Gas boilers from the Slovak brand Protherm are in demand due to their reliability, high quality and wide range of models. The devices are actively used by owners of private houses, industrial and domestic facilities. With their help, you can heat the room in a short time.

Some models are equipped with water heating elements, which increases their functionality.

It is important to choose the right gas boiler based on your needs. An overview of the features of popular models and reviews from owners will help with this.

The lineup

It should be noted that Protherm gas wall-mounted and floor-standing boilers are available in different modifications.

Therefore, it is worth considering widely used models in more detail. Among the wall ones is the Jaguar model. The boiler is used for heating country houses and cottages, the area of which does not exceed 220 sq.m. It also provides the organization of hot water supply. Heat exchangers are separate. The equipment mainly runs on main gas. Although the unit can be converted to run on liquefied fuel. For this you will need to buy a set of jets.

The technical characteristics of the Proterm Jaguar wall-mounted gas boiler are as follows: closed combustion chamber, efficiency is 90.2%, maximum net power is 25.3 kW, minimum net power is 10.5 kW, power consumption is 98 W, liquefied gas consumption ranges from 2.73 cubic meters/hour to 1.02 kg/hour.

The Panther model is also widely used. Hydraulic blocks of boilers are made of composite materials. This allows the strength of the structure to be increased significantly. The unit is equipped with a tank and pump. There is a “Comfort” option, which allows you to heat the water in just 5 seconds. Equipment power ranges from 12 to 35 kW. Many owners prefer to install a Protherm Panther 30 ktv gas wall-mounted boiler in their home to create an effective heating system.

The Lynx model is also chosen by many users. The series is characterized by two separate heat exchangers. It is possible to separately regulate the temperature level in each of them. There is an expansion tank with a volume of 7 liters. The Proterm double-circuit gas wall-mounted boiler is also equipped with a circulation pump. There are two versions of devices: with a power of 24 kW and 28 kW.

Among the floor-standing modifications are the “Bear” series of gas boilers. This is a single circuit type. Power is 18-44.5 kW. It can operate on main gas or liquid fuel. No electrical connection required. Most often used for heating industrial buildings. You can learn more about this model from our article “Gas boiler Proterm Bear - model range and advantages”

The Grizzly model is also widely used. The series is easy to operate. Designed for heating structures with an area of up to 15,000 sq.m. Productivity is 150 kW. Operates on main gas. It is considered the most environmentally friendly equipment among boilers with similar power. But this series is dependent on the power source. There are also floor-standing models “Wolf” and “Beaver”.

To summarize, we can say that Proterm gas boilers are widely in demand among domestic consumers. All products are distinguished by high performance characteristics, reliability, durability, and at the same time, affordable prices. Which model to choose depends on the parameters of the heated room and the preferences of the owner of the house.

Prevention recommendations

Maintenance by service center

Every year, preferably before the first turn on after the summer break, it is recommended to invite a specialist from a certified service organization to inspect and test the boiler. During a preventive inspection, the condition of the gas burner is checked, the power is adjusted, and the burner nozzles and heat exchangers are cleaned. A particularly important part of the inspection is checking the operation of the emergency thermostat and the combustion chamber thermostat.

Attention! When cleaning gas burner nozzles, under no circumstances should their internal diameter be allowed to change!

Boiler user maintenance

Cleaning the unit lining without removing the protective casing. Must be carried out after disconnecting the device from the network. Power supply is allowed only after complete drying.

The water pressure in the heating circuit must be checked weekly. If necessary, top up after the unit has cooled below 400°C.

It is necessary to regularly, at least once every three months, check the tightness of the connections of the chimney system, the cleanliness of the filter and mud pan, and remove dirt if necessary.

If a gas leak is detected, the device must be immediately turned off, the gas valve closed and a service specialist must be called. It is not recommended to repair the unit yourself. For example, the instruction manual for the Cheetah wall-mounted double-circuit gas boiler manufactured by Proterm does not recommend trying to fix faults yourself, so as not to lose the company’s warranty.

Benefits of operation

Installation of a floor-standing chimney boiler

If for other brands of boiler equipment produced earlier, it was mandatory to install a chimney and a separate room for a gas boiler, now such requirements are not relevant. The design of modern units produced by Proterm initially includes a coaxial chimney. And they can be located anywhere in the living space.

Important! Changes in gas pressure in main pipelines are controlled by special automatic devices. They prevent gas from entering the room if the burner goes out

Boilers can have different power levels, so they can heat both small houses and spacious mansions and cottages.

In the designs of heating units of previous times, only atmospheric burners were used. And gas boilers had to be installed in separate rooms with a chimney and its own exit to the street.

Currently, gas equipment is produced with burners of a completely different type, for which such requirements are not imposed.

