When listing the parameters of insulation, the thermal conductivity of the material is always put in first place. It depends on how much air the substance contains. After all, it is the air that serves as an excellent natural heat insulator. Note that the ability to conduct heat decreases with increasing rarefaction of the medium. So a vacuum layer retains heat best.

The operation of thermoses is based on this principle. But during construction it is problematic to create a vacuum, so they limit themselves to ordinary air. For example, the low thermal conductivity of expanded polystyrene, especially extruded polystyrene, is due to the fact that there is more than enough air in it.

In this article: [Hide]

- What affects the ability of polystyrene foam to conduct heat?

- Expanded polystyrene and other insulation materials: comparison

Lifetime

Most manufacturers indicate a service life of 20-30 years. This is the warranty time during which the useful properties of the material are within acceptable limits. Recent studies by European scientists have shown surprising and encouraging results. When demolishing houses built 40-50 years ago using polyurethane foam, scientists found that its properties remained virtually unchanged. The structure and texture remained the same as originally. Further laboratory studies only confirmed the durability of this material.

Environmental friendliness

An important parameter that modern builders are paying more and more attention to. During the production process, polyurethane foam goes from liquid to solid in 30 seconds

After this, harmful fumes from its surface stop. If it is heated to 450 Cº, carbon dioxide and carbon monoxide will begin to be released. However, the same thing can be observed when wood is heated. Polyurethane foam does not emit compounds harmful to the human body

Thermal conductivity characteristics of polystyrene foam

In order to consider such a characteristic as the thermal conductivity of polystyrene foam, let us first understand what the thermal conductivity of materials is, in principle. Thermal conductivity is a quantitative characteristic of a body's ability to conduct heat.

This is the amount of thermal energy (Watt) that any material is capable of conducting through itself (meter), at a certain temperature (C) for a certain time. It is denoted by λ and expressed as W/m•C.

Let us determine the optimal dimensions of this insulation based on its thermal conductivity characteristics. There are a large variety of insulation materials on the building materials market. Polystyrene foam, as we already know, has very low thermal conductivity, but this value depends on the brand of material.

The thermal conductivity of polystyrene foam is most noticeable when comparing values with other thermal insulation materials. For example, a sheet of foam plastic 30-40 mm is similar to the volume of mineral wool several times larger, and a sheet thickness of 150 mm replaces 185 mm of polystyrene foam. Of course, there are materials that have a lower coefficient. Penoplex is one of these. 30 mm of penoplex can replace 40 mm of polystyrene foam, under similar conditions.

What does thermal conductivity depend on?

The ability of polystyrene foam boards to retain heat depends mainly on two factors: density and thickness. The first indicator is determined by the number and size of air chambers that make up the structure of the material. The denser the slab, the greater the thermal conductivity coefficient it will have.

Density dependence

In the table below you can see exactly how the thermal conductivity of expanded polystyrene depends on its density.

| Density (kg/m3) | Thermal conductivity (W/mK) |

| 10 | 0.044 |

| 15 | 0.038 |

| 20 | 0.035 |

| 25 | 0.034 |

| 30 | 0.033 |

| 35 | 0.032 |

The background information presented above, however, most likely, can only be useful to home owners who have used polystyrene foam to insulate walls, floors or ceilings for quite some time. The fact is that when producing modern grades of this material, manufacturers use special graphite additives, as a result of which the dependence of thermal conductivity on the density of the plates is reduced to almost nothing. You can verify this by looking at the indicators in the table:

| Brand | Thermal conductivity (W/mK) |

| EPS 50 | 0.031-0.032 |

| EPS 70 | 0.033-0.032 |

| EPS 80 | 0.031 |

| EPS 100 | 0.03-0.033 |

| EPS 120 | 0.031 |

| EPS 150 | 0.03-0.031 |

| EPS 200 | 0.031 |

Dependence on thickness

Of course, the thicker the material, the better it retains heat. For modern expanded polystyrene, the thickness can range from 10-200 mm. According to this indicator, it is usually classified into three large groups:

- Plates up to 30 mm. This thin material is usually used to insulate partitions and interior walls of buildings. Its thermal conductivity coefficient does not exceed 0.035 W/mK.

- Material up to 100 mm thick. Expanded polystyrene of this group can be used for cladding both external and internal walls. Such stoves retain heat very well and are successfully used even in regions of the country with a harsh climate. For example, a material 50 mm thick has a thermal conductivity of 0.031-0.032 W/Mk.

- Expanded polystyrene with a thickness of more than 100 mm. Such dimensional slabs are most often used for the manufacture of formwork when pouring foundations in the Far North. Their thermal conductivity does not exceed 0.031 W/mK.

Calculation of the required material thickness

It is quite difficult to accurately calculate the thickness of polystyrene foam needed to insulate a house. The fact is that when performing this operation, a lot of different factors should be taken into account. For example, such as the thermal conductivity of the material chosen for the construction of insulated structures and its variety, the climate of the area, the type of cladding, etc. However, it is still possible to approximately calculate the required thickness of the slabs. To do this you will need the following reference data:

- an indicator of the required thermal resistance of enclosing structures for a given specific region;

- thermal conductivity coefficient of the selected brand of insulation.

