Traditionally, in private houses it is customary to use a gable ridge roof.

Few people think about its design and what it can affect.

Recently, one can observe a noticeable increase in the popularity of pitched roofs. This design not only looks more attractive and original compared to other structures,

but also has a lot of advantages :

- Proper insulation of a pitched roof can significantly improve the thermal performance of a room. The house will be warmer, and the microclimate will cool more slowly than in the case of a gable roof.

- Reduced roof weight, allowing to reduce the load on supporting structures.

- Reduced windage . This is especially important in open areas or if the region experiences strong winds.

- Easy to maintain both inside and outside.

- Possibility of creating an additional spacious room in the attic .

- Ease of installation of rafter structures and design of a pitched roof.

- The economic issue follows from the previous point - such a roof will be significantly more profitable . This also applies to the materials used in pitched roofs.

- A variety of roofing and rafter materials that can be used in such a roof.

- Original and interesting appearance . The design allows you to create a whole space for architectural and design creativity.

Unfortunately, a pitched roof has some minor disadvantages. For example, increased snow loads and all the ensuing consequences. We also recommend reading the article about insulating gable roofs yourself.

The vapor barrier is broken

The vapor barrier film is fixed to the rafters with strips.

However, here we see that the slats are shifted relative to each other by almost 4 cm. We can only guess what the film is attached to. In addition, the panels sag, which means that after filing the ceiling there will be no gap left between the plasterboard and the vapor barrier, which will subsequently negatively affect the condition of the finish. In addition, the junction of the vapor barrier to the wall is not sealed. If the joint is not taped with self-adhesive tape in the near future, the insulation will fill with moisture and stop working.

Initial situation: ondulin roof, under the sheathing and counter-lattice (about 8 cm in total) on rafters 15 cm high. Izospan AM is attached. The roof has several small slopes and mainly a ceiling, above which there will be a cold attic. The house is made of timber, has stood for more than a year and initially the roof was not insulated. Now I am starting the process of insulating myself (for the pitched roof I will use Izover KL-37, for the attic Izover KT-40 Twin, vapor barrier - all this has already been purchased). A few questions: 1. Is it necessary to insulate the overhangs in the pitched and flat parts of the roof? (The overhangs on the outside are sheathed loosely (for ventilation) with clapboard, and between the last crown of the timber and Izospan AM there are now holes at the height of the rafters and the question is whether these holes need to be closed - for the slopes they will be closed automatically with insulation, you need Is it possible to do this for the flat part of the roof, i.e. leave ventilation of the attic space or not?). 2. It so happened that in the flat part of the roof there are quite long and wide areas between the joists (boards 5 cm by 15 cm), where it is supposed to lay 15 cm. Izover KT-40. I am not sure that the vapor barrier film will hold all this without severe sagging. What can be done in this situation (without adding additional logs) so that the insulation lies horizontally, without sagging? (In particular Is it possible to first sheathe the bottom logs with, for example, hardboard (it’s just already available), put insulation between the logs on the hardboard, and then when the finishing is done in about six months (no one lives in the house now, but there is heating) attach a vapor barrier film to the bottom of the hardboard and then - through the gap, the inner lining or vapor barrier should come into contact only with the insulation?) Sincerely, Vladimir

Conclusion

Insulating a shed is not that difficult, and the costs can be minimal, although it is better to spend a little more and get better results. The video in this article will help you understand some of the nuances even better, and if you have questions, write them in the comments under the review.

Did you like the article? Subscribe to our Yandex.Zen channel

September 6, 2016

Buildings, Thermal insulation

If you want to express gratitude, add a clarification or objection, or ask the author something, add a comment or say thank you!

We make a frame for fastening

So, once you have decided on the material for the ceiling sheathing, it’s time to move on to making the frame for the sheathing.

Option #1 – metal slats

Attaching any facing material to such a frame is as easy as shelling pears: fireproof, lightweight, designed specifically for fastening. Today, metal slats for cladding are made mainly from two types of metal - steel and aluminum, as well as a special alloy “to look like metal”.

The rack structure is easier to assemble than a children's toy, and in the end it turns out to be almost weightless:

But there are also significant drawbacks: corrosion from the slightest scratch and a complete lack of sound and heat insulation. And also all the wooden elements that are located above such a frame quickly deteriorate.