Proterm heating gas boilers are equipped with all the attributes of safe operation. Despite the fact that gas equipment is manufactured outside of Russia, namely in Europe, it is adapted to Russian conditions - especially to uneven pressure in main networks. Therefore, calls to use only domestic gas boilers have no basis in reality.

Reviews

- Andrey G. “I built a house, winter is just around the corner, I need something to heat it. I wandered around the Internet, read reviews, and decided to buy a boiler from the Slovak company Proterm. I chose the wall option based on the area of the house. The boiler with the beautiful name Cheetah model 23 MTV was the best choice. Well what can I say? It is controlled very simply with three buttons. The instructions are very clear and explain everything in detail. It makes a little noise, but it doesn't interfere with falling asleep. Very compact. Maintenance is very simple - just occasionally clean the dirt filter and wipe the dust from the boiler. It performs its functions without any problems. I didn't notice any shortcomings. I recommend".

- Vasily V. “I decided to change my old gas water heater. And since in severe frosts there is often not enough heat from the stove, I decided to install a modern gas boiler with the ability to heat water. The choice was determined only by price. I took an inexpensive Jaguar 11 JTV from Proterm. The boiler turned out to be surprisingly silent, with a beautiful design. In 2 years it has never broken down. There are no shortcomings."

- Vladimir U. “I have been working for 11 years in a service center servicing heating boilers, including gas ones. During this time, we had to install and repair all types of boilers from all companies that are sold in our stores. I can’t say anything bad about Proterm gas boilers. With proper installation and proper configuration, they work like a clock. But if the service specialists have neither the skills nor the experience, or the owners adjusted something on their own, then problems in the work and, as a result, bad reviews are inevitable.”

Types of Proterm boilers

The Proterm line of boilers includes models running on gas, electricity and solid fuel

Protherm heating equipment is a device that runs on various types of fuel: gas, electricity, coal. They are designed for heating apartments, private houses, office and commercial premises. The company's factories produce boilers for floor and wall mounting, as well as high-power units. All products undergo strict quality control. Before being put into production, models are tested in the laboratory.

Electrical

The Skat series is an alternative to gas equipment; it includes 8 models with a power from 6 to 28 kW. The electric boiler is designed for connection to a 220 or 380 V network. The equipment heats the coolant to 85°C, the installation efficiency is 99%. Among the advantages of electric boilers:

- No connection to a chimney is required, the equipment does not emit combustion products.

- The compact boiler fits into any interior.

- High performance.

- Possibility of programming control of heating medium heating temperature.

- When installing electrical equipment, fewer requirements are imposed than when installing gas boilers.

Electric wall-mounted boiler Proterm Skat - economical, does not emit combustion products

The unit is manufactured with wall mounting. Its functions include:

- Diagnosis of breakdowns using error codes.

- Pump and valve blockage protection.

- Protection against freezing, pressure drop.

Gas

The equipment heats water for heating and domestic needs of house residents. Several series are offered, differing in the method of installation and heating. The product line includes:

- Single-circuit installations - heat water in the heating system. They are designed for houses up to 350 sq.m.

- Double-circuit models - in parallel with heating the premises, the boiler provides the owners with hot water.

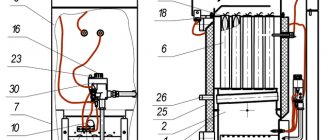

Floor-standing gas boilers differ in the design of the combustion chamber - open and closed

According to the type of combustion chambers, the equipment is presented in two types:

- Open - with a chimney and natural draft.

- Closed - a fan is used to force smoke out.

The equipment runs on main and liquefied gas. A distinctive feature of the units is the expanded functionality of the settings. Some models can be connected to the “smart home” system; it is possible to install low-temperature operation for heated floors.

Solid fuel

The units operate on coal and wood and are designed to heat rooms up to 500 sq. m

The Bober series are cast iron boilers for heating residential and industrial premises. A special feature of the equipment is the large area of the heat exchanger covering the entire firebox. Pros of the series:

- energy independence;

- durability;

- ease of operation;

- safety.

The unit runs on coal and wood. Its disadvantage is the need to add fuel every 2-4 hours. Non-volatile floor-mounted boilers. Their power ranges from 19 to 48 kW. They are designed for heating rooms ranging from 190 to 480 square meters. m.

Types of heating equipment

Gas heating equipment is designed to produce heat for space heating through the combustion of gaseous fuel and heating of the coolant, which is water. Gas (propane and methane) is the most affordable and efficient type of fuel.

The consumer is interested in high-quality and inexpensive gas equipment that will provide reliable protection from the cold and will reduce the consumption of natural gas consumed.

Protherm products meet these requirements.

