can also draw conclusions based on the operation of the boiler. If it hums quite loudly, and the color of the flame is closer to colorless, then the draft is too strong - it needs to be reduced.

Similar problems can arise at the very beginning of the boiler operation - in case of improper installation, with deviations from the diagram presented below.

Removing air pockets in the system

It's better to start with batteries. To remove air pockets, a Mayevsky tap is usually installed on them. We open it and wait for the water to run. Did you run? Let's close. Such manipulations must be done with each heating device separately.

How to start a boiler with your own hands photo

After the air is removed from the batteries, the pressure in the system will decrease and the pressure gauge needle will drop. At this stage of work, the solution to the question of how to start the boiler involves re-filling the system with liquid.

Now, the most difficult thing is that starting gas boilers requires bleeding air from the circulation pump. To do this, the boiler needs to be disassembled a little. We remove the front cover and look for a cylindrical object with a shiny lid in the middle, which has a slot for a screwdriver. After we have found it, we put the boiler into operation - we supply it with electrical power and set the water heating controls to the operating position.

Relieving air from the circulation pump when starting the boiler photo

The circulation pump will immediately turn on - you will hear a faint hum and loud gurgling and many incomprehensible sounds. This is fine. As long as the pump is aired, it will be so. Take a screwdriver and slowly unscrew the cap in the middle of the pump - as soon as water starts seeping out from under it, screw it back. After two or three such manipulations, the air will come out completely, the strange sounds will subside, the electric ignition will work and start working. Check the pressure again and add water to the system if necessary.

Basically, that's it. While the system is warming up, you can begin to study the instructions in detail (if, of course, you have not already done so) and start debugging the system that involves starting the boiler. Everything is simple here - the batteries closest to the boiler need to be screwed on, and the ones farther away need to be turned on to their full potential. This debugging is carried out using control valves installed on the supply connection pipe to the heating radiator.

If the boiler does not start at all

It may also be that the boiler does not turn on - i.e. there is no flame initially.

The reasons for this may be:

- The simplest is low voltage or other problems in the electrical network. What to do: you should once again check the connection, the integrity of the electrical wiring, and the serviceability of the outlet.

- The electronic control system does not work. Then you need to call a service technician, since it is almost impossible to fix such malfunctions yourself.

- The burner nozzles are clogged - you can carefully clean them at home. The cause of clogging is incomplete combustion of gas and soot deposition. Normally, the flame burns blue, but a blockage can be identified by the abundance of red, orange and yellow hues in the flame. How you can eliminate the cause is shown here.

- Low pressure in the gas pipeline network, fluctuations. You should clarify information about a possible accident or temporary failure by calling the service company.

This is important to remember

Gas devices are classified as high-risk equipment. Therefore, the main thing to do in case of a problem is:

- turn off the boiler;

- check if there is gas contamination in the room;

- ventilate the room.

Only after this can you figure out what to do if the gas boiler does not light.

After this, the main thing is to check the traction, and then study the error code on the display. This will help you understand whether you are able to fix the problem yourself or whether you will have to call a technician.

So, if the boiler does not ignite or if its flame is very weak and goes out after a while, then this may mainly be due to mechanical reasons (clogging). And such malfunctions can be eliminated yourself.

If the reason is different (or it cannot be determined reliably), it is preferable to contact a gas equipment servicing company to call a technician.

Price range

Conord boilers belong to the group of inexpensive equipment. Prices for units fall within the range of 11-47 thousand rubles, which is significantly cheaper than imported units.

A big bonus is the energy independence of the boilers, which frees the user from the need to purchase a voltage stabilizer as unnecessary.

IMPORTANT!

Purchasing water filters is necessary, especially for residents of regions with hard water. You also need to enter into a guarantee agreement, which you will also have to pay.

Why doesn't the boiler start?

Often problems are shown as an error code on the display. All modern models Vaillant (“Valiant”), Baxi (“Baxi”), Ferroli (“Ferroli”) are equipped with a self-diagnosis system. Each brand has its own codes and their meanings. If the display does not show symbols, then you need to look for the cause of the problem yourself.

