The circulation pump increases the efficiency of the autonomous heating system and allows 100% use of all heating circuits.

Professional installation of a heating pump guarantees high performance, reduces operating noise and reduces maintenance and repair costs. Installing the device does not cause any particular difficulties, but there are a number of nuances that are important to consider.

We will tell you how to choose a circulation pump, help you decide on the optimal scheme for inserting equipment into the system, outline installation requirements, and also provide step-by-step instructions for installing the device.

What is a circulation pump and why is it needed?

A circulation pump is a device that changes the speed of movement of a liquid medium without changing pressure. In heating systems it is installed for more efficient heating. In systems with forced circulation it is a mandatory element, in gravity systems it can be installed if it is necessary to increase the thermal power. Installing a circulation pump with several speeds makes it possible to change the amount of heat transferred depending on the outside temperature, thus maintaining a stable temperature in the room.

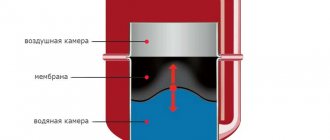

Cross-section of a circulation pump with a wet rotor

There are two types of such units - with a dry and wet rotor. Devices with a dry rotor have a high efficiency (about 80%), but are very noisy and require regular maintenance. Units with a wet rotor operate almost silently; with normal coolant quality, they can pump water without failure for more than 10 years. They have a lower efficiency (about 50%), but their characteristics are more than sufficient for heating any private home.

Hydraulic separator

If there is a need to install an additional pump, then another device must be included in such a heating system - a hydraulic separator. In the list of terms used, a hydraulic separator can also be called an anuloid or a hydraulic arrow.

Where to put

In the autonomous heating system of a private house, it is recommended to install circulation pumps with a wet rotor, which rotate without the use of special lubricants. The coolant and lubricating element here are the coolant. When installing such a device, the following rules must be taken into account:

- The pump shaft must be in a horizontal position relative to the floor surface;

- The movement of water flow in the system must coincide with the direction of the arrow on the device;

- To prevent liquid from entering the pump terminals, the box should be installed on the top or side of the equipment.

Correct installation of an additional pump in the home heating system

According to some users, it is better to install the pump on the return pipeline. Here the coolant temperature is minimal, which will increase the service life of the device, but not all experts agree with this statement. The fact is that the pump is designed for operation in a coolant environment whose temperature can reach 110 degrees.

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but on the supply or return pipeline it doesn’t matter. Modern units are made from materials that can withstand temperatures up to 100-115°C. There are few heating systems that work with a hotter coolant, so considerations of a more “comfortable” temperature are untenable, but if you feel safer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system; it makes absolutely no difference whether there is a pump in the supply or return branch. What matters is the correct installation, in the sense of strapping, and the correct orientation of the rotor in space. Nothing else matters.

There is one important point regarding the installation location. If the heating system has two separate branches - on the right and left wings of the house or on the first and second floor - it makes sense to install a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule remains on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal conditions in each part of the house independently of the other, and also in two-story houses to save on heating. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of movement of the coolant is set much lower, and this allows you to burn less fuel, without compromising the comfort of living.

Is it necessary, and in what cases?

Many owners of country real estate, and especially two-story houses, are interested in the question of installing an additional circulation pump in the heating system. They come to this conclusion after uneven heating of the radiators in the rooms, provided that the boiler has sufficient power. If the temperature difference between the boiler and the coolant in the pipelines exceeds 20 degrees, then it will be necessary to remove air plugs or set the existing pump to an increased speed.

Installation of additional pumping equipment is necessary in the following cases:

- When adding an additional circuit to the heating system, and especially when the pipe length exceeds 80 meters;

- For uniform movement of coolant in pipelines.

An additional pump in the heating system may not be needed if it is balanced using balancing and control valves, so before purchasing additional equipment, bleed the air from the radiators and add water to the system. If everything works fine, then there is no point in installing an additional pump.

Harness

There are two types of heating systems - forced and natural circulation. Systems with forced circulation cannot work without a pump; systems with natural circulation work, but in this mode they have lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is installed into it. This gives high heating efficiency and reliability. It is clear that the installation of a circulation pump in these systems is different.

All heating systems with heated floors are forced - without a pump, the coolant will not pass through such large circuits

Forced circulation

Since a forced circulation heating system without a pump is inoperative, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They can jam the impeller and stop the motor. Therefore, a mesh dirt filter must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also advisable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps and remove the unit. Only that part of the water that was directly in this piece of the system is drained.

Natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not working. One ball shut-off valve is installed on the bypass, which is closed the entire time the pumping is running. In this mode, the system operates as forced.

Installation diagram of a circulation pump in a system with natural circulation

When the electricity goes out or the unit fails, the valve on the jumper is opened, the valve leading to the pump is closed, and the system operates as a gravity system.

Installation features

There is one important point, without which the installation of the circulation pump will require rework: it is necessary to rotate the rotor so that it is directed horizontally. The second point is the direction of flow. There is an arrow on the body indicating which direction the coolant should flow. This is how you turn the unit so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, just when selecting a model, make sure that it can work in both positions. And one more thing: with a vertical arrangement, the power (pressure created) drops by about 30%. This must be taken into account when choosing a model.

Wet rotor pumps

In wet modifications, the shaft and impeller are in contact with the pumped resource, and it also serves as lubrication and cooling.

The stator is separated by a special flask that seals parts of the electric motor, otherwise voltage would be transmitted through water to all metal elements of the system.

