teplomex.ru

Gas boilers Conord: review, design, automation

It's no secret that imported floor-standing gas boilers are of higher quality compared to domestic boilers.

This applies to the material used to make the elements, the reliability of the automation, and the assembly of the device. However, the price of imported analogues differs noticeably upward. Our task is to find a Russian-assembled gas boiler with an optimal price-quality ratio. I propose to disassemble Conord floor-standing gas boilers, reviews of which can increasingly be found on various thematic forums. Let's consider the model range, technical characteristics, device, types of automation (gas burner devices), using the instructions for use.

Model range and description of Conord boilers

Conord floor-standing gas boilers are available with capacities from 8 to 30 kW. They come as single-circuit: KSts-G-8, KSts-G-10, KSts-G-12, KSts-G-16, KSts-G-20, KSts-G-25, KSts-G-30;

and double-circuit: KSts-GV-10, KSts-GV-12, KSts-GV-16, KSts-GV-20, KSts-GV-25, KSts-GV-30.

Single-circuit ones can only be used for heating from 30 to 300 m2. Conord double-circuit gas boilers can be used for both water heating and hot water supply (DHW).

Floor-standing gas boilers Conord

It is important to note that if you need a double-circuit boiler to fully use the DHW circuit, you need to buy a Conord boiler with a power rating of 20-25 kW. In this case, it will produce about 10-12 liters of hot domestic water per minute

There is no point in buying, for example, a double-circuit boiler KSts-GV-12 with a power of 12 kW. It will not give us a good volume of hot water.

Boilers can be used in both open and closed heating systems.

Installation of floor-standing gas boilers Conord

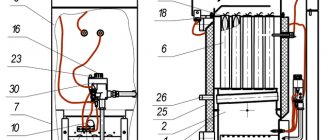

The boiler consists of a steel firebox 3 mm thick, a casing, a water jacket, smoke pipes with turbulators built into them to increase the efficiency of the boiler, a gas burner device (automation), a layer of thermal insulation made of basalt cardboard, and a thermometer to monitor the temperature of the coolant. In double-circuit models, a special coil for the water circuit is installed around the smoke pipes.

The coolant inlet and outlet, as well as the DHW coil, are located on the rear side of the boiler body. The thread diameter of the heating connection pipes for all models of this brand is 2 inches or 50 mm. For DHW circuit 1/2 or 15 mm. The chimney diameter for models with power from 8 to 12 kW is 115 mm, for 16 kW and above - 150 mm.

Conord boiler design

Due to the built-in turbulators and good thermal insulation, the efficiency of the Conord boiler reaches 90%. These heating devices are capable of operating at reduced gas pressure and are completely energy independent of electricity. The manufacturer claims a boiler service life of 15 years and a factory warranty of 3 years, which is also indicated in the operating instructions.

Automation for gas boilers Conord

Three types of automation can be installed on floor-standing boilers of this brand:

— domestic type AGU-T-M

- Italian Euro SIT

In general, the automation, although not particularly sophisticated, is unpretentious. In the event of a breakdown, it is not difficult to find spare parts for it. For example, a bimetallic strip that often fails costs about 50 rubles.

Automation type AGU-T-M

Euro SIT automation consists of a sectional burner and Polidoro tubes, as well as a safety system: igniter with thermocouple, temperature sensor, SIT gas valve, draft sensor and wires. If the pilot burner goes out, the gas is turned off, or there is no draft in the chimney, the automatic system instantly shuts off the gas supply to the burner.

Ignition occurs by pressing the piezoelectric element button or using a match. The coolant temperature is provided by the gas valve and set by the thermostat knob.

Automation Euro SIT

Honeywell automation from an American manufacturer has similar technical characteristics to a Euro SIT gas burner device. The principle of operation is the same, it differs mainly in the manufacturer and material of some elements.

Ignition is carried out by pressing the handle to the right of the thermostat and then turning it to the stop position to operate the boiler in economical mode.

Advantages of Conord gas boilers

- wide range of models

— three types of automation

— in case of boiler malfunction it is easy to find spare parts

Manufacturer information

The Conord plant has been on the market since 1979.

The CONORD plant is considered one of the largest enterprises in the production of heating and boiler equipment in Russia. The manufacturer has been on the market since 1979 and currently has a reputation for producing high quality products. This includes domestic boilers, including universal, gas and solid fuel, water heaters, AOGV, as well as burners and pellet boilers.