Problems with wall and floor units can be caused by external and internal factors.

External ones include:

- Insufficient gas pressure in the main;

- Chimney problems;

- Power surges in the network;

- Draft, low temperature in the room/boiler room.

How to deal with problems

If the boiler goes out and does not light up again, check the quality of ventilation in the room. This is a common cause of problems for atmospheric models “Proterm”, “Navien”, “Ariston”, “Bosch” with an open combustion chamber, because they take combustion air from the room.

- Organize high-quality ventilation in the room;

- Install ventilation valves on sealed window packages;

- Open the window in the boiler room for air flow.

Check the presence of draft in the boiler chamber. To do this, light a match and bring it to the control window or chimney outlet. If there is draft, the flame will deviate to the side. If not present, it will burn evenly. In the latter case, a chimney inspection is required.

Problems with the chimney part

This is excess, deficiency or backdraft. All this leads to the fading of the wick and automatic shutdown of the equipment.

Backdraft or blowing out occurs due to weather conditions: strong winds, pressure changes lead to the burner extinguishing. During installation, take into account the requirements for the height of the chimney:

- The height of the pipe on a flat roof is at least 50 cm;

- With a distance from the roof ridge of 1.5 meters - from 50 cm above the ridge;

- At a distance of 1.5–3 meters - level with the ridge.

Compliance with these parameters will help to avoid blowing and backdraft.

Excess air flow occurs with a powerful kitchen hood or ventilation. The solution is to turn off the hood while the boiler is operating.

Lack or absence of traction provokes:

- Blockages. Occurs in stationary chimneys. Clear the mine of leaves, debris, and construction debris. Fixed and coaxial pipes can become covered with ice in winter. Along with combustion products, hot steam escapes into the street, condensation forms, which freezes on surfaces. Insulate the chimney.

- Damage, burnout of the pipe. Only replacing the chimney will help.

Line pressure drop

Does the dual-circuit device “AOGV”, “Beretta” or “Vailant” turn off and not turn on? This is possible when the fuel supply is unstable. For the same reason, the burner does not light the first time. First of all, check:

- Pipes and joints for gas leaks. To do this, lubricate them with soap foam. If bubbles appear, there is a leak. Then turn off the valves, open the window and call the gas workers.

- Counter. If there is a breakdown, the meter readings do not change; noise and crackling are heard. You can’t fix the problem yourself—you need a specialist.

If everything is fine, wait until the gas supply is restored.

Does your equipment not start after a long shutdown? It may be worth using antifreeze as a coolant. It does not freeze when the temperature drops and allows you to safely start the system after a long period of inactivity.

Fan fault

All boilers with a closed combustion chamber - such as Buderus, Wolf, Danko, Lemax - are equipped with fans. They forcibly discharge combustion products into the street. If you hear strong noises when the blades rotate or do not hear operating sounds at all, carry out diagnostics and replace the element if it breaks.

Other faults

To find other problems, it will be useful to know the structure of the boiler you are going to repair. “Aton”, “Siberia”, “Buderus”, “Ferolli” or another brand may have their own characteristics. But the following sensors and components often break down:

- Circulation pump. If it fails, the boiler may make noise and the flame in the burner goes out. In such cases, the equipment will not work for heating and hot water supply. The only solution is to replace the pump.

- Igniter. Incorrect pressure adjustment results in flame failure. The protection is triggered and the operation stops. Set the correct fuel supply.

- Burner. The appliance has switched off and will not re-ignite. Check the burner nozzles for blockages. Clean them from soot and dust. Also clean the sensor photocell and try ignition again.

Diagnostics and replacement are also carried out in case of breakdown of the thermocouple, pressure and draft sensors.

Does the device not start after turning off? Check the remote control, replace the batteries. Examine the display. If it does not work, diagnose the controller.

