Although the collector principle of organizing heating and water supply systems has not yet become widespread in our country, more and more people are showing keen interest in it.

What is a water supply manifold?

Let's consider the design features of the system and installation rules.

What is a collector?

When installing a water supply system from scratch or replacing an old one, you need to think about the location of all consumers: toilet, washbasin, washing machine.

In a typical apartment, the number of plumbing fixtures varies from four to ten. Experienced plumbers recommend their customers to install a water collector.

A water collector is a kind of distributor, which is an important plumbing element of a cold and hot water supply and heating system. It is installed on the central riser and hidden in the plumbing closet. Access to the distribution comb should not be blocked by furniture or sewn tightly into the wall. However, professional repairmen will give the engineering unit an aesthetic appearance.

Criterias of choice

Distribution manifold for hot and cold water

Before choosing a device, it is important to calculate the total number of water consumers. These include toilets, taps, dishwashers, washing machines and other appliances. Their number must match the number of outputs. If you plan to connect additional plumbing fixtures in the future, you should choose a comb with a large number of pins. Unused exits are blocked with special plumbing plugs.

The type of device varies depending on the material and cross-section of pipe sections and fittings. To make it easier to install the collector, select a water comb with already installed taps.

If the number of points is greater than the number of pins, install several devices, connecting them into one.

It is worth familiarizing yourself with the technical characteristics of various combs to make a choice:

- pressure in the water supply line;

- device throughput;

- installation for hot or cold water supply;

- Possibility of connecting additional plumbing fixtures.

Situations arise when a flexible water hose is required for connection, which is determined by the location of the device and the area of the room. Hoses are easy to install, but they are less reliable in terms of leaks.

Collector design and principle of operation

The direct function of a collector in a water supply system is to distribute one water flow into several flows of equal pressure.

Combs with two, three and four outlets are available. If more branches are needed, the distributors are connected to each other. In this way, a water supply collector is assembled for the required number of outlets.

The collector is connected directly to the riser. On two opposite sides of the device there is a threaded connection (internal thread on one side, external thread on the other) for connecting to the main line and connecting the combs to each other.

A plug or an additional plumbing device, for example, a membrane water hammer absorber, is installed at the free end of the collector.

The diameter of the inlet hole is 20-40% larger than the outlet hole. For example, on a standard manifold for installing water supply in an apartment, the diameter of the inlet hole is 3/4 inch, the outlet hole is 1/2 inch.

1. Manifold with valves. 2. Manifold with ball valves.

Both ball valves and valves can be installed at the outlet openings, allowing not only to open and close the water flow, but also to regulate the power of the flow in this area.

Installation rules

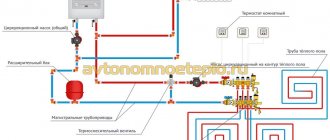

Collector water supply scheme

You can do the wiring of the water supply network with the installation of the collector yourself. It is assembled according to this scheme: the main pipe is connected to the comb directly, without any branches. Pipes supplying water to each plumbing fixture are connected to it. The devices are conveniently installed behind the toilet flush cistern. But other versions are also acceptable.

To choose a location for the comb, take into account:

- accessibility for repair and installation;

- humidity (moderate);

- the presence of a load-bearing wall on which the device is fixed;

- the ability to work in case of an accident at any time of the day thanks to additional lighting.

Sometimes the device is installed in a separate room or closet. To secure the collector, special clamps are used.

Combs are installed for both hot and cold water supply. For ease of use and to avoid confusion, manufacturers produce collectors in two shades: red and blue.

The installation should be carried out only after the wiring has been installed, meters, check valves, filters and other parts of the water line have been installed. At the connection point to the main riser, the system is equipped with ball valves that shut off the main flow. There is also a coarse filter and a meter that allows you to control water consumption.

It will be necessary to complete the installation of water lines for each point of consumption. To do this, it is worth leaving free outlets in the collector, plugging them with plumbing plugs. Only after this can the unit responsible for distribution be installed. Install it without additional sealing.

