Good day, dear reader! I don’t know for what reason, but our five-story house is heated so well that even in the cold it was too hot. The windows in my apartment were constantly open for ventilation, and I had to pay huge sums for heating. Something had to be done about this.

So I decided to install a separate heat meter and thermostatic valve into the system. Now my apartment is quite warm, and the amounts on my bills have dropped by almost half.

What is it and what is it for?

A thermal valve is a type of pipeline fitting. It allows you to maintain a given temperature in the room by optimizing the heat transfer of a separate heating device.

Purpose and scope

The thermal valve is designed for manual or automatic regulation of coolant flow through a radiator or distribution manifold.

Installation of such devices is recommended:

- In autonomous heating systems, where the medium is heated by a solid fuel boiler.

- On hot water pipelines. Water for domestic needs may be supplied too hot (up to 95 ºС) and, in the absence of a mixing tap, causes burns to users.

- In front of the plastic elements of the piping system. The thermal valve will protect the material from which the pipes are made from overheating.

Characteristics

For your information, here are a number of basic technical characteristics of thermostatic valves:

- The maximum operating pressure level is 1.0 MPa.

- Pressure testing before commissioning is 1.5 MPa.

- The maximum operating temperature is +110 ºС.

- The maximum permissible ambient temperature is +50 ºС.

- The valve capacity is from 1.6 to 2.5 m³/h.

- Temperature control range - +20…+60 ºС.

- Response time: 25 min.

- MTBF with manual control - 8000 cycles.

What materials are they made from?

Corrosion-resistant metals are used to make the thermostatic valve body:

- Brass.

- Bronze.

- Stainless steel.

Additionally, the surfaces of brass products are nickel-plated, and the bronze body is either also nickel-plated or coated with a layer of chrome.

Electronic variant

The electronic mechanism is a more complex design based on a programmable microprocessor that sets a certain temperature regime in the room. By pressing the buttons, the supply of coolant is regulated. Open type thermostats can be programmed for certain temperature indicators and operate in one mode or another, adjusted by a timer. Modern multifunctional models can be used in the control system of boiler and pumping equipment, as well as together with a mixer. Models should not be installed in the bathroom, due to their very high sensitivity.

Design and principle of operation

The thermal valve includes two main components:

- Valve.

- Thermostatic head.

The thermostatic valve is designed as a hollow body with a cover. Inside it there is a movable rod with a sealing surface that ensures a tight seal of the valve seat. The rod is spring-loaded with a return spring; a ring with washers is provided to secure it.

The threaded valve cover is equipped with a packing unit consisting of a packing ring and a nut. To ensure additional tightness of the connection, an O-ring is installed on the rod.

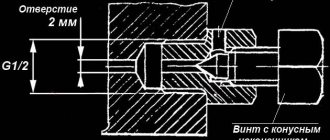

The radiator thermal valve is connected to the devices by means of a half-fitting, which has a lock nut with a Teflon liner. It is secured to the device body with a union nut through a sealing gasket.

In the cavity of the thermostatic head there is a bellows filled with a thermo-reactive substance and a rod. As the temperature rises, the filler in the bellows container expands and acts on the rod, which, in turn, transmits force through the extension to the thermostatic valve rod. When the valve stem lowers, it blocks the flow of coolant.

Circulation in the radiator slows down, heat transfer decreases. A spring mechanism is provided to return the rod. The thermostatic head is secured to the valve with a brass union nut.

Mechanical option

A mechanical thermostatic valve includes a regulator, an actuator, and a bellows filled with gas or liquid. The substance in the bellows changes the position of the lever in the thermostat by moving inside the spool and adjusting the rod. It is the rod that blocks the passage and limits the flow of coolant into the radiator, which allows you to regulate the heating temperature of the radiator in each room separately. Closed-type thermal heads do not automatically detect temperature and are adjusted manually, so temperature fluctuations are quite possible. Models should not be covered with curtains or pieces of furniture that reduce their sensitivity threshold.

Advantages and disadvantages

The advantages of installing thermostatic valves in the heating system include the following factors:

- Energy independence of the device.

- Compactness.

- High precision temperature control.

- Easy to operate and highly reliable.