- The principle of operation of a gas boiler is to supply fuel to the burner, which is ignited using an igniter connected to a piezoelectric ignition.

- Therefore, they are installed in places where power outages are excluded and its supply is stable.

- Piezoelectric ignition ignites the igniter, which starts the burner. The pilot light must be lit constantly, otherwise the boiler will not start.

A special feature of gas boilers is the mandatory presence of a chimney, which removes combustion products dangerous to people and provides air supply to the burner.

Why exactly Proterm boilers?

Proterm is a Czech brand that has gained a positive reputation in the domestic market of heating devices. The Protherm company produces modern gas heating boilers with excellent operational and technical performance. In terms of quality and characteristics, the products are not inferior to Asian and European analogues. Therefore, Proterm boilers are widely in demand among consumers.

The Proterm heating boiler is unique in that each device is assembled by one worker. The principle of personal responsibility comes into play here. The company produces floor and wall heating equipment, cascade boiler modules, and boilers. Having studied the reviews of Protherm gas boilers, we can safely say that the equipment is very popular and has gained trust among users. Buyers note the high quality, ease of maintenance, reliability and durability of units produced by Proterm. Boiler heating at home is an ideal option for the private sector.

The excellent quality and reliability of Proterm boilers is achieved thanks to:

- the presence of 7 production lines: one line for the production of high-power boiler appliances, three for the production of floor-standing types of units and three more lines for the production of wall-mounted gas boilers;

- output control of boiler devices is carried out on each production line;

- More than 200 types of components from European manufacturers are used in production;

- planning and management of the production process is carried out using the SAP information system;

- equipment is subject to annual testing in foreign laboratories. Also, the quality management system is checked every year by the organization “Bureau Veritas Quality International”;

- before putting the boiler into production, it is subject to rigorous testing for reliability and durability;

- safety elements and control units are carefully checked for each gas boiler;

- Every day, about 2% of manufactured products are subject to detailed testing;

- The technological base is constantly being modernized and improved.

Despite the European quality, the price for the Proterm gas boiler is quite affordable. The product range is quite wide and is represented by different models.

Advantages and disadvantages

The advantages of Protherm floor-standing gas boilers can be considered:

- High power, reliability, resistance to gas and water pressure changes.

- Ability to service large premises.

- Powerful installations can be assembled in cascades, creating high-performance systems capable of heating multi-story buildings or other large areas.

- The design of floor-standing models includes cast iron components, making heat transfer more efficient.

- There is a wide choice of power or model configurations.

The disadvantages of floor-standing boilers are:

- The dimensions of the devices are noticeably increased compared to wall-mounted units.

- The weight of floor-standing boilers is large, which makes transportation and installation difficult.

- The price of floor-standing boilers is noticeably higher than the cost of wall-mounted models.

IMPORTANT! An exception is the floor-standing Wolf series. These boilers will cost only 18-20 thousand

rub., but they are, in fact, one burner combined with a heat exchanger in the housing.

About the manufacturer

The Proterm company traces its history back to 1991, when the first floor-standing gas heating boilers were produced in Prague. And already in 1996 they appeared on the Russian market.

The high quality of the company's products is due to the introduction of the One-Piece-Flow program into high-tech production. This means that any product from the beginning until delivery to the control department is assembled by one master. And it is he who is responsible for all problems that occur with this equipment during the warranty period.

This turned out to be a good incentive to ensure high quality products. Now the company occupies a leading position in the global heating equipment market, producing more than 2 thousand gas boilers of various types per year.

The product range includes about 95 items:

- gas boilers for liquid and solid fuels

- electrically powered units

- boilers

- water heaters

- equipment for residential buildings and industrial enterprises

- accessories for heating systems and much more

All equipment is tested for quality and compliance with all standardization and environmental requirements.

Service of PROTHERM boilers

has been a trading and service partner of the PROTHERM brand in St. Petersburg and the Leningrad region since 2000. Our company represents on the market the entire model range of PROTHERM boilers of industrial and household series. We provide a full range of services from selection of equipment to its installation and commissioning. The company's staff includes certified commissioning engineers who have been trained at PROTHERM service centers, which allows for warranty and service maintenance of any PROTHERM boilers, as well as the supply of spare parts for them. We accept PROTHERM boilers sold by other organizations for service. Carrying out repairs and maintenance of PROTNERM boilers for more than 16 years, we have accumulated extensive experience in solving various technical problems. We will be glad to see you among our clients!

PROTHERM service center certificate | VAILLANT service center certificate |

Popular models

The company's product range includes electric and gas heating equipment of various capacities. Among the most popular modifications:

Cheetah

The wall-mounted version is equipped with a stainless steel heat exchanger. This is a 23 kW model. The operation of the system is automated and can be carried out using a temperature sensor. The compact housing allows the unit to be installed in apartments and cottages. The Cheetah boiler is available with forced and natural removal of combustion products.

