The circulation pump increases the efficiency of the autonomous heating system and allows 100% use of all heating circuits.

Professional installation of a heating pump guarantees high performance, reduces operating noise and reduces maintenance and repair costs. Installing the device does not cause any particular difficulties, but there are a number of nuances that are important to consider.

We will tell you how to choose a circulation pump, help you decide on the optimal scheme for inserting equipment into the system, outline installation requirements, and also provide step-by-step instructions for installing the device.

Purpose of the pump for heating

Previously, circulation pumps were used only in centralized heating systems, and for private housing construction the natural movement of the coolant caused by temperature differences was the norm.

Now forced circulation is used everywhere thanks to the emergence of compact and inexpensive models designed to service the heating networks of small houses and cottages.

Due to the increase in the speed of movement of the coolant in the pipeline, thermal energy flows faster to the heating radiators, and accordingly, the rooms are warmed up faster. The load on the boiler has decreased because the water is also heated faster.

The need to install bulky and inconvenient large-diameter pipelines has disappeared; contours have become easier to camouflage under floor coverings or be buried in walls.

The main disadvantage of pumps for heating systems is their dependence on electricity. If the power supply is intermittent or there is a risk of a complete power outage for some period, it is necessary to install a backup power generator or at least an uninterruptible power supply.

The remaining disadvantages relate to the designs and functionality of various types of devices. For example, monoblock units and devices with a dry rotor are noisier and require constant maintenance, while a pump with a wet rotor is demanding on the quality of the coolant and has a pressure limitation.

The best wet-running pumps for home heating systems

Models of this type have insulation only of the stator and other elements of the electric motor, while the rotor and impeller are in contact with the coolant.

Wet-running pumps are reliable, low-noise and do not require frequent maintenance, but have a low efficiency of about 50% and low power.

GRUNDFOS UPS 32-80 180

5.0

★★★★★

editorial assessment

100%

buyers recommend this product

See review▶

The main features of the model include flexible operation settings and economical energy consumption. It is ensured by selecting the speed mode of shaft rotation using a switch on the terminal box.

The device also has the ability to operate on a timer and with automatic performance control. The maximum pressure is 10 atmospheres, the liquid temperature is allowed within the range from -25 to +110 °C.

Advantages:

- easy connection;

- long service life;

- speed setting;

- silent operation.

Flaws:

- high price.

Grundfos UPS 32-80 180 produces a pressure of up to 8 meters and is designed for installation in one-story houses. An excellent choice for both closed and open-loop heating systems.

WILO Star-RS 25/2

5.0

★★★★★

editorial assessment

97%

buyers recommend this product

The reliability of the model is ensured thanks to a blocking current-resistant electric motor, a perforated stainless steel shaft design and a water filtration system.

Maximum pressure is 2 meters, productivity is 2.2 m³/h. Support for horizontal shaft positioning and double-sided connection of the terminal box make it easy to install the pump in various places in the pipeline.

Advantages:

- durability;

- ease of installation;

- low price;

- economical energy consumption.

Flaws:

- lack of fastenings in the package.

Wilo Star-RS 25/2 is suitable for home use. Quiet operation and a five-year warranty make the pump comfortable and reliable.

GILEX "Compass" 25/80

4.8

★★★★★

editorial assessment

88%

buyers recommend this product

Thanks to a convenient valve located on the body of the model, the user has the opportunity to quickly release air that accidentally gets into the heating system. This ensures uniform heating in all areas.

A three-mode shaft rotation speed switch ensures economical energy consumption and comfort during use. The noise level during pump operation is 45 dB, the maximum pressure is 8 meters.

Advantages:

- protection of fastenings from corrosion;

- speed shifter;

- air valve;

- low noise level;

- overheat protection.

Flaws:

- requires regular flushing of the system.

"Compass" 25/80 can be used in multi-stage heating systems. The right solution for installation in large buildings or low-rise buildings.

Criteria for proper selection of equipment

All installation efforts will be reduced to zero if the equipment is selected incorrectly. In order not to make a mistake, it is necessary to first analyze all aspects of a particular heating system and make the necessary calculations.

Main types of pumps

According to their design features, all devices are divided into 2 categories: with a wet and dry rotor.

Wet type pumps . This option is suitable for private homes. The unit is compact, almost silent and has a modular structure that is convenient for maintenance and repair.

But, unfortunately, it does not have high productivity - the maximum efficiency of modern models reaches 52-54%.

