Why does the pressure in the boiler increase?

This excess is sent to the expansion tank. If the volume of the product is too small, it will be completely filled with water. With a subsequent increase in temperature to 85-90 degrees, the tank will no longer be able to compensate for this 4%. Therefore, the pressure will increase.

Interesting materials:

When do tulips grow? When does growth stop? When do boletus grow in the spring? Is it possible to shave hair against the growth direction? Is it possible to measure your height with a tape measure? Is it possible to become a model with a height of 164? Is it possible to become a flight attendant with short stature? What does pomelo grow on? What does rice grow on? What do oranges grow on?

E1 - Ignition error

The gas heater turns on and the clicks of automatic ignition are heard. After an unsuccessful start, the column turns off and error E1 appears on the screen.

Reason #1. There is no gas supply in the gas main. Close and open the gas tap near the column, repeat the steps to ignite.

Reason #2. Solenoid valve failure. The E.M.C. valve does not magnetize. or the coil is faulty. Repaired by a specialist from the gas industry.

Note! Troubleshooting, replacement of parts and repair of the gas water heater is carried out by a qualified technician from the service center. Self-repair and installation of supply communications provoke gas leaks, use the services of trained craftsmen.

Reason #3. The ignition electrode is broken. Open the water tap, at the moment of starting, look under the column, sparks appear at the place where the wire breaks down.

Diagnostics

We diagnose the geyser over the phone, so the cost of this service for you is

0 Rubles

Call

We will charge 500 rubles for the call if the repair is refused, but this service is worth it to you

0 Rubles

Repair

The cost of the work performed excluding the cost of the required spare parts varies.

From 900 rubles

Guarantee

Before leaving, our employees will issue a guarantee from our company for the work done for a period of time.

Up to 12 months

E2 or 2 red LED flashes - DHW sensor is faulty

The gas water heater does not start when the water tap is opened, an error is displayed on the display.

Reason #1. Open circuit in the DHW sensor circuit. Restart the column after a few minutes. For diagnostics, the resistance of the sensor is measured under thermal load.

Reason #2. The flow sensor or reed switch is faulty. The mesh filter of the hydraulic unit is washed, then the flow sensor is measured with a tester.

First steps

The occurrence of error code 108 indicates a pressure problem in the coolant system. In the case of an Ariston boiler, the “Err 108” indication is an indicator of low water pressure in the heating circuit of the device. Accordingly, it is necessary to replace the water pressure switch and recharge the boiler using a feed tap.

Before proceeding with direct repairs, you need to check the readings of the pressure gauge located next to the display. If the pressure is 1.5 bar, then you will need to start repairs by replacing the sensor. To do this, you need to carry out a number of preparatory actions:

After this, the boiler must be removed from its mountings and disassembled.

E5 or 5 red LED flashes - overheating.

The column turns on, heats the water and goes out after 2 minutes. The malfunction is accompanied by a drop of soot, overheating of water and a burning smell in the room. Restarting is possible after the column structure has cooled.

Reason #1. The burner smokes, there is soot on the radiator honeycomb. The geyser is cleaned from dust and soot; the work is performed as part of annual maintenance.

Reason #2. Scale on the walls of the radiator tube. The heat exchanger is washed from scale with chemical solutions. Clean the filter elements.

Code 103

The error is due to the coolant heating too quickly, which can be caused by the following reasons:

- airiness of batteries;

- thermostat malfunction;

- problems with the board.

If such an error occurs, you can try to bleed air from all existing batteries. In most cases, this will fix the problem. If after such actions the code continues to be displayed on the display, then the problem is deeper and cannot be done without the help of specialists.

E3 or 3 red LED flashes - no flame when igniting.

The column starts, the main burner lights up and goes out after 5 seconds of gas burning. The automatic ignition clicks when the gas is burning.

Reason #1. The flame ionization electrode is faulty. The flame ionization electrode checks the current ionization. If no flame is detected within 7 seconds, the column will restart again.

Reason #2.

The electrode gap has increased or decreased. Adjust the ignition electrode gap. The wires are checked for the integrity of the insulator.

Peculiarities

The demand for heating equipment of this brand in our country is due to the high quality of the products. A Russian resident always chose a more reliable product, although somewhat more expensive. In addition, boilers from Ariston have a very affordable price. With proper use, they can last about 20 years or more, which makes such a purchase very profitable.

Another advantage that has affected the popularity of Ariston equipment is a wide range of models. You can find a boiler based on your preferences and requirements.

As a rule, all heating boilers are divided into four types:

- gas;

- electrical;

- liquid fuel;

- solid fuel.

In this article we are talking about gas boilers. So let's take a closer look at their subspecies.

First of all, gas heaters are divided by the number of circuits.

- Single-circuit boilers. Simple, therefore more reliable and cheaper technology. It is aimed exclusively at heating rooms, without the ability to heat water. Consists of one heat exchanger, circulation pumps and expansion tanks.

- Double-circuit boilers. Suitable for those who want to have hot water in their home, but do not want to purchase additional equipment. Inside, such boilers have two heat exchangers. Moreover, their sizes practically do not differ from the sizes of single-circuit boilers. The water in the hot water circuit is heated by water from the heating circuit circulating through the heat exchanger. This technique is more complex and therefore less reliable.

Double-circuit boilers can be bithermic. Their reliability is even lower. They differ in that the second heat exchanger is located inside the first.

All gas boilers require air flow.

Depending on how it is provided, heaters are divided according to the type of combustion chamber.

- In boilers with an open chamber, oxygen enters from the room where they are located. Such equipment has low productivity, but is demanding on the organization of conditions: the room must be equipped with good ventilation and a chimney through which combustion products will be removed. In this case, it is necessary to strictly observe fire safety rules. The advantages of such boilers include reliability and low noise level during operation.