Option #2 – wooden slats

In its design, the wooden sheathing for the ceiling of a pitched roof is similar to metal. The only difference is that wood, as a living material, is capable of expanding and contracting more rapidly depending on humidity and air temperature. In addition, moisture causes wood to become deformed. Be sure to treat the bars that you use to construct wooden slats with fire protection.

In general, there are no contraindications to the use of wood when arranging the ceiling of such a roof. Is it better to give preference to metal structures if you are finishing a sauna or bathhouse.

You will need bars with a cross section from 20x40 to 80x40. In addition, the wood must also be treated with an antiseptic and antifungal agent.

Construction of the rafter system

The main difference between the supporting frame of such a roof is its simplicity. Rafters and other elements are made from dried high-quality wood, treated with an antiseptic. Load-bearing capacity calculations help determine the cross-sections of parts. This stage is best left to professional builders.

Rafters are often supported on two walls of different heights. It is best if the smaller wall is located on the side of the prevailing winds - this will help reduce the wind load.

If the height of the walls in the building is the same, then it is worth forming a slope using racks, and sewing up the front with a suitable material.

It is advisable to immediately lay out the side walls or do them in the same way as the front part using cladding and a load-bearing frame.

If the walls are brick, then before installing the roof you need to take care of laying the Mauerlat, because it is on it that the edges of the rafter leg will rest. To make it, you will need a solid beam with a section of 150x150 mm.

To erect a pitched roof on a log building, sliding fasteners for rafters are used, which help compensate for thrust loads. The rafters are attached to the mauerlat with notches, the elements are additionally connected with construction brackets.

Selecting material for insulation

The correct choice of thermal insulation material will ensure optimal roof insulation with minimal size and weight. The most used materials include: fiberglass (wool), mineral wool, basalt, polystyrene foam, polyurethane foam, expanded clay.

Mineral wool is one of the most common insulation materials. It has excellent thermal insulation properties. Available in the form of rolls and slabs with a thickness of 5 to 20 cm. The main disadvantage is hygroscopicity, which requires careful protection from water penetration. The most famous domestic manufacturers: Thermosteps, AKSI, Izorok, Mineral Wool, as well as the companies Ragos (Finland), Rockwool (Denmark), Izomat (Slovakia).

Glass wool has increased durability and strength. Available in the form of slabs and mats. The most famous materials are those produced by Flyder-Chudovo, URSA, and Izover.

Expanded clay is a bulk thermal insulation material with very low thermal conductivity, good sound insulation, and non-flammability. Absolutely safe for the environment. The substance has very high frost resistance and resistance to temperature changes.

Figure 3. Scheme of external thermal insulation of a flat roof.

Expanded polystyrene or polystyrene foam is widely popular due to its high thermal insulation characteristics and low specific gravity. Requires additional waterproofing.

Extruded polystyrene foam of the M35 and M50 brands from TIGI-Knauf does not have this drawback.

There are good reviews when insulating roofs using semi-rigid sheets such as Penoplex and Styrofoam.

Sprayed polyurethane foam and polyisocyanurate foam insulation is one of the most modern thermal insulators. They have high water resistance.

So far, the main drawback is the high price and the need for special equipment for application.

Types of suitable materials, their pros and cons

The requirements for the material of the insulating layer are quite stringent - the insulation must at the same time be lightweight, environmentally and fireproof, moisture resistant and retain its shape and properties over a long service life. The upper recommended limit of its thermal conductivity coefficient is 0.05 W/m2∙°C, the lower this figure is, the better.

Special attention is paid to the ease of installation, the need for special equipment and additional materials and the cost of insulation.

Cellular and fibrous types of insulation (expanded polystyrene, mineral wool and its analogues, ecowool, polyurethane foam) have suitable properties.

The use of bulk types is undesirable, both because of the need for a bottom and because the granules roll down even with a small slope. It is worth noting that none of the listed materials meets the requirements 100%; each type has its own pros and cons (see table):

| Insulation | Advantages | Flaws | Optimal use, possible limitations |

| Basalt wool | Compliance with PPB, vapor permeability, low (up to 0.42 W/m2C) coefficient. Thermal conductivity, simple installation, ability to remove accidental moisture, biological resistance | Expensive, need for steam and water protection | Residential buildings |

| Mineral wool based on glass fiber or slag melts | The same, but with greater hygroscopicity and a higher flammability group; good noise absorption | Mineral wool is cheaper than basalt slabs, but it tolerates getting wet much worse and is prone to knocking down | Houses, cottages, outbuildings |

| Styrofoam | Good thermal conductivity, relatively low price, minimal moisture absorption | Near-zero vapor permeability, flammability, formation of cracks when laying slabs | The same, but better suited for non-residential buildings |

| PPU | Excellent heat and sound insulation, bio- and moisture resistance, high speed of work | High cost, need for special equipment for installation | Insulating hard-to-reach structures from the inside or improving the performance of initially cold roofs |

| Ecowool | Improving the microclimate in the house, compliance with PPB | The same + weight gain during compaction, subsidence over time | Residential buildings and attics |