Heating equipment that is additionally connected to the network suffers from power surges. If the values are lower or higher than the nominal value, the unit will not work. It is recommended to connect a voltage stabilizer.

It is important to understand that a boiler emergency stop can happen for a variety of reasons. It's good if a code appears on the display. For example, the display of the Proterm model may display error A6. This means that the temperature in the room has dropped and you need to connect an additional heater. So, thanks to symbolic codes, it is easier for the user to detect the problem. In other cases, you will have to check all boiler systems.

It is always easier to prevent a breakdown than to repair it. Therefore, monitor the operation of the boiler and carry out maintenance once a year.

Reasons for stopping work

There may be several reasons, let’s consider each one separately:

1. Long boiler downtime.

As a result, the boiler may defrost and become unusable. As a result, there is a sharp attenuation, and the sounds of wind blowing out the flame are heard from the combustion chamber.

Due to these factors, an alarm appears on the dashboard, indicating the need for urgent diagnostics of the device. Modern boilers are a rather complex and fully automated system

Therefore, if one of the sensors signals a problem, the unit stops working

There is no need to immediately change the boiler or install a new chimney; it is very important to understand the problem and find a way to solve it. 2

2

Chimney fault

If there are problems in the form of boiler attenuation, it is also important to check the serviceability and functioning of the chimney. The first reason may be the formation of ice on the walls of the chimney, which occurs through the settling of hot steam followed by the formation of condensation

After a certain period of time, the condensate freezes and becomes a thick layer of ice. After this, the draft decreases and the boiler goes out. The solution to this problem will be to insulate it in order to minimize the freezing of the condensate.

3.Reverse thrust. As a rule, this type of problem occurs during strong gusts of wind. The wind enters the chimney and accordingly blows out the boiler flame. Backdraft is the most common reason for the boiler to blow out and turn off

Please note: backdraft is quite dangerous, since some old-type boilers have outdated automation that does not turn off the boiler, and it continues to accumulate combustion products indoors. 4

Insufficient chimney rise. If the height of the chimney is not enough to prevent air from entering the boiler with subsequent attenuation, a good solution for quick ignition would be to increase its length, at which the top of the chimney should extend beyond the ridge of the roof by approximately 50-60 cm

4. Insufficient chimney rise.

If the height of the chimney is not enough to prevent air from entering the boiler with subsequent extinguishing, a good solution for quick ignition would be to increase its length, at which the top of the chimney should extend beyond the ridge of the roof by approximately 50-60 cm.

5. Pipe burnout.

Insufficient draft occurs as a result of the presence of a hole in the pipe into which the wind flows, and therefore the chimney begins to function poorly. In this case, a complete replacement of the chimney is required.

6. Voltage surges.

This reason does not depend in any way on external factors and occurs as a result of a drop in voltage level. When the proper voltage level is restored in many boilers, the flame lights up again, and therefore many owners do not even notice this problem. 7. Missing gas pressure.

Very often, the problem of a boiler dying out lies in the lack of sufficient gas pressure at the inlet to the boiler, at which point the unit plumps and dies out. The reason may be a malfunction of the network itself or internal reasons, namely:

7.1 Gas meter malfunction.

There are times when the boiler mechanism jams and it blocks the gas supply. To identify the source of the breakdown, it is necessary to check the operation of the counter mechanism, the readings of which must change.

7.2 The sealing of the fastenings is broken.

A gas leak provokes a drop in pressure, at which the system automatically operates and the gas apparatus goes out. This problem can be identified by the presence of a specific odor in the room.

Note:

You can carry out independent diagnostics and identify the problem using a regular sponge with soap suds - bubbles will appear at the leak sites.

The reason for the extinguishing of a gas boiler: why it lights up and goes out, methods of elimination

Hello, dear visitors of the site ballony.com.ua. Whatever the reason for the extinguishing of the gas boiler, it must be eliminated correctly and promptly. It is also necessary to have information about possible repair operations.