Bear

The Bear series consists of several modifications:

- TLO is a low temperature boiler with a cast iron heat exchanger. The model does not need to be connected to electricity; it is equipped with piezo ignition.

- KLOM is a floor-mounted stationary unit with a modulating burner. The boiler has an electronic ignition system and operates according to a given temperature schedule.

- PLO - the unit is equipped with an injection burner to change the water temperature. There is a step switch on the panel. The display shows the temperature and pressure in the heating system.

- KLZ - the boiler has a built-in 90 liter boiler and electronic burner ignition. The power can be adjusted from 70 to 100%. The equipment has a self-diagnosis function.

Wolf

Single-circuit boiler with steel heat exchanger. The model is attractive due to its energy independence and affordable cost. It is recommended for private houses and cottages. A piezoelectric element is provided to ignite the burner.

Bear

Wolf

Cheetah

Tiger

The double-circuit unit with a built-in boiler is equipped with a function for controlling temperature and water supply speed. Models are available with a power of 12 and 24 kW. Equipment power 24 and 28 kW. Mode selection, operation control and possible errors are displayed on the LCD screen. Seasonal programming allows you to save fuel.

Lynx

A gas boiler is suitable for rooms where there is no chimney. It is equipped with a system for forced removal of combustion products. The series is distinguished by its compact design and affordable price. The unit operates in two modes: “Comfortable” and “Economical”. It has a hot water preparation function. The heating equipment is equipped with a circulation pump and an expansion tank.

Panther

The series is intended for heating systems with forced circulation of coolant. These are mounted boilers made of durable composite materials. The power of the models ranges from 12-35 kW. Panther comes with an open and closed combustion chamber, condensation and convection type. The water heats up to the set temperature in a few seconds.

Tiger

Panther

Lynx

Scat

Scat

An electric boiler is a reliable heating equipment for a home, cottage or apartment. Skat models are characterized by high performance and ease of maintenance. New from 2022 - built-in storage boiler. The single-circuit boiler has a self-diagnosis function; it is completely protected from overheating and pump jamming.

Technical characteristics of boilers

Each model of heating equipment has its own operating characteristics, but there are common parameters:

- Equipment efficiency is 90-107%.

- Installation type – wall, floor.

- Type of fuel – gas (liquefied or main), diesel, electricity, solid fuel.

- Power – 12-150 kW.

- Option – heating water in a boiler.

- Protection against overheating and freezing.

- Built-in circulation pump.

- Electronic control.

All equipment has protective functions to ensure safe operation. Gas boilers are equipped with control modes - summer-winter.

Popular models

The company's product range includes electric and gas heating equipment of various capacities. Among the most popular modifications:

Cheetah

The wall-mounted version is equipped with a stainless steel heat exchanger. This is a 23 kW model. The operation of the system is automated and can be carried out using a temperature sensor. The compact housing allows the unit to be installed in apartments and cottages. The Cheetah boiler is available with forced and natural removal of combustion products.

Bear

The Bear series consists of several modifications:

- TLO is a low temperature boiler with a cast iron heat exchanger. The model does not need to be connected to electricity; it is equipped with piezo ignition.

- KLOM is a floor-mounted stationary unit with a modulating burner. The boiler has an electronic ignition system and operates according to a given temperature schedule.

- PLO - the unit is equipped with an injection burner to change the water temperature. There is a step switch on the panel. The display shows the temperature and pressure in the heating system.

- KLZ - the boiler has a built-in 90 liter boiler and electronic burner ignition. The power can be adjusted from 70 to 100%. The equipment has a self-diagnosis function.

Wolf

Single-circuit boiler with steel heat exchanger. The model is attractive due to its energy independence and affordable cost. It is recommended for private houses and cottages. A piezoelectric element is provided to ignite the burner.

Tiger

The double-circuit unit with a built-in boiler is equipped with a function for controlling temperature and water supply speed. Models are available with a power of 12 and 24 kW. Equipment power 24 and 28 kW. Mode selection, operation control and possible errors are displayed on the LCD screen. Seasonal programming allows you to save fuel.

Lynx

A gas boiler is suitable for rooms where there is no chimney. It is equipped with a system for forced removal of combustion products. The series is distinguished by its compact design and affordable price. The unit operates in two modes: “Comfortable” and “Economical”. It has a hot water preparation function. The heating equipment is equipped with a circulation pump and an expansion tank.

