It began its existence in 1955. In the small town of San Bonifacio, the Ferroli brothers opened a modest-sized production of gas-fired heating boilers. They did everything themselves: during the day they were salesmen and installers, and in the evenings and nights they made their own boilers. They relied not on quantity, but on quality, and as a result, within three years they received a municipal order for the production of 500 units for the district. Since then, the active development of the campaign began. Now the concern produces almost half a million units of heating equipment per year.

Specifications

In order to choose the most optimal option for a heating device manufactured by Ferroli, a number of parameters should be taken into account:

- Location - there are both wall-mounted and floor-mounted units. The first are intended for autonomous heating of an apartment or private house. The latter are characterized by high productivity and are installed in large rooms.

- The number of circuits, a mounted Ferroli double-circuit gas boiler and a floor-standing analogue are used for simultaneous heating of the coolant and hot water. Units with one circuit are connected only to the heating system. As an exception, we can note models with a built-in or separately installed indirect heating boiler. Read more about indirect heating boiler here

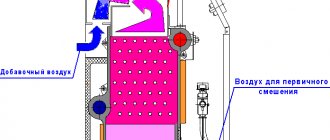

- Principle of operation - boilers that include an atmospheric burner are distinguished by a simple operation scheme and unpretentious operation, which explains their low price. Condensation-type devices with a closed combustion chamber have a forced supply of air masses. As a result, productivity increases and gas consumption decreases. In order to ensure the functioning of devices with a closed combustion chamber, electrical energy is required.

- Heat exchanger - units made of steel are characterized by high performance and heat transfer. That is why they are often installed in industrial premises. Boilers with a cast iron heat exchanger have much lower efficiency, but they will last longer.

Condensing units are connected to a horizontal coaxial chimney. Models with closed fireboxes must be connected to the home's energy saving system. By means of a fan, air is drawn in and combustion products are removed.

Review of popular models and prices

When choosing a boiler, you should take into account the type of fuel you plan to use. The power level is determined based on the heating area. On average per 10 sq. m of room requires 1 kW of performance.

Traditional wall-mounted gas boilers

Traditional devices use energy obtained from burning gas to heat water. During operation, part of the heat is released into the chimney along with the exhaust smoke.

Fortuna

The economy class model “Fortuna” has two modifications: with two circuits or one (Fortuna H). Heated area: from 35 to 400 square meters. The device has a wide power range and a standard design.

Design features:

- composite hydraulic block;

- LCD display;

- push-button control.

The cost of the model starts from 426 Euro.

Divabel

Double-circuit boiler with a closed combustion chamber. The Divabel model is capable of providing heat and hot water to a room with an area of 40–240 square meters. m. The protection and self-diagnosis system makes using the product convenient. The LCD display clearly displays information about the status of the unit. Next to it on the front panel is a pressure gauge.

Design Features:

- valve body made of brass;

- built-in low-noise pump “Vilo”;

- possibility of connecting a thermostat;

- convenient modes “economical” / “comfort” and “winter” / “summer”.

The price at which you can buy a Ferroli boiler of the Divabel model in the capital region is from 477 €.

Divatech D

Boiler with hot water supply and heating circuits for rooms from 35 to 380 square meters. By connecting temperature sensors, weather-dependent control can be realized. This useful feature can save up to 30% on heating costs.

Distinctive features:

- primary heat exchanger is copper, secondary is stainless steel;

- backlit control panel;

- self-diagnosis function;

- possibility of integration into a solar system;

- frost protection.

You can buy a unit of the Divatech D model at prices starting from 546 Euro.

Condensation series BLUEHELIX

Condensation-type boiler devices have greater efficiency compared to traditional options. Additional heat removal occurs as a result of cooling of vapors in the exhaust gases (condensation).

BLUEHELIX is Ferroli’s own development. The heat exchanger is a solid stainless steel pipe twisted into a spiral. This design ensures fast, uniform heating and easy cleaning of the part. The devices are equipped with a unique spherical burner with a self-cooling door.

The series is characterized by a long service life and cost-effectiveness.

BLUEHELIX TECH RRT

A series of wall-mounted boilers with increased energy efficiency up to 94% (the manufacturer indicates 109% when calculating using another system). When installing a thermostat and remote sensors, you can organize weather-dependent control. The chimney is protected by a non-return valve and allows connection to the general chimney system. The double-circuit version is designated by the letter “C”, with one circuit – “H”.

Design:

- DHW heat exchanger made of stainless steel;

- burner power modulation in the range of 15–100%;

- operation on methane and liquefied gas without additional reconfiguration;

- Possibility of connection to solar collectors for heating domestic water.