General requirements and design features of insulation of pitched roofs

In Western countries, where the climate is similar to Russia, houses consume much less energy, because the thickness of the insulation of building envelopes is greater than what is used in our country.

Insulation thickness in Russia Insulation thickness in Sweden

Thermal insulation of buildings is a proven way to save energy. In order to save money, using insulation of the minimum possible thickness leads to intense heat exchange between the room and the outdoor environment. This greatly increases heat loss, and therefore heating costs.

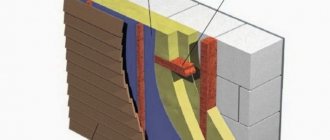

Roofing structures, in addition to roofing material, also include other elements and coatings, without which it is impossible to ensure the proper operation of the roofing system. Layers such as a vapor barrier, thermal insulation and ventilation are responsible for the practicality, durability and functionality of the structure.

The insulation rates for different roofing materials are approximately the same. The differences are mainly in the size of the ventilation gap, but the principle is the same. There must be a ventilation gap to remove excess condensate, especially for pitched roofs. It is impossible to lay the insulation close to the finishing coating, because the formation of condensation in such places is inevitable and it is impossible to create an absolutely sealed system into which air, and therefore moisture, does not penetrate. And if it penetrates there, it must be removed, otherwise the insulation becomes oversaturated with moisture, while its thermophysical characteristics deteriorate, and processes of rotting of the wooden elements of the rafter structure occur. Ventilation of the system is ensured using vents and spacer rails. The slats determine the height and number of air gaps above the insulation. They must be installed along the rafter legs so as not to interfere with air exchange and to prevent the formation of stagnant zones for drip water. In complex structures from an architectural point of view (the presence of attics, roof windows, parapets, etc.) it is much more difficult to ensure air circulation. Therefore, in such roofs it is necessary to provide additional ventilation holes along the ridge of the roof and overhang of the roof, along the entire perimeter.

When considering the various temporary labor costs for the construction of a particular type of roof, it is necessary to take into account not only immediate needs, but also the cost of time and money for its maintenance during operation. For example, if we compare metal tiles with natural tiles, the following picture appears. Due to the lighter weight of metal tiles, from an installation point of view it is much more convenient and simpler, but the low weight is also a disadvantage. Due to the lightness of the material and large area, a problem arises with its high-quality fastening. If piece tiles do not require additional fasteners for the most part, then metal tiles require about 10 - 12 screws per 1 m2 of coverage, so installation speed is naturally lost, despite the fact that laying large sheets is faster. In addition, the service life of roofing coverings made from natural materials is longer than those made from metal. This is explained by the fact that, unfortunately, no one has canceled corrosion and any mechanical damage can lead to defects, which can only be eliminated by replacing part of the coating. You will have to remove the entire sheet, even if the area of the defect is negligible. Soft roofing coverings have their advantages, one of them is that there are no restrictions on the shape and size of the roof itself.

Let's sum it up

One of the most important criteria for the effectiveness of thermal insulation is its proper installation. Most of the thermal energy losses of all kinds of buildings and structures occur through the roof, so it is necessary to address the issue of its thermal insulation first of all. Otherwise, if technological requirements are violated during work, the roofing itself may deteriorate during operation, which will lead to its dismantling and huge financial costs.

Work order

The sequence of laying layers depends on the method of insulation: external or internal.

Due to the low slope of a pitched roof, it is advisable to insulate it from the outside; in this case, to lay heat-insulating material, a lathing is attached to the underside of the rafters, on which a vapor barrier is laid in a continuous layer (inside the room).

After installing the insulation, it must be protected from moisture; roll waterproofing or membrane films are used.

If the work is carried out indoors, first the waterproofing material is nailed down, then the insulation is laid, and the last layer is a vapor barrier.