Components and how they work

Wet central pump design:

- housing that can withstand high pressures is made of cast iron, steel, aluminum. For standard home conditions, this is a small block that is attached directly to the pipe, bypass;

- a shaft (moving segment), also known as a rotor made of steel, ceramics with a bearing unit, a working disk with blades. The latter is fixed motionless, it consists of 2 wheels with holes connected by blades: on one - for moving the resource, on the adjacent one - for securing to the electric motor shaft;

- a stator (fixed unit) on the rotor with an excitation winding (inductor) to stabilize the rotation speed and flow, for which it has small blades at a certain angle. This part prevents flow stalling. This part consists of a core and a frame. In the grooves of the first there is a winding. The stator is also a magnetic circuit and a supporting structure;

- control chip, power terminals. On models without the first element there is a capacitor, and on the contact block there is a speed selector.

When starting, the blade disk rotates, a vacuum is created inside the pipe, the coolant is drawn in and moved by the rotor further along the equipment (from inlet to outlet). Fence and ejection are carried out. Centrifugal force helps move the resource throughout the circuit. The resulting pressure creates the required force on different segments of the pipe line and creates circulation on its rises.

Nuances, pros and cons

Wet circulation pumps, however, like everything else, are usually modular. The devices are selected according to the parameters of the circuit (pressure, required maximum amount of pumped volume). An important plus is that the device is prefabricated, which simplifies its repair; broken parts are replaceable.

Wet central heating systems are installed on the vast majority of home systems, this is the standard, and here’s why:

- the device is almost silent, which is suitable for living, for better comfort;

- compactness, light weight - the device is a small box that does not require special fastening, partitions, or space on the floor. The product simply crashes into the pipe and “hangs” on it;

- there is no need for additional cooling (unlike dry models), this function is performed by the water flowing inside;

- There are fewer spare parts, the ability to replace them, easy repairs, dismantling, minimal maintenance frequency;

- wide range of settings;

- long-term performance if there is a filter and working fluid without fine particles;

- cheaper if the device is for low standard productivity.

Disadvantages for home heating with a wet pump:

- if the water contains fine abrasive particles (lime, iron, etc.), then the impeller and other parts (hydraulics) in contact with the liquid will wear out relatively soon and fail. For such products, a closed system with a purified resource is recommended; a dirt filter is mandatory;

- low efficiency - about 55%;

- the performance range is more limited than dry options. But it is enough to service the average private home, therefore, and also because of the low price, it is often used for housing.

Purpose of the pump for heating

Previously, circulation pumps were used only in centralized heating systems, and for private housing construction the natural movement of the coolant caused by temperature differences was the norm.

Now forced circulation is used everywhere thanks to the emergence of compact and inexpensive models designed to service the heating networks of small houses and cottages.

Due to the increase in the speed of movement of the coolant in the pipeline, thermal energy flows faster to the heating radiators, and accordingly, the rooms are warmed up faster. The load on the boiler has decreased because the water is also heated faster.

The need to install bulky and inconvenient large-diameter pipelines has disappeared; contours have become easier to camouflage under floor coverings or be buried in walls.

The main disadvantage of pumps for heating systems is their dependence on electricity. If the power supply is intermittent or there is a risk of a complete power outage for some period, it is necessary to install a backup power generator or at least an uninterruptible power supply.

The remaining disadvantages relate to the designs and functionality of various types of devices. For example, monoblock units and devices with a dry rotor are noisier and require constant maintenance, while a pump with a wet rotor is demanding on the quality of the coolant and has a pressure limitation.

How to install heating batteries

Location of radiators

Radiators are designed to transfer thermal energy from the coolant to the room. In fact, they compensate for heat losses in the building. Therefore, before installing the heating radiator, you should choose its location correctly.

The best option is considered to be the place of greatest heat loss in a house or apartment - external walls and window structures. This must be foreseen at the heat supply design stage. Then you need to decide how to install the heating batteries correctly and choose the connection method:

- Upper. Used for vertical piping;

- Side. The method is suitable for horizontally located highways;

- Lower. The best option for hidden installation of pipes.

Types of connection of radiators

The efficiency of the battery depends on the correct choice of this parameter. The figure below shows how to correctly install the heating radiator in relation to the method of connection to the system.

Another important point is the location of the heating device relative to the walls and window structures. It is necessary to install the heating radiator so that it provides free air circulation. Almost all heating batteries operate on the converter principle. Those. air flows should pass through the maximum area of the devices. In order to correctly install heating batteries, you should adhere to the following recommendations:

- The distance to the window sill is at least 10 cm. In this case, it should cover only 2/3 of the battery.

- The distance of the lower part of the radiator from the floor is 12 cm.

For proper installation of a heating radiator, it is necessary to first insulate the walls. You can increase the heat transfer rate using a reflective surface. Most often, penofol with a foil layer is used for this.

Heat supply radiator piping

Example of piping

Ensuring normal operation of radiators is only possible with correct piping. Its elements must perform the functions of protecting and regulating the degree of heating of the heating device.

Correct installation of heating batteries depends on its type and design. Most often, manufacturers indicate optimal installation schemes in the instructions. The following components are used to tie batteries:

- Mayevsky crane. Designed for timely removal of air pockets;

- Thermostat. Necessary to regulate the volume of coolant flow;

- Shut-off valves. With its help, you can disconnect the radiator from the general heating system for further repair or replacement.