Pumps with a dry rotor are productive, unpretentious to the quality of the coolant, capable of operating under high pressure and do not require a strictly horizontal position on the pipe. However, they are noisier, and their operation is accompanied by vibration. Many models are installed on a foundation or metal support frame.

For installation of console, monoblock or “In-line” models, a separate room is required - a boiler room. It is advisable to use them when a flow rate of more than 100 m³/h is required, that is, for servicing groups of cottages or apartment buildings.

Brief overview of technical characteristics

When choosing a pump, you should definitely study the technical characteristics and compare them with the requirements of the heating system.

The following indicators are important:

- pressure , which covers hydraulic losses in the circuit;

- productivity - volume of water or supply over a certain time interval;

- operating coolant temperature , max and min – for modern models on average +2 ºС… +110 ºС;

- power – taking into account hydraulic losses, mechanical power prevails over useful power.

Structural details are also important, for example, the inlet/outlet diameter of the pipes. For heating systems, the average parameters are 25 mm and 32 mm.

An example of a unit for equipping a residential heating network with an area of 100 m² is a Grundfos UPS with a 32 mm pipe connection, a capacity of 62 l/s and a weight of 3.65 kg. The compact and low-noise cast iron device is inaudible even behind a thin partition, and its power is sufficient to transport liquid to the 2nd floor.

Pumps with built-in electronics allow you to quickly switch equipment to a more convenient mode depending on changes in temperature or pressure in the network. Automatic devices are equipped with digital displays that provide maximum information on the operation of the pump: temperature, resistance, pressure, etc.

Additional information on the calculation and selection of a circulation pump for heating is presented in the articles:

Requirements for installation of a circulation pump

There are a number of standards that regulate at the legislative level the installation of a circulation pump in a heating system. Some of the rules are set out in SNiP 2.04.05 “Heating...”. For example, it talks about the priority of schemes with forced circulation in heating networks.

Almost all requirements are justified by the operating efficiency of the system as a whole and the circulation device in particular. For example, the shaft of a device with a wet rotor must be installed on the pipe strictly horizontally in level so that there are no air pockets inside and the pump parts do not wear out prematurely.

A filter for dirt and abrasive particles is needed in any case, even when installing monolithic models. Filtered coolant will cause much less damage to pump parts than liquid with sand and suspended matter.

The mudguard is installed with the plug down in the direction of water movement to reduce resistance and facilitate system maintenance.

Some rules are dictated by manufacturers. For example, it was customary to install old models of certain brands exclusively on the return line, since they could not withstand high temperatures.

Now pumps have become more versatile and can be installed in any suitable location, but subject to power parameters.

Brief installation instructions

A common option is to install the pump on a bypass. This is due to two good reasons: it becomes possible to quickly dismantle or temporarily disconnect the device from the network, for example, if problems arise with electricity.

Various modifications of ready-made pumping units are available for sale: for welding or flange connection, with places for installing taps or valves, with a special area reserved for the pump.

But if you cannot purchase a ready-made unit or there is not enough space for its installation, you can independently organize the bypass piping and fix all the parts in the places allocated for them.

The following tools and materials are required for work:

- a set of open-end or adjustable wrenches for assembly;

- pliers:

- linen thread or tow;

- Unipak sealant.

American nuts are usually supplied with the pump, but taps, adapters or fittings will also have to be prepared. Attention should be paid to more reliable materials for making fittings and the diameter of the products.

- Assembling units with taps . Two will be located on the edges of the pump, the third will become part of a straight pipe. It is important to measure the “return” section in order to accurately weld the fragment with the tap.

- Assembling the pump loop. Tightening the nuts must be postponed until the final stage of installation, but for now they just need to be screwed on.

- Trying on the bypass loop . Mark the places where the units are welded into the pipe.

- Welding should be left to a qualified welder.

- Assembly of the lower unit is on the “return” side.

- Connecting the pump to the power supply.

As an example, install the GRUNDFOS .

Maintenance of the installed pump is carried out in operating mode. It is necessary to clean the filter more often and check the pressure gauge readings.

If the values do not correspond to the norm, the device must be removed and adjusted. It is better to do this in a specialized workshop.

Conclusions and useful video on the topic

Theoretical knowledge is quickly absorbed when accompanied by an interesting video that reveals the sequence and features of the work on installing devices.

Video review of the WILO pump – configuration and installation:

Practice shows that advanced home improvement enthusiasts can handle installing a circulation pump on their own.