- Aesthetic appearance.

- The optimal combination of price and functionality.

The disadvantages of using thermostatic valves are:

- Difficulty setting up.

- There is a danger of the thermal head malfunctioning under the influence of a draft or a nearby stove.

Recommended Manufacturers

Several global manufacturers are engaged in the production of such shut-off and control valves. The operation of the heat supply depends on the quality of materials, accuracy of settings and design. Therefore, it is recommended to buy original models rather than analogues. This will increase the reliability of the system.

You can find balancers on the market from Valtec, Danfoss, Herz and Honeywell. They differ only in appearance, their functional features are the same. The table shows popular heating balancers from these manufacturers.

| Manufacturer | Mechanical balancer | Automatic balancer |

| Valtec | VT.042.G | VT.040.G |

| Danfoss | Leno MVT or MNT | AB-PM, APT or ASV |

| Herz | 4017 M | TS-V |

| Honeywell | Kombi-3-Plus | — |

These models differ in size and connection methods to the pipeline. Some of them are designed only for cold water supply, but most are universal and can be used for heating and water supply. An example is Danfoss products. Air valve for heating to bleed air from the battery In modern heating systems, a special device is provided to remove accumulated air - an air valve for heating. Without this device, the heating would not be able to work properly....

Kinds

Thermal valves are divided into types according to the following characteristics:

- By installation method - straight, angular, axial.

- Purpose: mixing, balancing.

- By type of heating system - for a single-pipe or two-pipe system.

- According to the type of filler in the bellows container of the thermoelement - paraffin, gaseous or liquid substance.

- By type of thermostatic element - manual, mechanical or electronic regulation, with a remote sensor.

Manual

For manual thermostatic valves, the stem is activated to stop the movement of the coolant when the handle located outside the body is rotated manually. By turning the regulator, you can change the pressure in the thermostatic head, which will affect the sensing element and cause the stem to move. They come in straight or angular design.

Available in two passage diameters - ½" or ¾". They are distinguished by a simpler design and lower price. The main disadvantage of a thermostatic valve with manual adjustment is the low accuracy of temperature control and the need to control timely operation by a person.

Mechanical

These are devices with a more complex design that can automatically maintain a given temperature in the room. The basis of their thermostatic head is a bellows container filled with liquid with a high coefficient of thermal expansion.

When heated, the liquid in the bellows expands and moves the thermal head rod. Through an extension cord, it transmits force to the rod of the thermostatic valve, which blocks the flow of coolant. When the liquid cools, the process goes in the opposite direction.

Gas or liquid

The effectiveness of a thermostatic valve depends on the properties of the substance in the bellows. Gas-filled thermoelements are more accurate and reliable. They respond faster to temperature changes, but are more difficult to produce and therefore more expensive.

Liquid ones work a little slower, but are easier to manufacture. The advantages of liquid thermoelements also include the high accuracy of transfer of the internal pressure of the bellows to the thermostatic valve stem.

With remote sensor

Thermal valves with a remote sensor are designed for installation in radiators with a bottom connection or located in a niche. The thermostatic head is mounted on the valve using a threaded connection, and the temperature sensor is attached to the wall in any convenient place. The head and sensor are connected to each other by a capillary tube.

Such models maintain temperature more accurately, but are more expensive than others.

Electronic

Electronic thermal valves have larger dimensions. An electronic microprocessor is built into the body of the device, which controls the movement of the rod; there is also an additional compartment for two batteries. One of the advantages of electronic models is wider functionality. With their help, for example, you can set different temperatures in the room in the morning or evening, for each day of the week.

Design

*

There are a wide variety of models of such valves, but their design is similar.

Mandatory layout requires the following elements:

- body, usually made of brass;

- mixer used as directional control;

- control lever;

- other small parts in the form of seals, nuts, and so on.

The valve body has 2 inputs and 1 output. A liquid of different temperatures enters through the inlets, and through the outlet it exits, already heated to the required temperature. In the inner part of the body there is a mixer that regulates the direction. This element, depending on the valve model, functions differently. A simple option - the design has a spring locking element that responds to temperature and, accordingly, pressure. If the spring tension increases, the outlet temperature decreases.

