Today it is generally accepted that gas heating is the most affordable both in cost and in terms of the prevalence of this type of fuel. But the problem with holiday villages is that most of them are simply not connected to the gas mains. Accordingly, those who regularly use a country house during the cool season should look for a different fuel for the heating system. Most often, many people opt for ordinary wood, and heating a country house with wood is also popular today.

Firewood is a simple and affordable way to heat a summer house

Of course, this may cause some surprise - if there are many modern fuels, why use firewood? The fact is that sometimes a problem may also arise with the supply of solid or liquid fuel to the village. While stocking up on wood for heating a country house with firewood is quite simple.

Two-pipe scheme: efficient heating for the home

A two-pipe heating circuit is installed as follows:

1. A “hot” coolant circuit is connected to the upper pipe of the heating boiler, which rises to the ceiling and stretches at this level along the walls of the entire house. In this case, the “lift” - a vertical section of the pipeline that connects the upper section of the wiring with the boiler, ends with a tee, to the end of which the entire circuit is mounted. The upper branch of the tee is used to extend the heating circuit to the next floor or to install an expansion tank.

2. A waste coolant circuit (return) is connected to the lower pipe of the heating boiler, which stretches along the perimeter of the walls of the house at floor level. All branches with waste coolant, which are laid at the level of interfloor ceilings, can be embedded into the return line mounted at the level of the basement floor. For this purpose, special vertical “descents” are organized. The circular pump and drain pipe are installed at the lower pipe of the heating boiler, on the basement return.

3. Heating radiators are installed under the windows on each floor of the house. In this case, a nipple for bleeding air is cut into the upper left radiator pipe, and a valve is cut into the upper right pipe, which regulates the flow capacity. Accordingly, an outlet is connected to the lower left nozzle (a special corner bent down), and the lower right nozzle is closed with a plug.

4. Further assembly of the system proceeds as follows. An insert is arranged in the upper “hot” pipe, from which a vertical section of pipe extends, which connects the circuit with the control valve of the heating radiator. The same insert is installed in the “cold” pipe, which connects the radiator outlet with the return.

Two-pipe heating circuit

The result is a reliable, functional system that effectively heats even houses several stories high. The double-circuit wiring diagram allows you to regulate the temperature of each radiator, which is especially appreciated in individual residential buildings.

Making a wood-burning boiler yourself

not difficult at all. You just need to choose the right grade of steel. Its thickness must be at least 1.5 mm. It is recommended to manufacture the boiler by welding. But since this takes a lot of time, steel barrels with the required wall thickness are often used.

But if you intend to install a heating boiler made by yourself, you should know that it has some disadvantages. First of all, this is low efficiency and short service life. In addition, if you accidentally touch its surface, you can get burned, as it gets very hot.

A DIY wood-burning boiler is perfect for heating various outbuildings with a small area. For example, a barn, garage, etc. If you need to heat a country or private house, it is best to install a factory model, which will be of much better quality and will allow the building to be heated well.

Build process

The process of creating a boiler includes several stages. When manufacturing each element, it is worth taking into account the special operating conditions of the product being manufactured.

Air supply device

We cut a section from a thick-walled pipe with a diameter of 100 mm, the length of which will be equal to the height of the firebox. We weld a bolt to the bottom. From a steel sheet we cut out a circle with the same diameter as the pipe or larger. We drill a hole in the circle large enough to pass the bolt welded to the pipe. We connect the circle and the air duct pipe by tightening the nut onto the bolt.

As a result, we will get an air supply pipe, the lower part of which can be closed by a freely moving metal circle. During operation, this will allow you to regulate the intensity of firewood combustion and, consequently, the temperature in the room.

Using a grinder and a metal disc, we make vertical slits approximately 10 mm thick in the pipe. Through them, air will flow into the combustion chamber.

Housing (firebox)

The body will require a cylinder with a sealed bottom with a diameter of 400 mm and a length of 1000 mm. The dimensions may be different, depending on the available free space, but sufficient for laying firewood. You can use a ready-made barrel or weld the bottom to a thick-walled steel cylinder.

