For most people, room conditioning systems are limited to the usual sleep systems. And this is not surprising, because this climate control equipment can be found everywhere; they are installed in both residential and industrial premises. Many will be surprised, but the usual air conditioner, consisting of an external and internal unit, is far from the only equipment option used to maintain a stable temperature in the room. A fan coil is used for the same purpose.

Fan coil - what is it?

Like classic split systems, fan coil units are used to cool and heat indoor air. The easiest way is to consider a fan coil unit as one of the elements in a single air conditioning system. Another name for this device is a fan coil, consisting of two parts, one of which is a fan, and the second is a heat exchanger. It fully justifies and explains its use in the air conditioning system. In addition to the fan and heat exchanger, more and more often in modern fan coil models you can find a filter, the main task of which is to clean the incoming air from large dust, fluff and other particles. Also, fan coil units are increasingly being supplemented with a remote control for remote control of the device. From such a short description we can conclude that the device is indeed very similar to an air conditioner both in its operating principle and control method.

If we continue to compare the usual split system with a fan coil, we will notice that in both cases the operating principle is approximately the same. The only difference is the cooling method. In a split system, this is a refrigerant (in most cases, gaseous freon), and in fan coil units, liquid is used for cooling. This can be water or an ethylene glycol-based antifreeze solution.

How is it different from an air conditioner?

A fan coil unit does not use a cooling circuit, although it may be part of a heating or cooling module. Thus, the likelihood that freons will enter the atmosphere is incredibly low.

Although it is worth noting: the refrigerants used in modern air conditioners are relatively safe from an environmental point of view.

But if freons from old models entered the atmosphere, it was really critical. The differences include the fact that a fan coil unit is usually a more powerful device, and therefore it is more often used to heat or cool very large rooms.

Let's list a few more differences:

- installing a fan coil unit with a chiller is more labor-intensive than installing an air conditioner; installation work can also be considered longer;

- it is easier to connect a fan coil unit to the air supply unit, and in many buildings this device is often installed in ventilation ducts;

- the chiller-fan coil group is usually installed at the construction stage, and the air conditioner is connected in a building that has already been put into use, because its installation does not require serious intervention.

One has only to add that in terms of financial costs, a fan coil will be more expensive than an air conditioner.

How does a fan coil work?

The operating algorithm of the device is as simple as possible:

- The air from the room enters the heat exchanger using a fan.

- Depending on what operating mode the fan coil is set to, hot or cold liquid enters the heat exchanger.

- The air in the heat exchanger is cooled or, on the contrary, heated, depending on the specified operating mode.

- The air prepared for the room is returned.

- If the fan coil was working for cooling, then condensation may form. It accumulates directly on the heat exchanger. The resulting liquid is discharged into the sewer or outside using a pump.

Considering the above list of actions, everyone may wonder: where does the water come from in the device and where does it disappear when the cooling “circle” is completed? The question is logical, and without an answer it is impossible to fully understand how the device works. In fact, everything is extremely simple: to cool or heat the air, the fan coil requires additional equipment. In the case where the fan coil is used for cooling and heating, it is connected to a reversible chiller or heat pump. If the fan coil is used only for heating, it is connected to any heating boiler.

As already mentioned, a fan coil is part of a large air conditioning system. Its parts are units for heating and cooling water, as well as the fan coil itself. It is worth noting that the number of fan coil units may vary and depends on the needs of the room. Larger rooms will require more fan coil units. In this sense, this version of the air conditioner is most easily compared with heating radiators, the number of which is determined according to the same principle.

When choosing a fan coil unit, you must immediately decide what you expect from its use. Perhaps you are satisfied with only air temperature regulation, or maybe you want to get more functionality. So, some devices can be connected to supply ventilation. However, this option is only available with separate fan coil units.

Features of installation of such equipment

Installing a fan coil unit is not an easy task. If the home owner does not have much experience in installing heating and/or refrigeration equipment, it is better to turn to professionals. First, the fan coil itself is installed. The installation location depends on the type of device: ceiling, floor, wall.

In any case, it is necessary to ensure the free movement of air masses from the fan coil throughout the room for the device to operate effectively.

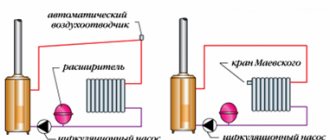

After installing the fan coil unit, it is necessary to assemble the piping unit, install pipes and lay a layer of thermal insulation. A number of elements such as shut-off valves, temperature sensors, pressure gauges, etc. should be supplied.