The cost of BLUEHELIX TECH RRT models is 920 Euro and above.

BLUEHELIX K 50

Mounted double-circuit boiler with increased DHW capacity. Has a built-in boiler of 50 liters. Suitable for rooms with a square area of 50–300 meters and an increased need for hot water.

Product cost - 25 kW/32 kW: 1,628/1,655 €.

Condensing series QUADRIFOGLIO B

The model is a floor-standing high-performance boiler. The heat exchanger is made of stainless steel in the form of a bundle of pipes bent in the shape of a quatrefoil. This device promotes increased heat transfer and enhanced condensation. The design provides two return line inputs. Serviced area: from 100 to 2,900 square meters.

Peculiarities:

- micro-flare burner with reduced emissions;

- two-way opening of the chamber door (convenient to maintain);

- control panel at the end;

- the ability to connect a remote control and remote sensors;

- enhanced safety group (sensors, valves).

You can buy the QUADRIFOGLIO B unit at prices ranging from 4,000 to 10,530 Euros.

Cast iron boilers PEGASUS

A line of floor-standing gas installations of the traditional type with an open combustion chamber. The devices are equipped with an atmospheric burner with the ability to regulate power. Due to the installation of a cast iron heat exchanger, the devices have a long service life. Antifreeze can be used in the heating system. The basic model is a single-circuit version of Ferroli Pegasus.

Its features:

- built-in mechanical pressure gauge;

- the ability to connect a boiler tank and outdoor temperature sensors;

- pump and expansion tank included;

- frost protection, traction control;

- control module with large LCD screen.

The cost of the PEGASUS heat generator is from 1,338 Euro.

PEGASUS D

The model is equipped with an electronic pressure gauge and an improved control panel with a bright screen. Modern automation allows you to control the device using a remote control.

Prices for Ferroli PEGASUS D depending on power: 984–1,248 €.

PEGASUS DK 130

Double-circuit boiler with built-in boiler for 130 liters. The advantage of the model is the ability to provide hot water supply in large volumes.

Price range for PEGASUS DK: 2,547–2,670 Euro.

ATLAS

The Ferroli Atlas series combines floor-standing cast iron boiler devices of a universal type. The devices have a stylish design. Equipped with a large functional control unit. A simple change of burner type allows you to easily switch the boiler to one of the acceptable types of fuel - gas/diesel.

Design features:

- low-turbulent gas outlet ensures low-noise operation;

- the end of the chimney is made in the shape of a cone for easy connection to any pipe;

- closed combustion chamber;

- mineral wool insulation reduces heat loss through the body;

- three-pass heat exchanger;

- Frost protection, fuel sensor;

- two types of control: analog and digital (Atlas Evo modification).

You can buy Ferroli Atlas models at prices starting from 813 Euro.

SFL

A line of floor-standing solid fuel boilers. In the basic version, wood and coal are used to generate heat. When installing a special adapter, you can use partially or completely pellets as fuel. Powerful installations are capable of heating areas from 190 to 500 square meters. m.

The unit is equipped with a convenient loading door across the entire width of the body and a spacious firebox. The draft is regulated using a deflector on the air outlet and a thermomechanical power regulator. The TRM is connected to the blower using a chain, opening and closing it if necessary. At the bottom of the boiler there is an ash compartment for collecting remaining fuel.

The advantage of the model is its complete autonomy from network highways. This option is indispensable for remote, hard-to-reach areas. The disadvantage is the same as with all solid fuel boilers: they need to be periodically cleaned and new portions added to the firebox.

The cost of the Ferroli SFL solid fuel unit starts from 1,072 Euros.

L.E.B.

A line of electric boiler equipment with a high degree of automation. The devices are installed on the wall. Single-circuit models, when connected to a boiler, are capable of providing the house with hot water. The devices have the highest efficiency in the Ferroli range: 99.5%. Suitable for heating areas from 10 to 240 meters.

Peculiarities:

- automatic power control;

- control unit with a large display and intuitive interface;

- useful programming functions: timer, temperature control;

- possibility of application for low-temperature systems;

- compatibility with heated floors;

- built-in room temperature sensor;

- The self-diagnosis function allows you to recognize common errors and, if possible, eliminate them.

Price range for Ferroli LEB series boiler models: 550–700 €. Read our article about vertical heating radiators.

Advantages of Ferroli gas boilers

As distinctive features of the units produced by the manufacturer Ferroli, first of all, it should be noted their reliability, innovative technological developments, as well as absolute adaptability to Russian conditions.

