Many private houses and apartments are equipped with automatic and semi-automatic gas heating appliances. A boiler is a reliable assistant for heating a room in winter. Even if it was serviced before the heating season, there is still a possibility of it breaking down. Let's look at the reasons why a gas boiler goes out or doesn't light up and how to restore the boiler's functionality if it lights up and goes out.

Reasons for the lack of flame in boilers with automatic ignition and ways to eliminate them

The ignition unit is damaged

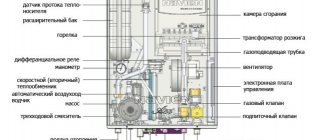

The photo shows the electrical part of the Ariston turbocharged boiler.

To determine the condition of the ignition unit, you can use an electronic tester in ohmmeter mode. The probes are connected to the output of the ignition electrode contacts (or to the electrodes themselves) located on the block. The unit is operational if the tester readings are within the range of 650 - 750 Ohms.

Checking the automatic ignition unit of the Ariston boiler.

In a damaged unit, the tester will detect an open circuit (1 will be displayed on the display) or a short circuit (0 will be displayed). The identified faulty part is replaced with a similar one.

Flame control electrode dirty

During the combustion of fuel, soot is formed, which gets on the working surface of the electrode and disrupts its proper operation. Clean the surface of the electrode with fine-grain sandpaper. If it doesn't help:

- move the temperature control knob to the heating off position;

- wait until the circulation pump and smoke exhauster turn off;

- on the instrument panel, press the switch off button;

- unplug from the socket and turn 180 degrees the plug of the device;

- insert the plug back into the socket;

- turn on the boiler.

Smooth shutdown of heating equipment extends its service life.

The operation of the flame control unit, due to its operating principle, depends on the phasing of the supply network (phase and zero connection points). Therefore, rephasing helps him restore the sensitivity of the gas ions.

Low mains voltage

The ignition unit and electronic gas valve may not work properly due to insufficient voltage in the network. To maintain a stable level of supply voltage, it is advisable to connect the boiler through a voltage stabilizer. It will provide protection for the electronic elements of the gas boiler during power surges.

Gas valve malfunction

The valve may be blocked by debris that has entered through the gas burners. In the device, the inductance coil designed to control the valve position may burn out. To check it, on a completely de-energized boiler, an ohmmeter is connected to the terminals. The coil is considered working when the reading is 80 - 90 Ohms.

Checking the gas valve coil.

To clean the gas regulator, the side part of the housing is unscrewed where the valve is located. Garbage is removed and his work area is cleaned.

Reassemble in reverse order. Often, to assemble a gas regulator, fasteners with a common head profile are used: an asterisk with a pin. To work with such hardware, you need to purchase a screwdriver with a blade of the required size and profile or sharpen a screwdriver with a flat tip.

Closed type burners

Currently, heating equipment is equipped with closed burners. Such boilers are called “turbocharged”. Their operation requires the installation of compact chimneys, which are often installed directly outside the wall when the house is just being built. In this case, the creation of ventilation ducts and a chimney system is greatly simplified.

A boiler equipped with a closed combustion chamber is a heating unit in which a gas burner is placed in a special chamber. Oxygen enters it from the outside through a coaxial chimney. It also removes products formed during fuel combustion.

All flows in the coaxial chimney are controlled by a powerful fan, in which the speed is regulated automatically. It is a structure consisting of pipes of different diameters. They are placed one inside the other.

A similar chimney serves to take in air and remove combustion products. They bring it out through a nearby wall, maintaining a distance of half a meter from the window openings; sometimes more stringent requirements are imposed on installation.

Gas appliances with closed burners have a number of advantages:

- Possibility of placement in rooms for different purposes - in the kitchen, in the bathroom, in the basement and even in the bedroom.

- Ensuring increased safety, since the fuel burns in a completely isolated chamber. If the gas suddenly goes out and the automation does not work, the gas-air mixture will be removed outside the building or room.

- High efficiency rate. Units with a closed burner type are more efficient, but this circumstance does not apply to all boiler models.

- Effective temperature control, for which they use a fan shaft speed control system.

- Environmental friendliness - gas burns almost completely.

There are also disadvantages:

- Complex device - a closed gas burner for a household boiler has a complex design, which will complicate repair work.

- Reduced degree of reliability. The greater the number of parts, the more often the equipment breaks down.

- High price. A “turbocharged” unit costs 10–15% more than its naturally aspirated counterparts.