Upon completion of installation, the tightness of all components is checked and the device is pressure tested.

During installation, the radiator or battery must not be tilted. This can lead to air locks and also degrade the performance of the heating system.

The video shows how to install a heating radiator yourself.

Criteria for proper selection of equipment

All installation efforts will be reduced to zero if the equipment is selected incorrectly. In order not to make a mistake, it is necessary to first analyze all aspects of a particular heating system and make the necessary calculations.

Main types of pumps

According to their design features, all devices are divided into 2 categories: with a wet and dry rotor.

Wet type pumps . This option is suitable for private homes. The unit is compact, almost silent and has a modular structure that is convenient for maintenance and repair.

But, unfortunately, it does not have high productivity - the maximum efficiency of modern models reaches 52-54%.

Pumps with a dry rotor are productive, unpretentious to the quality of the coolant, capable of operating under high pressure and do not require a strictly horizontal position on the pipe. However, they are noisier, and their operation is accompanied by vibration. Many models are installed on a foundation or metal support frame.

For installation of console, monoblock or “In-line” models, a separate room is required - a boiler room. It is advisable to use them when a flow rate of more than 100 m³/h is required, that is, for servicing groups of cottages or apartment buildings.

Brief overview of technical characteristics

When choosing a pump, you should definitely study the technical characteristics and compare them with the requirements of the heating system.

The following indicators are important:

- pressure , which covers hydraulic losses in the circuit;

- productivity - volume of water or supply over a certain time interval;

- operating coolant temperature , max and min – for modern models on average +2 ºС… +110 ºС;

- power – taking into account hydraulic losses, mechanical power prevails over useful power.

Structural details are also important, for example, the inlet/outlet diameter of the pipes. For heating systems, the average parameters are 25 mm and 32 mm.

An example of a unit for equipping a residential heating network with an area of 100 m² is a Grundfos UPS with a 32 mm pipe connection, a capacity of 62 l/s and a weight of 3.65 kg. The compact and low-noise cast iron device is inaudible even behind a thin partition, and its power is sufficient to transport liquid to the 2nd floor.

Pumps with built-in electronics allow you to quickly switch equipment to a more convenient mode depending on changes in temperature or pressure in the network. Automatic devices are equipped with digital displays that provide maximum information on the operation of the pump: temperature, resistance, pressure, etc.

Additional information on the calculation and selection of a circulation pump for heating is presented in the articles:

Varieties

Dry pump

In a “dry” device there is no direct contact of the rotor with water, since it is protected by several o-rings. O-rings are made from carbon agglomerate, high-quality steel or ceramics, aluminum oxide - it all depends on the type of coolant used.

The movement of the rings relative to each other initiates the start of the equipment. Perfectly polished parts, in contact with each other, form a thin film of water

. The difference in pressure levels between the outside space and the atmosphere of the heating system creates a sealing connection. Thanks to the springs, the rings are pressed towards each other, and as a result of wear of the parts, they fit together without outside help.

The service life of the sealing rings is at least three years, while the stuffing box packing is less durable and requires constant lubrication and cooling. The main feature of this unit is its high noise level, which means its installation in a separate room. The efficiency is 80 percent.

When using a “dry” circulation unit with sliding end rings, you should monitor

the presence of suspended matter in the pumped liquid and the general degree of dustiness of the room. This is explained by the fact that when a pump operates with a dry rotor type, air turbulence is created that attracts dust particles. When small debris gets into the coolant, it damages the surface of the sealing rings and breaks the seal. The operation of a “dry” pump is characterized by the gradual destruction of the end rings, so they need a water layer between the working surfaces. The water layer acts as a lubricant.

In turn, “dry” pumps are divided into:

- Vertical;

- Horizontal;

- Block.

Horizontal pumps

Otherwise they are also called console ones. The front part of the shaft is equipped with a suction pipe, and the housing is equipped with a discharge pipe. The electric motor is installed horizontally.

Vertical pumps

The pipes have the same diameter and are located on the same axis. The electric motor is mounted in a vertical position.

Block pumps

The coolant enters in the axial direction and is discharged in the radial direction.

"Wet" pump

It differs from a “dry” device in that the impeller is immersed in a coolant, which simultaneously lubricates and cools the engine. The electrical part of the engine is protected from moisture by using a sealed stainless steel cup, which is installed between the stator and the rotor.

Ceramic is used to produce the rotor; graphite or ceramics

. The equipment body is made of brass, bronze or cast iron. The main feature of the “wet” type is low noise level, durability, simple settings and repairs.

The efficiency of a “wet” pump is lower than that of a “dry” unit by approximately 30 percent and amounts to 50 percent. This is due to the fact that it is impossible to seal the metal sleeve, which separates the stator from the coolant, with a rather large rotor diameter. However, for domestic use, where there is no need for water circulation in long-distance heating systems, it is advisable to use such equipment.

The design of “wet” pumps includes:

- Equipment housing;

- Electric motor with stator;

- Box with terminal blocks;

- Working wheel;

- A cartouche consisting of a shaft with bearings and a rotor.

The modular assembly of the “wet” pump allows you to replace the broken part of the unit with a new one.

Single- or three-phase electric motors are installed in “wet” circulation units. The equipment is fastened to the heating system pipeline using a threaded or flanged connection - the type of fastening is influenced by the power and performance of the pump.

Due to the strictly horizontal position of the shaft, water access to the bearings

, which is used as a lubricant. Therefore, in order for the operation of the equipment to be uninterrupted and long-lasting, this rule must be observed.