Actually, the calculation itself is carried out according to the formula R=p/k, where p is the thickness of the foam, R is the thermal resistance index, k is the thermal conductivity coefficient. For example, for the Urals the R indicator is 3.3 m2•°C/W. Let’s say that a material of the EPS 70 brand with a thermal conductivity coefficient of 0.033 W/mK is selected for wall insulation. In this case, the calculation will look like this:

That is, the thickness of the insulation for external enclosing structures in the Urals should be at least 100 mm. Typically, home owners in cold regions sheathe walls, ceilings and floors with two layers of 50 mm polystyrene foam. In this case, the slabs of the upper layer are positioned so that they overlap the seams of the lower one. This way you can get the most effective insulation.

What is thermal conductivity

You can find out how well a material can retain heat by looking at its thermal conductivity coefficient. This indicator is determined very simply. Take a piece of material with an area of 1 m2 and a thickness of a meter. One of its sides is heated, and the opposite side is left cold. In this case, the temperature difference should be tenfold. Next, they look at how much heat reaches the cold side in one hour. Thermal conductivity is measured in watts, divided into the product of a meter and a degree (W/mK). When purchasing expanded polystyrene for cladding a house, loggia or balcony, you should definitely look at this indicator.

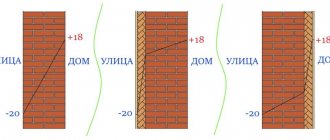

How to calculate wall thickness

In order for the house to be warm in winter and cool in summer, it is necessary that the enclosing structures (walls, floor, ceiling/roof) must have a certain thermal resistance. This value is different for each region. It depends on the average temperatures and humidity in a particular area.

Thermal resistance of enclosing structures for regions of Russia

In order for heating bills not to be too high, it is necessary to select building materials and their thickness so that their total thermal resistance is not less than that indicated in the table.

Calculation of wall thickness, insulation thickness, finishing layers

Modern construction is characterized by a situation where the wall has several layers. In addition to the supporting structure, there is insulation and finishing materials. Each layer has its own thickness. How to determine the thickness of insulation? The calculation is simple. Based on the formula:

Formula for calculating thermal resistance

R—thermal resistance;

p—layer thickness in meters;

k is the thermal conductivity coefficient.

First you need to decide on the materials that you will use during construction. Moreover, you need to know exactly what type of wall material, insulation, finishing, etc. will be. After all, each of them makes its contribution to thermal insulation, and the thermal conductivity of building materials is taken into account in the calculation.

First, the thermal resistance of the structural material (from which the wall, ceiling, etc. will be built) is calculated, then the thickness of the selected insulation is selected based on the “residual” principle. You can also take into account the thermal insulation characteristics of finishing materials, but usually they are a plus to the main ones. This is how a certain reserve is laid down “just in case.” This reserve allows you to save on heating, which subsequently has a positive effect on the budget.

We advise you to study - How to determine which washing machine is best for you

An example of calculating the thickness of insulation

Let's look at it with an example. We are going to build a brick wall - one and a half bricks long, and we will insulate it with mineral wool. According to the table, the thermal resistance of walls for the region should be at least 3.5. The calculation for this situation is given below.

- First, let's calculate the thermal resistance of a brick wall. One and a half bricks is 38 cm or 0.38 meters, the thermal conductivity coefficient of brickwork is 0.56. We calculate using the above formula: 0.38/0.56 = 0.68. A wall of 1.5 bricks has this thermal resistance.

- We subtract this value from the total thermal resistance for the region: 3.5-0.68 = 2.82. This value must be “added” with thermal insulation and finishing materials.

- We calculate the thickness of mineral wool. Its thermal conductivity coefficient is 0.045. The thickness of the layer will be: 2.82 * 0.045 = 0.1269 m or 12.7 cm. That is, to ensure the required level of insulation, the thickness of the mineral wool layer must be at least 13 cm.

If the budget is limited, you can take 10 cm of mineral wool, and the missing amount will be covered with finishing materials. They will be inside and outside. But, if you want your heating bills to be minimal, it is better to use the finishing as a “plus” to the calculated value. This is your reserve during the lowest temperatures, since thermal resistance standards for enclosing structures are calculated based on the average temperature over several years, and winters can be abnormally cold

Therefore, the thermal conductivity of building materials used for finishing is simply not taken into account