- Increased noise level, which depends on the selected modification. The fan built into the system makes a loud noise.

- Energy dependence. In the event of a power outage, the equipment stops working. Purchasing an uninterruptible power supply will help solve this problem.

Despite the presence of the above disadvantages, these types of boilers are quite in demand among consumers. Closed-type burners are equipped with condensing units, which are characterized by high efficiency due to the use of heat released by combustion products.

Reasons for the lack of spark and flame in boilers with semi-automatic ignition - methods for eliminating them

Most of these models are equipped with Eurosit 630 automatic transmission.

Photo of the Eurosit 630 automation.

One of the reasons why a gas boiler with automatic “Eurosit 630” does not light up or goes out may be:

The piezo element is faulty

The piezoelectric element is a reliable part of the gas boiler automation system and breaks down in rare cases. It is installed next to the coolant temperature control knob, but can be mounted separately.

To check the functionality, it is enough to disconnect the wire along which the generated voltage moves from the electrode and bring it to the valve body at a distance of 4-8 mm.

Piezoelectric element wire disconnected from the electrode.

Press the piezoelectric element's start button several times. If a spark appears between the wire and the housing, it means that the generator is working and you should pay attention to the electrode itself, the ceramic housing of which must be dry and intact.

The electrode mounting nut should only be tightened by hand.

The emergency electrical circuit is broken

The emergency protection system for a gas boiler consists of:

- connecting wires;

- bimetallic sensors installed in the chimney and heating supply line, triggered at a temperature of 75-85 degrees Celsius;

Classification of types of temperature sensors

The choice of sensor depends on the environment in which the temperature needs to be monitored: inside the boiler, in the room or in the heating system. The efficiency and safety of heating equipment depends on the correct choice.

The temperature sensor for a heating boiler is classified according to the following criteria:

- by the method of determining temperature,

- by type of interaction with the thermostat.

Types of sensors by method of determining temperature

According to the method of determining temperature, sensors are:

- Dilatometric, which are bimetallic plates or spirals, the operating principle of which is based on the thermal expansion of metals or other types of solids.

- Resistive, having a strong dependence on temperature in a certain measured range, which manifests itself in the form of sharp changes in electrical resistance.

- Thermoelectric, which are thermocouples (alloys of two dissimilar conductors, for example, chromel-alumel), in which thermo-EMF begins to induce at certain temperature intervals.

- Manometric, the principle of operation of which is based on changing the pressure of a gas or liquid in a closed volume.

Dilatometric sensors are made from materials with a high coefficient of thermal expansion that respond to minimal temperature fluctuations. The principle of their operation is based on the closing or opening of electrical contacts. To increase their sensitivity and quality of contact, magnets are used in structures.

Resistive temperature sensors are made from special alloys of conductors or semiconductors. Structurally, they consist of a coil with a wound thin copper, platinum or nickel wire and a ceramic housing or semiconductor wafers placed in a plastic or glass housing.

Semiconductor resistors come in two types:

- thermistors having a nonlinear temperature dependence, characterized by a decrease in resistance when heated,

- posistors, which also have a nonlinear dependence on temperature, but differ from thermistors by increasing resistance when heated.

Thermoelectric sensors are made of two specially selected dissimilar metals or alloys, at the point of contact of which, when heated, a thermo-emf is induced, the value of which is proportional to the temperature difference between the two junctions. In this case, the measured value does not depend on temperature, length and cross-section of wires.

Gauge sensors allow you to determine temperature in a non-magnetic way without the use of energy sources, which allows them to be used for remote measurements. However, their sensitivity is an order of magnitude worse than that of other temperature sensors, and there is also an inertia effect.

Types of sensors according to the method of interaction with the thermostat

Temperature meters based on the type of interaction with the thermostat are divided into the following types:

- wired, transmitting data to the controller via wires,

- wireless – high-tech modern devices that transmit data at a certain radio frequency.

Wired temperature sensor for boiler

Ignition operating principle

Electric ignitions, which are equipped with most modern models of gas boilers, include the following elements: diode, resistor, capacitor, transformer, spark plug, switch.

This convenient and practical invention facilitates the operation of the unit, speeding up its activation and configuration. With the help of a compact device, you can ignite a flame in a burner not only quickly, but also safely, without the use of matches and lighters, which tend to run out and deteriorate. The flame appears immediately after pressing a button or turning a lever.

