European] Vaillant[/anchor] is well known to specialists and users of heating equipment.

Founded more than 100 years ago, the company has accumulated vast production and technological experience and has developed a lot of its own patented components and parts.

Gas boilers manufactured by this company are known far beyond Europe and are exported not only to Russia, but also to most countries of the world.

The units are famous for their reliability and resistance to external loads, and are adapted to the technical conditions of the country where they will be used.

Emerging problems are immediately diagnosed by a system of sensors that send a signal to the display about the occurrence of a particular problem.

Let's take a closer look at this issue.

Popular malfunctions of Vaillant gas boilers

During the operation of equipment, situations constantly arise when one or another component is under increased load and may fail.

A variety of situations can arise, but most of them can be systematized and classified as the most typical. The manufacturer cares about the reliability of its units.

The design of each installation contains a set of special sensors that monitor the condition of certain parts and notify the user when mode failures or failures of a particular element occur . These sensors constitute a self-diagnosis system that sends signals to the electronic control board.

The presence of such a system greatly facilitates the process of localizing a fault that has arisen and allows it to be detected at an early stage. The error code takes precedence over other system messages and is displayed in any situation.

This facilitates repairs and ensures the safety of expensive equipment.

Procedure

Step 1

Perform a reset by pressing the button on the Vaillant control panel. Imported boilers are sensitive to the supply voltage, and if the network is unstable, they malfunction with an indication of some error. If it is false, it is easily reset.

Button 8 “Troubleshooting” for resetting specific faults

Step 2

Bring the thermostat into working position. In Vaillant boilers, it is “cocked” manually by pressing the rod (painted red). If error f20 is caused by a pump malfunction or other reason, it will disappear. To access the overheating thermostat, you need to fold back the front panel - in most Vaillant models, a protective device (fuse) is installed at the heat exchanger outlet, under the NTC sensor.

Location of the NTC sensor of the Vailant boiler

Step 3 – diagnostics of signal circuits. Defects are determined visually: line break, insulation melting, short circuit - the causes of error f20 and emergency stop of the Vaillant boiler. The reliability of the contacts and the absence of oxides are checked.

Step 4 – testing the overheat sensor. It is easy to determine serviceability with a multimeter by measuring the resistance. In the initial state, the contacts of the working device are closed, R = 0. The protective thermostat cannot be repaired - it is replaced.

The last reason that causes error f20 is the electronic board of the Vaillant boiler. It generates a fault code based on a signal from the overheating sensor. It will not be possible to identify a defect on your own without diagrams, experience, or appropriate equipment. If the measures taken to eliminate error f20 are unsuccessful, you need to contact a service center. After replacing the board, the boiler's performance will be restored.

Did you like the article? A repost will be the best thanks.

How to run self-diagnosis

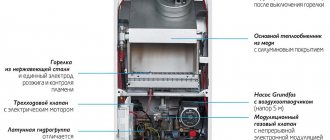

The self-diagnosis system is a complex of sensors consisting of NTC elements (thermistors) or software products.

All of them operate in continuous mode, monitoring the status of connected elements from the moment the boiler is turned on.

Therefore, the self-diagnosis system does not need to be started - it is always on and operates in constant mode, monitoring the operating mode of components and parts, immediately signaling the occurrence of problems.

In the event of an emergency, a special code will appear on the display indicating the problematic structural element. The user is only required to react appropriately when an error occurs.

Download instructions

Download instructions for Vaillant boilers.

Error F37 of the Vaillant boiler Leave a comment

Code 37 raises questions among users and technicians with a lack of experience - the symbols are displayed on the display, but there is no description in the fault table (for example, in the instructions for the Vaillant model of the WUV INT-362 series). Error f37 is typical for Turbo boilers and can be resolved independently. The article will tell you what to do.

p, blockquote 1,0,0,0,0 —>

Error F37 is displayed on the control panel of the Vaillant boiler

Basic error codes (f28, f75) and their brief explanation

There are a lot of codes for various errors or malfunctions.