Sometimes heating boilers are made from gas cylinders for a longer service life.

In the upper part of the body we form a hole for the removal of gases. Its diameter must be at least 100 mm. We weld a pipe to the hole through which the exhaust gases will be removed.

The length of the pipe is selected depending on design considerations.

Connecting the housing and the air supply device

We cut a hole in the bottom of the housing with a diameter equal to the diameter of the air supply pipe. We insert the pipe inside the body so that the air vent extends beyond the bottom.

The air supply pipe should end a few centimeters before the start of the chimney.

Heat Dissipation Disc

We cut out a circle from a metal sheet 10 mm thick, the size of which is slightly smaller than the diameter of the body. We weld a handle made of reinforcement or steel wire to it.

This will greatly simplify the subsequent operation of the boiler.

Convection hood

We make a cylinder from sheet steel or cut a piece of pipe, the diameter of which is several centimeters larger than the outer diameter of the firebox (body). You can use a pipe with a diameter of 500 mm. We connect the convection casing and firebox together.

This can be done using metal jumpers welded to the inner surface of the casing and the outer surface of the firebox, if the gap is large enough. With a smaller gap, you can weld the casing to the firebox around the entire perimeter.

From a steel sheet we cut out a circle with the same diameter as the firebox or a little larger. We weld the handles to it using electrodes, wire or other available means.

Considering that the handles can become very hot during operation of the boiler, it is worth providing special protection made of material with low thermal conductivity.

To ensure long burning, we weld the legs to the bottom. Their height should be sufficient to raise the wood-burning boiler at least 25 cm above the floor level. To do this, you can use various rolled products (channels, angles).

Congratulations, you have made your own wood-burning boiler. You can start heating your home. To do this, just load the wood and light it by opening the lid and heat dissipation disk.

Heating installation in a private house with a wood-burning boiler

Wood-burning boilers with a water circuit for heating a private house are connected to an existing heating system with forced or natural circulation of coolant. During installation work, the requirements of PPB and SNiP are met.

Another important issue taken into account during connection is the need to accommodate large fuel storage. The boiler burns 10-15 cubic meters of wood per season. The storage must be dry, accessible, spacious and safe.

Where can a wood boiler be installed?

A wood-fired hot water boiler for heating a private home can be installed anywhere, provided that it meets the technical and fire safety requirements. General recommendations regarding the choice of premises for a boiler room are:

- For the needs of a boiler room in a private house using wood, use any technical room that meets the following requirements: ceiling height of at least 2.2 m, area 8-12 m². There is supply and exhaust ventilation and lighting.

- You can install a wood-burning boiler in the basement, provided that the room is dry and heated. Compliance with these conditions will extend the service life of steel heat generators.

- A wood-burning boiler for heating a private house with water heating is installed on a solid foundation. If you connect a cast iron unit, you will need to make a concrete foundation.

- To prevent accidental fire when laying firewood, the wooden base, in the direction of opening the fire door, is covered with a metal or asbestos-cement sheet.

- The firewood storage is located in an adjacent room.

- The boiler is installed in a place convenient for maintenance. All components: the water treatment and filtration system are given free access.

- Modern heating of a private house with a wood-burning boiler often requires connection to the electrical network. Be sure to install a voltage stabilizer and an uninterruptible power supply. Automation is connected directly from the switchboard, through automatic devices and RCDs.

- The chimney is installed in compliance with fire safety requirements during installation. All heating elements, when passing through floor slabs and roofing sections, are insulated. I install a spark arrestor on the head of the pipe. Chimney options are discussed here.

The main requirement for operating a wood-burning boiler is compliance with safety regulations. Modern models are equipped with a multi-level security system that prevents smoke in the room and boiling of the coolant.

