The use of electrical energy for heating has many advantages. So, if we compare such a system with gas heating, it is worth noting that electricity is available in every home. An electric boiler does not require a permit; such boilers are small and their price is lower. Of course, the cost of electricity may completely offset the benefits for some users. But currently, developments are aimed at increasing the efficiency of boilers and reducing heat losses. And the most promising system in this case is inverter heating boilers.

Inverter heating boiler

Pros and cons of an inverter boiler

There are a number of advantages that inverter installations have, including:

- increase in operational parameters as a result of the absence of heating elements;

- slight inertia when heating, thus, if there is a centrifugal pump, the coolant will heat up faster;

- the operation of the system is not affected by the chemical composition of the coolant;

- the ability to install the device anywhere.

Like other heating systems, the inverter boiler has several disadvantages:

- the rather high cost of inverter equipment compared to similar devices operating on heating elements;

- has impressive dimensions and weight, and therefore requires strengthening of the base on which the boiler will be located;

- The device requires an electronic control system for subsequent power adjustment.

Despite minor shortcomings, inverter boilers are still very popular among consumers and the demand for them is constantly increasing.

Inverter equipment design

Equipment Features

An inverter boiler, like every type of heating device, has its advantages. Thanks to this, the equipment is quite popular among consumers and is gradually being used more and more often. At the same time, of course, one cannot do without disadvantages, although for such boilers they are not very significant.

Advantages and disadvantages of inverter heating

Inverters, in a broad sense, are devices that convert direct current into alternating current, and their operating principle is based on the phenomenon of electromagnetic induction. How does inverter heating differ from other types of heating systems? The list of differences is quite impressive:

- The design of inverter boilers has no moving parts or mechanisms, so the wear resistance of such devices is higher. Thus, the service life of inverter boilers is significantly higher than similar devices of other types and is usually at least 10 years.

- Inverter boilers have a fairly simple design, and if necessary, you can assemble it yourself.

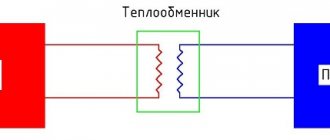

- The coolant in inverter boilers heats up much faster than in any other heating system. The reason is simple: inverter devices do not have the usual heat exchanger, so all the thermal energy is used to heat the coolant.

- Almost every inverter boiler can work with any type of coolant, since the working elements of the boiler do not come into direct contact with the coolant. The coolant can only affect the characteristics and performance of the heating system, but the boiler will operate normally.

- Inverter boilers are quite expensive: when compared with conventional household appliances, an inverter boiler will cost at least 2-3 times more.

- Household inverter boilers are heavy, but the dimensions of such devices compensate for this disadvantage. In addition, the successful shape allows you to place such a structure almost anywhere.

- The boiler is adjusted using complex electronic systems that will ensure continuous operation and control of the boiler parameters. Thus, despite the simplicity of assembling the boiler itself, to independently create control elements you will have to study electronics. Installation of electronic systems is mandatory, otherwise the equipment may be damaged and fail.

- Inverter heating devices do not create noise and are fire-safe devices: no fuel is used during operation, which can cause ignition, and there are no moving elements.

- Such systems are environmentally friendly: since no fuel is used, there are no emissions into the environment, because there are no combustion products.

We recommend: Potbelly stove for a summer residence: types, selection, prices, installation

Design of a vortex induction boiler

In fact, this technical solution is far from new; the phenomenon of electromagnetic induction, due to which electric induction heating boilers operate, was discovered by M. Faraday back in 1831. It’s just that thanks to modern materials and technologies, the phenomenon was taken as a basis and implemented in water heating installations relatively recently.

Heating of water occurs due to eddy currents (Foucault currents) appearing in the core of the coil. They are formed under the influence of an alternating electric field created by the turns of a coil with an alternating current of 50 Hz. The core is made in the form of a pipe, through which the coolant flows when heated. In essence, the device is an induction converter of electrical energy into thermal energy with an efficiency of about 98%. The diameter of the wire from which the coil is made, the number of turns and the dimensions of the core are designed in such a way as to heat the water to a maximum temperature of 95 ºС and at the same time prevent overheating of the winding.

Design and principle of operation

The principle of operation of the inverter as a separate element is quite simple. To provide power to a consumer (boiler) operating on alternating voltage, by connecting a direct current source (battery), you must first connect the source with one polarity, then disconnect and connect it with the reverse polarity. Accordingly, in order to obtain the required frequency of 50 Hz, it is necessary to carry out the switching algorithm 50 times per second, which is what modern inverters do.