However, if difficulties arise, it is better to turn to specialists: only qualified craftsmen know how to properly tie and install a heating pump, observing all the nuances of the chosen scheme.

Do you have personal experience installing a circulation pump? Do you want to share your accumulated knowledge or ask questions on the topic? Please leave comments and participate in discussions - the feedback form is located below.

Installing a circulation pump in homes with an individual heating system ensures uniform and high-quality heat distribution throughout all rooms of the house.

Types of pumps and their features

Various circulation units can be installed in the heating system of a private house. They are divided into two large groups. The circulation pump can be “dry” or “wet”. When installing devices of the first type with your own hands, you should take into account that their motor is separated from the working part by sealing rings. They are made from stainless steel. During the startup of the installation, the process of movement of these rings begins, which leads to sealing of the connection with a water (very thin) film. The latter is located between the seals.

Circulation pump unit

High-quality sealing in this case is ensured due to the fact that the pressure in the external atmosphere and in the heating system itself is characterized by different indicators. A “dry” pump makes quite loud sounds when operating. In this regard, its installation is always carried out in a specially soundproofed separate room of a private house. The efficiency of such a circulation unit is at the level of 80%.

There are three types of “dry” devices for connecting to the heating system: horizontal, vertical, block. The electric motor in units of the first type is placed horizontally. The discharge pipe is attached to them on the body of the device, and the suction pipe is attached to the shaft (on its front side). In vertical installations, the pipes are on the same axis. And the engine in this case is located vertically. In block circulation units, heated water exits radially and enters the system in the axial direction.

Caring for a “dry” unit is objectively difficult. Its elements must be regularly lubricated with a special compound. If this is not done, the mechanical seals will quickly fail, causing the pump to stop. In addition, in a private home, “dry” devices should be placed in rooms where there is no dust. Its turbulence during equipment operation often causes depressurization of the pump.

In “wet” units, the lubricant function is performed by the coolant itself. The impeller and rotor of such installations are immersed in water. “Wet” devices are much less noisy and easier to install with your own hands. And their maintenance is simpler compared to “dry” pumps.

The body of a “wet” installation is usually made of brass or bronze. Between the stator and the rotor there is always a special stainless steel separator. It's called a glass. It is necessary to provide the required tightness to the engine (more precisely, its elements under electrical voltage). It is “wet” units that are most often installed in a heating system in a private home.

They do a good job of heating relatively small areas. Such devices are not suitable for large objects, since their productivity usually does not exceed 50%. The low efficiency of “wet” installations is due to the impossibility of high-quality sealing of the cup placed between the stator and the rotor.

Pump device

Since the engine stator is energized, it is separated from the rotor using a glass made of stainless steel or carbon material

The main elements that make up the circulation pump are:

- housing made of stainless steel, bronze, cast iron or aluminum;

- rotor shaft and rotor;

- wheel with blades or impeller;

- engine.

Typically, an impeller is a structure of two parallel disks that are connected to each other by means of radially curved blades. One of the disks has a hole for liquid to flow through. The second disk secures the impeller to the motor shaft. The coolant passing through the engine acts as a lubricant and coolant for the rotor shaft where the impeller is fixed.

Since the engine stator is energized, it is separated from the rotor using a glass made of stainless steel or carbon material. The walls of the glass are 0.3 mm thick. The rotor is fixed on ceramic or graphite bearings for sliding.

About the choice of equipment and the rules for its independent calculation

The key indicator that determines the efficiency of the circulation pump is its power. For a household heating system, there is no need to try to purchase the highest-power installation. It will only make a loud noise and waste electricity.

Mounted circulation pump

You need to correctly calculate the power of the unit based on the following data:

- hot water pressure indicator;

- pipe section;

- productivity and throughput of the heating boiler;

- coolant temperature.

Hot water consumption is determined simply. It is equal to the power indicator of the heating unit. If, for example, you have a 20 kW gas boiler, no more than 20 liters of water will be consumed per hour. The pressure of the circulation unit for the heating system for every 10 m of pipes is about 50 cm. The longer the pipeline, the more powerful the pump you need to purchase. Here you should immediately pay attention to the thickness of the pipe products. The resistance to water movement in the system will be stronger if you install pipes with a small cross-section.