Insulation brand "Foundation" - parameters and properties

The “Foundation” brand is a renamed Penoplex 35 insulation without fire retardant additives, which can now be used to create thermal insulation for the bases and plinths of buildings, blind areas and basements. The strength, waterproofness and thermal conductivity of the “Foundation” penoplex series are its main advantages. The characteristics of the “Foundation” are given in the table below:

| Properties | Meaning |

| Specific gravity | 29.0-33.0 kg/m³ |

| Compressive strength | 0.27 (2.7; 27) MPa (kgf/cm2) |

| Bend limit | 0.4 MPa |

| Moisture absorption in 1 day | 0,4 % |

| Moisture absorption in 28 days | 0,5 % |

| Fire resistance | Group G4 |

| Sound insulation threshold | 39 dB |

| Thermal conductivity | 0.03-031 W/(m K) |

| Dimensions (width, length, height) | 600 mm x 1200 mm x 20, 30, 40, 50, 60, 80, 100 mm |

| Temperature range | -50/+750C |

Penoplex brand "Roof"

What you need to know about the thermal conductivity of polystyrene foam

The thermal conductivity of polystyrene foam is quite low, because the air that is at the base of the material also has such characteristics. Therefore, the described insulation parameter varies from 0.037 to 0.043 W/mK; as for air, this characteristic is 0.027 W/mK.

Expanded polystyrene is manufactured in accordance with GOST 15588-86 and is characterized by excellent energy saving, increased service life, and can reduce heating costs and protect against freezing. Such properties are preserved even when exposed to low temperatures and high humidity, so expanded polystyrene can be used in warehouse conditions, as well as in refrigeration equipment structures.

The thermal conductivity of polystyrene foam is low, so this material can be used not only for interior but also for exterior decoration. However, this characteristic will vary depending on the density. The higher it is, the higher the styrene content, the worse the polystyrene foam will retain heat. For example, if we are talking about extruded polystyrene foam, then its thermal conductivity will be 0.028 W/mK, because styrene granules in this case are in the structure of a single sheet, and there are no gaps between them.

What is expanded polystyrene

This material is made on approximately the same principle as any other foam insulation. First, liquid styrene is poured into a special installation. After adding a special reagent to it, a reaction occurs with the release of a large amount of foam. The finished foamed thick mass is passed through a molding machine until it hardens. The result is sheets of material with a huge number of small air chambers inside.

This structure of the boards explains the high insulating qualities of polystyrene foam. After all, air, as you know, retains heat very well. There are types of polystyrene foam, the cells of which also contain other gases. However, the most effective insulators are still considered to be slabs with air chambers.

The cells included in the structure of expanded polystyrene can have a size from 2 to 8 mm. Their walls account for approximately 2% of the mass of the material. Thus, polystyrene foam is 98% air.

Advantages and disadvantages of the material

Polystyrene insulation has the following advantages:

- does not create additional load on the foundation of the building and supporting structures;

- durability - the service life of the material is at least 40 years, while it does not lose its characteristics;

- ease of transportation and installation;

- good adhesion and interaction with adhesives;

- resistance to temperature changes and exposure to most aggressive environments.

Also, most modern types of polystyrene foam insulation are treated with special compounds that protect the material from rodents and pests.

At the same time, polystyrene foam also has disadvantages.

Low vapor permeability. To avoid the accumulation of steam indoors when using polystyrene foam as insulation, it is necessary to equip it with good supply and exhaust ventilation.

Not resistant to UV radiation. For this reason, the foam must be hidden from exposure to sunlight.

Loss of performance qualities when interacting with solvents, which does not allow applying paints and varnishes to EPS.

Low resistance to external mechanical influences

Polystyrene foam is a fairly fragile material, so when working with it, care must be taken so that it does not break or crack.

It is not the material itself that is toxic, but the fumes of stylol, which decrease over time and do not exceed the maximum permissible and safe for humans. Therefore, experts advise using PPP, which has been “staying” in the warehouse for quite a long time. The flammability of expanded polystyrene depends on the production technology. For example, polymer granules filled with carbon dioxide have the ability to self-extinguish.

Density and its influence on material properties

The density indicator determines the ratio of the mass of a material to its volume. A high coefficient means a significant load on the base; this fact is taken into account when choosing insulation. There are dense materials that are inferior in insulating characteristics to looser products. For example, a wooden beam with indicators of 510 kg/m3 has a thermal conductivity of 0.15 W/m*K, and mineral wool of 50 kg/m3 has a thermal conductivity of 0.35 W/m*K.

Modern heat insulators are classified according to density level into 4 groups:

- very light - polystyrene foam with a porous structure and gas-filled cells;

- light - mineral wool products;

- medium - foam glass;

- dense - rigid slabs made of basalt fiber.

Lightweight wall insulation does not withstand mechanical loads well, so it needs to create a protective layer. The weak bond between molecules cannot withstand external influences, and the material is destroyed. When installing mineral wool, polystyrene foam, extruded polystyrene foam, waterproofing and wind protection are installed, cladding is used or a layer of plaster is applied.

Main characteristics of insulation

Let us first provide the characteristics of the most popular thermal insulation materials, which you should first pay attention to when choosing. Comparison of insulation by thermal conductivity should be made only on the basis of the purpose of the materials and room conditions (humidity, presence of open fire, etc.)