Condensing gas boiler Ferroli ECONCEPT tech 25 A

Each model includes a digital microprocessor control system. In addition, automatic adjustment of permanent flame modulation is provided. The surface of the combustion chamber and heat exchanger is coated with a special compound that protects against corrosion. Its key element is aluminum. The burner has a steel head. The inside of the chamber is insulated using a special material that is environmentally friendly and absolutely safe.

Another feature of boilers of this brand is the presence of a frost protection system and an anti-lock pumping system for hot water supply and heating.

Boilers can operate on both natural gas and liquefied gas. The devices are also very easy to maintain - all elements are placed in such a way that they are easily accessible. If necessary, you can create remote control of their operation - to do this, you just need to connect the control panel.

Peculiarities

The Ferroli Fortuna F24 model has the following overall dimensions - 440x742x235 mm (WxHxD), and weight is 35 kg. Installation is carried out on the wall, it is convenient and saves space in the room.

Basic parameters and operating principle. The convection type of device involves the generation of heat by combustion of gas fuel, while the boiler operates on natural gas (methane, consumption 2.27 cubic meters per hour) and liquefied gas (propane-butane mixture, consumption 2.05 kg/hour).

To obtain the declared power of 24 kW, the natural gas pressure must be at the level of 10-25 mbar, and the permissible liquefied pressure must be 37 mbar; reducing these parameters will result in a decrease in thermal power. ExpertKotel.ru reminds that most often in domestic networks the pressure is 12-20 mbar. The efficiency of the installation, with such values, is declared to be at a very good level and amounts to 93.1%.

Heating of water and coolant in pipes. This boiler is capable of producing 13.7 l/min of hot water (t=30°C). The coolant temperature is 30-85°C, and in the hot water supply circuit - 35-55°C.

Heating of water and coolant in pipes. This boiler is capable of producing 11.3 l/min of hot water (t=35°C). The coolant temperature is 30-85°C, and in the hot water supply circuit - 35-55°C.

Primary heat exchanger. In the case of Ferroli Fortuna F24, copper is used, its advantages are good heat dissipation, compactness, low weight, and most importantly, corrosion resistance.

The expansion tank is designed to compensate for the expansion of the coolant in the pipes during heating and releases it back into the system when cooling. This maintains constant pressure in the circuit.

The circulation pump is designed to circulate coolant (water, antifreeze) through the heating circuit; it is a mandatory component of a closed-type heating system; in our case, the pump is included.

Fuel economy

Modulation of the burner flame smoothly changes the intensity of the fuel supply and, if necessary, reduces or increases the flame, which reduces gas consumption.

Automatic ignition (Electric ignition) allows Ferroli Fortuna F24 to start and extinguish the burner according to an algorithm when necessary, which saves fuel.

- Gas consumption

- Meaning

- Natural

- Liquefied

| 2.27 cu. m/hour |

| 2.05 kg/hour |

Management and control

The Ferroli Fortuna F24 gas boiler is electronically controlled, equipped with a display and has a port for connecting additional devices (usually thermostats, programmers, room remote controls, etc.). The advantage of the electronic system is that it does not require the constant presence of a person and allows significant fuel savings (as described above), the disadvantage is that it is more complex than a mechanical one and depends on voltage surges (it can fail during surges).

Thermometer and pressure gauge. A thermometer is necessary to control the temperature of the coolant in the boiler, and a pressure gauge shows the pressure of the coolant; this is an important parameter, because exceeding it can lead to breakdown of individual parts or the system as a whole.

Protection systems

Gas control - a useful and necessary function of the burner automatically stops the gas supply if the flame goes out for any reason.

Air vent. An important element of the safety group, when the pressure in the heating system increases, the air vent automatically removes excess air from it, usually working together with a safety valve.

The Ferroli Fortuna F24 safety valve stabilizes the water pressure in the circuit when an unsafe limit is reached.

Protection against pump blocking is activated when the boiler installation is idle for a long time; in this case, the pump turns on for a while and turns itself off. The function is useful in summer when the heating circuit is not activated.

Protection against freezing of the coolant automatically turns on the burner for a short time when the water temperature drops to a critical level and there is a risk of heating defrosting. ExpertKotel.ru reminds that for this there must be gas and electricity.

Protection against overheating of the coolant turns off the burner if an abnormal water temperature value is detected.

Connection

- The size for connecting the gas pipe is 1/2″.

- It is possible to connect a separate chimney - 80x80 mm.

- Hot water supply - 1/2″.

- To connect the heating circuit - 3/4″.

- The diameter of the coaxial chimney is 60/100 mm.

For power supply, a single-phase network (220 volts) with a pure sine wave and grounding is required.

