SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

Modern technologies that have come to our country encourage the population to also use the latest developments. Solar panels, room temperature controllers and other smart devices can not only reduce utility bills, but also maintain a comfortable room temperature. Of course, a recuperator for a private home cannot be called an innovation, however, the savings in money and heat energy are obvious.

Installation of a recuperator in a private house

Recuperator: what is it?

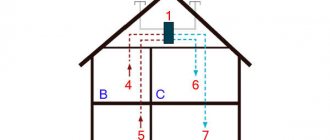

This device is a design similar to a house ventilation system. Their difference lies in the fact that conventional ventilation removes stale air from the room and fills it with fresh air. The recuperator performs similar actions, only it brings heated warm or cooled air into the house. An air conditioner performs similar functions, however, it requires electricity and a refrigerant - freon; the heat recovery unit does without it. Heating or cooling of the inflow occurs due to the heat exchange of the primary and secondary coolant through the wall separating the air masses.

Components of an air handling unit with a recuperator

The main link of the air handling unit with a recuperator is the heat exchanger. The device is equipped with a thermal electric heater or fan, check valves to prevent air movement in the opposite direction, and much more.

The use of such a system makes it possible to recover part of the thermal energy that is usually lost when passing through ventilation ducts. Warm air masses circulate freely in the heat exchanger, come into contact with the cold flow through the dividing wall and transfer their thermal energy to the latter.

A surface-type recuperator is a heat exchanger with double walls. One channel is occupied by the outgoing primary coolant, the other by the secondary, cooler one. The walls have high thermal conductivity and are installed to prevent mixing of air flows of different temperatures. The outgoing air element passes along the box, the incoming air element crosses. As a result of heat transfer to cold air, heated air masses enter the house.

Ventilation and heating of air through a recuperator in the house

The temperature of the incoming air depends on the temperature of the outgoing air. The warmer the outgoing stream, the higher the supply temperature.

Operating principle

The principle of operation of the recuperator is that it accumulates heat from the removed flow and communicates it with high efficiency to the air supply masses. This allows you to save money on heating and supply fresh heated air into the house.

The operating principle of the system is determined by two principles:

- Waste or stale air masses are removed from the room, pass through the ceramic recovery chamber and heat it. In this case, almost 97% of the thermal energy is released. When the recovery chamber heats up, the heat exchanger automatically switches to the fresh jet inflow mode.

- The air passes through the ceramic recovery chamber, is heated by the heat accumulated in it and is supplied to the house. Cooling of the regenerator serves as a signal to turn on the fan in exhaust mode.

Air circulation through the heat exchanger

Such a recuperator ventilation system allows you to reduce the consumption of gaseous, solid or liquid fuel, which may be necessary for the operation of other devices, and create comfortable living conditions.

Note! Installing a supply and exhaust air recuperator for your home will save up to 80% of the heat in the room.

Advantages of a thermal power device

A thermal power device of this type has been gaining great popularity recently. There is no need to ventilate the home in summer and winter, thereby releasing precious heat outside. On a dusty summer day, the device will supply the room with clean atmospheric air, which will first pass through an air purification filter.

The recuperator ventilation system is in wide demand among owners of country houses

There is also no need to use the mentioned system manually - the automation will do it for you. Cold masses in winter will be heated due to the outgoing warm flow, and hot summer days will cool down when heat is transferred to a cooler flow.

In addition, the system is characterized by the following number of advantages:

- saving money on heating;

- savings on separate exhaust fans;

- removal of unpleasant heavy odors;

- removal of dust particles;

- ease of operation and installation;

- low cost of use;

Recuperator - part of the ventilation system

- process automation;

- long service life of the system.

Even periodic use of a heating installation will allow you to saturate your home with clean atmospheric air masses without losing heat or, conversely, increasing the temperature.