The control knob is necessary to set a specific valve position. With its help, the spring stiffness is set and the position of the locking part is adjusted.

Valve design

How to choose

The thermostat is selected according to the operating characteristics of the heating system. The device must:

- Withstand pressure in the range of 16–40 bar and temperatures up to 200 °C.

- Be made of corrosion-resistant materials that are resistant to mechanical stress.

- Match the diameter with the size of the pipeline.

- Match the thread parameters on the pipe.

Popular manufacturers

Thermostats manufactured by the following companies are considered the most reliable and durable:

- Danfoss (Denmark). Devices from this manufacturer, despite their fairly low price, have an improved design. They are equipped with a flow stabilizer, so they operate silently. They do not become clogged when working with any contaminated coolant, since their rod stroke is 1.5 times greater, and the performance adjustment window has a larger cross-section.

- Oventrop (Germany). The variety of standard sizes of thermostatic fittings from Oventrop allows you to choose the ideal model for any engineering system. Excellent regulating qualities, high product reliability are combined with an aesthetic appearance.

- Luxor (Italy). Luxor thermostats are suitable for heating systems where the coolant is hot water. They are equipped with a thermostatic spindle that allows pre-setting of the flow.

What does the cost and approximate price depend on?

The cost of thermostatic valves varies and depends on:

- From the design.

- Material of body parts.

- Technical characteristics.

- Features of production.

See the table for approximately how much different models of thermostatic valves cost.

Installation and operation rules

I install the thermostatic valve according to the following scheme:

- I drain all the liquid from the heating system. In a private building this is easier to do, but to drain in an apartment building you will have to contact a service organization, since the valve is located in the basement.

- I cut out a part of the pipe that matches the size of the purchased device.

- I cut threads on the ends of the pipes.

- I screw the product into the threads on the pipes and seal the joint with linen thread and heat-resistant paint.

- I check the tightness of the connections and the immovability of the position of the valve body.

- Setting up the thermocouple.

When using thermostatic valves, I try to:

- The device was protected from direct sunlight.

- The valve was closed while ventilating the room, since cold air will quickly cool the thermostat and it will increase the flow of hot coolant into the radiator.

- If the device is configured to control the temperature in several rooms at the same time, then I make sure that the interior doors are closed.

- Until the next heating season, all valves remained in the open position. Otherwise, the spool may stick to the valve seat and the device may fail.

- In the summer, I remove the thermostatic head from the valve. This will increase its service life.

Adjusting the device

After installation, I adjust the device as follows:

- I open the valve completely until the temperature in the room heats up and stabilizes.

- Then I close it completely and wait until the room temperature becomes comfortable.

- I remove the handle of the thermostatic head and reinstall it so that the desired temperature value on its scale is achieved when the valve is fully open.

- After this, I begin to open it little by little until coolant begins to flow into the battery and the body of the thermostatic valve becomes warm to the touch.

Installation of three-way valves in the heating system

Mixing valve installation

When installing SVs, several rules should be followed:

- Follow the arrows on the valve indicating the direction of flow. You also need to know the designations of directions: A - straight, B - perpendicular, AB - common input/output.

- Consider the existence of two three-way models:

- symmetrical;

- asymmetrical.

For symmetrical ones, flows come from the side ends. At the exit through the central end, the flow is already mixed. In the case of asymmetrical ones, the warmer flow comes from the end, and the cooler flow comes from the bottom. The exit of the already mixed flow is through the second end.

3. Connect the valve with the thermal head (drive) facing up.

Inset

SK insertion options depend on the layout of the heating system.

- Excessive heating of the coolant in the heating return line leads to excess pressure in the system. This can be eliminated by installing a jumper (to input B).

Blue triangles connected by vertices indicate a pump, thanks to which water circulates in the system.

In autonomous heating systems, the valve is usually connected to the boiler. Then the balancing valve cuts in (blue in the diagram).

- If it is possible to bypass the coolant into the return (usually in an autonomous boiler room), the mixing valve also performs separation functions. Then another balancing valve cuts in (to inlet B of the three-way valve).