It is customary to distinguish between several types of electric ignitions for gas boilers - mechanical, automatic and semi-automatic. If the unit is equipped with mechanical ignition, to turn it on you need not only to activate the burner by turning the switch, but also to press a special button. The device will generate a spark and ignite the flame.

If the electric ignition is automatic, then the equipment turns on when you turn the handle - there is no need to use additional devices.

To be able to use automatic ignition, the heat-generating device must be connected to the network (a grounded socket must be nearby). If the electric ignition of a gas boiler fails, you should call a heating equipment repairman to your home.

Boiler priority relay

Most boilers for domestic use have the ability to connect to the electrical circuit of a target that controls a cylinder water heater. This involves, among other things, connecting the power supply to the circulation pumps and switching them. To correctly perform the operating algorithms of the heating system pumps and boiler (which is aimed at priority of water heating), a special boiler priority relay is used. This is a device that switches the power circuit of the pumps according to commands from the boiler control circuit. A relay is structurally a couple of groups of contacts controlled by a coil. The relay is used together with a socket, which is mounted in the boiler. The entire load is attached to the base. When installing a relay base, the priority of the DHW system is ensured. Without such a relay, both thermal loads operate independently.

Why the ignition may not work

Electric ignition is considered one of the most vulnerable elements of a gas boiler, since it is the one that most often fails than other components. The causes of failure may be errors made during operation of the device, wear of parts or mechanical damage.

Having discovered that the ignition is not working, first of all you need to make sure that it is connected to the electrical network and that there is voltage in it.

If everything is fine with the power supply, but the device still does not function, the reason may be a faulty power supply or button, or a damaged wire. To diagnose a breakdown, you will need a tester; it allows you to check for conductivity.

Series from Siberia

The manufacturer offers three series:

- Premium Topline-24. Premium models are designed for small buildings. Double-circuit - you can heat water for domestic needs. A special feature of the series is electronic ignition. There is ionization control of fire and exhaust gas. There is an anti-scale function. Efficiency 90%.

- Comfort Siberia. Modifications 23, 29, 35, 40, 50 (heat output, kW). Any option is offered - single-circuit or double-circuit. Designed for large rooms.

- Economy Siberia. Produced since 2005. Four models, differing in the number of circuits and power - 11.6 kW and 17.6 kW. The letter “K” in the marking means two circuits. It is possible to switch to liquefied gas - you can insure yourself in case of an accident in the gas pipeline. The cases are covered with enamel, which protects from mechanical damage.

How to fix the ignition yourself

Self-repair of household appliances or their components is a rather risky undertaking, since the likelihood of aggravating the problem is quite high. It is very difficult to repair the electric ignition of a gas boiler without special knowledge and skills. The device may fail due to contact with water or grease, power surges, or neglect.

The main sign of a device malfunction is the absence of a spark. If there is a spark, but the flame cannot be ignited, it is necessary to clean the contact areas of the burner and candle. If the electric ignition unit is broken, you should check the current-carrying paths and winding resistance. When repairing the ignition, new components may be needed.

Diagnostics at the service center

Repair of electric ignition of a gas boiler is included in the list of services of many service centers specializing in the maintenance of household appliances and heating equipment. By contacting qualified specialists, you can count on the fact that device malfunctions will be eliminated as quickly as possible. Reliable service centers that value their own reputation provide customers with a long-term guarantee for equipment repairs.

To determine the cause of a malfunction in the electric ignition of a gas boiler, technicians use modern diagnostic devices. During repairs, specialists use only high-quality original components. In addition, the service center offers to call a technician to your home. This service eliminates the need to deliver a large unit to the workshop yourself.

Repairing a gas boiler may involve replacing the ignition unit, restoring the control unit, eliminating leaks, or installing a new tap. An experienced specialist will be happy to answer all the client’s questions regarding the rules for operating the equipment, and will also tell you how to avoid breakdowns in the future. Service centers offer advice or order a particular service at any time of the day. This can be done by phone or through the website.

Hello, dear readers. What to do if the piezoelectric element in the gas water heater does not work? In what situations can you solve a dilemma with your own efforts? When is it necessary to contact specialists? And how to fix the problem in Amina, Zanussi cash advance businesses and other brands?

This material examines the reasons for the failure of a piezoelectric element in a gas apparatus. Cases with models of different brands are reflected. Methods for solving this problem are provided.