High-quality ventilation

Installing a recuperator will keep the house clean along with the flow of fresh outside air. Tobacco, fireplace or smoke of other origins, carbon dioxide or other unhealthy emissions, harmful or unpleasant odors - a rotary heat exchanger can handle everything. The operation of the system has a beneficial effect on the human body, drying air with high humidity, which is especially important for hypertensive patients, as well as people with atherosclerosis or cardiovascular diseases. In addition, high humidity threatens other ailments.

Operation of the air ventilation and heating system through a recuperator

Economical heating

By installing a heat exchanger, you will ensure stable savings not only in money, but also in the heat in the house. The outgoing warm flow will warm the cold supply air to a comfortable temperature, which will significantly avoid unnecessary operation of heating equipment. The heating system carefully handles the heat entering its box, practically preventing it from escaping into the atmosphere. There is also no need to monitor the temperature of the incoming air masses; this will be done by the heat exchanger, supplying them with only a small temperature difference compared to the outgoing flow.

Important! According to experts, savings in electricity or any type of fuel for heating devices range from 40 to 50%. Of course, you should not neglect the high-quality thermal insulation of the room.

Air recuperator

No additional ventilation

Gas stoves, fireplaces, water heaters and weeping metal-plastic windows require additional ventilation or periodic ventilation. Frosty and hot periods of the year significantly complicate this process: the first threatens to cool the room, the second threatens with dust and hot dry winds with low humidity. If you decide to buy an air recuperator, you will ensure high-quality ventilation of the entire house, avoiding unnecessary financial expenses and installation of equipment for additional ventilation.

Silent and high-quality air purification

Atmospheric supply air in any case brings with it dust particles, dirt elements, diluted exhaust gases from cars, chimneys and industrial enterprises. The air filter installed in the heat-energy device will rid the house of unwanted odors and dust particles. After undergoing high-quality cleaning, the atmospheric stream will fill the room with not only fresh, but also clean air. True, the latter will be determined by the necessary regular maintenance of the air filter and other elements of the system.

Main components of the recuperator

Note! A filter clogged with dust or uncleaned is a breeding ground for pathogenic bacteria. Its regular cleaning and periodic replacement will allow the home owner to avoid infectious respiratory diseases.

Recyclers for an apartment or house have high operating efficiency and low noise levels, which range from 25-35 dB. This is equivalent to the sound made by an air conditioner.

Heat exchanger power calculation

When planning the installation of a heat exchanger in an apartment or private house, it is important to correctly calculate the power and take into account the size of specific rooms.

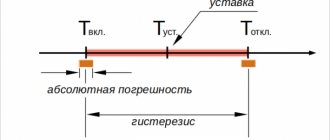

Calculate the power of the recuperator using the formula: P = 0.335 x Q x (TVn. - Tulich.), where:

- P—device power, W;

- Q is the volume of air in m3 that should enter the room every hour;

- TVn. — internal air temperature after the recuperator;

- Tulich. — outside air temperature before entering the recuperator.

When calculating power, take into account the standard volume of supply air. Its value is 60 m3/h for persons permanently staying in the premises, and 20 m3/h for temporary visitors.

Consider an example: you need to heat by 15 °C

an air flow of 100 m3 per hour coming from the street into the room.

P=0.335x100x15=500 W.

Recuperator for a private home: types and characteristics

Supply and exhaust recuperators can have various design features. A sales consultant in any specialized store of heating devices will help you choose the appropriate option.

Recuperator for home

The following types of equipment exist:

- lamellar;

- rotary;

- roof;

- recirculating water.

All of them are designed to create a favorable indoor climate, be it an apartment, a large mansion or a country house.

Related article:

How to choose an air conditioner for an apartment: effective cooling and ventilation

Types and features of devices, additional functions. Power calculation based on room parameters. Care tips.

Lamellar

It is the most common type due to its good performance, ease of operation and low price. This type of recuperator consists of fixed metal plates with a high specific heat capacity and relatively low weight. The plates are collected in a kind of cassette, which slightly resembles a beehive. Atmospheric air passes through the apparatus box with cassettes and is then heated or cooled, depending on the winter or summer season. The condensate formed during operation is discharged through a specially available drainage outlet or channel.