Let's look at the most common ones:

| Code | Decoding |

| F00 | Supply thermistor circuit open |

| F01 | Open return thermistor circuit |

| F02-03 | Opening the temperature thermistor or storage sensor |

| F04 | Return thermistor break |

| F10 | Supply thermistor short circuit (exceeding 130°) |

| F11, F14 | Short circuit of the return thermistor (exceeding 130°) |

| F22 | Dry running (pump fault) |

| F23 | Lack of water. Determined by the temperature difference between the forward and return lines |

| F27 | Parasitic Flame |

| F28 | Ignition lock |

| F29 | Failure in operating mode (occurs when the flame goes out and the ignition attempt fails) |

| F35 | Error in gas outlet |

| F37 | Unstable or abnormal fan speed |

| F72 | Error in forward and/or return line sensor readings |

| F75 | The pump is unable to raise pressure |

| F76 | Primary heat exchanger overheating |

IMPORTANT!

In addition to error codes marked with the letter F, there are status codes marked with the letter S. They inform about the ongoing process and are not errors.

Decoding

Error f37 informs about the incorrect operation of the Vailant boiler fan with supercharging: the shaft rotation speed is higher or lower than required. This problem is evidence of a traction problem.

The flow rate of volatile combustion products through the chimney is controlled by a manostat, and when code 37 is displayed in the process of searching for a reason, it is wrong to limit yourself to testing the turbine - the pressure switch is among the “suspects”. Understanding the meaning of the problem, it is easy to determine the procedure for troubleshooting.

Where to begin

- Restart the Vailant boiler (perform a reset). Depending on the type of Vaillant, the Reset, “On” or “Network” button is pressed. If error f37 is false, caused by a power failure, it will be removed.

Button to reset error F37 for boilers atmoTEC pro, turboTEC pro

Stable operation of Vailant is achieved by turning on the heating unit via a UPS. The unit ensures autonomous trouble-free operation of the boiler even when the facility is de-energized due to the capacity of the batteries (externally connected or built-in).

Connection diagram for backup power to the Vailant boiler

- Check the value of ~Uc. With a central power supply, the discrepancy is easy to determine by the brightness of the lighting bulbs. An increase/decrease in voltage when using an autonomous generator is associated with disturbances in its operation: adjust.

- Make sure the grounding is intact. Failures in the electronics of the heating unit are initiated by interference and stray currents. To check, you will need an indicator screwdriver. The presence of potential on the metal part of the Vailant boiler is the cause of error f37.

The problem with interference and its effect on the functioning of the Vaillant is solved by installing a separation (dielectric) coupling on the gas pipe.

Connecting a dialectical coupling

Malfunctions and how to fix them

The appearance of one or another error on the display does not mean that serious problems have arisen. Electronics sometimes perceive sensor readings as signals about the failure or breakdown of a particular component. Therefore, usually the first action is to reset the error and restart the boiler.

If the error appears repeatedly several times in a row, there is no longer any doubt about the malfunction.

Let's look at ways to solve the most common problems:

F 22

The lack of water may indicate that the pump has stopped (check the contacts or condition of the wire, replace the pump), problems with the feed tap or with the sensor itself.

F 28

Ignition blockage occurs due to the lack of a positive result when the device attempts to ignite the gas on the burner. The most likely reason is failure of gas fittings, lack of gas in the pipeline, air entering the gas pipeline and other problems with the gas supply system.

F 29

The reason for the cessation of gas combustion is most often the cessation of supply from the gas pipeline, the recirculation of exhaust gases, which reduce the ability of the gas to ignite, or the failure of the ignition transformer. Alternatively, you should check the condition of the ground electrode.

F 36

This error occurs only on boilers with an atmospheric burner and indicates that exhaust gases have entered the living room atmosphere. The predominant reasons are poor condition of the chimney, lack of draft (reverse draft due to external conditions), too short chimney pipe . Often the reasons are too high a room temperature or a small distance from the walls made during installation of the unit.

F 75

After 5 attempts, the pressure in the system does not rise. The cause may be either the presence of air in the pipelines or pump failure . Alternatively, the expansion tank may be mistakenly connected to the supply pipeline or the overall water pressure in the main line may be weak.

The most common error codes for Vailant boilers

F5

Error F5 means a break in the external exhaust gas sensor. Possible reasons may be incorrect operation of the exhaust gas sensor, the plug is removed or the cable is damaged, or the spare resistor is installed incorrectly. The code is valid only for the mounted model Vailant Atmo.