The installation of each layer has its own nuances and requirements.

Waterproofing

Protecting the insulation from external moisture is a must, otherwise it will lose its insulating properties. A gap of 3-5 cm is provided between the roof and waterproofing.

The moisture-proofing membrane sheet or film is laid with a slight deflection. For fastening, a construction stapler is used, the places of fastenings and joints are taped with tape.

With internal insulation, the rafters remain unprotected from moisture; it is recommended that these structures be treated with antiseptics. See about the protection of wooden structures.

Insulation

Before installation, fibrous materials such as glass or basalt wool are opened in advance so that they regain their shape. The space between the rafters is filled with insulation. Soft types of insulation cannot be knocked down or specially compacted, as this will worsen its thermal insulation properties.

Rigid slabs of extruded polystyrene foam are laid according to the same principle - in the gaps between the rafters, in at least two layers; to seal, all the cracks are filled with polyurethane foam.

Vapor barrier

The main purpose of this layer is to prevent the insulation from getting wet under the influence of rising moist air. This stage can be excluded only if you purchase insulation with a special protective layer (for example, lavsan).

When choosing the required installation side, the manufacturer's recommendations are taken into account; a mandatory overlap of 10-15 cm is provided. The material is attached to the rafters with staples, and the joints of the panels are treated with sealant tape.

1. 2. 3. 4.

An inevitable issue when building a house is the choice of roof type. Building a pitched roof with your own hands is the easiest option for arranging a roof. A design of this type will require a minimum amount of materials and effort. Let's understand how to do it.

Common mistakes

The main problems arise when saving on vapor and waterproofing materials or violating the rules for their installation.

Errors when choosing the side of the film, refusal to overlap and glue joints, excessive tension of the membranes.

The most dangerous thing is that the lack of ventilation gaps leads to the accumulation of condensation on the inside of the vapor barrier, inside the pie or under roofing coverings.

If there is no way to remove condensate, the insulation quickly loses its useful properties , wood structures rot and metal ones become covered with rust. As a result, seemingly insignificant errors when installing lightweight films lead to loss of roof tightness and heat loss.

Violations of insulation technology also include:

- Insufficient thickness of the insulating layer.

- Laying material with cracks and gaps.

- Excessive creasing of fiber insulation.

- Installation of materials on top of wood structures that have not undergone antiseptic treatment, or metal without corrosion protection.

- Carrying out work in unsuitable weather conditions (accidental moisture that gets inside the cake takes a very long time to be removed).

- Too tight abutment of the waterproofing layer to the insulation or lack of a ventilation gap between the water barrier and the roofing materials (which is especially dangerous when covering structures with flat or profiled sheets of metal).

It is almost impossible to eliminate the consequences without dismantling the structures. For minor problems or the need to take urgent action, you should :

- Disassemble and move the inner ceiling lining away from the vapor barrier by 2-3 cm.

- Tape the joints of the panel with tape.

- Insulate the ceiling of the house from the inside.

- Check the roof using a thermal imager and protect it from leaks in problem areas.

Thermal insulation technology for hipped roofs

The process of insulating a hipped or hipped roof is no different from the thermal insulation of a gable roof. These are all the same stingrays, only there are not two, but four. The volume of work being done is simply increasing.

The only negative point regarding slab heat insulators is the large amount of waste they generate. It's all about the shape of the stingrays. For a hip roof it is trapezoidal and triangular, for a hip roof it is only triangular. This means that in places where the structure narrows, the thermal insulation materials will have to be cut.

This does not apply to polyurethane foam and ecowool. Here the consumption does not change, and it corresponds to the area of the insulated pitched areas.

Roof overhangs classification and installation

A roof overhang is a structure that protrudes beyond the walls of a house. Another name for this structural element is a box. The main purpose of the roof overhang is to protect the walls from precipitation.

To ensure the greatest protection efficiency, the bases of the roof rafters are extended beyond the walls. The length of this output is 50–60 centimeters. This is the minimum roof overhang. However, this figure can be increased. The rafter system does not always provide for projections beyond the walls of the house. With this option, forced extension of the rafters is used. For this, “fillies” are used (more details: “Filly: do-it-yourself roofing.”)

Note that it is necessary to protect the front part of the walls of the building. This is especially true if the house is wooden. In such cases, you need to decide in advance how to sew up the pediment of a wooden house. The standard roof overhang is 500 millimeters in length. The roofing edge contains a cornice-type board.