Rubber-coated pipes may be an excellent option for installing this type of system. They are compact and have good thermal insulation properties.

If necessary, air ducts are installed. These structures should be equipped with sound insulation. To ensure that water is distributed evenly throughout the system and its correct hydraulics are ensured, balancing valves are used.

The presence of these devices greatly simplifies setting up the system, since regardless of its configuration, the same water pipes can be used everywhere.

Such a mixing unit must be installed when connecting a fan coil system to a chiller or boiler. It is better for inexperienced installers to consult with specialists

When drawing up a system design, it is necessary to take into account the length of the air ducts, which is strictly standardized. This is especially true when installing wall-mounted fan coil units under windows. Steel air ducts are equipped with a vibration muffler. A condensate collection and drainage system must be installed.

Trays for collecting moisture should be secured under the corresponding openings. After this, the fan and electric heaters (if any) are connected to the power supply. Then all contacts, channels and pipes are checked for leaks.

After this, the system is launched and pressure tested to check the quality of installation. If there are no flaws, you can continue finishing work.

Pipes that are connected to fan coil units must be carefully sealed and covered with a layer of thermal insulation materials. Before starting installation, you should draw up a project and perform calculations of the system

The easiest way to cope with the installation of a floor-mounted fan coil unit. It does not require installing a condensate drainage channel. The device has two pipes that are connected to the corresponding device.

When installing wall, ceiling and cassette models, the connection to the electrical network is made according to a more complex scheme than for a floor-standing fan coil unit.

In any case, installing a four-pipe system will be the most difficult. To install any type of system, it is important to correctly perform the design and a number of special calculations.

Types of fan coil units

When you come to a store or choose equipment on the Internet, you can see that the devices differ. First of all, fan coil units differ in installation options. On sale you can find models suitable for installation on walls, floors or ceilings. In addition, there are universal devices; if necessary, they can be installed both on walls and on the ceiling.

Another interesting feature of these air conditioners is that they are available in models with and without a housing. As you might expect, unframed fan coil units are cheaper. They are purchased for the purpose of subsequent decoration using panels and other finishing materials.

An equally important aspect in choosing a fan coil unit is the number of heat exchangers. Studying the store’s assortment, you can see how many varieties there are:

- two-pipe - in this case, water enters the heat exchanger through one pipe, and goes back through the other. Typically, this type of fan coil is used only for cooling. The design is very simple, so heating will require the purchase and installation of additional equipment;

- four-pipe - this device is equipped with two pairs of pipes, one circulates cold water, and the other circulates hot water. This fan coil can be used for both cooling and heating.

Surprisingly, this is not the last classification of fan coil units. Among other things, they can be divided depending on where the installation is planned. When installing a fan coil unit on a suspended ceiling, use a cassette model. It can be equipped with two or four pipes, that is, it can be used for both cooling and heating. Cassette fan coils are very quiet, and since they are used for installation on a suspended ceiling, they are usually produced without a housing. To provide fresh air or regulate temperature in large industrial and office premises, ducted fan coil units are used. They are mounted directly into the ventilation system; a ducted fan coil unit can be placed above a suspended ceiling, behind decorative partitions, in other words, anywhere.

Classification

There are two main types of fan coils - two-pipe and four-pipe. The former are connected to one source of working fluid, the latter can simultaneously use two - a chiller and a device for heating water.

In the latter case, it is possible to quickly switch the module from cooling to heating mode and back. For two-pipe models, this is labor-intensive work; physical switching of lines between sources of liquid treatment is required.

Classification by design:

According to the installation method - floor, ceiling or wall.

- Cassette. They are mounted in a suspended ceiling and do not have an external casing.

- Duct. Installed in the supply ventilation ducts. Models differ in the number of air flows - from 1 to 4.

- Air flow – low, medium or high pressure. The former create an air pressure of up to 45 Pa, the latter - up to 100 Pa. High-pressure ones can generate an air flow with a force of 250 Pa.

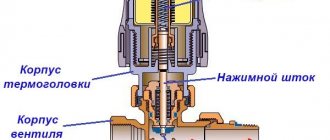

To smoothly change the temperature of the liquid, they are equipped with a three-way valve. The types of fans used are centrifugal or diametrical. The heat exchanger is serpentine and consists of a copper pipe. To increase the area, aluminum ribs are installed on it.

Advice. Some models have dust filters. They purify the air from foreign impurities and protect device elements from contamination.