Advantages and disadvantages

The advantages of Ferroli double-circuit boilers should be considered:

- High quality parts, elements and assemblies manufactured using modern technologies.

- Full functionality of boilers that allows you to heat rooms and provide them with hot water.

- Economical, relatively low gas consumption.

- Stability, stable operating mode.

- Availability of several types of design and functionality of units.

- Wide choice of power.

- Ease of Management.

- Availability of a self-diagnosis system.

- Compact, small size.

- Attractive appearance of the units.

The disadvantages of Ferroli double-circuit boilers are:

- Energy dependence. The need to use a voltage stabilizer and correctly connect the phase electrode. Mandatory grounding.

- Excessively high sensitivity of the electronics, often leading to failure of the expensive control board.

- A combined (bithermal) heat exchanger installed on some models requires the use of softening water filters; replacing it costs almost half the cost of the boiler.

Most of the shortcomings are not an exclusive feature of Ferroli double-circuit boilers and apply equally to all similar models from any manufacturer.

Although this does not reduce their negative value, such shortcomings should be treated as design costs.

IMPORTANT! You can avoid harmful consequences by installing a voltage stabilizer and a softening water filter. This must be done from the first days of operation of the boiler. As a result, breakdowns and failure of the electronics and heat exchanger can be eliminated.

Official website: where to view all models and operating instructions

A snapshot of the official Ferroli website in Russia.

In Russia, the official website of the manufacturer is located at https://service.ferroli.ru/

By going to the section “Equipment” → “Ferroli boilers” you can see all available models and their descriptions. For each model, in the “Documentation” tab, electronic copies of complete operating, installation and configuration instructions are attached. The manuals for each model describe the characteristics, installation diagram, algorithm for switching on and adjusting the operation, maintenance features, and contain clear schematic images.

Condensing wall-mounted gas boilers Ferroli

The high quality of Ferroli heating units is especially noticeable in condensing boilers, the performance of which is very high, the efficiency reaches 100%. The operating principle is based on the use of thermal energy of steam, which is formed as a result of the combustion of blue fuel. The temperature of the flue gases is used to obtain additional thermal energy, which in conventional models flows into the chimney.

We recommend: Why do you need a bypass in a heating system, installing a bypass line

Distinctive features of condensing double-circuit and single-circuit Ferroli units in wall-mounted versions are as follows:

- Gas consumption is reduced to a minimum. The design of the device has a modulation burner. Automation independently regulates the gas supply based on the specified temperature conditions and seasons. More information about gas boiler automation in this article

- Thanks to the control system, you can choose the intensity with which the house will warm up depending on the time of day for several days in advance. Some models have special outlets for connecting underfloor heating. Automation heats the coolant simultaneously in both heating circuits.

- Wall-mounted gas-powered units from the Italian manufacturer Ferroli are completely dependent on electrical energy. With frequent voltage drops, the microprocessor board quickly breaks down. If the voltage drops, the heating is turned off and the station must be restarted. This phenomenon is a significant disadvantage of Ferroli boilers; it is because of it that boiler ratings fall.

The sensitive burner in condensing-type boilers can also operate at low gas pressure. The coolant can be water or antifreeze.

Owner reviews of Ferroli gas boilers: advantages and disadvantages

| Advantages | Flaws |

| High technical characteristics | Known reliability issues that often raise questions about the viability of the purchase |

| Intuitive and functional controls | Some owners note noise during operation; expensive models do not provide sound insulation |

| Almost a complete set of security systems, the models are also well adapted to domestic conditions | All models are volatile and require connection to an electrical outlet. |

| Low cost, starting from 25 thousand rubles. | According to owner reviews, problems with hot water supply in dual-circuit models are common. |

| A wide range of gas boilers, there are floor and wall-mounted, single-circuit and double-circuit, convection and condensation models with open and closed combustion chambers | Vulnerability of automation to voltage surges |

| Stylish and modern design | |

| Developed service structure, availability of competent specialists in almost all regions |

Wall-mounted units with atmospheric burner

Atmospheric boilers are traditional devices that have an open combustion chamber and a burner, to which air is supplied through natural circulation. Air masses are taken from the room, which serves the needs of the boiler room.

The advantage of wall-mounted atmospheric gas boilers is their simple and convenient design. As a minus, it should be noted the high gas consumption and low productivity. There is nothing complicated in installing wall-mounted boilers classified as atmospheric.

The package includes important elements that affect the performance of the system as a whole. These are an expansion tank, a circulation pump, a gas valve and a burner. Electric or piezo ignition is provided. Piezo ignition is considered a more economical option, since the pilot burner is activated only when the flame extinguishes.