We have further arranged in order of importance the main characteristics of insulation.

Comparison of building materials

Thermal conductivity. The lower this indicator, the less thermal insulation layer is required, which means that insulation costs will also be reduced.

Moisture permeability. The lower permeability of the material to moisture vapor reduces the negative impact on the insulation during operation.

Fire safety. Thermal insulation should not burn or emit toxic gases, especially when insulating a boiler room or chimney.

Durability. The longer the service life, the cheaper it will cost you during operation, since it will not require frequent replacement.

Environmentally friendly. The material must be safe for humans and the environment.

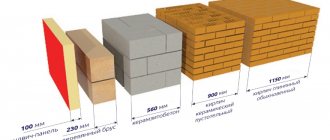

Expanded polystyrene and other insulation materials: comparison

Let's compare the thermal conductivity of mineral wool and expanded polystyrene. For the latter, this figure is lower and ranges from 0.028 to 0.034 watts per meter per Kelvin. The thermal insulation properties of EPS without graphite additives decrease with increasing density. For example, extruded polystyrene foam, whose thermal conductivity is 0.03 watts per meter per Kelvin, has a density of 45 kilograms per cubic meter.

Having compared these indicators for various insulation materials, we can draw a conclusion in favor of EPS. A two-centimeter layer of this material retains heat in the same way as mineral wool with a layer of 3.8 centimeters, ordinary polystyrene with a layer of 3 centimeters, or a wooden board with a thickness of 20 centimeters. You will have to lay out a wall 37 centimeters thick with bricks, and 27 centimeters thick with foam concrete. Impressive, isn't it?

If you notice an error, a non-working video or link, please select a piece of text and press Ctrl+Enter .

0

Scope of application of EPPS

Comparison of the required amount of insulation.

Another advantage of the material is its wide range of applications. Low thermal conductivity allows it to be used in road construction as insulating bases. Modern refrigeration units cannot do without the use of this material. In addition, it is actively used in the process of reconstructing heaving sections of highways.

The low thermal conductivity of the insulation allows it to be used in agriculture as a heat insulator on farms.

EPPS is widespread in the field of industrial and civil construction.

Among the new extensive areas of application of XPS, individual construction can be distinguished. A particularly promising area is the production of sandwich panels. This material is no less popular among individual developers. For example, when installing a roof, the slabs are laid over waterproofing, which additionally protects it from damage and temperature changes. And when carrying out reconstruction work, expanded polystyrene allows you to reduce costs. Moreover, it is permissible to carry out this kind of process when the existing heat-insulating layer has become unusable.

We advise you to study - Pros and cons of building with ceramic bricks

If it is intended to insulate a pitched roof, extruded polystyrene foam is laid on top of the rafters.

If it is necessary to insulate a wooden floor, heat insulation slabs must be laid between the rough and finishing layers, and fixation must be made between the joists. This allows for minimal heat loss through the floor. Sometimes it is necessary to insulate the floor of the first floor. The effectiveness of EPS in this case can be increased by laying the material in two layers, moving the sheets to overlap the seams. In this case, the EP slabs will be located between the waterproofing membrane and the screed. The material will guarantee not only excellent thermal protection, but also hydro- and vapor barrier, which will prevent the penetration of moisture from the underground.

EPS can be used in tandem with a heated floor system. This is possible due to the excellent strength characteristics of the plates. In this case, laying must be done on the interfloor ceiling, protecting it all with a dividing screed.

Due to its characteristics, EPS can be used when constructing the outer insulation layer of the foundation without the use of protection. The slabs will perform functions even in conditions that differ in groundwater pressure.

EPPS is a relatively new material, constantly being improved, which allows it to be actively used in construction.

Comparison of insulation materials by thermal conductivity

Expanded polystyrene (foam)

Expanded polystyrene (foam) slabs

This is the most popular thermal insulation material in Russia, due to its low thermal conductivity, low cost and ease of installation. Polystyrene foam is produced in slabs with a thickness of 20 to 150 mm by foaming polystyrene and consists of 99% air. The material has different densities, has low thermal conductivity and is resistant to humidity.

Due to its low cost, expanded polystyrene is in great demand among companies and private developers for insulating various premises. But the material is quite fragile and ignites quickly, releasing toxic substances when burned. Because of this, it is preferable to use polystyrene foam in non-residential premises and for thermal insulation of non-loaded structures - insulation of facades under plaster, basement walls, etc.

Extruded polystyrene foam

Penoplex (extruded polystyrene foam)

Extrusion (technoplex, penoplex, etc.) is not exposed to moisture and rotting. This is a very durable and easy-to-use material that can be easily cut with a knife to the desired size. Low water absorption ensures minimal changes in properties at high humidity; the slabs have high density and compression resistance. Extruded polystyrene foam is fireproof, durable and easy to use.