Heating schemes for a private house with a wood-burning boiler

Heating in a private house using a wood boiler can be done in different ways. The choice of wiring diagram largely depends on the design of the boiler and the parameters of the room. All options can be divided into several classes, according to the following features:

Coolant movement - forced heating systems use circulation pumps to create pressure in the water circuit. The disadvantage of the solution is its dependence on energy. Systems with natural circulation use the ability of a liquid to expand when heated. The coolant moves along the circuit by gravity. The disadvantage of the solution is the high requirements regarding compliance with slopes and angles. A professional installer can properly install heating to the radiators.

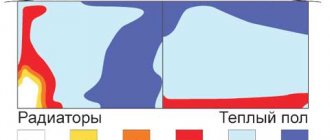

One and two pipe scheme. The single-pipe system involves connecting each battery in series. The water circuit feeds each radiator, after which the coolant returns back to the boiler. The disadvantage is that heat transfer deteriorates the further away from the boiler. A two-pipe system does not have this disadvantage. A supply and return pipeline is connected to each radiator. This scheme ensures uniform heat supply to each heating point.

A liquid heating system connected to a wood-burning boiler requires proper planning and execution of work in strict compliance with all existing building codes. The heating layout in a two-story house is especially carefully planned. Setting up a security group is required.

When installing circulation pumps. Additionally, a voltage stabilizer and an uninterruptible power supply are connected.

Modern wood-burning boilers are economical, safe and easy to control, and are successfully used as an alternative to gas equipment.

Calculation of power and temperature of a warm water floor

Calorific value of firewood: comparison table of different species

Wood is a rather complex material in its chemical composition.

calorific value of firewood

Why are we interested in chemical composition? But combustion (including the burning of wood in a stove) is a chemical reaction of wood materials with oxygen from the surrounding air. The calorific value of firewood depends on the chemical composition of a particular type of wood.

The main chemical binders in wood are lignin and cellulose. They form cells - peculiar containers, inside of which there is moisture and air. Wood also contains resin, proteins, tannins and other chemical ingredients.

What is wood moisture content and what does it affect?

A physical quantity that describes the relative amount of water contained in wood is called moisture content. Wood moisture content is measured as a percentage.

When measuring, two types of humidity can be taken into account:

- Absolute humidity is the amount of moisture that is currently contained in wood relative to completely dried wood. Such measurements are usually carried out for construction purposes.

- Relative humidity is the amount of moisture that the wood currently contains in relation to its own weight. Such calculations are made for wood used as fuel.

So, if it is written that wood has a relative humidity of 60%, then its absolute humidity will be expressed as 150%.

To calculate the calorific value of firewood at a known humidity, you can use the following formula:

Analyzing this formula, it can be established that firewood harvested from coniferous trees with a relative humidity of 12 percent will release 3940 kilocalories when burning 1 kilogram, and firewood harvested from deciduous trees with comparable humidity will release 3852 kilocalories.

To understand what a relative humidity of 12 percent is, let us explain that firewood acquires such humidity when it is dried outside for a long time.

What is wood moisture content and what does it affect?

Wood moisture content is an indicator that reflects the moisture content in the material. If we look at a specific example, then 100 kg of firewood, where the humidity is 25, contains 75 kg of wood and 25 liters of water. This indicator directly affects the heat generated: the less moisture inside the tree, the more heat it releases during combustion. Thus, several categories of wood can be distinguished by composition:

- Driftwood that contains more than 80% moisture. Usually it stays in water for a long time or is fused - due to this it gains such an amount of moisture.

- Freshly cut wood (moisture content from 45% to 80%) - it usually still contains natural moisture, since the cut occurred recently.

- The air-dry type contains from 20% to 45% - it is pre-dried in an open area.

- Room-dry type of wood (from 7 to 20%) - this type of material is kept in a dry and ventilated place for a long time, so almost all the moisture evaporates (sometimes a drying chamber can be used for this).

- Absolutely dry variety (0%) - in this case the material is thermally treated.

If you need to dry wood at home, then even with the most ideal indicators you will be able to achieve no more than 15-20% moisture. It is possible, of course, to improve this indicator, but the costs will not be recouped. That is why it is not recommended to spend money on special conditions for storing wood.