5ER

If the display alternates between the water temperature and the 5ER (or SER) error, this is a reminder that it is time to service the device.

The user can set the frequency of how often this reminder pops up. The value is set in diagnostic item D.084 within the range from 0 to 3000 hours with an interval of 10 hours (the number 300 corresponds to 3000 hours). To completely disable this function, enter the symbol “—“ instead of the numeric value.

F15

Error F15 indicates a short circuit in the external exhaust gas sensor. Presumably, there is a short circuit with the sensor plug body, a short circuit inside the wiring harness, or the sensor itself is faulty. Only shown in Vaillant Atmo wall-mounted boilers.

F20

Error F20 (F20) indicates that a protective shutdown of the device has occurred due to the fact that the STB temperature limiter has tripped. It is triggered when the maximum permissible temperature is exceeded.

This can happen due to the fact that the ground contacts of the wiring harness with the housing are incorrect, or the NTC of the return or supply line is broken (weak contact). A breakdown through the ignition wire, electrode or ignition plug is also possible.

F21

Error F21 means an emergency shutdown of the GFA flame control machine.

F22

Error F22 (F22) indicates that a protective shutdown has occurred due to insufficient water. The reasons for this are a malfunction of the pump cable or toggle switch, insufficient water, the pump does not work or is blocked, or its power is too low.

F23

Error F23 detects an emergency shutdown due to too large a temperature difference between sensors located on the supply and discharge lines.

This happens for the following reasons:

- Very low pump power, why pressure drops on one side;

- the pump is blocked;

- The return and forward line NTC sensors are not in the right places.

F24

Error F24 signals an emergency shutdown if the temperature rises too sharply. This means the presence of air in the device, reduced pump performance, blockage, or very low pressure in the heating system. The gravity valve may be incorrectly connected or blocked.

F26

Error F26 means that the flow of the stepper motor gas valve is not detected due to a breakdown of the gas fittings. Perhaps the servomotor of the gas valve is not connected or broken, the connector is incorrectly inserted into the board, or there is a break in the wiring harness.

F28

Error F28 (F28) shows that the equipment did not turn on, a malfunction was detected when starting the device, attempts to ignite were unsuccessful.

There are a number of options:

- the device that controls gas pressure or the meter is broken;

- there is too much air in the gas, low pressure in the gas pipeline;

- error in the operation of gas fittings due to a non-working magnet or operator;

- one of the elements of the ignition system is broken: ignition plug, cable or transformer;

Boiler ignition electrode

- Electronic malfunction, such as interruption of the ionization current.

- dynamic gas pressure is too low;

- when operating on natural gas, a liquid gas coding resistance is used;

- breakdowns in gas fittings;

- The mass flow sensor (Venturi nozzle) has failed.

Gas flow sensor

F29

Error F 29 (F29) indicates that the burner flame goes out during operation and further attempts to ignite are unsuccessful. The fuel supply may be temporarily interrupted, the ignition transformer may fail, or the equipment may not be properly grounded.

F33

Error F33 (Ф33) reflects that the device for measuring pressure force does not turn on. After the fan is turned off, the pressure switch does not disconnect the contact. Relevant for the Vailant Turbo TEK PRO line.

S33

Error S33 indicates that the device is locked and put into a 20-minute standby state, and the heat exchanger frost protection mode has been activated. The reason is that the contacts of the air-gas path relay did not connect. This condition may appear in the Vailant 242 Turbo double-circuit boiler.

Gas boiler Vaillant turboTEC PRO 242

F36

Error F36 (F36) - the thrust stall sensor has detected the release of combustion products. Indicates that the thrust is too weak. Most likely, the chimney is clogged or the ventilation is closed. The solution to this problem is to clean the chimney, turn off the active hood above the stove and open the window.

F37

Error F 37 (F37) means a deviation in the fan rotation speed (too fast or slow). The pressure sensor may be broken.

F38

Error F38 means that the fan has failed and requires replacement.

F53

Error F53 indicates incorrect combustion settings.

Possible reasons:

F61

Error F61 indicates an error in the control of the gas valves. The cable harness connection may be damaged and a short circuit has occurred, or the gas fittings or electronic board may be faulty.

