While various wood wastes in the form of sawdust and wood chips are quite easy to burn in long-burning boilers specially adapted for this, the situation is different with fine coal and dust. Anyone who has ever tried to fire a stove or boiler with small fractions of coal knows that half of the fuel is wasted, spilling through the grate into the ash pan, and the other half is sintered and blocks the access of air to the firebox. Because of this, the intensity of combustion is sharply reduced. At the same time, it is stupid to throw away such fuel, because it contains a lot of thermal energy. In such a situation, coal briquetting can help, which will be discussed in this article.

Briquetting technology for hard/brown coal and coke

Coal briquetting technologies are designed to produce commercial products from coal dust, screenings, substandard and low-quality coal. Black or brown coals, as well as coke, can be used as raw materials.

Coal briquetting is a very old technology that was developed using double-roller roller presses, which increased productivity and qualitatively improved the economic attractiveness of this business.

SAHUT-CONREUR was one of the companies that began producing double roller presses at the beginning of the 20th century. We are located in northern France and, since the beginning of the 20th century, have installed more than 1000 briquetting plants in different parts of the world, of which more than 350 are for briquetting coal screenings.

The technology of coal briquetting on roller presses was developed to produce briquettes from fine coal coming after coal screens and washing. Briquettes are intended for use as fuel for private or industrial boiler houses in the same way as conditioned coal, and are also packaged for retail sale and in this form can be exported.

In most cases, the process of coal briquetting occurs with the addition of a binder (coal pitch, petroleum bitumen, tar, molasses and lime, lignosulfonate, starch, polymers...). In some cases, briquetting is also possible without a binder.

Making coal briquettes at home

It is clear that industrial equipment for coal briquetting is inaccessible to the average homeowner due to its high cost. However, our grandfathers also knew how to make briquettes without any equipment. To do this, coal dust and crumbs were mixed with water in such a ratio that a thick mass was obtained, and then cakes were molded from it by hand. After drying, such products were successfully burned in a home stove. That is, contrary to production technology, the mixture for the production of coal briquettes is not dried, but, on the contrary, moistened.

At home, briquettes are made in 2 ways:

- using a hand press;

- on a homemade screw extruder.

The first method is good because you can buy a pressing machine inexpensively or make it yourself. Its disadvantage is low productivity; in order to make yourself a fuel briquette for the whole season, you will have to work very hard. In the second case, briquetting of coal dust occurs quite quickly, since the entire process is mechanized. But here the cost of the unit comes to the fore; even a homemade installation will require significant costs. You will need to purchase a powerful electric motor, gearbox and other parts.

The algorithm according to which you can make coal briquettes yourself is as follows:

- You must try to grind the coal chips in any available way. The smaller the fraction, the better the quality of the product;

- mix the resulting composition with water. It is not possible to indicate exact proportions, since they depend on the dust content. The main thing is that the mixture is very thick and molded by hand. There is no need to add clay, this will only increase the ash content;

- fill the mold with the composition and operate the manual mechanism;

- Remove the briquetted coal from the mold and leave to air dry.

As a result, we get fragile products that are unsuitable for transportation, but burn well in the stove. One of the ways to briquet coal at home can be found by watching the video:

When a screw press is available, production is greatly simplified and accelerated. Turning on the electric motor, the above mixture is loaded with a shovel into the receiving hopper of the extruder. The output is cylindrical “sausages” of excellent quality. It is worth noting that such briquettes made from coal dust have good strength and can even be transported.

For more information about the operation of the extruder, watch the video:

ADVANTAGES OF BRIQUETTED COAL

Technical solution:

- Receiving a product of the same size, volume, shape and weight.

- Elimination of the problem of dust formation and defects during transportation.

- Specified hardness and strength of the briquette.

- Recycling waste into commercial products

Consumer and marketing benefits:

- Higher energy value

- Longer burning

- Ash in powder form

- Less CO2 and sulfur emissions

- Easier packaging, transportation, storage

- Ready for automatic feeding into the firebox

- Possibility of packaging for the consumer market

- Export supplies

Briquetting of coal dust

Coal dust and debris are formed during the mining, storage and transportation of coal. An effective way to utilize coal dust is to process it into coal briquettes.