If a gas boiler suddenly goes out during the cold season, this causes huge problems for the owners. And often you have to wait quite a long time for the master’s visit. Therefore, you can try to carry out independent repairs. But for this you need to know all the possible causes of the problem and methods for eliminating it.

Main points

The boiler goes out when its automatic mechanism responds to the following violations:

- Reduction or disappearance of draft in the chimney.

- Drop in fuel pressure in the supply pipe.

- Flame extinguishment in the burner.

They arise from internal problems or the influence of external factors.

The simplest solutions are implemented if you have a floor-standing device installed, for example Danko, Zhitomir or Aton. They have a primitive design inside. And the answers to the dilemma of why a floor-standing gas boiler goes out are usually: powerful wind and other external influences.

Wall-mounted models are similar in design to a small autonomous boiler room. And there are more versions of turning them off:

- There is no coolant circulating in the heating circuit. This is indicated by the flow indicator.

- Air is supplied in weak volumes or its supply has been stopped. The pressure switch reacts here.

- Voltage surges.

- Power outage.

Heating boilers Conord

Rostovsky has a rich history and equally rich experience. Initially, the company was engaged in the repair of road equipment, but in the early 70s it was reoriented to the production of heating equipment.

At the same time, the name “Conord” appeared, which is an abbreviation for the words “Heating Boilers, Non-Standard Equipment, Rostov-on-Don.” The newly born plant began its activities with the production of the DON-16 boiler, famous throughout the USSR.

Heating equipment “Conord”

Today it is a modern enterprise, the technical equipment of which does not in any way remind of its advanced age. The production lines are equipped with the latest high-precision laser machines, imported presses and robots, which allow us to quickly and efficiently produce reliable and affordable devices. The main part of the range consists of gas water heaters, as well as heating boilers - gas, solid fuel and combined.

The range of boilers is quite diverse. First of all, the products differ in the gas burner device used (for short, they call it automatic). Three varieties are available.

Automation AGU-T-M (Russia)

- is cheap;

- does not require power supply (a bimetallic plate is used as a temperature sensor);

- does not impose special requirements on operating conditions and is inexpensive to repair (replacing the bimetallic plate - the only “weak link” - costs only 50 rubles).

This type of automation is quite common in our country and its use is not limited to the Conord brand. You can also see it in such Russian boilers as Mimax and some others.

There is no ignition system in the AGU-T-M, so the boiler has to be started using a lighter or a match.

Automation Euro SIT (Italy)

A boiler with such automation will be more expensive, but it simplifies setting the operating mode and ensures a higher level of safety. It contains:

- igniter with safety device (thermocouple);

- sectional burner with Polidoro tubes;

- gas valve SIT;

- temperature sensor;

- traction sensor

Unlike AGU-T-M, this automation reacts not only to gas shutdown, but also to deterioration of draft in the chimney.

The coolant temperature is set using a thermostat and is maintained automatically by a gas valve.

A piezoelectric spark gap is used to ignite the boiler.

Honeywell (USA)

The automation is of the same type as Euro SIT, only other materials are used for the manufacture of some elements.

An economy mode function has been added, to enter which the ignition knob must be turned all the way.

Conord boilers are also divided into single-circuit and double-circuit.

The former are intended for connection only to the heating system, the latter can additionally perform the function of an instantaneous gas water heater.

Unlike many other boilers with two circuits, Conord does not turn off the heating while using hot water. The 2nd circuit heat exchanger is heated by the smoke pipes. But still, the amount of heat supplied to the heating circuit decreases at this time.

Navien boilers from the largest Korean manufacturer, as a rule, work properly. But it is still a technique, and sometimes it can fail. Let's look at the types of malfunctions of the Navien boiler, as well as ways to troubleshoot problems.

We’ll talk about the functions of an inverter for a heating boiler in this topic.

Do you know why double-circuit gas boilers are purchased more often than single-circuit ones? Using this link https://microklimat.pro/otopitelnoe-oborudovanie/kotly/dvuxkonturnye-gazovye-kotly-dlya-otopleniya-chastnogo-doma.html we will consider the advantages of this type of equipment, as well as installation and selection features.