AGV heating of a private house is convenient, warm, inexpensive

Today, gas heating remains the most economical way to heat a house and provide hot water for household needs. And although modern gas boilers are more economical and easier to use, many homeowners continue to use traditional AGVs or install their newer modifications. An automatic gas water heater is used in central water heating systems in single-story and low-rise buildings.

AGV boiler

It can be single-circuit - only for heating, or double-circuit - for heating and water heating. Its modern modifications (AOGV and AKGV) are structurally different from the old model. Therefore, when replacing an old unit with a new one, as a rule, it is necessary to modernize the home heating system (for example, change pipes and / or radiators, etc.). A compromise could be the AOGV of the Italian company Beretta, which is manufactured specifically for the CIS countries according to “Soviet” GOSTs.

Operating principles of AGV

So, AGV heating - what is it and how does the boiler itself work? In its design, the simplest gas hot water boiler resembles an ordinary samovar. Its main part is a tank made of three-millimeter galvanized sheet steel, placed in a casing. A fire tube (heat exchanger) is mounted inside the tank, which is heated by natural gas burning in the combustion chamber. The water heated by the heat exchanger goes into the heating system, and combustion products are discharged through the chimney.

The boiler is equipped with a thermostat - it automatically turns on and off the gas supply magnetic valve, maintaining the desired water temperature. Warm water is lighter than cold water, so it rises through the pipes to the radiators, and when it cools in them, it returns to the tank for heating. This is how a heating system with natural (thermosyphon) water circulation works. With forced circulation, the circulation of water in the pipes is accelerated by the electric circulation pump that forces it.

The safety of the gas boiler is controlled by simple but effective automation. If the burner flame goes out or the pressure in the water line drops, the gas supply stops. It turns off if the draft in the chimney is disrupted (for example, if it is clogged).

Advantages and disadvantages of AGV heating

Among the main advantages of traditional AGW heating is the low price of the boiler itself, especially in comparison with imported water heating units, and its efficiency. The energy consumption of the circulation pump is low (with a power of 48 kW per month - approximately 34-35 kW). You can reduce energy consumption by installing an automatic system on the boiler to turn off the pump at a time when water is not heated. Thanks to its simple technical design, AGV is inexpensive to repair and maintain.

However, the AGV water heater is inferior to modern boilers in terms of efficiency and ease of use. In addition, it is massive, and since it exists only in a floor-standing version, it takes up quite a lot of space. The AGV heating system uses large diameter pipes, so the house takes a long time to warm up and takes a long time to cool down. This is not very convenient in the off-season - spring and autumn.

AGV in city apartments

Boiler room

Today, many people would like to refuse the services of a centralized heating network and equip their apartment with AGV heating. However, the transition to autonomous boilers is not possible in all buildings. It is easier to obtain permission to install an autonomous boiler in low-rise old houses, where chimneys of the required diameter have been preserved from the time of stove heating, and where the diameter of the underwater water pipe allows this.

In some cases, in houses where there are no chimneys, it is allowed to install so-called “attached chimneys” (they are brought out through the wall). If central heating pipes are abandoned, they are thermally insulated with special casings. However, with rare exceptions, Russian legislative standards do not allow the transition to autonomous heating and hot water supply in multi-storey buildings.

Methods for troubleshooting geysers

Geyser "Vector" is one of the most popular in Russia. This is evidenced by sales statistics.

When the piezoelectric element does not work in the Vector gas water heater, a spark does not appear and the burner does not ignite. The reasons for the problems are:

- Lack of draft in the chimney. It could simply be clogged and need to be cleaned. There is a special sensor in the column that monitors the presence of traction. If it is not there, it will not start working. If you cannot do this yourself, it is better to call a special service.

- No water pressure. If the water pressure is very good, then it affects the membrane, which presses on the valve. Very low pressure may indicate problems with the membrane or that the filter is clogged.

Solution: You need to disassemble the filter and wash it under water, and it is best to replace the membrane as it becomes damaged over time. You can do this yourself.

- The nutrient element is not working. Ignition is done using batteries, without which there will be no current to create a spark. You need to remove the panel, then take out the battery pack, pull them out and insert new ones.

Burners for universal equipment

Gas burners intended for solid fuel heating boilers have a complex design. They are intended for converting heating appliances from one type of fuel to another. Thanks to the special design, after purchasing a universal unit that runs on wood, when a gas main appears in a populated area, it can be converted to operate using natural gas.

They produce automatic gas burners for solid fuel appliances in accordance with the fan circuit. After supply, the gas is mixed with air, and then the prepared fuel-air mixture is sent to the nozzle. Here it is ignited, and a flame of high temperature is formed.