Supply and exhaust unit of a plate recuperator

Along with the listed advantages, the system has a certain disadvantage: the formation of ice in the box, which is especially evident in the autumn-winter period.

Rotary

A recuperator of this type carries out the inflow and outflow of the air stream due to the blades. The thermal energy system has from one to two drive rotors, depending on the model. Externally, the installation looks like a cylindrical barrel with a drum. As air is pumped out of the room and the cylindrical box is heated, atmospheric mass is taken in.

Advantages of this device:

- improved efficiency;

- increased efficiency;

- absence of condensate, and, consequently, drainage gutters;

- absence of ice;

Rotary recuperator

- does not dry out the air, which does not require additional humidification;

- adjusting the amount of air supply and intake due to the speed of rotation of the blades.

However, there are also disadvantages:

- increased electricity consumption;

- rotating elements wear out faster than stationary ones;

- the need for additional exhaust to prevent possible mixing of incoming and outgoing air masses.

Note! Before purchasing a rotary heat exchanger, you need to take into account its increased power, which can lead to an increase in the cross-section of the electrical wiring of the room.

The recuperator is located in the supply and exhaust ventilation unit

Roof

This recuperator processes large masses of air. The expediency of its use can be explained by a large mansion, other residential or non-residential premises. The principle of operation is in many ways similar to the plate unit, however, the latter differs from the roof unit in its smaller size. The ease of installation of the device, low cost of maintenance and operation have made it indispensable in ventilation devices of shops, repair shops, and production areas. Installing such a recuperator on the roof generally eliminates the penetration of any sounds or noise into the room.

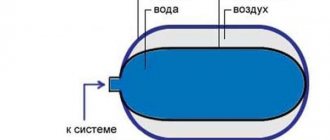

Glycol recuperator

The glycol (or recirculation) regenerative apparatus combines the qualities of plate and rotary thermal devices. Its main difference from the previous ones is the use of an intermediate coolant. The last is a water-glycol solution consisting of propylene glycol or ethylene diluted with distilled water. The mixture has a high heat capacity, which allows it to utilize a large amount of heat, and retains its working qualities at sub-zero temperatures. In severe low-temperature conditions, it is possible to replace the specified coolant with antifreeze. The equipment allows you to work simultaneously with several ventilation ducts, hoses or hoods.

Plastic recuperator

How to find out the efficiency of a recuperation system

Formula for calculating the efficiency of a recuperator

When making a recuperator yourself, it is not always possible to assemble a device with maximum efficiency. Moreover, the efficiency of the recuperator depends on the temperature and humidity of the air outside the room.

To calculate the efficiency of the recuperator, the formula is used: H = (tр - tу) / (tд - tу), where:

- tр – air temperature after recuperation;

- tу – air temperature before recovery;

- td – temperature of exhaust air leaving the room.

The total value should be multiplied by 100%. For example, let's calculate the efficiency of a device for specific conditions. The air temperature outside is 5 oC, after recuperation - 17 oC, indoors - 24 oC. Efficiency = (17 – 5) / (24 – 5) = 0.63 * 100% = 63%.

Recuperator for an apartment: calculation and review of manufacturers

An apartment heat and power device will be the best purchase, especially if the home is located in a big city or the center of a metropolis. Automotive and industrial gases, street noise, heat or cold will forever remain outside the room. The device will not only add a lot of clean air to the apartment, but will also allow you to save on heating, ventilation and cleaning the incoming atmospheric flow. This is achieved by simple heat exchange between the supply and exhaust flows passing through a heat-insulating box with a cleaning filter.

Diagram of air exchange through the recuperator

Recuperator calculation

You can calculate the required heat and power device yourself, without resorting to the services of specialized companies. Calculation of the efficiency and efficiency of the device is determined by knowledge of the energy costs for the supply or exhaust masses. The calculation formula is:

Q = 0.335 x L x (t1 – t2),

where L is the flow of air masses, t1 is the temperature of the inflow, t2 is the temperature of the outgoing masses, 0.335 is the regional coefficient.