The lower part of the roof overhangs should be sheathed. The most common lining material is tongue and groove board. It is worth saying that there is a difference between the design of a pitched overhang and the construction of a frontal overhang.

Is it necessary to insulate the roof?

Mandatory, except for rare exceptions. But first, let's look at the issue related to temperature fluctuations. The latter have a very noticeable effect on any type of roof. If you take the lower section of the attic, which is actually located under the roof structure, the temperature there is approximately the same as in the room itself.

From the outside, everything is completely different. Here the temperature varies depending on weather conditions. Insulation just solves the problem of temperature differences. What does this mean? Warm air masses do not seep out; external ones, on the contrary, do not get inside.

The question of whether it is necessary to insulate the roof, as such, should not arise. If you want to use the attic space and live in a comfortable home, insulation is a must. Moreover, take into account both the climatic conditions of the region and the characteristics of insulation materials.

Heating

There are times when thermal insulation alone is not enough to maintain a comfortable temperature, especially when there is bitter frost outside. As a rule, in such situations, suitable materials are purchased for the purpose of additional insulation of the building. They can be installed on walls, floors and ceilings

In addition, it is very important to remember to insulate the window structures and the entrance to the chicken coop. Otherwise, cold air will penetrate into the building through the remaining cracks.

For windows, it is best to use special masking tape. As for door cracks, you can get by using polyurethane foam, as well as insulating the door leaf itself.

In addition, for the purpose of additional heating, fairly powerful incandescent lamps are often installed in chicken coops. It is permissible to install special heat fans. Such products can be programmable, and they are what experts recommend for purchase because they are very easy to use. They may have time and temperature adjustments.

A good solution for heating a chicken coop is infrared lamps. Such products do not affect the surrounding air, but rather objects that fall within the range of their rays. Infrared lamps must be installed correctly, for example, above perches, as well as above the floor. But you need to take into account that if you turn them on and off frequently, these bulbs burn out quite quickly and require replacement.

Ventilation gap device

The first thing that had to be done during installation was to ensure a constant ventilated gap between the roofing material and the membrane, which is 20 mm. The easiest way to maintain the accuracy of the gap is to use 20 mm wide slats, which are nailed to the sides of the rafters close to the sheathing.

This is what the roof slope looked like from the inside before the insulation work began: Internal view of the roof slope before the insulation work began

I sawed the slats from scraps of boards left over from the construction site. The length turned out to be approximately 30-60 cm. I placed 2-3 2x30 nails in each rail so that their sharp ends did not protrude from the reverse side. And he quickly nailed the slats to the sides of the rafters.

Rail that determines the size of the ventilated gap: Rail that determines the size of the ventilated gap

Where the rafters were attached to the studs, nailing battens was not possible. So I:

- unfastened each post from the rafters,

- shortened by about 45 mm from the sheathing parallel to the rafters,

- I fixed the post in its previous position with a clamp and attached it back to the rafter with a screw.

On the right you can see a stand installed by the builders and preventing the membrane from being attached. On the left is the stand after shortening:

On the right you can see a stand installed by the builders and preventing the membrane from being attached. On the left - the stand after shortening

Trimming the stand with a jigsaw:

Trimming the stand with a jigsaw

Fixing the stand position:

Fixing the stand position

Then he proceeded to install the windproof, vapor-permeable membrane type A:

- First, I cut out a piece of windproof membrane 50 mm wider than the distance between the joists and 200 mm high.

- Then I attached the membrane with the same slats to the sides of the joists, and at the bottom to the wall beam. I haven’t secured the membrane at the top yet - it just lay adjacent to the longitudinal beam connecting the logs. So I nailed the slats to all the rafters on this side of the roof.

- Then he began to secure the membrane between the rafters. Since the distance between them is different, I measured the width of the canvas each time and cut it 50-60 mm more. The membrane was pressed with the same slats, but the driving step was reduced in order to press the membrane tightly to the rafters. I already hammered 3-4 nails into the slats for strength. The edge of the stretched fabric protrudes from the edge of the rail by the same amount.