Dilemmas with cravings

If before the incident the equipment was operating normally, but now the fuel supply is blocked due to the automatic valve, there may be several reasons simultaneously (and separately).

The most common reason for the extinguishing of a gas boiler in a private house is a decrease or disappearance of draft.

The first step here is to check the traction. A match or lighter is brought to the viewing window.

If the fire deviates away from the combustion compartment, then the draft is normal. With a vertical static flame it is absent.

Then the draft in the chimney is studied. A part of the tube connected to the outlet pipe is removed.

The presence of traction is checked in a similar way. If the verdict is positive, you need to clean the channels of your boiler. If negative, the chimney itself.

Soot deposits, combustion products, leaves and other debris can accumulate in it.

If pollution is concentrated at the entrance, cleaning operations are performed independently. If there are problems in the upper zone, the intervention of craftsmen with professional tools is necessary.

Product line

There are practically no wall-mounted boiler models in the brand’s line, so for a home heating system, consumers often purchase a Conord gas floor-standing boiler, which can be equipped with additional options. Floor-standing boiler models are produced in four series. The manufacturer makes all boilers from durable high-quality steel. To increase the stability of the boiler, its surface is treated with heat-resistant powder, which protects the device from high temperatures and loads.

Consumers who are interested in such a device as the Conord gas boiler, instructions for use are supplied by the manufacturer, should analyze devices from the following series:

- KSC-G-S;

- KSC-G-N;

- KSts-GV-S;

- KSts-GV-N.

Series KSts-G-S

In this series you can find a good single-circuit heating boiler, which is equipped with a functional gas supply regulator. Italian automation, which controls the operation of a domestic boiler, guarantees its safety, reliability and efficiency in the heating system of a house or apartment. Devices from this series can be adapted for heating buildings with an area of 80 to 300 sq.m., but for this you need to choose the right boiler in terms of power.

In order for boilers to meet the requirements of the heating scheme, it is important to pay attention to other parameters. Thus, the operating pressure of devices from the KSts-G-S series ranges from 0.2 to 1.9 bar, the minimum heating temperature of the coolant is 60 degrees, and the maximum is 90 degrees

Series KSts-G-N

More functional boilers can be purchased under the marking KSts-G-N. They are equipped with a unique cylindrical heat exchanger, which is made of high-quality cold-rolled steel. This solution allowed manufacturers to achieve the most efficient performance and ensure the ability to quickly and uniformly heat the coolant circulating in the circuit. This series includes single-circuit models that can be used to heat houses with an area of 100 to 300 sq.m.

Due to increased reliability, KSts-G-N boilers can operate in difficult conditions - they are designed for use in systems with operating pressures reaching 5 Bar. To optimize the heating process, excellent thermo-hydraulic automation is installed on the boilers. Since this series of products is more functional and versatile, the cost of boilers in it is somewhat more expensive - the minimum price of a basic device starts from 16 thousand rubles.

Series KSts-GV-S

An inexpensive double-circuit gas boiler Conord, reviews about which you should definitely read before purchasing, can be found under the marking KSts-GV-S. Models from this series are equipped with an additional circuit to provide hot water supply in the house. They operate under the control of Italian SIT automation and are designed to heat houses with an area of 120 to 300 sq.m.

Having studied reviews of the Conord gas boiler, purchasing a double-circuit unit, the owner solves two problems at once and equips his home with an appliance that will help heat the rooms and provide the necessary supply of hot water for household needs. The boilers are quite versatile - they can be used in almost any circuit.

Series KSts-GV-N

Among the products united under the marking KSts-GV-N, you can choose a good double-circuit gas boiler Conord, the technical characteristics of which are represented by the unique shape of the smoke collector and the presence of thermo-hydraulic automation.

KSts-GV-N boilers have a unique emergency protection system.