The efficiency is calculated using the following formula:

E = Qxn,

where: Q – energy or electrical costs for heating or cooling the jet, n – device efficiency.

Scheme of supplying warm air through the recuperator

Helpful advice! Before buying a recuperator for a private house or city apartment, you need to familiarize yourself with their types, technical characteristics and operating principles. It may be necessary to carry out preparatory installation work and draw up a project.

Recuperator PRANA

This manufacturer of heat power and ventilation equipment has been on the market for more than 15 years. Its equipment has a long service life, high efficiency and reasonable prices.

PRANA heat exchanger installation kit

Operating characteristics of the device:

- type – lamellar;

- electricity consumption – 5-90 V/hour, depending on the model;

- noise level – 25-140 dB;

- unit length – 500 mm;

- service area – from 60 m²;

- incoming jet – 115-650 m³/h;

- outgoing jet – 105-610 m³/h;

- Efficiency – 79-80%, depending on the model.

The PRANA recuperator has relatively small dimensions

The entire model range is equipped with a remote control and operates at ambient temperatures from -15 to 45°C. The relatively low price of the air recuperator, significant retention of the set temperature during heating or heating, and small dimensions make this device one of the most popular, which is confirmed by numerous positive reviews. The Prana recuperator can be built into the wall of a room or installed outdoors. Installation of the device is quite easy and is carried out within 2-3 hours.

You can notice such a decentralized system only by the presence of a ventilation grill on the wall. Not the least positive quality is heat exchangers made of copper, which has an antimicrobial effect. The average price of an air recuperator for a home of this brand is about 25,000 rubles. The cost of devices with increased productivity ranges from 50 to 110 thousand rubles.

Air heating system through the recuperator heat exchanger

Recuperators MARLEY

The compact German heat exchanger is equipped with a ceramic heat exchange element, which allows the device to be operated even at a temperature of -30ºC. Washing it and cleaning the air filters is a simple operation that can be carried out by the average user. The duration of continuous operation is about 6 months, after this period the indicator light will light up. Operating the device near highways or in the central part of the city will require more frequent cleaning. This operation does not take much time and lasts 15-20 minutes.

You can buy an air recuperator for your home, the price of which is 24,000 rubles, in a specialized store. At a fairly moderate cost, the device has the following performance characteristics:

- three power phases – 15, 25 and 40 m³/h;

- electrical power consumption – from 3.5 to 8 W;

- The electric motor rotor is brushless;

- noise level – 22, 29 and 35 dB;

- heat recovery – 80-85%;

- service area – from 60 m²;

- external dimensions – 285-500 mm. The small dimensions of the unit allow it to be installed in the wall.

Recuperator MARLEY

A new line from the manufacturer Marley is the menv 180 recuperator, which differs from previous analogues in its low power consumption - only 3 W. Nice functional additions are:

- temperature, carbon dioxide and humidity controllers;

- improved aerodynamics;

- low noise level;

- waterproofing coating for work in damp residential or non-residential premises;

- high category of supply jet cleaning.

By installing such a recuperator, the price of which is around 27,500 rubles, you will forget about street soot and exhaust gases, dust, fog and emissions from industrial enterprises.

The MARLEY recuperator is very economical in the use of electricity

Which one to choose for an apartment or a house?

The consideration of the types of existing recuperators can be continued further by talking about the types of ribbed plate recuperators, etc. But the issue of independent production of such a design and its practical application in one’s own house or apartment is of interest. First of all, you need to think about the required type of heat exchange unit. If all the windows in the apartment are plastic and effective ventilation is required, it is better to give preference to the ready-made industrial compact assembly DRTVV (“warm window”).

The recuperator will provide good ventilation in the room

For private households, where the issue of free space is not so acute, one of the cross-flow or counterflow plate designs is quite suitable. They are the easiest to make yourself. Below we consider the simplest way to independently manufacture a plate-type heat exchanger itself. Circuit solutions for automatic control, a damper device for switching to the bypass channel, etc. can be found on the corresponding Internet resources or in specialized literature.