Panther

The series is intended for heating systems with forced circulation of coolant. These are mounted boilers made of durable composite materials. The power of the models ranges from 12-35 kW. Panther comes with an open and closed combustion chamber, condensation and convection type. The water heats up to the set temperature in a few seconds.

Scat

An electric boiler is a reliable heating equipment for a home, cottage or apartment. Skat models are characterized by high performance and ease of maintenance. New from 2022 - built-in storage boiler. The single-circuit boiler has a self-diagnosis function; it is completely protected from overheating and pump jamming.

Criterias of choice

Boilers with cast iron parts last longer than steel ones.

When choosing heating equipment, several basic requirements are taken into account:

- Power is the main indicator of heating equipment. The manufacturer indicates the area for which its products are designed. When choosing a dual-circuit model, an additional 30-40% of power is provided.

- Fuel type – natural gas is the most convenient and economical heating option. If it is unavailable, electricity and solid fuel are considered.

- Purpose - the number of circuits depends on the requirements for the equipment - one is enough to heat the premises, and with two you can use hot water.

- Placement option - equipment can be wall or floor mounted. The choice depends on the available space in the room.

- Gas pressure - this parameter is important to ensure uninterrupted operation of the boiler.

- Heat exchanger material – cast iron elements last longer than steel parts.

- Type of ignition - piezo ignition is possible without electricity, but more gas is consumed. Electronic ignition is volatile.

When choosing equipment, the reputation of the manufacturer plays an important role. The Proterm company is one of the most respected and well-known companies producing thermal equipment.

The Gepard boiler has two smoke exhaust modes

The line includes two heater models:

- with natural smoke exhaust 23 MOV;

- with forced smoke exhaust 23 MTV.

This information about the Proterm Cheetah boiler can be found in the instructions. In units with natural draft, the combustion chamber is open type, that is, not sealed. The air for the flame in such heaters comes from the room in which it is installed (more precisely, hung on the wall, since they are all wall-mounted). This is neither good nor bad. You just need to ventilate the room more often. Such boilers require a stationary chimney. We have already written about how to install a chimney for a gas boiler, so we will not repeat ourselves.

It doesn’t matter if it is not possible to install a stationary chimney, because... for units with forced smoke removal it is not needed (see Chimneyless boilers). Such Gepard boilers are called coaxial. The smoke exits through a coaxial pipe. She is taken outside directly through the wall, which is very convenient. The advantage of a coaxial chimney is that it not only removes smoke, but also supplies oxygen to the combustion chamber. By the way, it is sealed in such units.

The circulation of gases in the coaxial chimney (in both directions) is forced. A fan installed above the combustion chamber is responsible for this. It operates from the network, so such boilers consume more electricity.

Each model has several options

Traction types:

- With natural draft provided by the chimney through the installed pipe. Air is supplied to the burner by taking it from the boiler room.

- Forced draft in the boiler is obtained using a built-in fan in the air ducts of a coaxial or separate chimney.

According to the use of combustion heat:

- Convection gas boilers use only the lower calorific value, which is formed when burning fuel, and the heated water vapor is removed along with the waste combustion products through the chimney.

- Condensing devices use higher calorific value during operation, which significantly increases their efficiency, efficiency increases to 92-93%, and gas consumption is reduced. The heat of steam is included in the process of heating the coolant.

The best wall-mounted gas boilers

This section presents single-circuit room heating systems placed on the wall. They are compact and easy to maintain, although they have some limitations in functionality.

Viessmann Vitopend 100-W A1HB003

4.9

★★★★★ editorial assessment

89% of buyers recommend this product

The A1HB line includes three boilers with a capacity of 24, 30 and 34 kW. This is enough to heat a home with an area of up to 250 m2. All cases are equally compact: 725x400x340 mm - such units have a place in any room.

Viessmann boilers are assembled on a single modular platform, which simplifies their installation and maintenance. In addition, there is no need to leave additional space near the body, so any Vitopend can be combined with kitchen furniture if there is a free corner for it.

Advantages:

- Low gas consumption - no more than 3.5 m3/h in the older model;

- The valve body is equipped with quick-release connectors;

- Automatic power adjustment depending on the outside temperature;

- Efficiency up to 93%;

- New coaxial chimney system with frost protection;

- Intelligent control with self-diagnosis function;

- Possibility of switching to liquefied gas.

Flaws:

There is no remote control panel.

Viessmann provides the opportunity to choose a boiler for an apartment of any size. The appearance and dimensions for the entire line are absolutely the same - the models differ only in performance and, accordingly, gas consumption.

Baxi Eco Four 1.24 F

4.8

★★★★★ editorial assessment

88% of buyers recommend this product

See review

Despite the prestige of the brand, the Eco Four model is relatively inexpensive. The boiler has a flat body measuring 730x400x299 mm, which allows it to be hung flush with kitchen cabinets. When used in northern latitudes, such a unit can heat an apartment up to 150 m².