These models are the safest and most reliable. They are equipped with detectors that stop the gas supply if there is a threat of explosion. Also, the boiler can independently stabilize the operating process when it detects short-term reverse draft. The power of devices in this series ranges from 12 to 30 kW. You can read how to choose a gas boiler for your apartment here.

The Russian company has earned itself a good and strong reputation in the market through the production of reliable heating equipment. Among consumers, Conord gas boilers, reviews of which are mostly positive, are in consistently high demand.

In the manufacturer’s line, you can choose a boiler for almost any heating system - after all, the power of various models ranges from 8 to 30 kW. By correctly selecting a boiler from the brand’s product range, the owner can make it the basic element of the heating system of an apartment, country house or large private mansion.

Clogged nozzles or burner filters

These components are starting ones. And if, when you turn on the device, the pilot light does not ignite, it means that blockages have formed in them.

The following parts need to be cleaned:

- ignition nozzle,

- input filter with small cells in a mesh,

- burner filter.

Handy tools help in the work. For example, filters can be easily blown out with a vacuum cleaner.

The injectors are cleaned carefully with a thin copper wire. The process continues until the jets reach their original diameter.

Problems with closed-type turbocharged equipment

If you have installed a new chimneyless appliance, but the fireplace in it periodically goes out, it is worth checking the components and parts. The problem can be identified by the following symptoms:

- When the igniter is lit, it periodically goes out. This indicates a malfunction of the thermocouple, which affects the operation of the gas valve. The thermocouple is made in the form of a copper tube. At the end there is a bimetallic part. When different metals come into contact, a voltage of 20-50 MW builds up, which keeps the gas valve open. If the thermocouple breaks down, it cannot be repaired and must be replaced.

- Floor-standing unit “Hephaestus”, “AOGV”, etc. doesn't light up at all. Check the automation and wiring from the traction sensor to the automatic unit.

- Ignition occurs with popping noises, a yellow flame bursts out - this is a clogged jet. They can become clogged with soot, dust, and dirt. You can clean them yourself if you understand gas equipment.

- Circulation pump malfunction. In this case, the fire will go out, or ignition will not happen at all. The unit is being diagnosed and replaced.

- The traction sensor is broken or clogged. This flat element is connected to the fuel valve. Close the leading contacts and light the burner. If a fire occurs, then the sensor needs to be replaced. When oxidized, the contacts are cleaned with fine sandpaper.

Reduced pressure in the line

The first obvious symptom of this problem is the burner turning off. In this case, the pilot light does not go out, and the boiler turns off.

Here the movement of fuel through the pipeline is studied: the hose coming from the pipes is unscrewed and the valve is opened to the limit:

- If there is a strong hiss and there is a smell of methane, the gas is supplied normally.

- If these signs are weak or absent, there is a problem in the gas supply network.

After examining the picture, close the valve, place the hose in the primary position, and check the tightness of the joint areas using a soapy mixture. The presence of foam and bubbles indicates a leak.

Immediately block the gas supply, open all windows and doors, leave the room and call a special service. Eliminating such difficulties is the job of gas workers.

If there is no leak, inspect the meter for rust or scale. Because of them, the fuel flows poorly and incorrect indicators are displayed.

Federal Law No. 261 prohibits cleaning the flow meter yourself. This is the work of licensed technicians from the gas company.

The coolant in the heat exchanger does not heat up

If the coolant does not heat up either for heating or for supplying hot water, the reasons are as follows:

- The settings are set incorrectly. They need to be adjusted.

- The pump is blocked. You should try to reconfigure its indicators and put it into operation.

- A lot of scale has accumulated in the heat exchanger. It is recommended to descale the element using special products or home methods.

- Damage to temperature sensors. They need to be replaced with new ones.

If the water is not heated only for hot water supply, the problem is hidden in the three-way valve, which switches between heating and domestic hot water.

Also, the causes of this breakdown are clogging in the coolant, leaks in the heat exchanger or connections.