Peculiarities

Energy conservation in the 21st century is literally feverish. Of course, when organizing heating in private homes, special attention is paid to it. But any achievement inevitably has a downside. The negative effect of heat conservation is that the physiologically complete passage of air is disrupted. Since its circulation is blocked, dampness and all sorts of bad odors inevitably accumulate in the room. And this is not only a subjective disadvantage - both the health and safety of many things are at risk (which can be affected by mold and other fungi).

But, fortunately, there is no need to abandon the achievements of civilization and return to “good old windows with slits”!

A recuperator for a private home comes to the rescue. This device also perfectly saves from excessive concentration of carbon dioxide. A recovery system (also known as forced ventilation) is highly recommended for the bathroom. No matter how well designed the washroom is, dampness will invariably accumulate there.

And only constant removal of water will help solve the problem. It is also worth noting that the recuperator prevents all kinds of plant pollen, ordinary dust and other foreign particles from entering the house. And this is not just “allergy insurance”, but also a contribution to maintaining cleanliness in the house. But to enjoy comfort and coziness, you need to choose the equipment wisely. And to do this, first understand how it functions.

INCORRECT installation:

thanks our highly respected customer Yulia, who laid the foundation for this column! We invite you to share your experience, which will help other buyers of ventilation equipment avoid mistakes when installing recuperators.

Poor choice of installation location.

- installation in close proximity to the external unit of the air conditioner - noise and fumes enter the room.

- installation in the inner corner of the building - increased wind loads on high floors.

— this installation method significantly complicates service maintenance.

Installation in thin walls is not permitted.

The minimum wall thickness for installing a recuperator is 170 mm. Failure to comply with this requirement may result in the formation of cold bridges and, as a result, condensation on the inside of the outdoor mounting plate. This problem is eliminated by installing another hood on the side of the room. When using a hood, we recommend installing the motor as recommended.

WRONG:

RIGHT:

Bottom line

A recuperator for a private home is a device necessary to maintain an optimal microclimate and economical energy consumption. This device will reduce heat loss in winter and help maintain a comfortable room temperature in summer.

Factory models of household recuperators should be selected taking into account their ease of use and energy efficiency

It won’t be difficult for a home craftsman to make a simple plate exchanger with his own hands.

Save time: selected articles delivered to your inbox every week

Every day more and more diverse devices and devices enter everyday use. But not all people can cope and get used to such a rapid flow of innovation. It is definitely important to know, for example, how to choose a recuperator for a private home, and what subtleties there are.

Model rating

When choosing a heated supply and exhaust system, many people rightly pay attention to Mmotors eco-freshness 01 standard. The standard channel for air passage here is 100 mm . The manufacturer guarantees normal installation in walls with a thickness of 0.27 m or more. An optimal microclimate in the house is maintained, since the supply air remains fresh even after passing through the filter. Energy consumption is relatively low, and there is also a wired control panel.

It is worth noting:

the presence of a carbon filter that suppresses burning odors;

carbon dioxide concentration determinant;

suitability for individual premises, including medical institutions;

two-stage speed adjustment;

sensor for measuring humidity;

low-noise electric motor on very advanced radial bearings.

The total power of the electric drive is only 18 W. In an hour, air renewal is ensured over an area of up to 100 square meters. m. If desired, a control panel operating on infrared rays is added. But, of course, the market is far from limited to this model. And many experts believe that a high-end wall-mounted heat exchanger may be the best choice.

We are talking primarily about SHUFT/RHPr designed for rectangular ventilation ducts. They can be inserted into a channel with a cross-section of 0.2x0.4 m.

You just need to carefully select the linear size to ensure compatibility. For the manufacture of Shuft heat exchangers, high-quality galvanized steel with a thickness of at least 0.7 mm is used. The drainage pan is also made of galvanized steel and can be removed if necessary.

Important Features:

suitability for residential, administrative and main production facilities;

unsuitable for aspiration systems;

unsuitability for air containing toxic and caustic impurities, flour, glue fumes;

condensate drain pipe with a diameter of ½ inch;

aluminum heat exchange cassette.