Coal briquettes are high-quality fuel with a moisture content of 10% and high strength. Due to their low humidity, the energy value of coal briquettes is superior to the original coal; the standard size and shape of briquetted coal increases its consumer qualities. Thus, briquetting coal dust

is one of the ways to attract investment in the coal mining industry.

COAL BRIQUETTING WITHOUT BINDER

The binderless coal briquetting plant consists of the following components:

- coal sorting and grinding area if the coal size is too large

- drying area if the moisture content of the coal is too high

- briquetting area on a two-roller press

The capacity of a coal briquetting plant without binder can range from several tons per hour to approximately 25 t/h.

BRIQUETTING COAL WITH BINDER

The plant for briquetting coal with a binder consists of the following sections:

- coal sorting and grinding area if the coal size is too large

- drying area if the moisture content of the coal is too high

- binder addition area

- briquetting area on a two-roller press

- (optional) post-processing area (cooling, ripening and drying depending on the binder used)

The capacity of a plant for the production of briquettes from coal with a binder can range from several tons per hour to 100 t/h for large presses.

Possible binders

- coal pitch

- petroleum bitumen

- resin

- molasses and lime

- lignosulfonate

- starch

- polymers, etc.

The specific binder for charcoal briquettes is determined by regional availability and end product requirements. The optimal proportions of the binder and the parameters of the finished briquette are determined during pilot testing of coal in France.

Home packaging of solid fuel

The process of artisanal briquetting differs from what occurs in a factory in its low level of mechanization and in the fact that instead of drying the original components, they are wetted. For the heating needs of a standard private house, you do not have to organize a grand production with serious energy costs and expensive equipment. It is possible to prepare three or four tons of economical solid fuel for the autumn-winter period using old-fashioned methods.

Stages of home briquette production:

- Coal dust is taken in pure form or with clay additives in a ratio of 10:1 and diluted with water until the required density is obtained. A safe clay binder prevents the destruction of finished briquettes, but increases the ash content. High quality mixing allows you to use a construction mixer.

- The prepared forms are filled with a homogeneous solution. Both special containers and pots, buckets or used containers are suitable for this. Briquettes can simply be sculpted by hand, as they did before.

- Finished products are dried and stored in storage areas.

Homemade coal briquettes differ from factory ones in disadvantageous qualities. They have an imperfect shape, different levels of humidity and heat transfer, and low strength, which makes transporting products difficult. But this does not prevent homemade coal briquettes from being economical and easy to use, having low cost and high calorific value. These advantages distinguish them favorably from caked dust.

Home production can be automated if desired and if funds are available. To do this, you need to purchase or make your own manual briquetting machine.

When creating equipment similar to industrial equipment, a press for producing homemade bricks is taken as a basis. It will be improved with a loading hopper and a device for forming briquettes in the form of bars, pillows or cylinders. If you provide for the formation of through holes, this will promote better combustion and increase the heat transfer of finished products.

You can do pressing at home

The technology for handicraft pressing of briquettes looks like this:

- Coal dust and substandard materials are thoroughly crushed, and the final strength indicators depend on this.

- The raw materials are mixed with water and clay until a viscous and sticky consistency is obtained.

- The mass is loaded into the hopper and, by pressing a lever, it is squeezed out, filling the mold.

- When the lever moves back, the finished briquette is pushed out, removed and laid out in the sun to dry.

The production of a machine for home briquetting of charcoal using the extrusion method should be entrusted to a professional turner. You will have to pay a considerable amount for materials and labor for manufacturing the housing, matrix and screw, but the productivity of such equipment will also be higher.

Testing of raw materials and binders for coal briquettes

Coal in each specific deposit has individual chemical and physical characteristics, and different binders may be available in each region.

To accurately determine the required composition and characteristics of the equipment, it is necessary to conduct preliminary testing of the customer’s material at the manufacturer’s plant in France. To conduct tests, the customer needs to send coal to France for testing.

As a result of the tests you will be able to:

- determine the required composition and characteristics of the equipment

- determine the type and proportions of the binder

- obtain a finished briquette and determine its characteristics

- calculate accurate economic indicators of production

Also, only through testing is it possible to determine whether coal is suitable for briquetting without a binder and what the technical and economic indicators of production will be in this case, as well as the quality characteristics of the briquette.