The brand’s equipment meets European quality standards and is presented in a wide range, the model range of which includes more than 50 items. It is produced in Rostov-on-Don from galvanized metal and other materials, using coatings made of high-quality polymers. Brand products retain their ideal appearance for many years and are able to operate without failures if the operating instructions and safety regulations are followed.

Review: Floor-standing single-circuit gas boiler Conord KSts-G-12N - Reliable and economical!

Advantages:

Inexpensive, works properly, economical, 3 year warranty

Flaws:

there are small ones

Gas heating has its pros and cons. On the one hand, living in an apartment, you don’t have to bother with boilers, installing them somewhere, periodically cleaning them, lighting them, etc. You wait until the heat is turned on, and that’s it. But on the other hand, they don’t always turn it on when you want. And you have to freeze without heating in the fall and spring, and sometimes, on the contrary, die from the heat. This is a huge advantage of gas heating - when you need it, you turn it on, when you don’t need it, you turn it off. We live in a private house, and we, in fact, don’t have to choose: if you want heat, install a boiler. So we installed the Conord KSts-G-12N when the previous one gave up its life.

Some technical data: overall dimensions 412/342/786, weight about 40 kg. Designed for 120 square meters (we have 100, we took it with a small margin). The efficiency is stated to be at least 90%, but how to check this? Gas consumption at nominal heating output is indicated at 1.35 cubic meters per hour. The boiler is steel, white, covered with heat-resistant powder enamel. All the “stuffing” is behind the door:

As you can see in the photo, the top cover is loose - this is not a defect in the boiler, it was after a preventive inspection and cleaning that the gas workers (!) installed it incorrectly, we didn’t notice right away, but we didn’t want to disassemble, remove the pipe and redo it ourselves, so we decided to leave it until next time . This boiler model is single-circuit; we use a gas water heater to heat water. The boiler is non-volatile, but our heating is with a circulation pump, i.e. when the power goes out, the pump does not work, the boiler overheats and automatically turns off. Fortunately, this rarely happens. There is one inconvenience during the initial ignition - you need to hold the button pressed for a while, your finger gets tired)

The instructions are the same for several models, for me personally it is not very clear, but still boilers should be installed and maintained by specialists, or at least technically competent people, this is not about me:

The boiler does not, of course, have all sorts of useful and pleasant functions such as programmable switching on at a certain time and the like, like its more expensive counterparts. But the manufacturer gave a 3-year warranty, and the promised service life is at least 15 years. The boiler was installed in the summer of 2010 and survived 2 winters. It was not very warm at home only in the most severe frosts of 30 degrees. In general, everything is fine so far, only this spring, however, it unexpectedly began to smoke, I had to urgently clean it (I confess, it was cleaned for the first time, although it needs to be at least once a year). It is more economical compared to the previous boiler, heating a 2-storey house with an area of 100 sq. m., an average of 500 cubic meters per month is consumed (naturally, more in winter, much less in summer, but I’m used to paying one amount all year round, it’s more convenient for me). PS Unfortunately, we have to add a fly in the ointment to the previous positive impression. Today it suddenly started smoking again, 9 months have passed since the previous cleaning. So, during cleaning, specialists removed one of the turbulators and discovered that it had burned out in one place. After less than 3 years of work.

Use time: 2 years

Cost: 9600 rub.

Year of manufacture/purchase:2010

General impression

.

Reliable and economical!

Installation features

We have already said that boilers are highly efficient and can last quite a long time. However, in order for all these key points to be effective, it is necessary to carry out the correct installation of the equipment, which should be entrusted to specialists. Service center employees are required to make notes about the operations performed in the technical passport of the heating unit. In addition, specialists must annually inspect the boiler and all its components; this must also be indicated in the technical passport.