The switching functions are performed by an electronic board with a set of transistors or tristors operating in switching mode. Converters with a power of over 300 Watt emit a large amount of thermal energy during such operation, therefore they are additionally equipped with a cooling system.

A diagram showing the operating principle of a voltage inverter.

Let's look at the principle of operation of the inverter using the example of the schematic diagram above. On the left is a UA with terminals 1 - 2 and an RHLH1 active-inductive boiler with terminals 3 - 4 . At time I , the boiler is connected with terminals 3 - 4 to terminals 1 - 2 UA , and the current direction is from UA to LHRH1 . At the next moment of time II, terminals 3 - 4 change their position and the direction of the current changes to the opposite relative to the boiler - the consumer of electrical energy.

Advantages and disadvantages

The real advantages that induction boilers have for heating a home or industrial building are as follows:

- High, as with all water heating installations, operating efficiency is in the range of 97-98%.

- Durability due to the absence of moving parts and simplicity of design.

- Small dimensions allowing heating equipment to be placed in a room of any size.

- High heating rate of the coolant and lack of inertia when it is turned off.

- Comfort during operation, an induction electric boiler does not require constant attention from the owner of the house, and the frequency of its maintenance depends entirely on the quality of the water used in the system.

Vortex heaters are supplied with automatic control kits, which makes it possible to connect heat generators with other climate systems at home.

Sectional view of the heater

This equipment also has disadvantages. The main one is the high cost, especially for heat generators of the Sibtekhnomash type. While using these units for industrial purposes is quite acceptable, induction heating of a private home may turn out to be unreasonably expensive.

The experience of practical use of vortex heaters by homeowners and maintenance personnel of service companies is not yet very extensive, but at the moment there are no significant complaints about the equipment.

Benefit and safety

It is worth highlighting the high reliability, durability and unpretentiousness of the inverter system. Convectors have a high class of dust and moisture protection, which makes it possible to use the equipment in damp rooms. Inverter convectors have passed all the necessary tests and have a fire safety certificate from the Ministry of Emergency Situations.

An analysis of the Electrolux inverter system showed that its use, including installation, is more profitable and cheaper than the operation of electric boilers. An important factor is flexibility - individual modules can easily form a system that will be adapted to a specific living space; if necessary, the house can be divided into zones and controlled, including using power limiting technology.

Features of inverter heating boiler

An inverter heating boiler uses electric current in its operation. However, in this device it forms a magnetic field, which in turn contributes to the appearance of an electromotive force in the conductor. This conductor is located inside the circuit.

As a result, vortex flows arise in the device, which heat the conductor material. As the frequency increases, heating also increases. Previously, this type of boiler was used in the metallurgical industry and forging, since thanks to the induction field it is possible to heat the workpiece to a given temperature with high accuracy. In addition, similar structures were used in production to heat rooms.

Depending on the power of the unit, it is connected to a single- or three-phase network. In the first case, the power of the device does not exceed 10-12 kW. Typically, these models are used to heat a country house or a small private building. Three-phase designs are designed for performance in excess of 6 kW.

Devices with a power of 6-12 kW are connected to an alternating current network with a voltage of 220 or 380 V. They can be operated without creating an additional circuit. Inverter-type units are allowed to be used in gravity and forced heating systems. Due to the high heating rate of the coolant, a device for metered water supply into the heating system is usually installed. This allows you to increase the efficiency of the device.

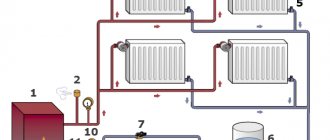

When installing inverter heating, the system must be equipped with an automatic air vent and an expansion tank. Pumping equipment is installed in networks with forced circulation.

Design and principle of operation

The inverter electric boiler has three nested circuits:

- The internal contour is made in the form of a sealed cylindrical container. This is where the water is heated. However, there are no heating elements or electrodes inside the container, but only coolant. The circuit consists of two pipes. The first of them is designed to supply heated liquid to the heating system, and the second is to return the cooled coolant back to the device.

- An electric induction coil acts as the middle circuit. It is wound around a container of water. Since all wires are insulated, no electrical current is transferred to other surfaces. Only high-frequency current flows into a coil with a toroidal or cylindrical winding. The toroidal version of the coil consists of two ferromagnetic steel pipes wrapped in wires. Pipes are installed at the top and bottom of the heating unit and inside each turn. The weight of the toroidal coil is less and the efficiency is higher.

- The external contour is a body with thermal insulation. It is needed to protect against human contact with wires, and is also designed to prevent heat loss.