Requirements for installation of a circulation pump

There are a number of standards that regulate at the legislative level the installation of a circulation pump in a heating system. Some of the rules are set out in SNiP 2.04.05 “Heating...”. For example, it talks about the priority of schemes with forced circulation in heating networks.

Almost all requirements are justified by the operating efficiency of the system as a whole and the circulation device in particular. For example, the shaft of a device with a wet rotor must be installed on the pipe strictly horizontally in level so that there are no air pockets inside and the pump parts do not wear out prematurely.

A filter for dirt and abrasive particles is needed in any case, even when installing monolithic models. Filtered coolant will cause much less damage to pump parts than liquid with sand and suspended matter.

The mudguard is installed with the plug down in the direction of water movement to reduce resistance and facilitate system maintenance.

Some rules are dictated by manufacturers. For example, it was customary to install old models of certain brands exclusively on the return line, since they could not withstand high temperatures.

Now pumps have become more versatile and can be installed in any suitable location, but subject to power parameters.

Dry rotor pumps

The entire internal working unit of dry devices does not come into contact with water and is completely isolated. These products are slightly larger and heavier. There is noise and vibration. Here, more often there is a need for a separate place, a fence, installation on the floor with larger piping and wiring. But the devices can also crash in the standard way, like wet ones - directly into a pipe, bypass on the line.

“Dry” pumps are installed to transport significant masses of coolant along long-distance circuits, for example, for a large number of apartments in a high-rise building, for objects with several floors, entertainment centers, administrative and industrial buildings.

The design features are as follows. Between the electric motor and the hydraulic working segment there are sealing insulating gaskets (2 rings). There are 2 discs with a close fit. One is movable on the shaft, the other is static, firmly fixed inside the housing. A thin film of the pumped resource is created between the wheels, pressing on the elements, increasing the tightness.

The efficiency of dry pumps is 85%, according to this parameter they are the best, but they are used less often for home systems due to the noise and vibration created by the cooling fan.

Dry circulation pumps can be of the following sizes:

- monoblock - motor, all parts of the pump in a single body. Advantages: ease of maintenance and installation. But such devices, like console ones, are more often installed for MKD, on large objects, and these products are usually with a stand-foundation;

- console option. Assembled on a single base, the axes of the elements are on 1 line, but the shaft and pipes are remote from the drive;

- in-line. Compact, placed directly on the pipe. The pipes are on the same line (there are no snails, as in the previous version). There is automatic compensation for seal production. These are the popular options; they are usually used for not particularly demanding standard home heating.

In-line pump:

Advantages and disadvantages of dry circulation pumps Advantages of dry circulation pumps:

- productivity, higher power, efficiency 85%;

- more energy efficient;

- does not require horizontal positioning;

- low requirements for cleanliness of the coolant; abrasive particles will not damage the working parts of the mechanism, since they do not come into contact with it. Can be used on all systems - open, closed. The filter does not have to be mounted, although it is desirable;

Minuses:

- Dimensions and weight are slightly greater. For high performance, a typical installation option is on the floor (not directly on the pipe, as with most dry pumps). Accordingly, installation becomes more complicated and costs increase. But such a need does not arise often, since for home systems a compact, not particularly powerful model is sufficient; in most cases, the device is mounted directly on the pipe;

- Large devices require lubrication. For compact sizes, such a procedure may not be required or may be required extremely rarely, but this should be prescribed in the instructions;

- if the cooler breaks down, the device will overheat, with a high probability of failure;

- The cooling impeller is noisy and vibration occurs. A very significant drawback, since extraneous sounds, unnerving users, will nullify all the advantages. Sound insulation will be required, at least a box/fence with it or installation in a remote segment;

- repairs and replacement of spare parts are somewhat more labor-intensive: the design is complicated by the cooling impeller, there are features associated with the insulation of internal parts;

- expensive.

This type of equipment is productive, unpretentious to the coolant, works with high pressures, and does not require horizontal placement. But the device is noisy, with vibration, and is often made in overall sizes; this sometimes entails the need for installation on a foundation or a metal frame.

Analysis of installation technology

The installation process itself is quick; to secure the housing, you need to secure two union nuts. This is very convenient for further maintenance and repair work. But before installation, it is necessary to choose the right installation location, otherwise the pump will either work intermittently or will soon fail.

Schemes for inserting a pump into the network

When choosing one of the schemes, it is necessary to take into account the type of heating system, boiler model and ease of maintenance.

Option 1. This is the most common solution: the pump is mounted on the “return”, through which the cooled coolant returns to the boiler. Warm water does not have such an aggressive effect on the parts of the device, so it lasts longer.

Option 2 . This solution is relevant if for some reason it is not possible to install a pump on the return line. Then it is fixed at the beginning of the circuit, at the supply, but not near the boiler, but after the safety group.

Modern devices can easily withstand high temperatures, but there are still experts who reject such a scheme.

There is such a heating network option as an open system with an expansion tank installed at the highest point of the circuit.

If you install a circulation pump, you will be able to operate it in two modes: natural and forced. Natural circulation will come in handy if there are power outages.

The last scheme applies only to networks with a solid fuel boiler. The supply pump is not installed due to the risk of explosion. The fact is that with solid fuel boilers it is impossible to quickly stop the heating process, as a result of which the water boils.