COMPARISON OF OPTIONS for coal briquetting with and without binder

Coal briquetting using a binder:

- +

Suitable for any hard or brown coal - +

High productivity (up to 100 t/h) - +

Low specific energy consumption - +

Possibility of obtaining moisture-proof briquettes - +

Low cost of consumables - —

More expensive and complex equipment; binder required

Briquetting coal without binder:

- —

Applicable only to certain coals - —

Drying is required - —

Limited capacity (up to 25 t/h) - —

High specific energy consumption - —

High cost of consumables - +

No binder, simpler and cheaper equipment

The technology of coal briquetting without binder additives seems more attractive at first glance, however, at the same time, energy costs increase significantly, and the productivity and quality of the briquette decreases.

After testing, it usually becomes clear that briquetting using a binder is more economically justified, even taking into account the costs of purchasing, delivering and storing these materials.

Stages of the technological process of coal and coke briquetting

Grinding coal in a hammer crusher

Grinding of coal is necessary to obtain the required homogeneous fraction, therefore, before or after drying, the coal is passed through a hammer crusher.

Drying coal in a drying drum

Drying is necessary to reduce the moisture content of the coal before adding the binder. The degree of drying depends on the binder used and technology. The final product has a moisture content of 5-10%.

Pressing of crushed coal and coal dust

Pressing of coal dust and crushed coal fraction is carried out on two-roller presses that meet industry requirements:

- High performance

- Low specific energy consumption

- High reliability

Our partner is the world leader in the production of this equipment, French.

Post-processing (maturation) of coal briquettes

Depending on the type of coal and binder in the technology, it may be necessary to specially cool and keep the finished briquette for some time in special bunkers, during which the briquette acquires strength.

The holding time is individual and determined at the testing stage.

If you are interested in the technology of producing coal briquettes, we will be happy to answer your questions.

Industrial production

Distinctive features of dust and fine coal fraction: low specific calorie content and density. But these materials are considered as cheap raw materials that make it possible to organize the production of coal briquettes. The products will have good density and heat transfer at low cost.

To produce briquettes in a factory, a special production line is used, consisting of a crusher, dryer, and press. The movement of semi-finished products between machines is ensured by a conveyor belt.

Pressed coal without additives is produced in several stages

:

- Grinding raw materials to a particle size of 6 mm and smaller.

- Drying the mixture to 15% humidity using steam and gas dryers.

- Next, the dust is cooled and fed to a stamp-type press, which acts on the mixture under a pressure of 20-150 MPa (depending on what technology is used). After this processing, the finished briquettes are sent to the finished product warehouse for storage.

The purpose of the fuel and the equipment used are the main factors influencing the size of the particles, the level of humidity and the amount of pressure under which they are turned into briquettes. At the same time, the energy intensity of the finished product directly depends on the quality of the raw materials. It is important to use the fine fraction of anthracite, and not brown or other types of coal. For strength, it is permissible to add mineral or organic additives.

Coal briquetting press

Coal briquettes can be compressed in two ways

depending on what briquetting equipment is used:

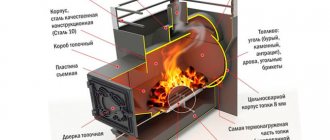

- Stamp press. The heated coal mixture is filled into special molds, in which it is compressed with a force of 100-120 MPa. After cooling, the briquettes are packaged. The finished product looks like bricks or cylinders with holes, and may look like “tablets” or “pads.” This manufacturing method is suitable for the production of briquettes in large quantities due to the high energy and financial costs.

- Extrusion machine. In this case, the plastic coal mass is pressed through the matrix by a press. A screw-pressed briquette (pini-key) made from coal dust has a cylindrical shape, resembling a “sausage”, with a calibrated hole in the middle. The technology is less expensive, but also less productive.

The technology for producing briquettes for industrial use involves the addition of cement, oil-bitumen mixture, liquid glass and others. The use of these substances in metallurgy is permitted. But you cannot buy coal briquettes with oil bitumen for heating a living space according to the requirements of the SES.