In pipelines with a diameter of half an inch, the coolant flow rate is 5.7 liters per minute at the generally accepted (1.5 m/s) speed of water movement, with a diameter of 1 inch - 30 liters. But for pipes with a cross-section of 2 inches, the flow rate will already be at the level of 170 liters. Always select the diameter of the pipes in such a way that you do not have to overpay extra money for energy resources.

The flow rate of the pump itself is determined by the following ratio: N/t2-t1. In this formula, t1 refers to the temperature of the water in the return pipes (usually it is 65–70 °C), and t2 is the temperature provided by the heating unit (at least 90 °C). And the letter N denotes the boiler power (this value is in the equipment passport). The pump pressure is set according to the standards accepted in our country and Europe. It is believed that 1 kW of power of a circulation unit is quite enough for high-quality heating of 1 square meter of a private home.

External factors influencing work

The main factor is the temperature outside. The amount of heat required for heating, and therefore the operation of the device itself, depends on it. As an example: a pump that is “frozen” will not be as efficient as one that is already “warmed up”. One important point regarding the choice: the device often overheats if it is not selected correctly (it simply cannot cope). Therefore, it is so important to find out about the features of the system before purchasing.

Another important factor is the diameter of the pipeline. The larger it is, the more working fluid needs to be distilled, therefore, the more powerful the pump is required. Finally, it is not advisable to install a device designed for 2.5 centimeters into a pipeline with a diameter of 3.2 centimeters using connecting adapters. This often leads to a decrease in pressure.

Is the device model important?

There are a lot of pump models from different manufacturers on the market, but almost all of them have the same characteristics. The differences can only be in service life and degree of reliability. The most popular manufacturers are rightfully considered: Grundfos, Speroni, Wilo, Elsoterm and Wester. There are also many Chinese models, as well as outright fakes made in China. But the quality of the brands mentioned above is superior to them, as they are reliable, durable and almost silent. The only negative is the high cost (from 2500-3000 rubles ).

What to choose? Certainly not Chinese pumps. It is better to overpay for one of the above brands, but get really high-quality equipment.

Do-it-yourself pumping equipment installation diagrams and standards

Circulation pumps are installed in two ways. The first connection diagram for the unit is two-pipe. This connection method is described by a high temperature difference in the system and variable coolant flow. The second scheme is one-pipe. In this case, the temperature difference in the heating system will be insignificant, and the media consumption will be constant.

Installed circulation pump

Connect the pump yourself according to the instructions that come with the unit. It also indicates the installation procedure for the functional reinforcement chain. Before installing the pump, be sure to drain all water from the system. Often there is a need to clean it. During the operation of the heating boiler, a lot of debris accumulates on the internal surfaces of the pipes, which worsens the technical performance of the system.

Experts advise placing the circulation unit in front of the boiler - on the return line. This is done in order to eliminate the risk of boiling of an open type heating system due to the vacuum that is created when installing the supply pump. In addition, if you install a circulation unit on the return line, its trouble-free operation will be significantly increased due to the fact that it will operate at lower temperatures.

Warm floor from a central heating battery in an apartment - diagrams, installation and first start-up

Today, when solving the problem of heating their homes, most owners pay attention to the next type of heating - heated floors.

At the same time, the most popular type, both in a private house and in an apartment, is water-heated floors powered by a battery, and in the bathroom hydrofloors are often made from a heated towel rail.

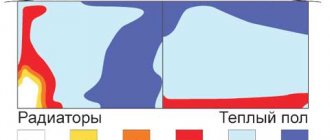

The advantage of heated floors over radiators

Unlike radiators, heating with warm water floors leads to uniform heating of the room. In addition, this device provides more comfortable conditions for a person, since, with floor heating, the temperature below is higher than at the top.

Therefore, your feet will be warm and your head will be in a cooler space, which is good for your health.

Another positive aspect of such heating is savings, heat loss is reduced by up to 20%. Without a doubt, a big plus is the aesthetics of the design. The “filling” of the heated floor is hidden under the floor covering, thereby not spoiling the interior of the apartment, in comparison with radiators that are placed on the wall.

Of no small importance is the fact that the air does not dry out and hot currents do not drive dust particles around the room, as with radiator heating.

The disadvantages of such a structure include a rather labor-intensive and lengthy process that requires significant financial costs. In addition, when connecting a heated floor to a radiator, it will only function if there is heating in the radiators.

Is it possible to make a heated floor from a battery - is the connection legal or not?