All these characteristics, along with low thermal conductivity in comparison with other insulation materials, make Technoplex, URSA XPS or Penoplex slabs an ideal material for insulating strip foundations of houses and blind areas. According to the manufacturers, an extrusion sheet 50 millimeters thick replaces 60 mm of foam block in terms of thermal conductivity, while the material does not allow moisture to pass through and you can do without additional waterproofing.

Mineral wool

Izover mineral wool slabs in packaging

Mineral wool (for example, Izover, URSA, Tekhnoruf, etc.) is produced from natural materials - slag, rocks and dolomite using special technology. Mineral wool has low thermal conductivity and is absolutely fireproof. The material is produced in slabs and rolls of varying hardness. Less dense mats are used for horizontal planes; rigid and semi-rigid slabs are used for vertical structures.

However, one of the significant disadvantages of this insulation, like basalt wool, is low moisture resistance, which requires additional moisture and vapor barrier installations when installing mineral wool. Experts do not recommend using mineral wool for insulation of wet rooms - basements of houses and cellars, for thermal insulation of steam rooms from the inside in baths and dressing rooms. But even here it can be used with proper waterproofing.

Basalt wool

Rockwool basalt wool slabs in packaging

This material is produced by melting basalt rocks and blowing the molten mass with the addition of various components to obtain a fibrous structure with water-repellent properties. The material is non-flammable, safe for human health, and has good thermal insulation and sound insulation properties. It is used for both internal and external thermal insulation.

When installing basalt wool, you should use protective equipment (gloves, a respirator and goggles) to protect the mucous membranes from cotton wool microparticles. The most famous brand of basalt wool in Russia is materials under the Rockwool brand. During operation, the thermal insulation slabs do not compact or cake, which means that the excellent properties of low thermal conductivity of basalt wool remain unchanged over time.

Penofol, isolon (foamed polyethylene)

Foil penofol

Penofol and isolon are roll insulation materials with a thickness of 2 to 10 mm, consisting of polyethylene foam. The material is also available with a layer of foil on one side to create a reflective effect. The insulation is several times thinner than previously presented insulation materials, but at the same time retains and reflects up to 97% of thermal energy. Foamed polyethylene has a long service life and is environmentally friendly.

Isolon and foil penofol are lightweight, thin and very easy to use thermal insulation materials. Roll insulation is used for thermal insulation of wet rooms, for example, when insulating balconies and loggias in apartments. Also, the use of this insulation will help you save useful space in the room when insulating inside. Read more about these materials in the section “Organic thermal insulation”.

Factors influencing thermal conductivity

Thermal conductivity depends on the density and thickness of the insulation, so it is important to take it into account when purchasing. Density is the mass of one cubic meter of materials, which according to this criterion are classified as very light, light, medium and hard

Lightweight porous products are used to cover interior walls and load-bearing partitions, while dense ones are used for exterior work.

Modifications with lower density are lighter in weight, but have better thermal conductivity parameters. A comparison of insulation materials by density is presented in the table.

| Material | Density indicator, kg/m3 |

| Minvata | 50-200 |

| Extruded polystyrene foam | 33-150 |

| Polyurethane foam | 30-80 |

| Polyurethane mastic | 1400 |

| Ruberoid | 600 |

| Polyethylene | 1500 |

The thickness of the material also affects the degree of heat transfer. If it is excessive, the natural ventilation of the premises is disrupted. Small thickness causes cold bridges and condensation on the surface. As a result, the wall will become covered with mold and mildew. You can compare the thickness parameters of materials in the table.

| Material | Thickness, mm |

| Penoplex | 20 |

| Minvata | 38 |

| Cellular concrete | 270 |

| Brickwork | 370 |

Table of thermal conductivity of materials

| Material | Thermal conductivity of materials, W/m*⸰С | Density, kg/m³ |

| Polyurethane foam | 0,020 | 30 |

| 0,029 | 40 | |

| 0,035 | 60 | |

| 0,041 | 80 | |

| Expanded polystyrene | 0,037 | 10-11 |

| 0,035 | 15-16 | |

| 0,037 | 16-17 | |

| 0,033 | 25-27 | |

| 0,041 | 35-37 | |

| Expanded polystyrene (extruded) | 0,028-0,034 | 28-45 |

| Basalt wool | 0,039 | 30-35 |

| 0,036 | 34-38 | |

| 0,035 | 38-45 | |

| 0,035 | 40-50 | |

| 0,036 | 80-90 | |

| 0,038 | 145 | |

| 0,038 | 120-190 | |

| Ecowool | 0,032 | 35 |

| 0,038 | 50 | |

| 0,04 | 65 | |

| 0,041 | 70 | |

| Izolon | 0,031 | 33 |

| 0,033 | 50 | |

| 0,036 | 66 | |

| 0,039 | 100 | |

| Penofol | 0,037-0,051 | 45 |

| 0,038-0,052 | 54 | |

| 0,038-0,052 | 74 |

- Environmentally friendly.