When installing equipment, it is necessary to take into account a number of requirements that apply to the Conord heating boiler:

If the unit is placed on a combustible floor, then it is necessary to take care of a fireproof substrate, which should be larger in size than the device itself by 50 cm on both sides. To ensure normal water circulation in the system, the lower pipe must be located lower than the heating radiators. The pipes in the system may be different. If they are connected by welding, it is recommended to leave a pair of threaded connections for future repairs. Laying of horizontal sections should be carried out with a slope for air removal of at least 10 mm per 1 meter from the structure itself. A prerequisite is vertical risers; a deviation of three millimeters per three meters of the structure is allowed; the angle of inclination of the outlet to the heating devices should be 10 mm per 1 m of pipe. At the outlet of the coil, you should install shut-off valves. The finished chimney to which the equipment will be connected must be located in the load-bearing wall of the building. It is advisable to cover the chimney with thermal insulation, especially if it passes through an area that is not heated. The diameter of the chimney should in no case be greater than the diameter of the outlet pipe. This is a prerequisite for stable operation of the equipment and sufficient traction. Make sure there are no ledges at the chimney

It is also important that it is positioned strictly vertically. All indicators must be strictly observed, in accordance with regulatory documents and fire safety rules

If you are going to install a Conord gas boiler, be sure to coordinate your actions with specialized authorities.

How to light it? Why does it go out? Why doesn't it turn off automatically?

Not all users experience problems with ignition of Conord boilers. The usual cause is contamination of the burner nozzles, which have not been cleaned for a long time. The same reason causes the boiler to suddenly go out.

In addition, external conditions can affect the flame attenuation - drafts, insufficient or reverse draft in the chimney caused by strong gusts of wind or improper placement of the pipe.

The absence of automatic shutdown of the boiler indicates an incorrect setting of the operating mode or a failure of the automatic control unit of the unit.

Overview of markings and its interpretation

You can find out about some of the technical characteristics of the boiler if you pay attention to the markings. It may have the following form: KSts-G-10S or KSts-GV-12

The letter "K" stands for "cauldron". The letter “C” indicates that it is made of steel. If the design has a cylindrical firebox, you can recognize this by the letter “C”.

Gas boiler equipment is designated by the supplier with the letter “G”. If you have a boiler in front of you that provides the function of hot water supply, then you can find out about this by two letters - “GW”. After the letter designation you will see numbers. They indicate the maximum power level.

In order to determine the required power when purchasing a boiler, the area of the room is taken into account. For every 10 m2 you will need 1 kW of power. This is true if the ceiling height is 2.5 m

It is important to consider that this choice is relevant for the average level of heat loss

What are they?

If you are interested in the products of the Rostov manufacturer, you can choose a boiler from four series.

- With Italian automatic equipment SIT: KSts-G-S/ KSts-GV-S - single-circuit/double-circuit.

- With thermo-hydraulic automation: KSts-G-N/KSts-GV-N - single-circuit/double-circuit.

The manufacturer offers heating boilers with two types of heat exchangers: steel and cast iron. All gas heaters produced by the Rostov enterprise are only floor-standing. If you're interested in a wall-mounted unit (with a closed firebox), you'll have to look to a different brand.

Steel

Heaters with steel heat exchangers have the following advantages:

- Steel is more ductile compared to cast iron.

- Specific gravity is less.

- High heat dissipation.

There is one minus, but a very important one - low resistance to damage and corrosion. That is why consumers who know a lot about materials choose cast iron analogues. Manufacturers try to minimize this by using durable coatings, but they cannot provide 100% corrosion protection.

Cast iron

The main advantages of cast iron heat exchangers: high thermal conductivity and immunity to corrosion.

- Cast iron is less flexible and ductile than steel and is not as resistant to deformation.

- Inferior to steel in strength.

- Brittleness is the main disadvantage of cast iron. Particularly dangerous situations arise during transportation and installation, which is why installation should be entrusted to specialists. After delivering the device home, be sure to check the integrity of the cast iron heat exchanger. Even the presence of microcracks is a most dangerous situation for equipment. If they appear, the equipment will soon fail and the heat exchanger will need to be replaced.

Advantages and disadvantages

The positive features of gas appliances from Conord can be determined according to the reviews of those owners who actively use them:

- large model range;

- models have 3 types of automation;

- efficiency;

- high efficiency;

- in the event of a boiler breakdown, you can find spare parts quite quickly;

- good thermal insulation;

- guarantee of flawless operation for 3 years;

- uninterrupted operation for almost 15 years;

- steel heat exchangers help withstand thermal deformations;

- the use of water from the water supply system as a coolant;

- the ability to connect to a system with various types of circulation of the working environment;

- almost complete absence of wall-mounted appliances;

- energy independence of devices;

- use in certain series of automation parts made in Italy and Poland;

- simplified process of using the device.

Boilers from this manufacturer are created in accordance with the characteristics of the domestic climate and are designed to generate the required amount of heat to warm the home even in the most severe frosts.