It is possible to install a warm water floor using a radiator in an apartment in a multi-storey building, but a number of issues will need to be resolved. The main thing is to obtain permission to tap into the central heating of the house from heating networks, as this may affect the operation of the neighbors’ radiators. In addition, incorrect installation work can lead to an emergency situation and flooding of the apartment from below.

For your information! Without this permit, installing a heated floor will be illegal, and if such an installation is discovered, you will be subject to penalties.

To maintain the thermal balance in the house, there are three legal options for installing a heated floor to a radiator:

- If the apartment has a two-pipe battery connection circuit;

- If the heating main is located in the basement of the house, for residents of the first floor, it is easier to obtain consent to connect a separate input for the supply and return circuits;

- If there is overhead wiring in the attic, it is easy to obtain such permission for residents of the top floor.

Is it necessary, and in what cases?

Many owners of country real estate, and especially two-story houses, are interested in the question of installing an additional circulation pump in the heating system. They come to this conclusion after uneven heating of the radiators in the rooms, provided that the boiler has sufficient power. If the temperature difference between the boiler and the coolant in the pipelines exceeds 20 degrees, then it will be necessary to remove air plugs or set the existing pump to an increased speed.

Installation of additional pumping equipment is necessary in the following cases:

- When adding an additional circuit to the heating system, and especially when the pipe length exceeds 80 meters;

- For uniform movement of coolant in pipelines.

An additional pump in the heating system may not be needed if it is balanced using balancing and control valves, so before purchasing additional equipment, bleed the air from the radiators and add water to the system. If everything works fine, then there is no point in installing an additional pump.

Winterm

Heating systems using alternative energy sources are interesting primarily because they can significantly reduce the cost of a kilowatt of heat. The installation of a solar thermal system (solar collector) is relevant primarily for a private house. For an apartment, this will be a specific “marginal” solution, although it is found in everyday life.

But a heat pump for an apartment is a completely different matter. Modern examples of this equipment are capable of heating an apartment completely independently. Let's look at the most popular options for using heat pumps for apartments. This information will be useful to you if you are wondering whether you need a heat pump installed in your home?

Bivalent heating system - boiler + heat pump

The most common option for using heat pumps in an apartment or house in Ukraine is a bivalent system. A heat pump covers the needs of the heating and hot water supply system for most of the year, and an electric or gas boiler is used only during periods of severe frost. What temperature this will be depends on the specific equipment. On average, we will assume that the transition to the boiler will occur at temperatures in the range from -10 to -15 degrees. The heat pumps we offer from Viessmann, Vaillant and LG are capable of operating at -20 degrees (and even lower), but an engineer must calculate the economic feasibility. At temperatures bordering the minimum permissible, the efficiency of the heat pump decreases. If you have a gas boiler installed, then based on the SCOP curve you can calculate when it will be cheaper to use it. If we are talking about an electric boiler, then the heat pump can operate at temperatures close to the minimum permissible temperatures. It will still be cheaper, because for 1 kW of electricity consumed there will be more than 1 kW of heat.

If we talk about winter 2019/2020, then such low temperatures at which it would be necessary to turn on the boiler when using heat pumps offered by Winterm in Ukraine simply did not exist.

In what case do we recommend installing a heat pump in an apartment?

First of all, if you use an electric boiler. Even despite the nightly tariff, this is a fairly expensive way to heat a home.

Let's take a simple example - the SCOP of the LG THERMA V heat pump is 4.65. This means that at the point of its maximum efficiency it is capable of delivering 4.65 kW of heat to the heating system, spending only 1 kW of electricity.

In high-rise multi-storey buildings, only electric boilers and an air-to-water heat pump are installed for individual heating; this is the best solution for the future. You not only save money, but also seriously reduce the load on the network. After all, the second problem with heating with an electric boiler is the power allocated to the apartment. In some cases, in winter it simply may not be enough to simultaneously use electrical appliances such as a microwave, oven, washing machine and iron. But at the same time the refrigerator, lighting, TV or computer are working.

Hydraulic separator

If there is a need to install an additional pump, then another device must be included in such a heating system - a hydraulic separator. In the list of terms used, a hydraulic separator can also be called an anuloid or a hydraulic arrow.

- The pump shaft must be in a horizontal position relative to the floor surface;

- The movement of water flow in the system must coincide with the direction of the arrow on the device;

- To prevent liquid from entering the pump terminals, the box should be installed on the top or side of the equipment.