The Korf/PR 40-20 heat exchanger is equipped with a fitting for the condensate drainage channel The manufacturer claims that heat transfer efficiency can reach 70%. The plate device, like previous models, is designed for channels measuring 0.2x0.4 m. Aluminum plates, the maximum thickness of which is no more than 0.2 mm, help increase efficiency. Accurate calculation allows you to achieve an optimal balance between performance and mechanical strength.

For 150 sq. m., even 200 sq. The Dantex DV-200HR E model is confidently designed. This recuperator perfectly maintains the microclimate in the house at temperatures from -20 to 40 degrees. The use of 146 mm channels is envisaged. The sound volume when working in various conditions is stated to be from 32 to 39 dB. The manufacturer promises that it will be possible to clearly regulate the level of humidity in the house.

Other parameters:

external atmospheric pressure in static conditions up to 60 Pa;

efficiency at enthalpy 49/51%;

own weight of the device is 18 kg;

power supply from the mains voltage 220-240 V;

time programming option;

possibility of connecting an additional electric heater (inside or outside the heat exchanger).

RCS 350 has a wider temperature range. This device will help out both at -28 and at +50 degrees. Its total productivity is even higher than that of the previous model - in an hour you can refresh the air on an area of 330 sq. m. This is already quite worthy even for a large private cottage.

Importantly, the stated sound volume limit is 26 dB (which is significantly less than a quiet conversation).

Electrolux STAR EPVS-1100 cannot boast of a wide temperature range, which ranges only from - 15 to + 40 degrees. But the productivity is record high - up to 1100 sq. m. in 1 hour. The “star” will drive air through a channel with a diameter of 250 mm, creating noise up to 41 dB. Which, however, still won’t drown out even a conversation in a normal voice. The highest static pressure will be 350 Pa, and the total mass of the unit is 66.5 kg.

Making a plate apparatus with your own hands

To make a structure with your own hands, you need to prepare the following materials:

- galvanized iron, sheet aluminum, textolite, copper, special paper or getinax in the amount of 4 sq. m.;

- a technical plug, 0.2 cm thick, or a strip is required as a gasket between the recuperator plates;

- silicone sealant;

- to make the case you will need a box made of metal or plywood;

- sensors that record pressure drop;

- corner for racks;

- mineral wool as an insulating material;

- hardware;

- jigsaw

Manufacturing process:

- Using a jigsaw, the prepared sheets are cut into square blanks with a side of 20-30 cm. You need to try to ensure that all the squares are the same. Their number should be 70 pieces.

- A strip is glued to the opposite sides of the squares, which is equal in length to the side. Only the last blank remains free.

- All plates are connected into a cassette. The free blank is the last one in the design.

- Using a corner, a frame is formed around the cassette.

- All seams are treated with silicone sealant.

- The housing is equipped with a special fastener for fixing the flanges. A hole is made in the lower part. A condensate drain pipe is located here.

- To make the cassette easily removed for repairs, guides are made from corners in the housing.

- Mineral wool is used as an insulating material. It insulates the inside of the walls. The layer thickness is 40 mm.

- A pressure sensor is installed where the warm air passes.

- The recuperator is installed in the ventilation system.

How to find out the efficiency of a recuperation system

Formula for calculating the efficiency of a recuperator

When making a recuperator yourself, it is not always possible to assemble a device with maximum efficiency. Moreover, the efficiency of the recuperator depends on the temperature and humidity of the air outside the room.

To calculate the efficiency of the recuperator, the formula is used: H = (tр - tу) / (tд - tу), where:

- tр – air temperature after recuperation;

- tу – air temperature before recovery;

- td – temperature of exhaust air leaving the room.

The total value should be multiplied by 100%. For example, let's calculate the efficiency of a device for specific conditions. The air temperature outside is 5 oC, after recuperation - 17 oC, indoors - 24 oC. Efficiency = (17 – 5) / (24 – 5) = 0.63 * 100% = 63%.