The reliability of these popular devices is guaranteed by the increased level of durability of heating devices, and their independence from electricity will allow them to function without any failures or delays, especially in conditions where there is no electricity.

The low level of noise impact during operation, compact size and stylish design will allow you to place the device in the kitchen or any other room without harming the design of this room.

A gas unit with 2 circuits from Conord can heat the room as quickly as possible, and also provide home owners with heated water for personal needs.

The safe operation of the products is guaranteed by the arrangement of various protection components of the automation box, which will help turn off the product when the traction is lost. In addition, the boiler will be turned off in the event of any breakdown or any other type of failure. You will be able to automatically adjust the heating temperature of the device, and if the fuel pressure level is too low, the device will provide rapid forced air injection to maintain the functionality of the device.

Disadvantages of Conord products:

- not the highest build quality of some models;

- the steel thickness will be no more than 3 mm;

- ban on the use of antifreeze.

Circulation pump

Air often accumulates in it, and its blades sometimes seem to get stuck (the boiler will display a corresponding error).

It is recommended to rotate the shaft manually before starting.

To do this, you need to remove the front panel of the housing, unscrew the central bolt on the pump and use a straight-bladed screwdriver to turn the shaft in the direction indicated by the arrow.

An air vent is installed above the pump. You need to pull the bright lid up and let the air escape.

Floor-standing boilers are usually more powerful than wall-mounted ones. If you need to heat a large room, it is better to choose this option. Floor-mounted gas boilers for home heating – overview of design options and models.

Read about the installation features of combined heating boilers in the following material.

Conclusion

At first, the system may make gurgling sounds, all because during startup it is impossible to bleed air down to the last atom. It will gradually be removed through the expansion tank valve. Periodically check the pressure on the pressure gauge - it should be within the operating range. Temperature adjustment and other boiler settings are described in the instructions for each model.

Recommendations for the use of equipment

Reviews of Conord boilers indicate that they are chosen mainly due to their reliability and affordable price. However, many consumers complain about one drawback: boilers often go out for no reason. This may be due to the following factors:

- the burner is dirty and you need to clean the gas and air supply nozzles with a vacuum cleaner and brush;

- there is not enough air for the pilot burner to operate fully. To fix this, you need to clean the air supply nozzles and improve the ventilation of the room;

- Thermostat contacts have oxidized. They need to be cleaned or “stirred up”;

- The draft sensor or flame sensor is broken.

- Some reasons, as you have seen, can be eliminated yourself, but to eliminate others it is better to call the service department.

Also, the temperature of the coolant in the system can drop significantly. To eliminate this, move the thermostat switch to the maximum position or increase the gas supply to the burner, if such a recommendation is included in the instructions for the boiler.

Also, Conord boilers have their own operating characteristics in the summer. So, to turn off the heating circuit, you need to turn off the water supply tap. If only the pilot burner is working, the water heats up to 60 degrees in an hour. If there is no further water consumption, then it will be enough for a couple of hours for small household needs. After heating the boiler, if active consumption of hot water is not planned, it should be turned off, otherwise the water will boil and the boiler may break.

Device

The design of Conord floor-standing boilers is simplified as much as possible. The main elements are a gas burner and a heat exchanger, which together heat the coolant into the heating circuit.

Air intake and smoke exhaust occurs naturally, due to stove-type draft . The coolant circulation is natural and occurs due to the upward movement of hot layers of liquid.

The operation of all components occurs exclusively on a mechanical basis, which eliminates the risk of the boiler stopping due to failure of the electronics, sudden power outage, burnout of any elements, etc.

This is the main feature of Conord gas boilers - reliability and complete independence from external energy sources.

Advantages of the furnace and heat exchanger

The cylindrical firebox withstands high pressure well, so the equipment can be used with circulation pumps. There is also no middle weld in the Conord firebox, since the product is created from a seamless pipe with walls 3 mm thick. If we remember that seams are a weak point, then their minimum actually increases the service life.

The heat exchanger is made of cold-rolled metal - it withstands thermal deformations that will certainly occur during operation. In systems with gas Conords, tap water is used as the coolant, and antifreeze is prohibited for this role.

Basic faults

The design of Conord boilers is very simple and does not have many details. This can significantly reduce the number of weak points in the design and reduce the number of malfunctions .