Carrying out installation in this order will reduce the load on the connections and help avoid their deformation. This is especially true for non-professionals.

When installing, you need to take into account the following points:

- The device responsible for distribution is certainly equipped with shut-off elements for adjusting and shutting off the flow.

- The cross-section of the connection point to the main line must be larger than the standard 15 mm. This diameter of the inlet pipe makes it possible to provide the consumer with the required amount of water while simultaneously using several plumbing fixtures.

- To neutralize water hammer, which can cause serious damage to the water supply, you need to install a special damper.

- Adapter fittings are installed on the threaded connection of the valves or the outlets from the manifold. Pipes supplying water to points of consumption are connected to them.

- When equipping a building with two or more floors with water supply, it may be necessary to install a circulation pump.

If a hidden water distribution system scheme is chosen, you will need to install thermal insulation material on the supply pipes. This method allows you to avoid cracking of the screed or the places where the grooves are sealed. Heat loss in the hot water supply pipeline will also be reduced.

Why do you need a collector?

A water supply system with a separator and a separate pipe supply to each consumer will cost more than a classic wiring. Is it worth overpaying for a collector for water and heating?

- The device is used to regulate water pressure in the apartment. In standard wiring, the pressure in an open tap often decreases if someone opens another tap or flushes the toilet. This threatens not only discomfort, but also burns due to too hot water, which suddenly begins to flow. The well-thought-out diameter of the manifold eliminates pressure problems. No matter how many taps are open in the apartment, the water pressure remains the same.

- There are taps at each outlet that allow you to regulate the flow of water along the branch. If the mixer is being repaired, it is not necessary to completely turn off the supply of cold and hot water from the risers. It is enough to switch only a certain branch.

- The absence of joints and tees built into the wall minimizes the risk of leaks. If a faucet or fitting fails, it can be easily replaced by disassembling the manifold system in the cabinet. The lining in the bathroom will not be damaged.

- If you need to add another consumer to the water supply system, you will not have to redo the entire wiring. Connection will be inexpensive and will not require much time.

When installing a water supply system using a collector, its cost increases. The number of pipes to the collector, be it metal, metal-plastic, polypropylene or cross-linked polypropylene, compared to tee wiring, increases by 8-10 times. However, modern pipes, especially metal-plastic and polypropylene, are not very expensive, so such a system is available to most residents.

Collector water supply system

If a collector is included in the system, then whatever device is installed in the circuit, a separate outlet will be laid to it. The total length of the pipes increases, but the following positive aspects appear:

- There will always be stable and equal pressure at all water intake points;

- When inserted into the manifold branch of the reducer in this branch, suitable for any plumbing fixture, the pressure can be adjusted, and it will be different from the general value;

- Each insert between the collector and the point of water collection is a single piece of pipe that can be discreetly fixed in the floor, in a wall or in a wall niche;

- Any plumbing fixture can be turned off without stopping the entire cold water supply or domestic hot water supply for repair or replacement.

Disadvantages of the collector circuit:

- A larger pipe length automatically increases the hydraulic resistance in the line;

- Due to the increase in the length of the line, the collector will not operate in natural water circulation mode, which may affect the choice or change of the heating system;

- If it is impossible to ensure that the pipe system is hidden in walls or niches, then a large accumulation of pipes can force you to change the interior or even the design of the premises.

Reservoir classification

Separating combs for water supply differ in both their design and materials. Before choosing a collector, study the entire range on the market.

Separators are made from different materials:

- Stainless steel is resistant to corrosion, fire and high temperature. The weight of the stainless steel collector is light, which makes it easy to attach it to the wall. This is an absolutely harmless material that gives the product an attractive appearance.

- Brass is an incredibly durable metal that is not afraid of corrosion and high temperatures. Brass combs are expensive, but they guarantee maximum strength.

- Dividers made of polypropylene are not afraid of rust and are lightweight.