The boiler does not start (the burner does not turn on)

Problems with starting a boiler occur most often, since there are many reasons for such a situation.

Among them may be:

- The gas supply valve is closed.

- Gas valve problems.

- The burner nozzles are clogged with soot.

- The control board has failed.

- The boiler is blocked due to a problem with a component.

Most possible causes are detected by the self-diagnosis system and display the corresponding code.

However, some possible reasons - failure of the gas supply system, a closed valve and other mechanical obstacles may not be noticed by the system, so you should independently verify that it is ready for operation . In addition, it is necessary to take into account the phase dependence of the boiler and the need for grounding.

Sometimes, after connections have been made, the wires on the panel are mixed up.

IMPORTANT!

If the phase is connected to the wrong electrode, the boiler will not start. It is also extremely undesirable to have an electrical potential between the working zero and the ground, which causes error A02 to appear.

Floor standing atmospheric boilers

The floor-standing units manufactured by Ferroli are represented by a number of models, the most popular of which are Pegasus devices.

Cast iron gas boiler Ferroli PEGASUS 67 LN 2S

Let's look at their technical characteristics:

- the heat exchanger is made of cast iron, it is thermally insulated and shielded;

- if necessary, you can reconfigure the equipment to operate on liquefied gas;

- thanks to the built-in boiler, immediately after opening the tap you will receive hot water;

- it is possible to adjust the power;

- There is a self-diagnosis function; the liquid crystal display displays information about all faults in the form of coding. Due to this, maintenance is carried out in the shortest possible time; Ferroli boiler errors and their codes here

- there is a safety group, which includes a safety valve and two thermostats;

- a gas boiler can be combined with another heating device in one network. All stations will need to be controlled via a control board;

- If the consumer expresses a desire, the unit can additionally be equipped with a remote control and room temperature sensors.

Ferroli Pegasus floor-standing gas boilers have permission from Gosgortekhnadzor and a certificate of conformity that allows the installation of these devices for domestic and industrial purposes.

Features of Ferroli brand boilers

Boiler devices from Ferroli are of high quality and reliability. All stages of production are automated and proceed in strict compliance with standards. The final product undergoes comprehensive testing. All boilers supplied to Russia are assembled at a plant in Italy.

Specifications

Ferroli boiler equipment has a wide range of parameters, so you can choose the ideal option for any room.

General characteristics:

- Efficiency: 90–99.5%;

- serviced area: 10–2900 sq. m.;

- number of circuits: 1–2;

- thermal power: 6–289 kW.

Advantages

The main advantage for domestic consumers is the complete suitability of the Ferroli boiler for operation in harsh conditions. It withstands pressure drops and low quality coolant in Russian heating networks.

Other benefits:

- efficiency: high efficiency of devices allows you to get maximum heat with economical use of resources;

- comfort: automated control and self-diagnosis, errors displayed on the control panel;

- safety: sensors and valves contribute to stable operation;

- low noise: the use of special materials and design solutions are designed to ensure quiet operation;

- variety: the ability to select types and models of units for any task.

More information about the production process of Ferroli boilers can be seen in the following video.

Series and models

Ferroli double-circuit boilers are represented by the following series:

- Divabel. Turbocharged boilers with a capacity of 10, 13, 16, 18, 20 and 24 kW. Produced at the company's own enterprises in the Republic of Belarus.

- Fortuna. Atmospheric and turbocharged models with power from 10 to 40 kW. Produced for use in Russia at Chinese production facilities.

- Divaproject. Manufactured in Italy, the series consists of a single turbocharged model producing 24 kW.

- Divatech D. Series produced in Italy. Consists of three models with a power of 24, 32 and 37 kW. There are atmospheric or turbocharged burner options.

- Bluehelix Tech RRT. Condensing boilers with a capacity of 24, 30 and 34 kW.

- Domiproject D. Boilers with an open or closed combustion chamber. Two models with a power of 24 and 32 kW.

- Diva F. Turbocharged boilers equipped with a separate heat exchanger. Power is 11, 13, 16, 20, 24, 28, 32 and 37 kW.

All of the listed series of double-circuit boilers are wall-mounted. Of the floor-standing units, only boilers of the Pegasus DK 130 series, with a power of 30, 40 and 45 kW, are dual-circuit models.

We recommend: Gas double-circuit boiler: what is it, single-circuit or double-circuit, with a boiler

Types of Ferroli units

produces a wide range of household and industrial boiler equipment.

Types of units:

- gas (there are traditional and condensing);

- universal (gas/diesel);

- solid fuel;

- electric boilers.