The inverter boiler also contains a temperature sensor, an electronic control circuit and an electrical converter. The last device is designed to adjust the characteristics of the electric current to parameters that are optimal for the operation of the coil. Boiler inverters supply a current with a frequency of 20 kHz to the coil.

The operating principle of inverter heating equipment is as follows:

- electric current goes to the converter;

- boiler inverters increase the frequency of the electric current and its voltage to the required parameters;

- the converted current goes to the toroidal winding, as a result of which a magnetic field is formed and eddy currents arise;

- through an electromagnetic field, currents enter the internal steel circuit;

- As a result of the interaction of currents with the circuit, the heat exchanger is heated, and consequently, the coolant circulating in it.

Heating electric boilers for 220 V

What to consider when choosing a heating boiler:

- type of structure;

- boiler price;

- stability of electrical networks and the ability to obtain the necessary power.

If paying for used kilowatts is not scary, and the electrical networks are stable and allow you to get the necessary power, and in the place where you live there is no central heating and gas, and there are also problems with installing a solid fuel device, then 220V electric boilers will help solve this problem.

Select a 220V electric boiler according to the required power for heating a room of a certain area. The calculation formula is as follows. For 10 m2 you need 1 kW of power from a 220V electric boiler with a ceiling height of up to three meters.

Professional installation of an inverter for a gas boiler or for a home

The last factor influencing the reliable, safe, long-term and efficient use of inverters for gas boilers or for the whole house is the competent installation of the devices by experienced specialists who use professional equipment.

To assess the condition of the wiring, measure the starting power of household electrical appliances, correctly break the line and connect the cables coming from the electrical panel to the input and output of the inverter for a country house, and also perform a test run, contact CyberPower specialists. We will provide free consultations and install the UPS for the boiler at the proper level.

Purpose of uninterruptible power supplies

Residents of the private sector have repeatedly faced the problem of power outages. To avoid such troubles as breakdown of household appliances, interruption of heating or water supply, it is necessary to take care of a backup power source. The wide range of CyberPower products will pleasantly surprise you with their variety and functionality.

A properly selected inverter can provide your home with electricity for the required period. The most important criterion when choosing an uninterruptible power supply is its power. To determine it, it is necessary to sum up the power of the main appliances in the house.

UPS for boilers from professionals

Holiday villages often suffer from power outages, so for comfortable life it is important to have backup batteries. Clients of our company order inverters for necessary household appliances, such as boilers, boilers, refrigerators, TVs

Clients of our company order inverters for necessary household appliances, such as boilers, boilers, refrigerators, TVs

.

Boilers for autonomous heating, electric or gas, are highly sensitive to voltage changes. During the cold season, they turn off on their own due to increased electricity consumption. This negatively affects their effectiveness.

In order not to buy an uninterruptible power supply for the whole house, you can install a backup power source specifically for the gas boiler

. the price of which is significantly lower than an inverter for conventional household appliances.

For long-term use, you need to purchase a set of additional batteries.

High-quality installation of equipment

We advise clients on all issues of interest.

This ensures maximum safe and reliable operation.

An inverter is a source of uninterruptible power supply in any home; it will provide comfort and peace at any time of the year in any weather.

Why should you buy an electric boiler?

There are many options for heating your home.

The choice depends on the availability of a particular resource and conditions of use. So the gas main may be located away from a private building. In this case, you will not be able to connect gas equipment. Heat generators operating on solid or liquid fuels require special conditions. To store raw materials you need to allocate a specific place. In addition, constant monitoring of the operation of the unit is required. In this regard, the 220 electric boiler is more practical and easier to maintain. Its installation is quite simple, the device works stably and does not take up much space. Of course, the cost of electricity is constantly rising. But this does not reduce the popularity of units of this type. Moreover, today there are energy-saving models.

Many owners of suburban areas prefer boilers powered by electricity.

Some models of these units can provide the room not only with heat, but also with hot water. In city apartments, electric boilers are sometimes also installed. It should be noted that an electric sauna boiler can also be successfully used. There are devices that can be controlled remotely. This way you can turn on the boiler while still on the road, so that upon arrival the bathhouse will already be sufficiently warmed up. Therefore, in many cases, electric heaters are an excellent alternative to other types of heat generators.

Inverter heating boilers: how they don’t stop working, pros, cons, photos and videos

In any case, using electricity for heating is considered a new trend in today's world. Using inverter heating boilers is much more profitable and has many good qualities. For example, electricity, unlike gas, is available in any home and even cottage.

Prospects for an inverter boiler

Using an inverter boiler is quite easy, due to the fact that you do not need a permit to use it, they cost less than traditional devices, and are smaller in size. All the advantages of inverter boilers can be negated if you take into account the cost of electricity for some customers.