F62

Error F62 – time delay for turning off the gas fittings. It can be triggered if there is extraneous light inside (the control electrode does not indicate flame extinction).

F71

Error F71 indicates a failure of the temperature sensor in the supply line. It is probably faulty or is located too far from the supply line.

F72

Error F72 appears when the return or flow temperature sensor fails. It may be faulty or there may be a very large temperature difference in the forward or return line of the NTC sensors.

F75

Error F75 (F75) means that there is no pressure surge when the pump is turned on. There may be oxygen in the heating system or the pump or water sensor is not working correctly. To correct the situation as quickly as possible, the adjustable bypass is checked and the expansion tank is connected to the return line.

Gas boiler pump

SER

Error SER is the same as code 5ER (the letter “S” and the number “5” are equally displayed on the electronic display). After the problem has been resolved, the errors are reset by pressing the “Reset” button or turning the boiler on and off from the network.

Why does blood pressure drop?

The pressure drop in the boiler has a single cause - a coolant leak. If, after several attempts to increase the pressure using the supply valve, no positive results appear, you should look for a leak in the boiler itself or in the heating circuit.

Difficulty may arise if the boiler is a condensing boiler and is connected to a floor heating system.

Finding leaks in such conditions is extremely difficult. It may turn out that the fault is hidden in the discharge valve connected to the sewer system .

The optimal way to search for causes is to consistently eliminate possible causes of leaks, so that ultimately only one, the correct one, remains.

NOTE!

Certain information can be obtained if you try to determine the intensity of the leak and analyze the throughput capacity of the boiler elements involved.

Pressure is rising

An increase in pressure can be caused by an open make-up tap. This can be determined simply - continuous replenishment sharply reduces the possibility of heating the coolant, causing the outlet temperature to decrease.

At the same time, the valve should operate, releasing excess heating agent pressure into the sewer system . It is possible for the heating agent to boil in the heat exchanger, which also causes an avalanche-like increase in pressure due to a sharp expansion of volume.

Alternatively, the control board may have failed. The issue can be resolved by resetting to the settings made at the factory during manufacture.

Doesn't restart

There are many reasons for failure to restart a boiler. It is almost impossible to name them all, since most problems one way or another lead to the installation being blocked, and restarting becomes impossible until the cause is eliminated. However, some possible reasons can be named immediately.

For example, the power plug in the outlet may be upside down. Vaillant gas boilers are phase dependent, i.e. cannot work when the contacts are rephased . If a reconnection occurs during repair work, starting the unit will no longer be possible.

In addition, it is possible that the injectors become clogged with soot, which stops passing gas in the required quantity, resulting in immediate blocking upon startup.

Error f33 vaillant how to fix and what to do?

Occurs only in turbocharged boiler models. The source of the error is the pressure switch in the exhaust pipe. The operating logic of all modern gas boilers is approximately the same. When a request for ignition is received, the control board turns on the fan (smoke exhauster), which creates a vacuum. When the required draft is achieved, the contacts of the differential relay close and thereby transmit a signal to the board to open the gas valve and ignite the burner. Accordingly, if there is no signal from the relay or it is in a closed state after the fan is turned off, the vaillant automation generates error f33.

Vaillant boiler error f33 reasons:

- The fan does not work (can be checked visually)

- breakdown of the pressure switch (condensation may accumulate in the tubes, which, flowing into the sensor, renders it unusable;

- error when installing the exhaust pipe (condensation can also accumulate and flood the relay)

- clogging of coaxial pipelines, preventing normal air flow

- pitot tube clogged (accumulated dirt or insects)

You can check the operation of the relay by creating a vacuum yourself through the tube (a characteristic click should occur). It happens that the relay “sticks”, i.e. in normal condition it will be closed, which can be checked with a conventional multimeter. In this case, it will have to be replaced.

It happens that the tubes themselves or the pitot tube are damaged, for example, from exposure to high temperatures.

The slightest change in shape can affect the readings and cause error F33.

It is worth noting that this is a problem with almost all gas boilers. Some manufacturers solve this by installing a special extension (this is what BAXI did) to collect condensate, and some even make heated tubes to evaporate it.