Gas equipment runs on blue fuel. Hybrid devices have the ability to change gas to diesel fuel. Solid fuel units burn wood or coal to produce heat. Electric versions operate on 220 V.

Wall mounted

Mounted models are represented by gas and electric products of low and medium performance. Having light weight and modest dimensions, they can easily be placed on the wall without cluttering up the room.

Most of the units are designed to heat rooms using a coolant plus the preparation of hot water (hot water). The DIVATOP H model is intended for heating only.

Water for hot water supply is heated using a flow-through method. In DIVATOP 60, the liquid is heated indirectly in a stainless steel boiler. The remaining boilers have two types of heat exchangers installed: plate type or three series-connected pipes of larger diameter, in which coils of thin pipes are placed.

The liquid in the heating circuit heats the copper heat exchanger. It is allowed to use water with a hardness of no higher than 25° Fr (1°F = 10 ɩɩɦ CaCO3), antifreeze, inhibitors and additives as a coolant. Of the non-freezing liquids, only those designed specifically for heating systems can be used.

Based on the type of combustion chambers, there are two types of wall-mounted boilers:

- with an open firebox, they are marked in the form of the Latin letter “C”, such modifications require a chimney;

- with closed - marked with the letter “F”, combustion products are removed using a turbine.

The combustion chambers in Ferroli boilers are made of steel, with an aluminum-based anti-corrosion coating applied on top. Almost all models have an injection burner with stainless steel heads. The flame is ignited without the help of an igniter (there is no pilot burner) using an electric spark.

A special sensor monitors the correct operation of the device; in case of failure, it shuts off the gas supply. Two-position burners are controlled by a microprocessor.

Each wall-mounted boiler has:

- a system that prevents pump blocking;

- anti-freeze system (the burner turns on when the coolant temperature drops below 5 oC);

- control of the removal of combustion products; if the smoke content is high, the burner function is blocked;

- built-in automatic bypass that protects against sudden changes in fluid pressure;

- self-diagnosis;

- It is possible to reconfigure the burner for liquefied gas (performed by service center employees).

The main difference between boilers is the control board: an LCD screen or LEDs can be installed, and there are different ways to change parameters: switches or buttons.

Floor-standing

More powerful units are installed on the floor. It is necessary to allocate a separate place for them, leaving intervals for servicing.

Only four models belonging to this category and operating only on gas are produced:

- PEGASUS D;

- PEGASUS 67–107 2S;

- PEGASUS F3 N 2S;

- PEGASUS DK 130.

All of them are equipped with an open combustion chamber, work with conventional or coaxial chimneys of natural draft, ignition is electronic, the heat exchanger is made of cast iron, sectional, injection burner with stainless steel heads.

Heat exchangers are made of special thermoplastic cast iron, then subjected to tests: peak loads at high water pressure. Service functions include self-testing and frost protection.

Prices for the Ferroli boiler range

Ferroli boiler

Device

Ferroli double-circuit boilers are designed based on the most efficient designs used in the global heating industry. The main elements are the gas burner, which is located in close proximity to the heat exchanger.

The hot coolant passes into the secondary heat exchanger, where it transfers some heat to prepare hot water.

IMPORTANT! In models with a bithermal heat exchanger, both processes occur simultaneously.

At the exit from the secondary heat exchanger, the heating agent enters a three-way valve, where the hot and colder return flows are mixed in the required proportion to obtain the desired temperature, after which the liquid is sent to the heating circuit.

All processes are controlled by an electronic control board equipped with an extensive network of sensors.

They form the core of the self-diagnosis system, which constantly monitors the condition of the boiler components.

Basic faults and main error codes

All malfunctions of Ferroli double-circuit boilers are immediately detected by the self-diagnosis system and displayed on the display as an error code.

The most common ones are:

| Code | Decoding |

| A01 | No flame (ignition attempt failed) |

| A02 | False presence of flame (voltage at the ionization electrode when the burner is off) |

| A03 | Boiler overheating |

| A06 | No flame after ignition cycle |

| A08 | Coolant temperature sensor malfunction |

| A09 | Gas valve malfunction |

| F04 | Smoke thermostat overheating |

| F05 | Smoke removal system failure or fan shutdown |

| F08 | Primary heat exchanger overheating |

| F10 | Break or short circuit of the exhaust temperature sensor |

| F11 | Break or short circuit of the DHW temperature sensor |

| F14 | Malfunction of sensor No. 2 direct line of the heating circuit |

| F34 | The supply voltage has dropped below 180 V |

| F37 | Pressure drop in the heating circuit |

| F40 | Excessive pressure in the heating circuit |

| F47 | Open or short circuit coolant pressure switch |

| F50 | Problems with the control board |

General tips and recommendations for the proper operation of Ferroli boilers

To reduce the risk of breakdowns, it is enough to follow simple but effective tips:

- Do not use a faulty boiler if the codes appear on the display constantly. You need to call a specialist.