Boiling water with steam gets inside the pump, it reduces productivity, the cooled water in the circuit does not have time to flow back into the boiler in the required quantity - and it heats up even more. The result of overheating is an explosion.

If you run cooled water from the circuit into a heating boiler, condensation will form. To prevent this from happening, the water is first heated in the small circuit to +55°C, and then the thermostatic valve smoothly switches to the large circuit.

As a result, cold water is mixed with already heated water and “temperature shock” does not occur for the boiler.

How piping is done

The circulation pump piping is the equipment necessary for its proper functioning, as well as for the smooth operation of the entire heating system.

First you need to finally decide how many pumps there will be. For one simple circuit, one device is enough, but with complex wiring it is possible to install two or more.

If you plan to use a “warm floor” system in your house or install an indirect heating boiler, then it is better to increase the number of appliances to two. If two boilers are installed - solid fuel and electric - you will also need a separate pump for each unit.

As mentioned above, ball valves are mandatory elements. They are mounted together with the pump, and in the event of an emergency, they will have to be used.

A check valve made of brass or cast iron is also required so that the coolant moves in one given direction. It is mounted on the pipe immediately after the pump, in the direction of water movement.

A “dirt filter” will be required to prevent solid particles from entering the device housing. Fine filters are not installed in heating circuits. If clean water is needed, it is pre-purified before being poured into the system.

There is a risk of air getting into the network, so there is a need to install an air valve. It can turn on automatically, but there are also manual models.

After installing all the devices, the pump is connected to power. A big mistake is to use an ordinary outlet without grounding. This is a safety violation and can cost lives in the event of an accident.

There are smarter ways to power power:

- via uninterruptible power supply (UPS);

- through a differential circuit breaker;

- by connecting to the boiler automation.

The easiest way is to use a circuit breaker: you will need an 8 A switch itself, contacts, and wires. But for practical use, a solution with a thermostat is very convenient.

If you plan to install a UPS, you can connect an uninterruptible power supply to both the pump and the boiler at the same time.

Selecting the right unit

To ensure long-term uninterrupted operation of the system, it is better to entrust the selection of equipment to a professional technician.

- low energy consumption,

- durability,

- uniform heat distribution,

- noiselessness,

- automatic regulation of maximum and minimum pressure,

- sufficient water flow in the heating system.

To do this, it is necessary to calculate the following parameters: the total length of the system line, the material and diameter of the pipes. Take into account the type of heating units and quantity, types of control and shut-off equipment, automation characteristics. The heating circulation pump, which has the function of regulating the frequency and speed of the rotary shaft, is characterized by reduced energy consumption, noiselessness, and durability. An automatic change in the speed occurs when the temperature of the water (glycol mixture) decreases or increases. Retrofitting the device with air vents eliminates the problem of air locks.

Among the many models, professional craftsmen call a popular, cost-effective, low-noise device a Wilo circular pump (Wilo Top and Wilo-Stratos), which has a wet rotor installed inside the coolant pipeline. The low weight of the device allows it to be mounted on the pipe surface without additional supports. The models are high-performance, universal: suitable for any heating system. Popular domestic units are linear units TsVTs, Livgidromash.

Choose a heating pump model that has two or three operating modes, and through testing you will find the optimal option for heating the room.

Approximate circulation calculation: for an area up to 250 sq. m. – the circulated volume of water is 3.5 cubic meters. m. per hour, at a pressure pressure of 0.4 atm.

Increasing the area to 350 sq. m. requires 4.5 cubic meters. m per hour and 0.6 atm.

If the area exceeds 350 sq. m, close to 800 sq. m. you need permission up to 10 cubic meters. m., at 0.8 atm.

When the room in the house is larger, it is necessary to install an additional pump in the heating system.

The correct installation of the pump influences the smooth functioning of the device.

Brief installation instructions

A common option is to install the pump on a bypass. This is due to two good reasons: it becomes possible to quickly dismantle or temporarily disconnect the device from the network, for example, if problems arise with electricity.

Various modifications of ready-made pumping units are available for sale: for welding or flange connection, with places for installing taps or valves, with a special area reserved for the pump.

But if you cannot purchase a ready-made unit or there is not enough space for its installation, you can independently organize the bypass piping and fix all the parts in the places allocated for them.

The following tools and materials are required for work:

- a set of open-end or adjustable wrenches for assembly;

- pliers:

- linen thread or tow;

- Unipak sealant.

American nuts are usually supplied with the pump, but taps, adapters or fittings will also have to be prepared. Attention should be paid to more reliable materials for making fittings and the diameter of the products.

- Assembling units with taps . Two will be located on the edges of the pump, the third will become part of a straight pipe. It is important to measure the “return” section in order to accurately weld the fragment with the tap.

- Assembling the pump loop. Tightening the nuts must be postponed until the final stage of installation, but for now they just need to be screwed on.

- Trying on the bypass loop . Mark the places where the units are welded into the pipe.

- Welding should be left to a qualified welder.

- Assembly of the lower unit is on the “return” side.

- Connecting the pump to the power supply.

As an example, install the GRUNDFOS .

Maintenance of the installed pump is carried out in operating mode. It is necessary to clean the filter more often and check the pressure gauge readings.

If the values do not correspond to the norm, the device must be removed and adjusted. It is better to do this in a specialized workshop.

Features of installing a pump in a system with natural coolant circulation

In order to ensure the operation of the heating during a power outage, it is necessary to create a minimum hydraulic resistance in all sections of the circuit.