An automation system, a powerful fan, a special filter and a gearbox are mounted on board the gas burner. For the unit to function, a power supply is required. The device itself has a modular (removable) design.

An example of such a device is a product for Cooper boilers. The device itself is pellet, but it can be converted to natural or liquefied gas if a replacement burner is connected to it.

There is a spark, but no ignition

When this dilemma arises, the following factors appear:

- The valve responsible for the gas supply is closed. Measure - twist it all the way.

- Low water pressure. It may be not only in the main line, but also at the inlet section of the boiler, where the filter may become clogged.

- The water is slightly fixed annuity interest rate heated. Solution: cleaning the heat exchanger (HE). Fastenings on which plaque has accumulated can be cleaned using VD-40, and the radiator can be placed in a basin with a composition based on citric acid. Then heat on the stove for half an hour until the scale disappears completely.

- The burner is clogged. Sometimes a lot of soot and soot appear in the jets. You can get rid of it using a thin copper wire.

If the piezo did not work in the Electrolux geyser or other similar equipment, then you should periodically check it for gas leaks using a soap emulsion. If there are no bubbles, then everything is fine.

Operating principle of the boiler

Gas is used not only for space heating, but also for heating water. For this purpose, either water columns or double-circuit boilers are used. The equipment used these days is equipped with highly effective safety systems - they keep the gas combustion process under control. But, nevertheless, there are mandatory rules for the use of gas equipment and compliance with them can become a guarantee of safety.

Before putting the equipment into operation, the user must ensure:

- There is the required amount of working fluid in the heating system.

- The fact that the burner and safety valve are in working order.

- Measuring instruments show correct data.

- The operating temperature of the boiler device should not fall below 65 degrees. This may lead to condensation.

Lights up and goes out immediately

The reasons for this problem are:

- Weak traction. The chimney needs cleaning. If there is poor ventilation in the kitchen, then you need to open the windows or install a ventilation valve on the window frame.

- The ignition button is pressed poorly. It needs to be held for 20 to 30 seconds.

- The sensor that removes combustion products does not work. This can be found out using a multimeter. If the sensor is working, there will be a sign on the screen indicating infinity.

- Mixing streams. You need to set the regulator to a constant normal temperature.

- High pressure in models with low power. Set water parameters as indicated in the instructions.

- Systematic switching off of the overheating sensor. Solution: replacing it.

- Adjust the igniter. Disconnect the electrode from the igniter so that the spark is in the central part of the burner. Inspect and test the tube connections for leaks.

If ignition is delayed, clean the burner. There is a high probability that soot and soot have accumulated in it. The problem may also lie in the microswitch.

Installation

The kit comes with a passport and instructions. The latter is necessary to familiarize yourself with the device, operating principle and rules for using the boiler. After reading the instructions, the user will be able to find out how to turn on the device. It is advisable to entrust the installation to specialists. Installation features:

• Registration of permission for installation - from gas workers.

• Installation is carried out by specialists with a license for the relevant work.

• The kit does not include an expansion tank and a circulation pump - you will have to buy them additionally.

• The device is placed against the wall, so you must leave a gap - at least three centimeters.

• For surface mounting, the device requires a foundation. Usually it is made of brick. Wall-mounted models are firmly fixed.

• There must be no gas leakage during connection. Connections must be carefully insulated.

• If you start the device for the first time, condensation will accumulate on the heat exchanger, which will disappear when the system warms up.

The advantage of domestic speakers

There are many types of faults, so it is easier to find domestically produced parts. Therefore, speakers made in Russia, such as Neva, are in great demand.

And the newer model “Neva 4511” consumes even less gas and is completely silent.

A gas water heater called “Oasis” is in demand, which can operate at low pressure and is protected from scale.

It is also equipped with a safety system that blocks operation if the column overheats.

Maximum pressure switch (gas)

Relay devices for maximum gas pressure are designed to protect boilers from possible overheating or from the danger of destruction due to an uncontrolled increase in pressure on the burner. This can lead to an increase in the size of the torch itself and ultimately to burnout of the combustion chamber, which is not intended for this. In addition, gas valves may not close as gas pressure increases. A rise in pressure can also be caused by a breakdown of the gas fittings on the supply line.

The relay is connected in series with the minimum pressure switch in the electrical circuit. This is done in such a way that the operation of any of them somehow turns off the boiler. The design of the relay is similar to the first one.