This factor is significant, especially in the case of insulating a residential building, since many materials emit formaldehyde, which affects the growth of cancerous tumors. Therefore, it is necessary to make a choice towards non-toxic and biologically neutral materials. From an environmental point of view, stone wool is considered the best thermal insulation material.

- Fire safety.

The material must be non-flammable and safe. Any material can burn, the difference is at what temperature it ignites. It is important that the insulation is self-extinguishing.

- Steam and waterproof.

Those materials that are waterproof have an advantage, since moisture absorption leads to the fact that the effectiveness of the material becomes low and the useful characteristics of the insulation after a year of use are reduced by 50% or more.

- Durability.

Thinner, warmer

In order to visualize this physical quantity, let’s compare the thermal conductivity of polystyrene foam with other building materials. Imagine that you are standing and looking from the end at sections of walls made of different materials. First, a concrete wall 3.2 m thick floats before your eyes, then brickwork of 5 bricks (1.25 m), then a relatively thin wooden partition the width of an adult’s forearm (0.40 m). And somewhere at the very end, an inconspicuous sheet of foam plastic 0.1 m thick. What unites all these materials of immense thickness? Only one.

Using its low thermal conductivity, you can significantly reduce the consumption of building materials that are quite expensive to purchase and install. A house built with 2.5 bricks is as reliable as a house with walls 5 bricks thick. Only in the first case, heating costs are higher. Do you want a warmer home? There is no need to build another wall like this. It is enough to insulate the wall with a 50 mm slab. Feel the difference. 2.5 bricks around the perimeter of the house and a sheet of foam plastic 50 mm thick. We save time, money, effort.

Insulation comparison table

To show clearly and schematically which insulation, figuratively speaking, what it costs, compare, it is easier to depict this in a table. Here are the most popular insulation materials. They are evaluated according to such categories as the above thermal conductivity, hygroscopicity and density.

| Material | Thermal conductivity | Hygroscopicity | Density (kg/m3) |

| Mineral wool | Low | High | 30-125 |

| Penofol | Low | Average | 60-70 |

| Expanded polystyrene | Very low | Average | 30-40 |

| Expanded clay | High | Low | 500 |

| Plastiform | Low | Very low | 50-60 |

| Styrofoam | Very low | Average | 35-50 |

| Penoplex | Low | Low | 25-32 |

| Cellular concrete | High | High | 400-800 |

| Basalt fiber | Low | High | 130 |

Foam plastic can be considered a kind of leader in the ranking of insulation materials. Availability and quite inexpensive price will also be competitive here. But it would be incorrect to advise one thing without knowing the situation, the area of insulation, financial capabilities, amount of work, etc.

Classification of expanded polystyrene

Regular foam

Thermal insulation material obtained by foaming polystyrene. As mentioned above, its volume is 98% air, which is sealed into granules. This speaks not only of its excellent thermal insulation qualities, but also of its sound insulation properties.

The main advantage of the material is the lack of ability to absorb moisture. In addition, it does not rot or biodegrade. Durable material, light weight and easy to use. It can be glued to any building material.

Expanded polystyrene is easy to burn, but it contains a substance called a fire retardant. This is what gives the foam the ability to self-extinguish. In addition, expanded polystyrene cannot be used to insulate facades. This is due to its low vapor permeability. And in order to carry out work with foam plastic under the roof, you should carefully consider the ventilation system.

Use depending on the brand of material

- PSB-S 15. The marking of polystyrene foam indicates that it can be used to insulate structures that are not subject to mechanical stress. For example, insulation of the roof, the space between the slings and the ceiling.

- PSB-S 25 and 25F. Common markings for polystyrene foam. It says that any surface can be insulated. Walls, facades, ceilings or flooring, roofing.

- PSB-S 35 and 50. This material can be used to insulate objects that are under constant high load.

Extruded polystyrene foam

Thermal insulation material, which has high effect and quality. It is most often used to insulate building envelopes. And the thermal conductivity coefficient ranges from 0.027 to 0.033 W/m K.

The structure of the material is cellular. And the complete closure of each cell provides absolute protection against water penetration. Therefore, this material is recommended for use where humidity is high or where the material can come into contact with water. This is insulation of the basement or foundation of a cottage. Even in conditions of insufficient waterproofing, extruded polystyrene foam will retain its thermal insulation qualities.

In addition, this material is highly resistant to various deformations. This feature allows it to be used as insulation for surfaces bearing heavy loads. For example, facades can be insulated with extruded polystyrene foam. Especially if the cladding material is very heavy.

As for the temperature. Expanded polystyrene is able to withstand sudden changes, from -120 to +175 degrees. At the same time, its structure remains intact and unharmed.

The disadvantages of this material are flammability, but, like polystyrene foam, its constituent elements can cause it to extinguish. Contact of polystyrene foam with complex carbohydrates can lead to destruction.