The normal movement of the thermal agent is hampered by any turns and height differences in the pipeline, the resistance of shut-off equipment and a decrease in the cross-section of the pipeline.

Therefore, when installing the circulation pump, the following requirements are observed:

- the insertion is performed without opening the main circuit, in parallel to it. The required pipeline diameter must be at least 32 mm, and the cross-section of the pipes for connecting the pump must be a quarter smaller;

- Shut-off valves are installed before and after the pump so that if the equipment malfunctions, it can be dismantled without the need to discharge the coolant;

- In the area between the pump taps, a ball valve is mounted, which is closed during the forced supply of coolant. Otherwise, it will circulate in a small circle between the pump insertion points.

A check valve installed instead of a ball valve will help automate the switching process in the absence of electricity.

The so-called bypass will be closed until the pump turns off and the pressure in front of the valve does not exceed the force of the operating spring.

The disadvantage of spring check valves is the additional resistance to fluid flow, so the best solution would be to install a ball-type device.

Conclusions and useful video on the topic

Theoretical knowledge is quickly absorbed when accompanied by an interesting video that reveals the sequence and features of the work on installing devices.

Video review of the WILO pump – configuration and installation:

Practice shows that advanced home improvement enthusiasts can handle installing a circulation pump on their own.

However, if difficulties arise, it is better to turn to specialists: only qualified craftsmen know how to properly tie and install a heating pump, observing all the nuances of the chosen scheme.

Do you have personal experience installing a circulation pump? Do you want to share your accumulated knowledge or ask questions on the topic? Please leave comments and participate in discussions - the feedback form is located below.

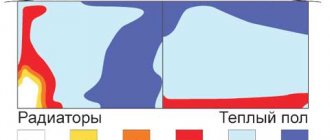

One-pipe and two-pipe systems

Experts distinguish between two heating schemes with forced circulation of the thermal agent - one-pipe and two-pipe.

The choice of one or another option determines not only the location of the circuits, but also the length of the pipelines, as well as the type and quantity of equipment for shutdown, regulation and control.

A single-pipe heating system is characterized by the sequential inclusion of heating radiators in the circuit. The coolant returns through a separate pipeline to the boiler only after it turns one by one through all the devices of the system.

The disadvantage of this method is that radiators that are closer to the thermal block become warmer than those further away, and this reduces thermal efficiency and equipment life. Introducing a circulation pump into the circuit and equalizing the temperature is achieved at all points of the system.

A two-pipe arrangement has advantages over a single-pipe arrangement, since all heating devices are connected in parallel to the supply and return lines, which promotes uniform temperature distribution throughout all rooms.

Forced circulation of the refrigerant leads to increased efficiency of the system and the ability to regulate its thermal power.

Installation Rules

The circulation pump is a hydraulic unit that converts the movement energy of a mechanical engine drive into an energetic fluid flow. It transports liquid in a closed circuit and imparts directed pressure energy to it.

The circulation pump is sold in specialized stores at a reasonable price

In order to install and connect the pump, there are certain rules.

These rules use knowledge of the operation of a closed fluid flow system. To begin, select a scheme for increasing the hot water pressure and connecting to the heating system (mounting to the wall). You can turn on the pump through the bypass into the system when the pressure allows the maximum part of the boiler energy to be used to support normal circulation of the coolant. In this case, it is necessary to follow the rules for installing these pumps in order to do without (additional) replenishment of the process at times. In the case when the system cannot do without additional replenishment, the pump must be placed vertically on each heating riser (multi-storey heating scheme). In the heating pipeline, the device is placed in each circuit.

What rules should you follow:

- Follow the flow diagram for the direction of the coolant on the housing according to the marks;

- To prevent the device from overheating and its performance from decreasing, install the rotor in a horizontal (or vertical) position;

- Follow safety rules;

- Before starting the device, it is necessary to fill the system with water and rid it of any air lock that has formed.

If you have previously dealt with pipes (cuts, devices, connections), then installing and placing a circulation device will not be difficult.

With warm floor

When filling the system with coolant, it is not always possible to get rid of the air present here. Accumulated gases often block the movement of fluid, and not every manifold can be used as a relief valve. To solve this problem, the circulation pump has a special outlet valve made in the form of a disk.

To release accumulated gases, you need to turn this part with a screwdriver counterclockwise. After supplying water from the slot, the disk is tightened and the pump is started again. A similar procedure is repeated several times in a row.

Circulation pumps are installed in heating systems with forced or natural circulation. It is needed to increase heat transfer and to be able to regulate the temperature in the room. Installing a circulation pump is not the most difficult task; if you have a minimum of skills, you can do it yourself, with your own hands.

Connection methods

The pump can have a variety of connection options and wiring diagrams.

There are two possibilities for connection: direct contact - to the electrical network and to an uninterruptible power supply.

The first method involves installing an electrical outlet close to the place where the circulation pump is being installed. Sometimes they come complete with a plug and cable. In this case, you can simply connect the device to electricity using an outlet. You just need to make sure that there is a third (grounding) contact in the outlet. The wires must be stranded copper, which will provide resistance to bending. For a permanent connection, a non-flexible copper or aluminum cable can be used. Its immobility must be ensured by installation. To do this, the cable is secured with clamps along the entire route. A differential circuit breaker (residual current device) is used in this embodiment. You can use a regular single-pole circuit breaker instead and pass only the phase wire through the device. The cable from the machine to the pump must be three-core if the device is installed in a panel with a PE bus. If there is no such bus, then the PE terminal should be connected to a grounding device. This connection can be made with a separate wire.