The heat exchanger and ignition equipment are usually considered to be the most loaded and most likely to fail. The heat exchanger is susceptible to lime deposits. The additional layer isolates the coolant from the walls, reducing heating efficiency.

It is necessary to increase the combustion mode, which increases the load on the external part of the heat exchanger, which fails faster . The ignition equipment fails due to thermocouple failure or other reasons.

There is also a constant danger of burner nozzles becoming clogged with soot, which can be eliminated by periodically cleaning the boiler.

Installation of Conord gas boilers

In order for the factory’s warranty to be valid, installation, configuration and commissioning of the boiler must be carried out by specialists from factory-certified service centers. There must also be a corresponding entry in the registration certificate. The connection of the gas main to the boiler must be carried out by gas service workers and again with an entry in the technical passport. Warranty claims will not be accepted in the absence of annual preventive inspection marks.

Heating boilers "Conord" have a low price

Installation highlights:

- If the boiler is installed on a combustible floor, it is necessary to make a fireproof substrate, which should be 50 cm larger than the overall dimensions of the boiler on each side. The fireproof base can be a metal sheet laid on asbestos or mineral wool cardboard.

- For normal water circulation in the system (without using a pump), it is necessary that the lower pipe be located below the heating radiators.

- The pipes in the system can be anything. When using welding for connections, it is advisable to leave a few threaded connections for easy repair if necessary.

- When installing the system, the following requirements must be observed:

- risers must be vertical, the permissible deviation is 3 mm per 3 m of pipe;

- horizontal sections are laid with a slope for air removal - at least 10 mm per meter of pipe;

- bends to heating devices must also have a slope of at least 10 mm per meter of pipe;

It is imperative to install shut-off valves at the coil outlet. Requirements for chimneys:

The finished chimney to which the boiler is connected must be located inside the building in a load-bearing wall. When a smoke exhaust pipe passes through an unheated room, it must be protected with heat-insulating materials. The diameter of the chimney must be larger than the outlet pipe. Failure to comply with this recommendation leads to unstable operation (switches off due to insufficient traction). The chimney must be vertical without ledges. The parameters, design and height must comply with regulatory documents and also be agreed with the fire department. Gas boilers must be installed according to a project agreed upon with all special organizations.

How to serve

Maintenance of Conord boilers consists of maintaining the cleanliness of the body, timely removal of soot or ash from the burner and performing other necessary procedures.

Most of the work is performed by the owner of the unit, but for some activities it is necessary to invite a specialist from a warranty or service organization. This must be done annually, or as urgently necessary - in case of problems or breakdown of the boiler.

Attempts at self-repair can cause permanent failure, so you should entrust complex operations to professionals.

Any attempt to independently interfere with the boiler design will be regarded as termination of the warranty agreement at the initiative of the owner.

Types

Conord floor-standing gas boilers do not need to be connected to the power supply. This means that the use of fans or pumps is eliminated.

The combustion chamber of all units is of an open type (atmospheric), circulation of liquids occurs either naturally or using an external circulation pump.

The fundamental difference in design is only the functional features:

- Single-circuit boilers designed for heating.

- Double-circuit, capable of preparing hot water for household needs simultaneously with heating the coolant for the heating system.

IMPORTANT! Most single-circuit models can be connected to an external indirect heating boiler, which makes them capable of providing hot water to the home in larger volumes than double-circuit models.

In addition, there are differences in the design of the heat exchanger:

- Steel heat exchangers 3mm thick.

- Cast iron components with increased efficiency.

In addition, there are different types of control automation. These are mechanical gas supply and adjustment units.

Exist:

- Italian SIT nodes. In the boiler marking they are designated by the letter S.

- Thermohydraulic elements. They are designated by the letter N.

Recently, American-made components have been installed in some boiler models, which expands the range of boilers. In the marking they are designated by the letter M.

Specifications

Let's look at the parameters of Conord boilers:

| Parameter | Meaning |

| Boiler type | Gas heating |

| Installation method | Floor |

| Feature Set | Heating and hot water supply |

| Efficiency | 90 % |

| Unit power range | 8-50 kW |

| Combustion chamber design | Open (atmospheric type) |

| Fuel type | Natural or liquefied gas |

| Heat exchanger material | Stainless steel 3 mm, cast iron |

| Energy consumption | Absent |

| Service life declared by the manufacturer | At least 15 years |

| Guarantee period | 3 years |