- The next stage is to increase the width of the rafters. In my case, this operation turned out to be forced, because the original width of the rafters was not enough to lay the required number of heat-insulating boards. I bought 140x20 mm boards, 3 m long, from the building materials market. Using a circular saw, I cut them in half lengthwise and got boards about 70 mm wide. These boards were attached with screws at the bottom to the rack, and at the top to the ceiling board. Then these boards were additionally secured with wooden overlays: at the bottom of the rafters and in two places between the rack and the ceiling board. So I increased the width of all the rafters.

Generalization

Building a barn for keeping poultry is the most important point. The dimensions of the building will depend on the number and breed of birds. For example, to keep broilers even in the countryside, it is necessary to allocate a fairly large area for them, because the birds have a large build and already weigh about 3 kg at 2-3 months. For such representatives, the recommended stocking density is no more than one bird per 1 square meter. m. In a summer cottage, you can use an old barn that was left over from other animals, properly converting it to meet the needs of poultry. To set up a winter poultry house, you need to take care of insulation. The shed needs to be insulated on all sides:

- the walls are covered with metal sheets with foam panels laid in them;

- the floor can be insulated using corrugated sheeting;

- the ceiling is insulated with felt.

The inside of poultry houses should be equipped with a simple ventilation system, access to the walking area, perches where the birds have sweet dreams, as well as feeders and drinkers. For feeding, it is better to prefer automatic designs

They allow you to save maximum time and ensure constant access to feed, which is very important when keeping broilers that must eat to their heart's content

After birth, chickens are kept in separate warm rooms or a brooder is built - a special warm container with an infrared lamp for heating and round-the-clock illumination; details can be found in many photos on the Internet. Some novice poultry farmers try to replace the structure with a cardboard box, but it is better when the chickens and chicks are in the barn. This method is only suitable as a temporary brooder; if you plan to raise poultry in the future, you will have to build a real house for chickens.

DIY pitched roof step by step

In principle, a pitched roof can be covered with any roofing material, but you should always pay attention to a few points:

- on the weight of the roofing material - not only the design of the foundation (its width and depth), but also the pitch of the rafters depends on the weight with which your roof will press on the walls;

- on the recommended roof slope (for the roofing material you have chosen) - it also depends on the type of roofing material and its ability to withstand a snow load (in other words, to hold a certain amount of snow on itself without deforming);

- the appearance of the sheathing (solid or made up of individual elements).

Tip: If you cannot remember which sheathing should be laid under the roofing material you have chosen, look carefully at its underside:

- if it is smooth (like bitumen shingles), then a continuous sheathing is required under this material (in the form of a continuous surface made of boards, OSB or other similar materials);

- if there are protrusions and depressions on it (like tiles or slate), then the sheathing will have a certain pitch (that is, you will lay boards or bars with a certain distance between them).

Slope

Without going into too much detail, only three characteristics of any roof depend on the slope:

- its ability to withstand the weight of snow (until the snowdrift accumulated on it slides down under the influence of gravity);

- waterproofing - all rainwater, or water formed when snow melts, must “roll off” from the surface of the roofing material, without remaining in its irregularities, seams and fastening points;

- withstandable wind load (the stronger the roof slope, the greater the pressure the wind will exert on it).

Most builders recommend the following roof inclination angles, at which a do-it-yourself pitched roof will be strong, reliable and durable:

- ordinary slate – no less than 1:10;

- soft (flexible) tiles - at least 1:10;

- ceramic tiles - no less than 1:5;

- metal tiles - at least 1:3;

- cement tiles - at least 1:5;

- ondulin – no less than 1:3.

Scheme for calculating the roof slope

Tip: To avoid confusion in determining the correct dimensions (width and height of a pitched roof) for the selected slope, use the following calculation method:

- Measure the width of your building.

- Divide the resulting number (in centimeters) by the second digit of the roof slope (for example, if the recommended slope for your roofing material is 1:5, then you need to divide your number by 5).

- The result of dividing the numbers will be the height of the second edge of the pitched roof (in centimeters).

Rafters

However, no matter how attractive a pitched roof is for those who like to do everything themselves, there is a certain limitation for such a roof: the length of the rafter leg should not exceed 6 meters. Where did this figure come from? The fact is that when selling wood, it is customary to cut it into separate boards (or beams) 6 or 4 meters long. Therefore, if the width of your building does not allow the use of boards less than 6 meters long for rafters, then you will have to do one of the following methods:

- instead of a single-pitched roof, install a gable roof on your building;

- replace a simple rafter leg with a more complex structure - a triangular truss;

- strengthen the long simple rafter leg in its central part by placing a column of timber or brick underneath it.