But the world does not stand still, and currently work is underway to improve electric boilers. Great strides have been made in the area of increasing their efficiency (hereinafter referred to as efficiency) and reducing heat loss. Based on these factors, it follows that inverter boilers are the most promising system at present.

How an inverter heating boiler does not stop working

Direct combustion boilers operate on the principle of heat transfer to a heating medium using an electric tubular heater. As a result, when designing the boiler, it is worth considering the place where the coolant will be heated, and taking into account its protection from the penetration of the coolant onto the surface of the tubular heater in order to eliminate corrosion. Heat loss should also be considered and reduced.

Inverter heating boilers are also called induction boilers. They work on the principle of electromagnetic induction. For this, an alternating magnetic field and a voltage converter are used, which will operate both from an industrial electrical network and from a battery. A voltage converter is used to change from AC to DC current. Due to the electric current, the inductor produces a magnetic field, and it, for its part, already heats the heat carrier in the heat exchanger, and then the remaining one moves in the pipe system.

Working diagram of an inverter boiler

Such boilers are mostly sold in double-circuit form:

- Magnetic circuit. Used to generate an alternating magnetic field;

- Pipe coil. This element is used to heat the coolant.

Pros and cons of an inverter boiler

Like every product, inverter heating boilers have their own negative and positive sides.

Good points in using such boilers:

- The operating characteristics have been increased due to the fact that there are no parts for heating the coolant;

- Slight inertia in heating the coolant. When using a circular pump in a heating system, the heating rate of the coolant increases significantly;

- Reduced requirements for thermal fluid and its chemical composition. The component that heats the thermal fluid is considered a winding. It does not come into contact with the heat carrier and therefore is not influenced by it. Therefore, the composition of the coolant is determined by the characteristics of heating pipes and radiators, which significantly reduces the cost of such a heating system.

Working diagram of inverter heating supply

However, there are also disadvantages of inverter boilers:

- The first and very important disadvantage is the price. Such a boiler will cost much more than its rival on Tubular heaters;

- Very impressive dimensions. The larger the room needs to be heated, the more pipe coil is needed and, naturally, the more turns of the inductor coil there are;

- To control such a boiler, a rather complex heating system is needed.

But, regardless of everything, an induction boiler will be available to every client in the future. And at this time, objects with systems of this type of heating are more and more popular.

Don't know the answer to your own question? Ask our expert: Ask

Separation of electric boilers by type of installation

Depending on their installation location, electrical devices are available in two versions:

Floor-standing versions are used for large volumes of heating of buildings and structures. For small volumes, such as small apartments, private residential buildings, country houses, compact wall-mounted 220V electric boilers are used. They are hung on the wall. They take up little space. They are very convenient to use.

The design of the 220V electric boiler consists of two parts. This is a heat exchanger and a control cabinet. In the heat exchanger, water is heated using thermal heaters; a control cabinet allows you to control the performance of a 220 V electric boiler and maintain the specified parameters of the coolant.

Since heating of objects using these 220V electric boilers is mainly of a closed type, many electrical devices have a built-in or additionally included expansion diaphragm tank. which compensates for excess coolant pressure in the network. They can also have circulation pumps for better distribution of coolant with large volumes.

Thermostats and programmers can be installed, which allow the operation of an electrical device to be used more economically in automatic mode. 220 V electric boilers are most often made as single circuit boilers. To obtain hot water, it is necessary to install an additional water heater, storage or instantaneous.

Advantages and disadvantages

The positive qualities of inverter heating devices include the following:

- The unit can work with antifreeze or water. In this regard, it is significantly superior to electrode boilers, which can only work with liquids with good electrical conductivity (usually only water), so antifreeze is not suitable.

- The advantage lies in the low heating inertia. In other words, the device quickly heats the coolant to the required temperature. When using a centrifugal pump, the heating rate increases significantly. All this allows you to quickly and effectively regulate the air temperature in the house.

- The impressive service life of the device is considered its main advantage. This is due to the fact that the induction coil does not come into contact with the coolant liquid, since it is well insulated. Boiler inverters, coils and automation have a large safety margin. If untreated water is poured into the system, then over time, plaque may appear on the walls of the water tank, but there are no high demands on the quality and purity of the coolant.

- There is no need to worry about coolant leakage, because the housing has increased strength and tightness.

- If we compare the fire safety of a gas boiler, an inverter unit is much safer in this regard.

- During operation, inverter equipment does not make much noise, and its efficiency reaches 100 percent.

- The device has compact dimensions, which cannot even be compared with gas and solid fuel units.