To install the circulation pump you need to have the usual tools

What materials are needed for installation:

- Detachable connections;

- Shut-off ball valves;

- To arrange a bypass - pipes;

- Reliable additional filter, which is necessary for rough cleaning;

- Connection couplings and various limit switches.

The location of the device and the characteristics of the heated object determine the choice of a specific option.

Pump operating principle

Circulators operate on electricity. There are two approaches to the system, which leads to their division into “dry” and “wet” type devices.

The principle of operation of a dry chain is that the drive is completely isolated from each pump and turbine, and rotation is transmitted through the shaft. As a rule, such devices are quite massive.

Dry pumps for circulating water in a heating system are powerful and efficient devices that provide very high flow rates and high pressure in the system.

Without them it is difficult to control the heating. They must be installed in an apartment or private house. However, there are some disadvantages:

- The shaft that transmits rotation is a complex sealing system that prevents leakage of liquid under pressure. These seals gradually wear out, requiring regular preventive maintenance, including replacement with new ones.

- The operation of the pump is always accompanied by an air-cooled sound effect.

Finally, the system is a very expensive choice; the best option would be to purchase a wet rotor pump. The vertical wet rotor pump also comes in different types.

Source: https://pochini.guru/byt/ustanovka-tsirkulyatsionnogo-nasosa

Is it possible to install the pump on supply or return?

You can install circulation devices using both of these methods. Their durability and performance will not be affected in any way by the location where they are installed.

When installing a boiler, the main condition must be met - ease of maintenance.

If you put it on the supply side, the device will fail faster, since the temperature is higher here. If it is on the return line, the unit will not last long. The density of water is less at supply and it is difficult to pump. In the return, the pressure is higher - this means it is easier for the pump to work. All these arguments are not entirely correct and cannot be treated unambiguously. In what position the device will stand is up to you.

Operating principles of the device:

- The permissible temperature is +110-115 degrees. The correct temperature in the heating system usually reaches 80 degrees, and sometimes 90. Therefore, where to install the pump does not matter here.

- It also does not affect the density of water. The difference between this parameter is so small at temperatures of 50 and 80 degrees that it will not affect the operation of the unit in any way.

- The pressure difference between the value in the main line and the coolant is very small. It makes no sense to calculate it.

The main thing during installation is to do everything correctly.

Device and principle of operation

Circulation pumps are highly specialized equipment whose purpose is to force water circulation. Pump includes:

- The body is made from stainless metals (steel, cast iron, brass, bronze) and alloys;

- Rotor. Ceramic or high-quality steel is used for production;

- Rotor shaft. Includes an impeller wheel with blades;

- An electric motor having a certain power to drive the rotor.

A vertical pump, as part of a closed pipeline, sucks in liquid

on the one hand, due to the rotation of the impeller, it accelerates its movement, and then pushes out the water on the other side. Thanks to this process, a discharged space is created at the inlet, and compression is created at the outlet pipe.

Due to the uniform operation of the equipment, a certain level of pressure in the heating system is maintained. However, to increase its indicator it is necessary to use a special device. The circulation pump is primarily used to overcome resistance in areas of the heating system.

Popular manufacturers, prices

The question of how to choose affects not only the technical characteristics of the device. Most often, consumers understand this as a brand or manufacturer.

The modern market offers a fairly wide range. There are both foreign and domestic analogues here. Accordingly, the prices for these pumps are different. You can find models starting from RUB 3,000. — 15,000 rub. But also some models can cost about 60,000 rubles. Here are just a few models.

Italian pump Aquario

Its model AC204-130 is one of the most popular. Used for small private houses. Its power is 2.4 m³/h, pressure up to 3 m, power consumption 0.64 kW, weight 3.4 kg.

Italian DAB device VA-VB-VD

It has a wide range of technical characteristics: pressure up to 6 m with power from 0.5 to 3.3 m³/h. This sample is equipped with a special thermal relay that turns off the pump if it starts to overheat. Many experts advise choosing this particular model.

Grundfos The Danish company Grundfos offers pumps in five modifications. In Russia, the UPS model has gained great popularity as the most economical in terms of electricity consumption (0.55 kW). At the same time, its head is 3 m, and the volume of pumped coolant is 3 m³/h.

Russian models

Among domestic manufacturers, it is necessary to highlight pumps of the “Khozyain” brand from Podolsk and “Tsirkul” from. Several technical characteristics:

- Owner 4.25.180 – head 4.2 m, power 3 m³/h;

- Owner 8.32.180 – head 8 m, power 9.6 m³/h;

- Compass 25/40 (pressure 4 m, volume 2.5 m³/h) - the smallest sample;

- Compass 32/80 (pressure 8 m, volume 3.2 m³/h) is the largest.

Both brands produce pumps that are connected to the pipeline with a flange connection. So, knowing the brands and models offered by manufacturers, you can choose the right pump, taking into account not only its technical characteristics, but also the price.

Source: https://www.tproekt.com/kak-pravilno-ustanovit-cirkulacionnyj-nasos-v-sistemu-otoplenia/

DIY installation

It is important to know how to properly install a heating pump.

You also need to know which pump to install in the heating system. Each unit comes with instructions, which you carefully study in order to correctly perform the installation yourself. All liquid is drained from the system, part of the pipe is cut off in the place where the pump is to be installed.