Oxygen deficiency

This phenomenon is usually caused by poor ventilation. It is determined by the following factors:

- window sealing,

- interior doors equipped with dense insulation and no gaps,

- a kitchen hood that is too powerful,

- unnatural ventilation.

The boiler may go out due to a powerful kitchen hood directing air through its channel.

The solution to the dilemma lies in installing supply valves on windows and walls. In the second case, ventilation devices are installed. They forcefully draw in air from the street.

Electrical problems

When the solenoid valve (EMV) does not make good contact with the thermocouple, there is incorrect information about the absence of a flame. This causes the fuel supply to be blocked.

For this reason, the gas boiler lights up and goes out after a short time or when selecting options.

This is a sign of a problem in the electrical circuit:

- The thermostat and thermocouple or vacuum indicator are not in contact.

- The thermocouple is outside the flame or does not provide the required voltage.

- The marked parts and the EMC coil are broken.

These difficulties can be eliminated with your own hands by strictly following this algorithm:

- Consistent resistance testing on indicators and contact devices. Indicators of 0.3 - 0.5 Ohm are considered normal.

- Cleaning all oxidized areas with fine sandpaper. Tightening loose contacts.

- Disconnecting the thermocouple from the main unit. Connecting the tester. Turning on the pilot burner by pressing the release button.

- Voltage measurement. Standardized values: 10 – 50 mV.

If the readings are normal, adjust the thermocouple position. If there is no voltage, the following measures are needed:

- remove the top cover of the main unit,

- The thermocouple is heated using a torch,

- Pressure is applied to the safety valve, after which it is released.

If the thermocouple does not work correctly, the wire contacts are checked.

If after pressure and release the valve is static, you need to remove the complex with contacts and direct 220 V voltage to the coil, bypassing the thermostat.

Then the boiler starts. If problems persist, it is necessary to change the EMC coil and thermocouple.

Low coolant pressure

On the front panel of each boiler there is a pressure gauge indicating the pressure in the heating system. It has red zones for readings that are too low and too high. A pressure of 1.5 bar is considered normal for a cold boiler: at 1 bar the arrow is already in the red zone, and at 0.5 bar the boiler will turn off due to a CE or CF error until the pressure is restored.

If the boiler was installed recently - a few weeks ago, this situation is common, you just need to add clean water through a special tap. But do not rush to add water to a system that has been in operation for several years.

When water heats up, it expands and the pressure rises - this is the norm. However, if it immediately jumps by 0.7 - 1.5 bar, this indicates a lack of air in the expansion tank.

If in such a situation you add water, heating up, it will increase the pressure too much and the safety valve will operate, releasing excess coolant.

The built-in expansion tank differs from the external one: it is flat and located at the back of the boiler. Inflator fitting – on top, with a threaded cap

To pump up the tank, you first need to relieve the pressure on the switched off boiler by draining some water. Then connect the pump or compressor to the fitting at the top back of the tank and pump it up to 1.3 - 1.4 bar. After turning off the pump, add water, bringing the pressure in the cold system to 1.5 - 1.6.

If even when the boiler heats up, low pressure in the heating circuit remains, then it is really necessary to add water. Where to find the tube intended for this is indicated in the instructions for the device model, but we will only remind you of the need to fill this tube with water before opening the tap so that air does not get into the pump and batteries.

Be sure to check all the taps, connections and radiators, as well as the insides of the boiler for leaks - the water circulating in the system has gone somewhere.

Common problems with turbocharged models

The indicated difficulties also arise in turbocharged vehicles. And since this technique has an isolated combustion compartment and additional components, it is characterized by the following difficulties:

- The hood or coaxial chimney is covered with ice.

- The integrated air blower is broken.

The culprits of the first problem are accumulated condensation and adhered snow.

You can avoid it by protecting the chimney from aggressive factors - installing a deflector.

If ice plugs have already formed, they can be melted with a hairdryer or a torch - a spray can.