- Be sure to connect the boiler to electricity through a stabilizer. This brand is vulnerable to fluctuations, which affects the board.

- Go through preventive diagnostics every year, and don’t forget to descale the heat exchanger.

- Monitor the pressure in the system and do not forget to close the feed tap.

- Do not use the boiler at full power. If it is not enough to fully heat large areas, you need to choose a more powerful model.

Never use faulty gas equipment, as this is life-threatening. If breakdowns occur, you cannot open the boiler yourself, much less repair individual parts. Only a licensed specialist is authorized to perform this type of work.

Price comparison for Ferroli boilers

To make it clearer, the average market prices at which you can purchase a Ferroli gas boiler are given in the form of a table. Let’s immediately make a reservation that all prices are average, and specific figures largely depend on the type of model.

| Ferroli boiler model | Number of circuits | Method for removing combustion products | Average cost, in rubles |

| DomiProject D | 2 | Chimney/turbo | From 39700 to 60000 |

| Divatop Micro | 2 | Chimney/turbo | From 63500 to 89200 |

| DomiTech | 2 | Chimney/turbo | From 49000 to 71000 |

| Divatop (with boiler) | 2 | Chimney/turbo | From 107700 to 121800 |

| ECONCEPT | — | Turbo | From 115800 to 117400 |

| Pegasus (56 kilowatts) | 1 | Chimney | Approx. 117000 |

| Pegasus 2S | 1 | Chimney | From 163000 to 236700 |

| Pegasus D | 1 | Chimney | From 79200 to 101000 |

| Pegasus D K | — | Chimney | From 20000 to 225300 |

| Atlas | — | Chimney | From 81500 to 131600 |

| Atlas D (supercharged burner) | — | Chimney | From 230000 to 252000 |

| Atlas (supercharged burner) | — | Chimney | From 68200 to 99800 |

How do Ferroli boilers differ from their competitors?

The main difference between Ferolli gas boilers and units of other brands specializing in the production of gas equipment is that there is the above-mentioned microprocessor control system that regulates the flame level in the devices. The company's specialists created (and immediately patented, of course) a unique small-sized copper heat exchanger, which is coated with an aluminum-based anti-corrosion agent. Typically, such a heat exchanger is found exclusively in Ferroli products.

Domestic buyers are well aware of the products, since it (the company) has been present on the domestic market for over fifteen years. Over the course of all these years, many consumers have appreciated the heating boilers of this brand. They managed to acquire numerous positive reviews left not only by grateful customers, but also by specialists installing or maintaining gas equipment. Excellent external characteristics, ease of use and adjustments - all this is about the Italian Ferroli gas boiler, for which, in fact, consumers value it.

Useful video

In this video you will learn the advantages and disadvantages of a Ferroli double-circuit gas boiler:

Wall mounted

Fortuna

The most common dual-circuit model. It has extremely high technical characteristics, efficiency, depending on power, is in the range of 92.4-93.1%, and the maximum gas consumption of the most common version with a power of 24 kW is 2.72 m3/hour. The primary heat exchanger is made of more heat-conducting and corrosion-resistant copper, the secondary (for hot water supply) is made of stainless steel. The boiler implements the previously mentioned secondary heat exchanger preheating system, which significantly reduces the delay in the supply of hot water.

Available in 10, 13, 16, 18, 20, 24, 32 and 40 kW versions. Mostly in demand are modifications with a closed combustion chamber (F), but there are also cheaper and slightly less productive modifications with an open combustion chamber (C). There are also single-circuit models - Fortuna H, but their cost is only 5-10% lower. The production of Fortuna models is now carried out in China, and not in Italy.

We recommend: Heating boilers using pellets: operating principle and advantages

Cost: 25,600-34,000 rubles.

Domiproject

An aging two-circuit model, discontinued, but still available in sufficient quantities in warehouses. Due to its obsolescence, it also has a corresponding, extremely affordable price, which is why it is in demand.

It differs from Fortna in being slightly less efficient, with a bithermal (double) heat exchanger, which is cheaper to manufacture, allowing the boiler dimensions to be made more compact, but is extremely difficult to descale. Otherwise, the design is as simple as possible; the most inexpensive materials are used, which, of course, also determines its price. There are versions with a power of 24 and 32 kW.