Fourth generation boilers were developed taking into account our operating conditions. That is why the presented model operates even when the inlet gas pressure is reduced to 5 mBar. In addition, it has two separate thermostats: for heating radiators and for the “warm floor” system.

Advantages:

- Built-in water flow meter;

- Pump with air vent and post-circulation mode;

- It is possible to connect to solar collectors;

- Dual-mode thermal control;

- Pressure switch for protection against low coolant pressure;

- You can connect a remote thermostat and remote control.

Flaws:

Low-informative built-in display.

As for Baxi, Eco Four's price is very attractive. In addition, this is an excellent solution for placement in a small kitchen or studio apartment.

Vaillant AtmoTEC Plus VU 240/5-5

4.7

★★★★★ editorial assessment

87% of buyers recommend this product

This boiler has all possible means of protection: gas control, pressure switch with safety valve, pump air vent. Here, overheating of the medium and combustion chamber, freezing of liquid in the system and in the chimney are completely excluded. The built-in auto-diagnostics helps monitor the correct operation of all systems.

AtmoTEC is adapted for operation in Russia: it takes into account the low quality of main gas and can operate on LNG. The programmer control is fully automated, and the panel itself is covered with a neat decorative cover.

Advantages:

- Volumetric expansion tank 10 l;

- Low gas consumption – 2.8 m³/h (or 1.9 m³/h when connected to a cylinder);

- Almost eternal chrome-nickel burner;

- Possibility of combination with other heaters;

- The minimum side clearance during installation is 1 cm.

Flaws:

Classic (atmospheric) chimney.

The boiler dimensions of 800x440x338 mm and a maximum power of 36 kW are more suitable for a private home than for a city apartment. Although in a spacious kitchen there will be no problems with its placement.

Service and care

- Image

- Text

11

interval of at least 1 minute or a drop in coolant temperature by 8°C.

Note:

If the boiler was turned off by a command from the room regulator, this restriction does not apply.

overheat protection

The overheating protection function turns on the heating pump when exceeding

the value of the water temperature in the heating system set by the user or if the temperature of the coolant in the boiler exceeds 85°C. If the temperature of the coolant in the boiler exceeds 90°C (fault F3), the boiler will automatically turn off.

Starting the pump depending on the coolant temperature

The boiler control system allows you to set the start time of the heating pump depending on when the boiler reaches a certain temperature. This temperature can only be set by an employee of an authorized service center.

Chimney draft control system

The boiler is equipped with a chimney draft control system (SKTD). If there is insufficient draft in the chimney, the flue gas thermostat will work and the boiler will automatically turn off (the gas supply to the boiler will stop).

Power outages

If there is a power outage, the boiler will turn off. When the power supply is restored, the boiler

will automatically turn on without losing the set operating parameters.

If, after the power supply is restored, a fault message appears on the boiler display, unlock the boiler using the RESET button.

Note:

Blocking of the boiler can occur due to its overheating as a result of stopping the pump after a power outage.

The malfunction is eliminated by pressing the RESET button located on the boiler control panel. If the fault cannot be resolved in this way, you must contact an authorized service center.

Warning:

All specified protective functions are valid only if the connection to the electrical network is correct (correct connection of the phase, neutral and ground wires) and the main switch is in the switched position (position ON (I)).

Heating safety valve

The boiler is equipped with a 3 bar safety valve. The safety relief valve is activated if the operating pressure of the coolant in the heating system is exceeded and protects the boiler from hydraulic damage.

Provide a relief line to the safety relief valve in accordance with applicable codes and regulations.

It is strictly forbidden to service the safety valve by persons who are not employees of specialized service organizations! If the safety valve trips, you must turn off the boiler and contact a service organization.

Service and care

Boiler care by the user

If necessary, you can clean the front panel of the boiler without removing it. Cleaning is carried out after disconnecting the boiler from the electrical network (necessary

turn the power switch to the “off” position). If moisture gets on the front panel, restarting the boiler is possible only after it has completely dried. Blood pressure needs to be monitored periodically

Device series

The boilers are presented in two lines - Protherm Capybara Solient Plus and Protherm Beaver DLO.

The first product line represents classic models of solid fuel boilers.

Has features:

- power when working on wood can be from 13 to 48 kW, on coal - from 17.5 to 70 kW;

- suitable for installation in private homes, dachas, and any other objects;

- three-way horizontal circulation of flue gases determines the high efficiency of such installations;

- easy maintenance, attractive design;

- uniform, rapid heating of the area is observed, without heat loss.