As a rule, condensate settles in pipes of convection modifications, for example Lemax PRIME-V10.

Traffic jams form here due to temperature differences in air flows coming from the street and heading outside. They block the path to the combustion compartment.

The solution lies in lighting the chimney with a portable burner. When you remove the plug, insulate the pipes.

If the boiler has a built-in blower, as in the Baxi ECO-4s 24 model, and it goes out during operation or the wick does not start immediately, pay attention to the sounds that appear.

With stable functions there are measured beeps. Excessive noise is a sign of a problem.

Turbocharging, as a rule, is not repaired, but quickly replaced.

If there are no sounds when the device is operating, it means that the automatic mechanism is preventing the safety valve from opening and the filter does not ignite.

Call specialists to replace the turbocharger. Because this work is quite complex and associated with a certain risk.

Floor steel models Conord

Let us immediately note that all boilers of this brand are produced in a floor-standing version. “Steel” boilers are those whose heat exchanger is made of steel. It is easy to find such a device in a catalog or price list by the marking, which begins with the letters “KS” (steel boiler).

For example, it is the steel heat exchanger that is installed in the boiler of the KSC-G-16 brand.

Here the letter “C” denotes the cylindrical shape of the heat exchanger, “G” is the type of fuel (gas), and the number “16” is the power in kilowatts.

The presence of the letter “B” in the marking (for example, KSC-GV-20) means that the boiler is 2-circuit.

Boilers with a steel heat exchanger are lighter and heat up quickly. However, they are less reliable and not as durable as cast iron. A significant disadvantage of steel is its susceptibility to corrosion.

Situations with dual-circuit devices

This technique may fade due to the reasons mentioned above. But if none of the signs are suitable, then the difficulties are caused by the specifics of the boiler. This category includes the response of the protective system against water overheating.

Documents for devices with separate heat exchangers, for example Ariston Clas B Evo 24 FF, usually indicate prohibitions on the simultaneous opening of two taps.

And in the settings, the optimal temperature for heating water is initially selected. To do this, use the regulator on the control console. Example on the Navien Ace device:

It should be taken into account that when cold water is turned on, the consumption of hot water is reduced and heat is generated in an identical mode. As a result, the heat exchanger overheats. Then the automation reacts, shuts off the gas, and turns off the boiler.

If you operate the device strictly according to the instructions, but it still goes out, the gasket of the water mechanism must be changed. There is a high probability of it wearing out.

All identified problems can be avoided if you carefully monitor the boiler’s condition and regularly arrange its technical inspection.

If you find it difficult to identify the cause, or there is already a noticeable smell of gas in the room, call the experts immediately.

Excursions on models and brands

The indicated reasons may apply to boilers of different modifications and brands. Below are some examples of specific models.

First: Why does the AOGV 2321 gas boiler go out? As a rule, the wick goes out with a characteristic metallic click. Most often the reason lies in poor traction.

Second. The Zhukovsky boiler goes out. This unit has old automation. The problem lies in the oxidation of the contacts on the EMC and the burnt-out thermocouple. The valve is thoroughly cleaned in the connecting areas of the copper tubes. It is better to replace the thermocouple.

Third: If the Zhitomir-3 boiler goes out. The most common problem is that it only works briefly after startup.

The reason for this was the thermal breaker, which was poorly screwed into the EMC. There was weak contact between them by default. During the season of work it got even worse. After tightening it a little, the boiler stopped turning off.

Tips for use

Conords have the advantage over many competitors of the absence of service functions - everything is performed by thermo-hydraulic automation. There are only a few problems that can be encountered when using this reliable equipment - the boiler can go out for three reasons:

- the burner is dirty - it needs to be cleaned with a vacuum cleaner or brush;

- there is not enough air for the pilot burner (then it goes out first) - again, clean the nozzles and improve ventilation in the building;

- oxidation of thermostat contacts - you need to clean or move them.

This problem can also occur if the draft sensor or flame sensor is faulty. They are eliminated by service workers.