Advice: For any type of roof (including a pitched roof), when choosing the pitch of the rafters, it is better to follow the recommendations of the manufacturer of the roofing material.

Where it all started

Two years ago we inherited land and decided to build a house there for year-round use. We chose a project from a company and ordered it to build a house from laminated veneer lumber.

This is our house

The house was built, but when they began to live in it, it turned out that it was too small even for a small family. Therefore, they decided to insulate the second floor and equip it with a bedroom. We studied the instructions of different companies for roof insulation, received comprehensive advice from the Rockwool Design Center and began to think through the insulation project and purchase the material.

To keep the second floor warm, it was necessary to insulate two gables with windows and both roof slopes without removing the roof. I’m going to talk in detail about how to insulate the slopes.

The roof in our house consists of rafters made of edged boards with a section of 100x20 mm, unevenly installed with a pitch of 550-620 mm. Along the rafters there is 80x20 mm lathing with a pitch of 350 mm. Waterproofing is laid on top of the rafters, and metal tiles are laid over it.

A complete roof slope insulation system consists of the following layers (from top to bottom):

- roofing material,

- waterproofing,

- sheathing,

- ventilated gap for removing water vapor from the insulation,

- windproof membrane,

- insulation,

- vapor barrier membrane,

- finishing layer for the interior.

We clarified with Rockwool specialists that the thickness of the roof thermal insulation layer for the Moscow region, where we live, should be at least 200 mm. They also suggested a scheme for laying insulation with overlapping seams and installing the last layer covering the rafters.

We bought Light Butts Scandic insulation, windproof and vapor barrier membranes, galvanized nails of different sizes (2x15, 2x30). And the work began.

Video description

About diffuse vapor and waterproofing in the following video:

- A two-layer anti-condensation film is spread with the smooth side facing the insulation, and the rough side facing the source of warm, humid air, the living quarters.

- The foil film is laid with a metal layer to the living spaces - this way it can return some of the heat inside, increasing the thermal efficiency of the building.

- Diffusion double-sided membranes provide the roofing pie with the ability to “breathe”. If both surfaces of the membrane are identical, it is laid on either side. If you have chosen a one-sided membrane, it is better to check the data on the front and back surfaces with the manufacturer (in most cases, the membrane is adjacent to the thermal insulation with a rough surface).

Laying a vapor barrier in a roof with steep slopes Source bostonglobe.com

Algorithm for roof insulation - how to lay thermal insulation

Installation of a roof with insulation comes down to the following sequence of actions:

First, the installation step of the rafter legs is measured. The heat-insulating material slabs are cut in accordance with the obtained dimensions, but 1 cm is added to them - this will allow the insulation to stay in place on its own. You can simplify this stage of work when installing a new roof by calculating it so that the distance between the rafters corresponds to the width of the insulation boards. A waterproofing layer must be installed in the space between the rafters and the finishing coating. The membrane must be attached to the rafters so that it envelops them. For fixation, you can use a construction stapler, which attaches the waterproofing to the rafters and sheathing. Waterproofing material must be applied to the eaves so that the collected moisture escapes beyond the roof. The described method of fastening does not allow for proper ventilation, so only a special waterproofing membrane should be used as a material. If waterproofing is already installed under the upper part of the roof, then nails are driven into the rafters every 10 cm so that the distance between them and the membrane is at least 3-5 cm. The driven nails allow you to stretch a cord along the line of which the air gap will pass in the space between waterproofing and thermal insulation material. If the insulation itself is attached using a cord, then the nails will also need to be hammered along the outside of the rafters. When using insulation materials produced in the form of slabs, installation is reduced to inserting them into the space between the rafters (naturally, they will have to be compressed a little so that they fit into the gap). Before properly insulating the roof, more rigid materials must be carefully adjusted to fit the gaps in the rafter system. For maximum efficiency, it is worth installing two-layer insulation. When installing narrow fragments that require joining along one of the planes, you need to make sure that the joints of the first and second layers of thermal insulation do not coincide with each other. The thermal insulation layer should not extend beyond the rafters, and if this happens, then additional timber will have to be placed on the rafters. To attach the insulation, a cord stretched between nails or a lath made of slats can be used. These slats need to be nailed to the rafters at a distance of 30-40 cm from each other. In this case, the vapor barrier layer must be attached before the sheathing is installed - due to the thickness of the slats, an air gap is provided. When installing a vapor barrier, you need to make sure that the material is installed hermetically. To do this, the joints need to be covered with two layers of adhesive tape.