Equipment and materials of systems

Boiler Viessmann Vitopend 100-W

Boiler Buderus Logano G124 / G234 / G334

Boiler Viessmann Vitorond 100

The cost of heating finished houses

Individual cost calculator

The popularity of water heating is facilitated by high user characteristics and a wide selection of equipment that you can install in your home - boilers, heating devices (radiators, batteries), control automation and modern materials, as well as several types of fuel. To heat the coolant (water or antifreeze), different types of boilers can use natural gas, diesel fuel, electricity or solid fuel. There are universal boilers that operate on two or more types of fuel.

Heating with solar panels

Absorbing the sun's energy is a popular idea that has lived in people's minds for decades. Modern technologies have made solar panels more accessible; today solar panels are appearing on cottage houses throughout the country. The heating device with solar panels is simple:

- Solar energy is absorbed by the panels, turning into thermal energy.

- Thermal energy is used in room heating systems.

Solar panels are an environmentally friendly way to obtain additional free heat to heat your home or to obtain hot water (which is what they are most often used for). It is worth remembering that the method is applicable when there are a large number of panels involved, depending on weather conditions and the geographical location of the building. Not suitable for residents of northern regions with little daylight. The method, again, is very expensive,

Modern solution

Heating a dacha using new technologies has significantly improved the possibilities of heating rooms with wood. This can be done easier and more efficiently with the help of pyrolysis boilers, specially designed for wood heating.

Operating principle

The operation of these boilers is based on the principle of pyrolysis combustion. At high temperatures (up to 800 °C) and lack of oxygen, wood decomposes, releasing flammable gas. Mixing with oxygen, the gas burns and releases a large amount of heat.

The main advantage of pyrolysis is that the combustion process occurs much slower than with conventional wood burning. In this case, the amount of heat generated increases several times.

On one tab, the device can operate for up to 12 hours, which significantly saves fuel costs.

Advantages

- environmental friendliness due to complete combustion of fuel;

- absence of ash and soot;

- adjustable control.

Heating your home with alternative fuels

Each option for heating a home without using gas or wood has its own advantages and disadvantages. Therefore, before you decide to purchase equipment and install the entire heating system in your house, you should do a thorough analysis. What equipment is more convenient to install, what type of fuel is more economical and what heating is the most efficient for a particular home or cottage?

Heating systems are classified according to characteristics and are often installed in combination, which optimizes operation in extreme situations and makes it possible to make fuel consumption more economical.

Diagram of the heating system of a private house.

In a modern heating system, it is possible to use different types of coolants simultaneously, combine heating functions, and heat water. They can work to heat or even cool water.

Types of heating for a country house or cottage are divided by type of equipment:

- with heating boilers;

- with heat pumps;

- systems with mini-CHP;

- combined with a heating boiler;

- solar panels.

By type of boiler or generating equipment:

- condensing or low-temperature liquid fuel boiler;

- solid fuel boiler;

- mini-CHP;

- Heat pump.

Boiler room arrangement

Wood heating of a country house involves the allocation of a room in which the boiler and devices for its control will be located. This room must meet the following parameters:

- the presence of a smoke channel with a height of at least 4 m;

- area of at least 6 m²;

- the presence of combined lighting;

- ceiling height is not less than 2.5 m;

- presence of forced ventilation.

Attention: The decoration of the room must be made from fire-resistant materials. If the boiler has electrical elements, there must be an electrical supply line.

Fireplaces for home

Fireplaces have the longest history among home heating devices. At first they were an open fireplace in the middle of the room. Over time, various structures for removing smoke - smoke collectors - began to be built above the fireplaces. Nowadays, a fireplace is no longer needed so much for heating as for aesthetics and comfort.

There are the following types of fireplaces: electric, wood-burning, gas, bio-fireplaces, fireplace-stoves and decorative fireplaces.

According to the name, the principle of operation of electric fireplaces is the use of electricity. This eliminates the problem of constructing a chimney. Wood-burning fireplaces “work” on wood and are designed to create real comfort in the home. Date: September 25, 2022