This is important for rooms with special microclimate requirements

An integral part of the design is the chiller

The chiller is necessary to cool the liquid, which in turn will be used to cool the air. In fact, the chiller is used not only to operate fan coil units. In addition, they are necessary when filling rollers and for cooling medications. When operating in an air conditioning system, the chiller is installed on the roof of the facility or in a technical room.

Despite the fact that the functionality of the chiller is quite narrow (it is used only for cooling), this device can be divided into two types:

- air cooling - the refrigerant is cooled in this case using a flow of cold air;

- Water cooling – water is used for cooling.

Some models can also operate in heating mode. Chillers can also operate in heating mode; they are also called reversible. In this case, one device is capable of both heating and cooling. Chillers operating only for cooling are still common.

Depending on what cooling method is used in chillers, they can be divided into absorption and vapor compression. The first variety has not yet become widespread in Russia, but, of course, such chillers still have a long way to go. In devices of this type, freon replaces a solution of water and lithium bromide. Much more often, users from Russia choose to install vapor compression chillers. The design is practically no different from the air conditioner, which used freon for operation. Only in this case it was replaced with water. To convert water into steam, the device is equipped with a compressor, condenser, thermostatic valve and evaporator.

Pros and cons of SCV with closers

The obvious advantage of fan coil air conditioning is the precise maintenance of the desired temperature in different rooms. Multi-zone systems allow very wide adjustment of microclimate parameters within one building. Other advantages compared to conventional air conditioners:

- the cost of equipment for 2-3 rooms will be clearly less than the price of a multi-split system of identical power;

- sources of heat and cold are located in the technical room or on the street, external units do not clutter the façade;

- fan coil units can be installed 50...200 meters from the chiller;

- communications between units are made of inexpensive plastic pipes - low-density polyethylene or polypropylene (the latter needs to be soldered);

- in the event of an accident or leak, it is easier to make repairs and replenish the system with purified water.

Comment. The distance from the chiller to the fan coil is limited only by considerations of expediency, since high heat (cold) losses occur on too long lines, plus the energy consumption of a powerful pump increases.

Do not think that chiller-fan coil type SCR is applicable only in industrial buildings. The brands Daikin, Carrier and Gree produce small two-fan chillers with a capacity of 3...10 kW, which are quite suitable for private homes.

Disadvantages of fan coil units:

- A 2-room SCV is still more expensive than two separate split systems;

- decent size and weight of the chiller unit;

- Qualified installation and commissioning of equipment is required;

- The equipment will have to be serviced and technicians will have to be called in every year.

On an industrial scale, the main competitors of water SCRs remain freon VRF systems operating on the “split” principle. Up to 50 indoor units are connected to the external vapor compression module alone. The cost of the equipment is approximately the same, but fan coil units benefit from the ease of laying lines and the lower price of plastic pipes compared to copper ones. A separate story is a freon leak from a huge system, which is not easy to find and eliminate.

Chiller operating principle

Fan coil units can most often be found in retail and office premises, so most people have no idea how this air conditioning system works, and if everything is approximately clear with the fan coil unit itself, the principle of operation of the chiller remains a mystery to many. It is necessary to correct this omission and get to know it better:

- The compressor pumps up the necessary pressure to use the refrigerant, reduced to a gaseous state.

- Freon enters the condenser. Here it cools and becomes liquid.

- Freon enters the thermostatic valve, where it boils and then evaporates.

- The evaporating freon cools the water.

- After the entire mass of freon is reduced to a gaseous state, the cycle begins again.

- The cooled liquid enters the fan coil unit, and from it into the room.

Design parameters

The structure of the air unit is a rather complex mechanism consisting of various technical parts:

- Compressor.

- Specialized capacitor model.

- Evaporator.

- Regulator of atmospheric flows.

- System control unit.

- Pipeline accessories.

- Hydromodule.

The listed elements are placed on one frame, forming a closed system of operation, in which the refrigerant circulation is provided by the compressor. A stable freon cycle in a closed mechanism helps lower the temperature of the liquid and remove the existing heat to the outside by drawing air through the condenser. To regulate the volumes used, a special tube or valve is used.

Advantages of fan coil units

In conclusion, I would like to say a few words about the advantages of this type of climate control equipment. Having taken a closer look at the principle and operating features of the fan coil and chiller, we can already draw some conclusions about whether they are needed when there are familiar split systems. And the conclusion suggests itself. Of course they are, because they have several advantages.

This system is suitable for any room, regardless of area. If the room is very spacious, just add additional fan coil units and the air temperature will always be ideal. In addition, the fan coil and chiller will operate successfully in the winter season, and, as you know, not all sleep systems can do this. The use of liquid coolant reduces the likelihood of an accident, thanks to which we can talk about the high reliability and safety of fan coil units. It’s worth summing up by remembering an equally important advantage of the fan coil-chiller : it can fit into any interior, because this air conditioner can be completely camouflaged using decorative panels.