Manifold made of polypropylene.

Some craftsmen can make a collector with their own hands from polypropylene pipes, which is in no way inferior in quality to factory products.

Collectors differ in the way the pipes are attached. Depending on the material of the pipes used, the comb model is selected.

1. A comb for installing taps and any plumbing fixtures at your discretion. 2. With compression fittings - designed for installation of pipes made of metal-plastic or cross-linked polyethylene. 3. For installation of polypropylene pipes. 4. Under the Eurocone. Suitable for installing pipes from almost any material through an adapter (Eurocone).

Separating combs differ in the number of bends. Minimum – 2 outputs, maximum – 6. Bends that are not currently in use can be closed with plugs. If it is necessary to make more than 6 outputs, several collectors are connected to each other.

Main manufacturers

Some people pay little attention to this aspect. Confident that the design is simple, they do not think about the fact that over time, water supply collectors fail. Each of them will need repair or replacement. The only question is how soon this will happen, and how often problems will arise. Now there are several “whales” on the plumbing market:

Despite the fact that the products of this company can be classified as a budget segment, the quality is very acceptable. The products are reliable, easy to use, unpretentious, and durable.

The price of this product is higher, but the consistent German quality allows you to use the products of this company for a long time. The brass from which the structural elements are made can withstand aggressive environments, does not rust or rot.

- Tiemme (Italy).

The products belong to the middle price segment, which has made them popular among professionals, developers, and contractors. Low cost combined with reliability are the main characteristics of collectors of this brand.

The main advantage is the use of innovative technologies in production. Each product is tested for functionality before leaving the assembly line. Material: brass.

The company produces a full range of components with which you can install a supply or heating system. The range is constantly expanding, and now there are more than 1000 items.

Products on the market

The catalogs of accessories for collector water supply systems provide a wide variety of not only combs, but also their components.

- Dividers without taps are much cheaper. They allow you to assemble a device that will best suit the object. This option is preferable, as it allows you to easily replace only the failed faucet. While the one-piece design will require complete replacement.

- Devices with shut-off valves greatly simplify the installation of a water supply collector. They simplify the assembly of the unit - there is no need to install taps.

- Accessories allow you to adapt the system according to your wishes: valves, pump groups, plugs, valves, brackets, couplings, ends, servos, fittings.

- Manifold cabinets are sold separately, which are mounted into the wall and provide an aesthetic appearance, as well as access to the engineering unit.

Adviсe

The collector is needed in apartments and private houses, public, medical and educational institutions, and retail facilities. In a word, it is useful wherever there is a water supply system and there are several water consumers. The collector performs an important function and is one of the most important elements in the water supply system. Therefore, the choice of this element must be approached consciously and competently. It is advisable to use a number of recommendations:

- For hot and cold water, two corresponding models are selected, which are marked differently in blue and red.

- Choosing a high-quality collector from a trusted manufacturer will ensure stable operation of the system.

- Proper installation and adherence to technology will minimize the likelihood of leakage and allow you to enjoy stable operation of the system.

- A manifold with locking mechanisms on each outlet is convenient, especially when one of the elements needs repair.

- The manifold material must be selected in accordance with the pipes used during the installation of the system.

- The number of outlets must correspond to the number of water consumers or groups created from several consumers.

- It is better to buy a manifold, fittings and all other additional elements (FUM, gaskets, adapters and pipes) from one company. In this case, all elements will fit together. Otherwise, there may be discrepancies in dimensions, and parts will have to be replaced.

- To make changes to the system, it is necessary to leave free outlets in the comb, which will be closed with plugs. In this case, there is no need to change the collector or add an additional comb to it.

- It is better to choose a manifold with valves. In this case, there is no need to perform separate installation for each of them. Choosing such a collector will reduce the time and volume of installation work, and minimize the likelihood of leaks at the connection points.

See the following video for assembling the water supply collector.

How to install?