Dividing valve installation

A separating valve is used when it is necessary to reduce the temperature of the coolant from the source. After the flow is divided, the coolant reaches the consumer without overheating.

This situation requires a pump.

Recommendations

Mandatory rules when installing any three-way valve:

- It is mandatory to install pressure gauges on both sides of the valve;

- a filter is mounted in front of the device to protect against any impurities;

- the device body is not loaded;

- install devices in front of the valve that reduce excess pressure;

- the valve is not located above the actuator;

- Maintain straight sections on both sides of the device if recommended by the manufacturer.

Layout diagrams

- The simplest scheme with a solid fuel boiler:

A three-way valve in such a heating circuit protects against condensation and overheating and maintains the temperature in the circuit.

- A more complex scheme - with an electric boiler and heated floors:

Hydrocollectors are used to organize several floor contours.

- A boiler with a three-way valve and a boiler allows you to get by with one circuit:

Frequent errors and problems during installation

Since the thermostat head must be in free contact with air during operation, the following errors must not be made when installing the device:

- Install the head in a vertical position. The thermostatic head will be exposed to air heated by the supply pipe, which will not allow it to correctly assess the room temperature.

- Install the device without taking into account the direction of flow.

- Block access to the main air mass valve with furniture, thick curtains, decorative screens, etc.

- Place under a wide window sill or in a niche where there is a high heating zone.

Errors in the placement of the thermostatic head lead to the creation of a zone around it with warmer air than in the room. Therefore, the device will block the movement of the coolant too early and will not allow the optimal temperature regime to be created in the room.

Flow regulator

Having installed energy metering devices, the question naturally arises of how you can regulate and control the supply of coolant, limit or add its flow. For this purpose, there are all kinds of automatic regulators, the use of which allows you to save money; they operate from outside air temperature sensors and return pipeline sensors. Another advantage of temperature controllers is that they control the temperature directly at the radiator installation site, unlike other devices. This advantage gives priority in obtaining a uniform temperature background for a comfortable stay in the room. The regulator will prevent overheating of the air in the room, which sensors on centralized automation cannot always track. It is possible to adjust the temperature for each room separately. Sometimes, when solving the adjustment issue, ordinary taps are installed. Of course, this solution reduces financial costs, but deprives a number of useful advantages. The faucet has limited functionality to open and close. There is a danger of stopping or airing the riser. By adjusting the heating using taps it is impossible to achieve the required temperature. Using automatic regulators, you can adjust the system accurately and efficiently.

Expert advice

A few tips from professionals will help the apartment owner install and configure the thermostatic valve with his own hands and in accordance with all the rules:

- It is important to mount the device in such a way that the direction of water movement coincides with the direction shown by the arrow shown next to the marking on the body, otherwise the operation of the thermostatic valve will be incorrect.

- For underfloor heating systems, it is better to choose thermostats with a side valve - this makes settings easier to access.

- In public areas, thermostatic valves with remote control or pre-setting should be used for installation to protect them from outside influence.

- To seal the threaded connection, you should not use fum tape, but polymer or linen threads with heat-resistant paint. When heated and significant temperature changes occur, thermal expansion of the pipes occurs, the density of the tape may be disrupted, which will lead to the formation of a leak.

- It is more appropriate to place the valve on the supply pipe.

- The distance from the floor to the installation site of the thermostatic valve should be at least 40-60 cm. Initially, manufacturers configure them to capture temperature changes at this level. If it is necessary to change this parameter, then additional configuration of the device is performed.

- The thermostatic head must be installed on the valve in a horizontal position and turned towards the inside of the room. If you install the thermal head vertically, the warm air from the riser will interfere with the normal operation of the sensor.

- When installing a thermostatic valve in a one-pipe heating system, it is necessary to install an additional bypass section - a bypass. It should be located between the sections of pipelines entering the heating device and leaving it (as in the photo below).

Installation rules

To install the thermal mixing valve in the position specified by the circuit, it is necessary to take into account a number of important nuances:

- Mounting method. Installation can be flanged or with internal/external thread. During fastening, conditions must be created to ensure a tight connection - using special gaskets, materials and mixtures.

- Installation on the return line to pumping equipment.

Only in this case can the condition of an always open outlet pipe be met.