Well-known models of the Protherm Capybara Solient Plus boiler group:

- Solient Plus 3. This is a lightweight version of a three-section heat exchange unit. Thermal power when operating on coal is 17 kW, on wood – 13 kW. Heating temperature from 30 to 90 degrees;

- Solient Plus 4. Four-section heat exchanger. Thermal power 25 and 17 kW. Temperature range - from 30 to 90 degrees;

- Solient Plus 5. Durable unit with five heat exchanger sections. Thermal power 34 and 23 kW. Temperature - from 30 to 90 degrees;

- Solient Plus 6. Number of sections - 6. Thermal power - 46 and 30 kW. Temperature - 30-90 degrees;

- Solient Plus 7. Number of sections - 7. Thermal power - 58 and 38 kW. Temperature - 30-90 degrees;

- Solient Plus 8 - Number of sections - 8. Thermal power 69 and 48 kW. Temperature - 30-90 degrees.

The body of the models is made of cast iron, and the ash pan is made of stainless steel.

IMPORTANT! Equipped with a thermomechanical regulator for power adjustment, as well as automatic overheating protection.

The Protherm Beaver DLO boiler line has the following features:

- the housing and heat exchanger are made of cast iron;

- the heating temperature is changed by a mechanical regulator;

- the presence of a large combustion chamber;

- high efficiency due to the removal of combustion products naturally through a horizontal air duct;

- acts as an independent heat source or as an addition to more powerful equipment;

- there are combined models that use solid fuel and gas, or electricity;

- power - from 18 to 48 kW.

Models differ in thermal power, water tank volume, size and price.

They are considered more advanced units due to the presence of:

- chimney dampers. It allows you to adjust the draft, change the combustion rate and heat transfer power;

- thermal pressure gauge on the front panel;

- a special regulator that prevents hot fuel from entering the room;

- attractive design. Any model (DLO 20, DLO 30, DLO 40, DLO 50, DLO 60 - they will be described below) will become the highlight of the room.

Instructions for setting up, connecting and starting

After delivery of the boiler, it is installed on a pre-selected surface. The delivery set includes a special bracket that is mounted on a solid wall. Installation on surfaces covered with plasterboard, thin or temporary partitions with low load-bearing capacity is not allowed.

After installation, all relevant pipelines are connected:

- Gas supply.

- Forward and return lines of the heating circuit.

- Cold water supply.

Work on connecting all communications must be carried out carefully, in compliance with all technology requirements.

Gas pipe connections are checked for leaks using a soap solution. After this, the boiler is connected to the power supply network.

It is necessary to control the correct connection of the phase to the corresponding electrode, otherwise the boiler will not start.

Filling with water is carried out until the nominal pressure is obtained, which is shown on the display.

The feed tap opens and the system is slowly filled with water so that air has time to escape. After this, the air pockets in the boiler itself and radiators are released, after which the pressure is adjusted again.

The first start of the boiler is a short-term switching on of the unit to check the functionality and correctness of the connection and settings. Detected malfunctions are immediately eliminated, loose connections are carefully sealed.

Sometimes the first launch is immediately interrupted with an error. This is a consequence of an air lock in the pump or other component.

The error is reset and the attempt is repeated again. Sometimes the first start must be repeated several times until the air leaves the pump. .

NOTE! The connection and first start-up must be carried out by service center employees who will correctly set the boiler system settings. Self-tuning and starting the boiler will automatically cancel the warranty agreement and service will be refused.

Classification by installation method

Floor-standing boilers require a separate room with ventilation and a window.

Based on design features, Proterm products are divided into 2 lines: wall-mounted and floor-mounted. Modifications differ not only in the installation method, but also in power, size, and installation requirements.

Wall mounted

Compact wall-mounted models are marked with the names of felines: Cheetah, Lynx, Panther, Tiger, Leopard. They are intended for installation in private houses and apartments. The equipment does not require a separate room. It can be placed in the bathroom or kitchen. Single-circuit and double-circuit models can be supplemented with a boiler. The units are equipped with an expansion tank and have an informative display.

Price range

Most double-circuit boilers belong to the group of wall-mounted devices. Their cost is in the range of 40-50 thousand rubles. for convection and 50-70 thousand rubles. — for condensing units.

Floor-standing double-circuit boilers are noticeably more expensive, which is explained by increased power and structural strength.

The price for such installations reaches 250 thousand rubles. There are often complaints about excessively inflated prices, but it must be borne in mind that all the parts and assembly of the European level cannot be cheap.

IMPORTANT! Prices for Protherm devices belong to the middle segment, accessible to the mass buyer. The cost of most European installations is significantly higher.

Solid fuel – main, electric – backup

If you adopt such a scheme, you will solve several problems at once: you will reduce financial expenses on electricity, increase the time between firing the boilers (this is especially true at night), and protect the heating system from freezing if you have to leave home for a while.