In many cases, an old system that has accumulated dirt and rust will need to be cleaned. It is inconvenient to do this through the drain valve due to the small cross-section of the hole, so use the cut point. A hose is connected to one side through which water is fed under pressure, and on the other side the water flows out.

A bypass is installed at the pump site. This is necessary in case of device failure or power outage. The coolant will then flow through the main line, which is manually opened. It is better to install an automatic one instead of a conventional ball valve, which reacts to changes in pressure in the system.

On the bypass, two ball valves are placed on each side of the pump to turn off the water for maintenance or, if necessary, remove it. At the top of the bypass line, install the air release valve vertically. To install the pump, it is recommended to use the following sequence of actions:

- Drain the water and clean the heating system.

- For a system that has been in use for a long time, it is recommended to flush it a couple of times, filling it with water and then draining it.

- Install the purchased pump into the designated location according to the plan, following the principle of energy management.

- After installation, fill the device with liquid (water).

- Check the operation of the heating system. In case of any errors, their strict correction is necessary.

- Remove accumulated air from the system using the central screw. Outgoing water is a sign that the operation was carried out correctly.

- Turn on the built-in pump after filling it with water. When connecting equipment to the network, it is recommended to use an automatic fuse with a special flag.

The fuse has an additional function as a switch

To install an additional pump in the system, please note that it turns on only after a relay signal. To synchronize the operation of both pumps, you need to connect the second device to the relay or use an alternative parallel connection

Partitions

The interior of the kitchen and living room begins to be thought out from the junction of the two zones.

- Here are some of the ways and objects that delimit space:

- installation of a bar counter;

- kitchen island;

- big table;

- installation of a low partition.

Designers advise installing a wide counter, since you can sit at it like at a regular table, and high chairs are quite suitable for the whole family.

However, in small rooms (16 sq m), narrow counters are installed. Kitchen islands are convenient to use, but are only suitable for large kitchen-dining rooms (25 sq m or 30 sq m). Capital low partitions are installed only if it has been decided in advance what they will be used for (for example, as a TV stand).

Useful tips

Circulation pumps are divided into 2 groups, according to the specific location of the rotor - “wet” and “dry”. What is the difference? Without going into the specifics of engineering solutions, it is enough to just note the pros and cons of each modification.

With a “dry” rotor. Higher efficiency. But there are also disadvantages - increased “noise”, the need for regular maintenance (primarily lubrication of seals) and special requirements for operating conditions.

Such circulation pumps must be installed in separate, absolutely clean rooms. The explanation is simple - the slightest dust leads to a decrease in their efficiency or breakdown.

Recommendation - it is advisable to purchase a “dry” pump if there is no analogue in the boiler itself, and the product is the only device that ensures water circulation through the pipes of the heating system.

With a “wet” rotor. As a rule, these pumps are installed more often.

The fact is that all modern household heating boilers are initially equipped with such a device (located under the casing of the unit), and the newly installed one serves only as an additional element that ensures better coolant circulation.

For example, when choosing the wrong heat generator model, when increasing the length of the heating circuit, when installing radiators not provided for in the primary circuit.

The disadvantage of such a pump is low efficiency. But taking into account that it is not the only one in the system, this drawback is leveled out, since it does not particularly affect the heating efficiency. An additional advantage is that no maintenance is required.

Such pumps function properly until their service life is completely exhausted, provided that the rules for their installation are followed. Recommendation - if your household boiler already has its own pump, then you can safely choose a product with a “wet” rotor.

Features of operation

When operating, circulation pumps increase the rate of energy exchange in the heating system by half. The operating principle of the device, regardless of its structure and type, lies in certain parameters:

- the liquid passes into the cavity, which is created like a shell;

- inside the cavity there is an impeller and a flywheel, which creates a certain pressure inside;

- The work of the coolant is greatly accelerated. Using centrifugal force, the liquid flows back to the spiral channel, which is connected to the water circuit;

- Warm air enters the heating water circuit at certain intervals. Using the process of twisting air flows, hydraulic resistance when water enters is reduced.

The operation of a heating system with an installed circulation device differs from devices with a natural circulation system mainly in that the liquid does not flow independently. The air heating rate is not affected by the slope, the number of all radiators, or the total diameter of the pipes.

The functioning of circulation systems may differ in the type of configuration, but the operating principle is always the same. Manufacturers produce a large number of device models for customers, which have different performance and control indicators. According to their configuration, all pumps are classified into several separate groups:

According to the type of installed rotor - to accelerate coolant circulation. For this purpose, it is recommended to use configurations with a dry and wet rotor. The devices differ from each other in the location of the wheel and moving parts inside the device.

Dry devices have a high performance indicator, but they also have several disadvantages: there is a high level of noise from the pump, and it is important to carry out frequent maintenance of the equipment.

For use in a private home, experts advise using special modules with a wet rotor. All moving parts, as well as bearings, are installed inside the coolant, which acts as a lubricant for mechanisms that are under heavy load.

The operating time of the pump inside the heating system reaches up to seven years. There is no need to service the device. According to the type of control, the traditional device, which is most often used for private homes, has a mechanical regulator with three set operating speeds. Providing the required temperature to a room using a mechanical circulation device is quite difficult. The module usually consumes a large amount of electricity. An electronic control unit is installed in the optimal pump. The housing contains a special thermostat. The automation independently calculates the temperature inside the room, and then automatically changes the operating mode to a suitable one. In this case, the rate of energy waste is reduced several times.