Thermal insulation material “Wall” - properties and characteristics

The “Wall” brand is a renamed Penoplex 31 insulation with fire retardant additives, which has been improved for use in insulating “wet” facades, building foundations, plinths and basements, partitions and walls of houses outside and inside, roofs and attics. The characteristics of penoplex brand “Wall” are in the table below:

| Properties | Meaning |

| Specific gravity | 25.0-32.0 kg/m³ |

| Compressive strength | 0.20 MPa (kgf/cm2) |

| Bend limit | 0.25 MPa |

| Moisture absorption in 1 day | 0,4% |

| Moisture absorption in 28 days | 0,5% |

| Fire resistance | Group G3 |

| Thermal conductivity | 0.030 W/(m K) |

| Sound insulation threshold | 41 dB |

| Dimensions (width, length, height) | 600 mm x 1200 mm x 20, 30, 40, 50, 60, 80, 100 mm |

| Temperature range | -50/+750С |

Insulation series “Foundation”

Technical characteristics of extruded polystyrene foam

The performance and mechanical characteristics of this thermal insulation material require special consideration.

Thermal conductivity

, regardless of brand, lies in the range from 0.03 to 0.04 W/(m 0 K). Such indicators make it possible to use expanded polystyrene foam for insulating any building elements, as well as highways, runways, etc.

We advise you to study - Tables of characteristics of heating radiators

Density of slabs

, depending on the modification of the material, can be from 20 to 50 kg/m 3 ;

Moisture resistance. Thanks to the closed porous structure and chemical composition, the material does not deteriorate under the influence of dampness, condensation and even direct contact with water

The only weak point is the end surfaces, the waterproofing of which should be given special attention

Health safety

allows the use of extruded polystyrene foam even in medical and children's institutions. The plates do not emit harmful fumes even at high temperatures. In addition, the thermal insulation layer is usually covered with a layer of finishing materials (plaster, putty, drywall, etc.).

High strength parameters

. The permissible stress, depending on the modification, ranges from 18 to 20 t/m2.

Other characteristics of extruded polystyrene foam include:

- Frost resistance.

The material retains its thermal insulation properties even at -70 0 C; - Low vapor permeability

, from 0.007 to 0.008 mg/(m h Pa); - The antiseptic properties

of the material practically eliminate the occurrence of fungal colonies; - Long service life

. Regardless of operating conditions, expanded polystyrene foam is guaranteed to last at least 45 years.

Such indicators will certainly arouse increased consumer interest. In addition, it is also important that installation can be done with your own hands, and the cost of the material is relatively low.

Production of penoplex and types of material

The production of penoplex is organized using the following technology: small polystyrene granules in a sealed chamber are exposed to high temperatures (1300C-1400C), as a result of which they melt, and after adding blowing agents they foam. Porophores are synthetic additives that, when heated, release nitrogen and carbon dioxide, which, after the penoplex cools, turn into frozen air bubbles, evenly distributed throughout the material.

Comparison of thermal conductivity of penoplex and other building materials

Components of blowing agents for the production of extruded polystyrene foam (penoplex):

| Penoplex components | Volume by mass |

| Polystyrene | 100 |

| Fine perlite | 1 |

| Sodium bicarbonate Na2CO3 | 1 |

| Citric acid C6H8O7 | 0,8 |

| Zinc stearate (C36H70O4Zn / Zn(C18H35O2)2) or barium stearate (C36H70BaO4) | 0,2 |

| Tetrabromoparaxylene - an additive to provide self-extinguishing properties to foaming polystyrene | 1,2 |

Production of penoplex

Cured foam may contain some synthetic fillers, the presence of which determines the direction of application of the insulation - for walls, foundations, etc. The most common additives are flame retardants to increase fire safety (reduce the degree of flammability), antioxidants to protect the material from oxidation in the open air, antistatic substances to relieve static and dynamic stress during insulation operation, light stabilizers (protection from the negative effects of UV radiation), modifying additives and etc.

Polystyrene foam is pressed under pressure from the extruder chamber onto a conveyor for final formation into slabs or blocks. The percentage of gases in the insulation reaches 98% of the total volume of the finished penoplex, so the products are light in weight with impressive dimensions. Dimensions for each functional line of insulation are given in the tables below.

Sizes and types of penoplex

The small size of the pores (0.1-0.3 mm) and their complete isolation from each other guarantees high thermal insulation performance of any brand of penoplex. For different construction projects, it is necessary to select the appropriate series and brands of insulation, since structures can be operated under different conditions:

- Brand “K” is designed for insulation of pitched or flat roofs and roofs. Specific gravity (density) of the “K” series – 28-33 kg/m3;

- Series “C” – insulation for internal and external walls with a substance density of 25-35 kg/m3;

- Brand “F” is used to insulate foundations, basements and basements. Material with high moisture resistance, biological stability and specific gravity ≥37 kg/m3;

- Penoplex brand "Comfort" is a universal series of insulation with a density of 25-35 kg/m3. Direction of application – insulation of apartments, houses, basements, balconies and loggias;

- Brand “45” has the highest frost resistance and strength, specific gravity 35-47 kg/m3. Designed for thermal insulation of road surfaces, runways, and other heavily loaded objects and structures.