Protherm Beaver as a solid fuel boiler Protherm Skat as an electric boiler . Before describing the entire connection diagram, let’s take a closer look at both boiler models.

Variety of gas equipment Proterm

This manufacturer offers consumers gas equipment of the following modifications:

- Boilers "Gepard". In these wall-mounted units, the coolant moves forcibly.

- Double-circuit devices "Tiger". They are also placed on the wall, but they are equipped with an electronic control system.

- Heating devices “Grizzly” and “Bear” have automatic control of the combustion process and a special ignition system.

- The Lynx and Leopard boilers are equipped with bithermal heat exchangers. They are also double-circuit.

- Wall-mounted “Panther” devices are capable of functioning in closed heating systems.

Price range

Floor-standing gas appliances from Protherm are distinguished by increased power and durability. Cast iron components are used, making the work more efficient. all this affects the cost of the equipment, which differs markedly from the price of wall-mounted models.

The average price starts from 62 thousand rubles, rising to 280 thousand rubles. This range is due to a large range of indicators, mainly power, which reaches 150 kW. However, there is a series of floor-mounted Wolf boilers, non-volatile devices, the price of which is only 18-20 thousand rubles.

These models are designed for heating small rooms, do not have circulation equipment and only work to heat the coolant.

How to connect and configure

Basic conditions for installing gas heating equipment from:

- installation of the boiler and the necessary auxiliary equipment is carried out in accordance with the design documentation, taking into account the requirements of SNiP and the manufacturer’s recommendations;

- installation of equipment is carried out in a room specially designed for these purposes, and in case of special modification of the unit - exclusively in well-ventilated outbuildings;

- the installation and commissioning process is carried out by specialists who have completed a training course in the installation and maintenance of gas equipment;

- any boiler malfunctions are repaired by a service organization authorized by the manufacturer of heating and water heating equipment;

- independent installation work entails deprivation of the consumer's warranty on the unit and its repair;

- When unpacking heating equipment, the supplied boiler must be checked for completeness and compliance with the type of fuel used.

Before proceeding with installation, you must carefully read the instructions supplied with the gas boiler, and during the installation process all recommendations given in the accompanying documents must be followed. Markings on equipment must not be damaged or removed.

Standard technology for connecting and setting up a gas boiler:

- the unit is fixed to the wall using screws with appropriate spacers;

- connection pipes should not be loaded with a pipe heating system, hot water supply system or gas supply elements;

- the installation size of the tube connections, including their height and the required distance from inlet to outlet, must be strictly observed;

- the hydraulic group is placed on the lower part of the gas equipment, and the system is necessarily equipped with a filler valve and safety relief valves;

- when the maximum pressure inside the system is exceeded, steam or water is released from the safety valve;

- connecting the unit to the heating system presupposes the ability to carry out the full scope of maintenance and repair work;

- water is delivered to the heating system via a filling valve, and a drain device is used to reduce pressure or partially drain the coolant;

- special outlets installed in designated areas of the heating system have full drain and fill functions;

- the pressure of hot water supply to the equipment must exceed similar indicators in the heating system;

- in the “Filling” tap position (hydraulic group), the operation of the system must be monitored using a boiler pressure gauge;

- The valve opens counterclockwise and closes strictly clockwise.

Boiler equipment maintenance items covered by the warranty do not include activities such as deaeration and adjustment of the expansion tank.

A little about the Protherm brand

The Czech company protherm was founded in 1991 in Prague and was initially engaged in the manufacture of electric boilers. Growing sales volumes and the need to expand production capacity forces the company to move production to the city of Skalitsa, to a new plant. Let's consider the main stages of development of this company:

- 1994 - the company develops and launches production of its own gas boilers.

- 1995 – entry into foreign markets of Germany and Ukraine.

- 1996 – first delivery of products to Russia.

- 1997 – certification according to European standards ISO 9001.

- 2000 – modernization and expansion of production facilities.

- 2001 – merger with the German manufacturer Vaillant Group. Release of the first condensing unit.

- 2005 – opening of an official representative office in Russia.

Today, protherm heating boilers are produced at three sites. In addition to the plant in the Czech Republic, the company launched lines in Skalice (Slovakia) and Istanbul (Turkey). These production sites produce 95 types of products, including:

- water heaters,

- boilers,

- components and accessories for heating systems.

The main production, of course, is home heating boilers, among which there are:

- electric models;

- solid fuel units;

- liquid fuel devices;

- gas boilers.

Advice! The large model range includes floor-standing and wall-mounted boilers with the ability to heat running water or connect a storage boiler, as well as a single-circuit version.