Particular attention should be paid to the points where the material connects to the wall and chimney. When all structural elements are installed, you can proceed to the final stage - installation of the sheathing.

Conclusion

Roof insulation is a very important part of the structure, which allows you to increase the thermal efficiency of the roof. Knowing how to properly install insulation on a roof and high-quality performance of all work will allow you to create a reliable and high-quality structure that will perform its functions throughout the entire period of operation.

Roof insulation has been of concern to people since time immemorial. Even in the most primitive buildings, various tricks were used to prevent heat from the fire from leaking out. With the development of construction, technologies changed. Not so long ago, the upper sections of buildings were insulated with clay concrete or furnace slag, including ordinary shavings and cement. Today, such materials are gradually becoming a thing of the past. Modern products and insulation methods have replaced them.

Video description

About the membrane installation technology in the following video:

- The main condition for installation is that the film is fixed without tension , with a sag of approximately 2 cm. The reserve is created due to the ability of the wooden frame to change its dimensions with the change of seasons (with changes in humidity); otherwise there is a risk of the film tearing.

- For horizontal installation, installation is carried out from above (from the ridge). The strips are laid with a reverse overlap (the lower strip overlaps the upper), for additional protection of the insulation; they are connected with tape and secured to the structure with galvanized nails or a stapler.

- If the thermal insulation layer is not dense, the rolled sheet is fixed using slats , which must be antiseptic.

- Particular attention is paid to junction points (attics, windows, hatches, pipes, ventilation ducts); they are isolated especially carefully.

Fixing the film Source pro-uteplenie.ru

Technology

Contrary to popular belief, it is better not to do insulation during the construction process. After completion of the work, the house undergoes shrinkage, which can cause minor deformation of all structural elements. As a result, gaps appear on the surface of the heat-insulating cake, which negatively affects the quality of the work performed. Professional builders recommend waiting about a year and only then doing insulation. The process can be divided into several stages that require detailed consideration.

Preparation

Independent insulation of the roof of a wooden house begins with an inspection of all structural elements. This is especially true for old buildings where the roof leaked.

During the inspection, it is necessary to pay attention to damp areas where traces of rot are visible or fungal spores are observed. Such elements are cleaned and treated with special compounds, and if necessary, a complete replacement is carried out.

This rule cannot be ignored. Despite its many undeniable advantages, wood is very dependent on a humid environment, so if there are traces of rot on the surfaces, it makes no sense to engage in thermal insulation until such phenomena are completely eliminated. Dampness will gradually destroy the rafters and ceilings, which will at least lead to damage to the thermal insulation layer.

About the benefits of hydro- and vapor barrier

It is no secret that high-quality thermal insulation is a multi-layer cake, where each element performs a strictly defined function. In the standard version it looks like this:

- waterproofing;

- sheathing (if necessary);

- insulation;

- vapor barrier;

- finishing.

The first layer is waterproofing. Here you can use ordinary polyethylene film, which will do its job perfectly - protect the insulation from exposure to dampness.

Oversaturation leads to separation of the compressed granules with subsequent destruction of the insulation board. Attach the waterproofing directly to the base, fixing it to the rafters with the staples of a construction stapler. If your budget allows, you can purchase a superdiffusion membrane with a reflective layer. This is an expensive material, but it solves 3 problems at once: it protects from moisture, reflects thermal energy, creates additional insulation and sound insulation.

Then the thermal insulation is laid. The recommended thickness of the insulating layer varies between 10–25 mm depending on the climatic characteristics of the region. Ideally, a dense layer of insulation fills the free space between the rafters. A small ventilation gap is usually left at the top of the roof, which will ensure air circulation and prevent condensation from forming inside the insulating pie. Let us add that if mineral wool is used as roof insulation, it should not be used to cover the electrical wiring.

The final layer is a vapor barrier. This is a film that is designed to trap warm, moisture-laden air rising from residential premises. Here you can also use polyethylene, the joints of which are glued with construction tape. If the work is done correctly, the insulation is in a kind of waterproof cocoon, while the ventilation holes left do not interfere with natural air circulation. A finishing coating is laid on top of the vapor barrier.