Before installing a water distribution unit for cold and hot water supply, give an accurate answer to the following questions and consider the following points:

- How many water consumers are there on site? The number of collector outlets should be the same or slightly greater than the number of consumers. Excess branches are closed with plugs.

- What type of pipes will be used to install the water supply? It is necessary to purchase devices designed specifically for pipes made of the selected material.

- Estimate in advance the position of all engineering elements in the space of the plumbing cabinet (you can make markings on the wall). Please note that a water meter and a water filter are installed in front of the distribution comb. The convenient location of all devices facilitates maintenance and repair work.

- Get reliable fastening - a poorly secured distribution unit can lead to depressurization of connections and damage to the pipeline.

- Before installation, make sure that you have all the necessary consumables on hand: sealing material, gaskets, adapters.

Installation of the water distribution unit occurs in the following sequence:

- Install the inlet shut-off valves on the water supply riser.

- Install the meter, filter and check valve.

- Connect the manifold and securely fix it to the wall

- Install a water supply to each consumer. Secure the pipes with fasteners.

This operating algorithm will allow you to avoid errors. Regardless of whether the collector is needed for water supply or heating, its installation is the same. Such wiring requires more time, skill and money, but pays off quickly and provides comfort in further use. Collectors are appropriate not only in cottages and large houses, but also in apartments.

Design Features

If the heating system is combined, that is, in addition to radiators, it has a “warm floor” circuit, then the collector at the point of its connection should be equipped with a mixing unit. This scheme works as follows: a coolant cooler than in the main system circulates in the “warm floor” circuit in isolation, and as it cools, the mixing unit adds a hot medium from the collector to it.

If the system consists only of underfloor heating, there is no need to install a mixing unit. It is important to take into account one feature: unlike conventional systems with radiators, control valves with servo drives are installed not on the supply, but on the return manifold.

When purchasing a product, take into account the center distances between the supply and return manifolds. In many Chinese models, this parameter does not meet EU standards. For this reason, installing a mixing unit may not be possible.

Manifold for water heated floor

Collectors for “warm floors” are equipped with pipes with diameters of 16, 18 and 20 mm. In private homes, it is most rational to use pipes with a diameter of no more than 16 mm.

If the “warm floor” circuits connected to the same collector have different lengths, the distributor must be equipped with a balancing flow meter. This need is caused by the desire of the coolant to follow the path of least resistance.

By rotating the ring on the flow meter, you can change its throughput. In this case, using a special window with a scale, you can accurately determine the flow rate of the medium through the device. By balancing the flow of coolant through each circuit, we will achieve uniform distribution of heat over the entire area of the room.

Calculation of comb throughput

The calculation of the parameters of the distribution comb includes determining its length, the cross-sectional area of its cross-section and pipes, and the number of heat supply circuits. It is better if the calculations are done by engineers using computer programs; in a simplified version, they are only suitable at the preliminary design stage.

In order to maintain hydraulic balance, the diameters of the inlet and outlet manifold combs must match, and the total throughput capacity of the nozzles must be equal to the same parameter of the collector pipe (the rule of total sections):

n=n1+n2+n3+n4,

Where:

- n is the cross-sectional area of the collector4

- n1,n2,n3,n4 - cross-sectional areas of the pipes.

The choice of comb must correspond to the maximum thermal output of the heating system. What power the factory product is designed for is written in the technical data sheet.

For example, a distribution pipe diameter of 90 mm is used for a power not exceeding 50 kW, and if the power is twice as high, the diameter will have to be increased to 110 mm. This is the only way to eliminate the risk of unbalancing the heating system.

The cross-section of the collector pipe is equal to 3 diameters of the connected pipes, the distance between the supply and return combs is 6 diameters, the distance of the pipes from each other is 3 diameters

The 3-diameter rule is also useful (see picture above). As for calculating the performance of the circulation pump, the specific water consumption in the heating system is taken as the basis.

Each pump is calculated separately - per circuit and for the entire system. The figures obtained in the calculation are rounded up. A little extra power is better than too little.