Cost: 15,800-23,000 rubles.

BLUEHELIX K

A noteworthy condensing model, one of the best and most trouble-free Ferroli gas boilers for heating a private home. The condensation principle of operation implies the presence of another additional heat exchanger that accumulates the heat of condensate formed from waste combustion products. Thus, a significant part of the heat no longer “flies into the pipe”, but is additionally accumulated and sent to heat the heating return line.

Efficiency is 109%, the heat exchanger is made of steel, but is made using a special technology without welding seams, which in theory and even in practice implies its durability.

The main difference is the presence of a built-in 50-liter boiler in the housing, which seriously increases the performance of heating hot water and increases operating comfort. Produced exclusively in Italy, but available only in 25 and 50 kW versions.

Cost: 96,000-125,000 rubles.

Floor-standing

Pegasus D

Single-circuit atmospheric gas boiler, almost problem-free compared to wall-mounted Ferroli models. It features a cast iron heat exchanger that is corrosion resistant and therefore durable. It also has good efficiency indicators - 90.9-91.7% and gas consumption that is simply excellent for an atmospheric floor-standing unit; the maximum natural gas consumption of the 23 kW version is 2.68 m3/hour.

The model has all the safety systems of mounted boilers: protection against overheating, freezing, pump blocking, etc. A safety valve and an air vent are pre-installed from the factory, which facilitates and minimizes the boiler piping. It is possible to connect underfloor heating and external control. Compared to other cast iron analogues, the boiler is quite lightweight - from 106 to 164 kg, which simplifies the requirements for the boiler room floor. Available in 23, 32 and 45 kW versions.

Cost: 60,000-93,500 rubles.

Pegasus 2S

Still the same atmospheric floor-standing boiler unit with a cast iron heat exchanger, with a similar device and technical characteristics, but much more power. Available in versions with a heating capacity of 56, 67, 77, 87, 97 and 107 kW, it is designed for heating large private houses and commercial premises; for its price it has not many analogues.

Unlike the previous Pegasus D, it is equipped only with overheating protection and an air vent; external control can be connected. There is automatic ignition, the burner is two-stage. In general, it is a fairly simple and understandable design.

Cost: 118,000-180,400 rubles.

Floor-standing Ferroli boilers for gas and liquid fuel with forced-air burner

In this category, Ferroli today produces five lines; there are several more discontinued (their technical characteristics are worse than those of the new ones). The units differ in design: the burner unit is located outside and is inserted into a hole specially provided in the door. The performance and technical characteristics of the boiler largely depend on the parameters of the burner, since it is responsible for the complete combustion of the fuel.

ATLAS (“Atlas”) is a cast-iron floor-standing boiler with a cast-iron sectional heat exchanger. It has a three-pass firebox structure: a labyrinth is arranged inside the firebox in such a way that the heated air, before exiting into the chimney, passes through this labyrinth and gives off the maximum amount of heat. This heat is then transferred to the coolant. These models have an analog control panel on which data is set using switches.

ATLAS D boilers have a different power range, a cylindrical firebox with a three-pass chimney duct, other powers, slightly lower efficiency. The control system is digital, the panel is LCD, you can connect a remote control, room and external thermostats, based on the readings of which the automation will regulate the power of the equipment. You can connect an external boiler to heat water (indirect heating) or use the ATLAS DK 100_130 model with a built-in 100 or 130 liter stainless steel tank.

Atlas floor-standing boilers with forced-air burners. Can work with gaseous or liquid fuels

High-power floor-standing cast iron boilers GN2 N and GN4 N also work with forced-air burners using liquid or gaseous fuel (natural or liquefied gas).

The body of the GN2 N units is assembled from several sections, which are connected using special steel pins and bushings. The housing is insulated on top, and a metal casing, painted using powder technology, is installed on top of the insulation. The boiler firebox is reversible, the geometry of the heat exchanger with a large number of fins guarantees high efficiency - above 90%. The updated control panel is located under a hinged lid.

Control panel for floor-standing boilers GN2 N and GN4 N

There is an on/off button, an adjustment thermostat, a thermohydrometer, and a restart thermostat. There is also space for installing an electronic adjustment and control unit.

Powerful boilers for heating private houses, offices, etc.

GN4 N have high power (220-650 kW). This line has a three-pass firebox with cooling. The boiler can operate in a normal or low-temperature circuit; it is possible to install external electronic control and cascade connection.

Today, the Ferroli concern also produces solid fuel and condensing boilers. Moreover, all solid fuel models can be converted into full-fledged pellet boilers by installing a burner, hopper and auger.