The atmosphere at home and at work should always be pleasant and installing a modern air conditioning system is simply necessary to ensure people's comfort.

Popular system models

Taking into account the difficulties that accompany working with a chiller-fan coil system (mentioned above), there is no point in considering any popular models of fan coils, pumps or chillers. All of these are niche units that are not so common in Russia.

Let’s also take into account the fact that there are no ready-made solutions in the case of a chiller-fan coil unit (all elements must be selected separately according to an individual project).

Based on this, it is obvious that ranking popular models is pointless. Chiller, fan coil units, pipes, pumps - all this is ordered separately and installed in accordance with the project. Chiller-fan coil units are not an air conditioner that can be easily purchased and easily installed without drawing up detailed projects and without serious financial investments.

For air cooling

Chiller-fan coil system

- a centralized, multi-zone air conditioning system, in which the coolant between the central cooling machine (chiller) and local heat exchangers (air cooling units, fan coils) is a cooled liquid circulating under relatively low pressure - ordinary water (in tropical climates) or an aqueous solution of ethylene glycol ( in temperate and cold climates). In addition to the chiller(s) and fan coil units, the system includes piping between them, a pumping station (hydraulic module) and an automatic control subsystem.

Terminology

There is no translation for the English “chiller” in GOST 22270-76 “Equipment for air conditioning, ventilation and heating”. For the term “fan coil unit” GOST gives the translation “fan coil unit” (a closer that, using a built-in fan, carries out local recirculation and supplies a mixture of internal air with external air into the room, which has previously been processed in a central air conditioner, as well as heating and/or cooling air).

Differences

Compared to VRV/VRF systems, in which gas refrigerant circulates between the refrigeration machine and local units, chiller-fan coil systems have differences:

Twice the maximum distance between the chiller and fan coils. The length of the routes can reach hundreds of meters, since with a high heat capacity of the liquid coolant, the specific losses per linear meter of the route are lower than in systems with a gas refrigerant.

Wiring cost. To connect chillers and fan coils, ordinary water pipes, shut-off valves, etc. are used. Balancing water pipes, that is, equalizing the pressure and flow rate of water between individual fan coils, is much simpler and cheaper than in gas-filled systems.

Safety. Potentially volatile gases (gas refrigerant) are concentrated in the chiller, which is usually installed outdoors (on the roof or directly on the ground). Piping failures within a building are limited by the risk of flooding, which can be reduced by automatic shut-off valves.

Flaws

Chiller-fan coil systems are more economical in terms of electricity consumption than rooftop systems, but they are certainly less economical than systems with variable refrigerant flow ( VRF)

).

However, the maximum performance VRF

systems is limited (the volume of cooled rooms is up to several thousand cubic meters).

Malfunctions

- Freon leak.

Freon leakage can occur as a result of a leaky connection in the freon circuit. - Compressor failure.

In a compressor, the stator winding usually burns out or the valves (piston group) are destroyed. - Moisture in the refrigeration circuit.

Moisture (water) can enter the refrigeration circuit as a result of a leak in the evaporator, resulting in mixing of two freon-water circuits.

Basic liquid cooling schemes

- Direct cooling..

The most common option. Cooling of the liquid occurs in the liquid/freon heat exchanger. The temperature difference between inlet/outlet is no more than 7°C. Standard air conditioning mode +7/12°С. - Cooling using an intermediate coolant.

This type of circuit is used when the difference in liquid temperature at the inlet and outlet of the chiller is more than 7°C.

Recommendations for use

If you are installing a fan coil at home, then carefully study the instructions for the user. Usually all the points on which questions may arise are spelled out there.

How often they are required depends on the load on the system. Typically, the operation of the device should be checked every 7-8 months. You can learn how to clean or replace the filter yourself, as well as check the performance of valves and evaluate the operation of shut-off valves.

In some cases, professional services may be required:

- if necessary, diagnostic monitoring of air and water filters;

- when balancing the water circuit;

- to eliminate fluid leaks;

- to check the operation of the drainage - pump diagnostics and cleaning of pipelines.

If the climate control unit makes noise, you should also call a specialist. This can happen due to incorrect operation of the fan or vibration of the pipes. Specialists will quickly cope with the shortcomings of the door closer.

The following video provides an overview of wall-mounted Mycond fan coils.