Expanded polystyrene sandwich panels

A separate category produces sandwich panels, which are an improved thermal insulator for insulating attics and mansards, facades and foundations of buildings. The sandwich panel has 2-3 layers and a cement bonded particle board as the bottom layer.

Positive and negative properties of polyurethane foam

For a more convenient understanding of the essence, properties and scope of the material, you need to have an idea not only of the physical and chemical properties, but also know its positive and negative sides.

Positive

- Polyurethane foam has good adhesion. It adheres to wood, metal, and concrete surfaces without any problems. It does not require additional fasteners. Due to its elastic structure and method of application, polyurethane foam fits well on uneven substrates. Before applying it, the surface does not require additional treatment with primer or paint.

- PPU has a low cost. It is produced directly on the construction site by mixing two components. There are no costs for additional transportation and manufacturing.

- Polyurethane foam is a lightweight material that does not load building structures.

- In addition to heat and sound insulation, polyurethane foam strengthens load-bearing walls, making the structure stronger and more durable.

- It is practically unaffected by extremely low and high temperatures. PU foam is not destroyed by cyclic freezing and thawing.

- The polyurethane foam coating has a monolithic structure. There are no gaps for the appearance of cold bridges. The wind doesn't blow through it.

Negative

- Polyurethane foam quickly degrades under the influence of ultraviolet rays. Therefore, it does not remain open, but requires protection. It can be covered with a layer of paint or plastered. The use of various cladding panels is also suitable.

- Polyurethane foam is a non-flammable material. Still, it is not recommended to use it in places of possible contact with open fire. If this is technically impossible, then the polyurethane foam is covered with fire-resistant plasterboard.

Penoplex "Roof" - properties and characteristics

Penoplex insulation of the “Roofing” series is a renamed material “Penoplex 35”, which is recommended for use in insulating pitched and flat roofs of any design. The use of the “Roof” series makes the further operation of the roof as simplified as possible, since the reliability and long service life of the insulation minimize the possibility of repairing the roof surface. The popularity of this innovative insulating material is also due to the fact that greenhouses and summer gardens can be built on such a surface - such trends are now in fashion. Penoplex can withstand such high loads that it doesn’t care about soil loads of up to several tons. Characteristics of the foam insulation brand “Roof” are in the table below:

| Properties | Meaning |

| Specific gravity | 28.0-33.0 kg/m³ |

| Compressive strength | 0.25 (2.5; 25) MPa (kgf/cm2) |

| Bend limit | 0.4 MPa |

| Elasticity modulus | 15 |

| Moisture absorption in 1 day | 0,4 % |

| Moisture absorption in 28 days | 0,5 % |

| Fire resistance | Group G3 |

| Sound insulation threshold | 23 dB |

| Thermal conductivity | 0.03-032 W/(m K) |

| Dimensions (width, length, height) | 600 mm x 1200 mm x 20, 30, 40, 50, 60, 80, 100 mm |

| Temperature range | -50/+750C |

“Comfort” is a universal brand of heat insulator

Fire resistance

Being a combustible material, polystyrene foam has good fire resistance, since the spontaneous combustion temperature is +4910 C. This indicator is 1.8 times higher than that of wood, for which +2600 C is enough. In the absence of fire within 4 seconds, the combustion dies out. During combustion, the material releases about 1000 MJ/m3 of energy, while wood - 7000-8000 MJ/m3 - which means that when burning polystyrene foam, the temperature increase will be much lower.

Manufacturers offer self-extinguishing polystyrene foam made with the addition of fire retardants. However, experiments show that the self-extinguishing effect is lost over time, and in the design the material, which was initially classified as belonging to the G2 flammability group, after some time already corresponds only to the G4 class (research carried out at the Research Institute of Industrial Safety and Emergency Situations of the Ministry of Emergency Situations of Belarus).

At the same time, it should be recognized that the products released during the combustion of different brands of polystyrene foam are still poorly studied.

Insulation properties

When choosing insulation, it is necessary to take into account a wide range of its characteristics. The most important of them will be:

Scheme of glass wool wall insulation.

- Density. Thermal conductivity is directly dependent on this indicator. The denser it is, the higher the thermal conductivity. In addition, this indicator is largely decisive for differently oriented surfaces.

- Thermal conductivity. This is the main indicator of insulation. The lower the ability to retain heat, the more material is required for insulation. In turn, this indicator depends on the ability to absorb moisture.

- Hygroscopicity. Insulation materials that have this indicator low do not absorb moisture well and, accordingly, have a low ability to conduct heat, which affects both the required quantity and durability.

In addition, according to their mechanical properties, insulation materials are usually divided into four classes:

- bulk - granules or crumbs - foam substances of various fractions;

- cotton wool – directly rolled material or various products using it;

- plates – plates of various sizes, made by gluing and pressing;

- foam blocks - made of foam concrete, glass or other materials with appropriate properties.