- Boilers with a closed combustion chamber are less reliable, but more efficient. They are also not so demanding on the arrangement of the room and are practically not harmful to the environment. Their operation is based on a special burner and fan. With the help of the latter, air is taken in and combustion products are removed. However, keep in mind that the fan makes a lot of noise when operating.

Heaters can also be divided according to the type of their placement.

- Wall-mounted. Due to their compact size, they are most often purchased for placement in apartments. They are light in weight and easy to install. They usually have a closed combustion chamber and are easy to handle, which ensures additional demand. Wall-mounted boilers are not very powerful, but they are enough to heat a residential apartment.

- Floor-standing. They have increased power. But in size and weight they are noticeably superior to their wall-mounted counterparts. The price is also slightly higher. Such boilers are usually used for heating rooms and buildings with a large area.

Whatever level of reliability the boiler you choose has, it is unlikely that you will be able to avoid errors in operation. Fortunately, most modern units are equipped with control sensors and a self-diagnosis system.

The first ones will stop the boiler in order to prevent more serious breakdowns. In addition, the sensors will block all functions of the unit. You will have to fix the problem to remove the blockage. The second will notify you of a problem that has arisen by highlighting an error code on the display.

They are divided into two types:

- problems that the user can fix with his own hands;

- breakdowns, for which you should contact specialists to correct them.

You can find all code values on the Internet or in the instructions for your specific model. Next, we will talk about the most common errors that occur in the operation of Ariston boilers.

About company

Hotpoint-Ariston is a world-famous brand owned by the Indesit Company. The company itself was founded in 1975 and at first dealt exclusively with mechanical engineering issues. However, in subsequent years, Indesit Company entered the home appliance market. Products under the Hotpoint and Ariston brands quickly gained popularity in many civilized countries. In 2007, these two brands were merged.

One of the most popular Hotpoint-Ariston products in Russia are boilers, mainly gas.

Ariston boiler errors, malfunctions and do-it-yourself repairs - Cold +

Dear visitors!!! If you suddenly decide to repair a gas boiler with your own hands, without having the proper qualifications, then you must understand that you are going to interfere with the design of gas equipment.

The information in this blog is provided for informational purposes only, what I encountered and how I fixed it in my case.

You must understand that you perform all work at your own peril and risk, and therefore, before you undertake it, think about whether it would be better to turn to specialists.

The boiler does not light up, the display shows an error - 607

The first malfunction that happened to my boiler and marked the beginning of studying this unit was the following: the boiler does not light up, the error on the display is 607.

And it’s winter outside, it’s brrrrr cold. Let me remind you that we are talking about the Ariston Clas 24 FF boiler.

So, having a specialty in radio engineering, perseverance and a little time to avoid freezing, I perform an autopsy and begin to search.

What did I manage to find out and how to solve this, as it later turned out, a typical problem for boilers?

What we immediately pay attention to

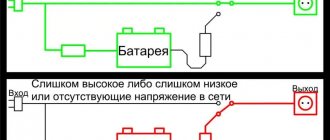

If the boiler behaves this way, it displays error 607 - pay attention to this detail!

The combustion product exhaust fan in the boiler is constantly running. Even if you turn off the boiler with the button on the control panel, it will still spin.

The fan will stop only when you completely turn off the power to the boiler, for example by unplugging it from the socket. As soon as you connect it to the network again, the fan immediately starts spinning.

This sign is a one hundred percent guarantee of the malfunction described below.

Reason: fan control relay stuck

Treatment - replacement of the relay!

In general, as it later became clear, many boiler malfunctions are related specifically to the relay.

And since all this relates to malfunctions of the electronic control unit of the ECU, service technicians sometimes recommend replacing the entire ECU, and this is very decent money.

Repairing the electronic control unit - do it yourself

In this topic, I don’t just want to point out the reason - the relay is stuck. You will learn why the boiler reacts this way to a malfunction, which relay on the board is responsible for the fan, how to replace it and where to get it.

In subsequent articles from this section, I talk about other faults related to the ECU and more.

First, we look at the block board and get acquainted with the location of the Ariston Clas 24 FF boiler relay

RL01 - Fan control relay.

RL02 - Three-way valve control.

RL03- Pump speed control.

RL04 - Pump control (Supplies power supply to the pump)

RL05 RL06 - Supply power to the ignition unit and gas valve.

Relay serial numbers are indicated as they are indicated on the board.

The malfunction we are talking about now is caused by a malfunction of relay RL01. Relay type JZC-43F (coil power supply - 24 volts)

It is this relay that is responsible for controlling the fan.

Since I was running out of time for repairs, and did not have the required relay, I installed a relay with a lower coil supply voltage, using a stabilizer chip - this design works reliably.

I removed the detailed description of this alteration from the article, but if anyone needs it, write, ask, I will explain.

Relay for Ariston boiler

Somewhat later, an analogue of the required relays was found on AliExpress.

This is the G5NB-1A-E relay. It is also 24 Volt. The relays are manufactured, work and look great - original.

I already had to repair the boiler for myself and my friends using the “Omron” relays that I received: They become like family, they work reliably!

By the way, sellers mainly offer these relays in batches of 10 or 50 pieces. That's how I ordered the batch. So now I have some reserve.

Later I found a seller from whom I can order them individually, at a good price, good reviews, here is a link to this seller

By the way, there is an opportunity to use Cashback.

PS I would like to add about cashback, for several small purchases I received $2.32. So it really works. Register and get a refund on every purchase. About what cashback is here.