Correct installation of an additional pump in the home heating system

According to some users, it is better to install the pump on the return pipeline. Here the coolant temperature is minimal, which will increase the service life of the device, but not all experts agree with this statement. The fact is that the pump is designed for operation in a coolant environment whose temperature can reach 110 degrees.

What is individual heating in an apartment?

Individual apartment heating is a small boiler room in the apartment. The owner of the living space independently regulates the temperature, turns the system on and off at any time of the year. For apartment heating, a boiler, heat metering devices, pipes for gas and smoke exhaust, as well as equipment for air intake are installed. In addition, the heating device is equipped with draft monitoring clamps, flame control, and a shut-off valve, which is activated automatically in the absence of fire.

In modern apartment buildings, individual heating systems are more often installed. But in older apartments there is also the possibility of abandoning central heating and connecting apartment-by-apartment heating.

Is it possible to make individual heating in an apartment with central heating?

If the house has central heating installed, then residents can refuse it and install an individual system.

There are several reasons for this:

- High tariffs.

- The apartment owner can turn on the heating himself without waiting for the heating season.

- Poor performance of the organization that maintains thermal systems. Due to insufficient temperature, an unfavorable microclimate is created in the apartment, which negatively affects the health of residents. Due to unscrupulous work performed by the organization, dampness and mold are formed in residential premises.

In order to switch from central heating to individual heating, you must:

- documents for the apartment;

- technical passport of the residential premises;

- consent of all residents of the apartment;

- statement and reconstruction project.

The owner of the residential premises should find out from the management organization whether it is possible to disconnect only one apartment from the heating system or whether all residents of the apartment building need to switch to a new heating option.

If the company has issued a permit, then you need to obtain a gas wiring drawing, consumption calculation and other technical documents. This is necessary if the heating is gas. If the owner has chosen an electrical system, then it is necessary to contact Energosbyt with a fire inspection certificate. When using a coaxial chimney with outlet to the facade, it is necessary to legalize the actions in the Sanitary and Epidemiological Supervision Authority.

To install a heating system in an apartment, you should contact a company that has a license for this type of work. Gas heating is connected and started by a gas service employee. Then the boiler must be put in for service.

ORDER A SERVICE FROM ACCREDITED COMPANIES

It is possible by law to transfer an apartment to autonomous heating from central heating. In rare cases, the management organization may refuse. If everyone living in the apartment agrees with the transition, the organization has given permission and other necessary documents have been received, then there should be no difficulties connecting the new system.

What is the difference between central heating and individual heating?

In order to understand the difference between central heating and individual heating, it is necessary to consider each system separately.

Central heating is a system in which hot water is piped into apartments and heats them. In addition, the resource is used in the form of hot water supply.

With individual heating, a heating boiler is installed in the apartment, which heats water to heat all rooms. Water is also used for household needs.

The main advantage of individual heating is the ability to turn on and regulate the temperature at any convenient time. Thus, the owner of a residential premises can turn on the system earlier than the heating season or reduce the temperature to save money. In addition to regulating the coolant, you can control the temperature of hot water heating.

Apartment heating consists of the following elements:

- The heating boiler is electric or gas.

- Pipelines for the movement of the coolant.

- Radiators for heating all rooms.

Installation diagram

In practice, two schemes for installing a circulation pump are used in a single-pipe and two-pipe heating system. Before carrying out installation work, you must carefully study the attached instructions. At the preparatory stage of work, water is drained from the system and the pipes are cleaned of contamination by additional pumping of liquid. The pump is installed according to the attached diagram, then coolant is poured into the circuit and the unit is turned on.

As we have already said, it is best to install the pump on the return side using a tap or, as it is also called, a bypass. Such a device is necessary to shut off the water and replace the pump in case of breakdown. The diameter of the outlet pipe should be smaller than that of the central pipeline.

Installation diagram of an additional pump in the heating system

At each edge of the bypass, before entering and after exiting the pump, taps are installed for emergency shut-off of the coolant. Another valve is installed on the central line to direct the flow of liquid through the pump. Before entering the pumping equipment, a special filter is attached that will accumulate harmful particles in the water.

With warm floor

When filling the system with coolant, it is not always possible to get rid of the air present here. Accumulated gases often block the movement of fluid, and not every manifold can be used as a relief valve. To solve this problem, the circulation pump has a special outlet valve made in the form of a disk.

To release accumulated gases, you need to turn this part with a screwdriver counterclockwise. After supplying water from the slot, the disk is tightened and the pump is started again. A similar procedure is repeated several times in a row.

“>