- If desired, you can make an inverter-type heater yourself.

- There is no need to allocate a separate room to install the equipment. Also, this does not require any approvals or permissions.

- Due to the absence of a combustion chamber, there is no need to install chimneys.

- The device does not require professional installation and can operate for up to 25 years without breakdowns.

Among the disadvantages is the greater weight compared to other models of electric boilers. With these parameters, the boiler power will be average. For this reason, they are not fixed to the wall, but are installed only on the floor. The price of such a device is higher than that of its electric counterparts. These units can only operate in closed heating systems.

To adjust the heating mode and control the operation of the device, complex electronics are needed. The final price of inverter-type heating equipment depends on the cost of the control system. During operation of the unit, electromagnetic interference may occur that may affect the operation of other electronic equipment.

The best known manufacturers and models: characteristics and prices

CyberPower SMP550EI

One of the most common and well-known, trusted manufacturers. The SMP550EI model is one of the best in terms of price-quality ratio; it is a backup inverter with optimal parameters for a heating boiler and the necessary minimum protection. There is a built-in battery, the ability to connect external ones. According to customer reviews, it works almost silently. It also has a nice design.

Exmork NB-Y300W LCD DC12V

A Russian-made linear-interactive model that combines fairly wide functionality and optimal parameters at an extremely affordable price. The built-in stabilizer implies a clean, although not ideal, sine wave in comparison with on-line models. Equipped with a charger. It is distinguished by the presence of a large number of protections: overload, short circuit, overvoltage, low voltage, excessive heat, etc. Available in 300, 600, 800 and 1000 Watt versions

Cost: 6,100-6,500 rubles.

POWERMAN ONLINE 1000

On-line voltage converter, one of the best inverters for a heating boiler. The output voltage shape is always pure sinusoidal, independent of the power supply parameters. There are two built-in 9 Ah batteries. It also has a very large operating range - 115-295 V, so it is perfect if a private house is located in a rural area with a very weak and unstable, often overloaded substation.

The only drawbacks are the high noise level (about 45 dB) and the lack of models with a power of less than 900 Watts, but an inverter of even this power is quite inexpensive for an on-line type.

SibKontakt IS2-12-300

Inexpensive and very simple, but reliable and proven off-line inverter made in Russia. It has good parameters and the possibility of short-term double boost in terms of power delivered to the load. This implies the ability to connect to the device devices that consume power during the switch-on phase that exceeds the rated power consumption of the device. Those. - an ideal property for boilers that consume an average of 100 Watts above the nominal when turned on; even the most inexpensive Watt model will be enough for any heating system with one pump.

Also for this amount there are a lot of built-in protections: from short circuit, overload, overheating, overvoltage, battery protection from complete discharge.

Types of economical electric boilers for home heating

Various reasons force us to organize indoor heating using electrical energy. First of all, this is prompted by the remoteness of buildings from main gas pipelines and the inability to use liquefied gas. Sometimes this is dictated by considerations of economics, because the creation of a parallel source for heating the coolant at night using electricity significantly reduces the cost of heating rooms. An electric boiler, if necessary, can solve the issue of autonomous heating of some part of a large building (floor, building). This option is considered when there are differences in temperature requirements in the premises of one building by different owners or tenants of space. Most often, electric boilers are used by homeowners to create comfort and coziness in country houses or dachas (more details: “Electric heating boilers for a dacha: comfortable heating”).

Electric boilers are divided into three types based on their operating principle and design. We list them in order of prevalence:

- heating elements (a thermoelectric heating element is used);

- electrode (the coolant reacts with the electrode and heat is released);

- induction (based on an inductor).

Boilers that use electricity to produce thermal energy are classified according to placement: wall-mounted and floor-mounted. The main characteristic for their systematization is the rated power. It varies from 3 to 60 kW. When determining the power of an electric boiler for heating a private house, a proportion is used. 1 kW of power allows you to maintain a temperature of 20-23 degrees Celsius over an area of 10 square meters. meters with a room height of 2.5 meters. The error on the complexity of the heating system, the degree of insulation of the building and the decrease in boiler performance during long-term operation does not exceed 10%. Thus, to heat a private house with an area of 100 square meters. meters, it is necessary to use economical electric boilers with a power of 12 kW and above. This formula undergoes changes when calculating for electrode boilers.

Distinctive feature

The inverter heating system consists of convectors connected by a single control. A convector is an electric heater whose operating principle is based on convection, that is, heating and mixing hot and cold air masses.

When heating with electricity, all electrical energy is converted into heat. Therefore, every extra degree means additional energy costs. Extra degrees occur when the operation of the device is controlled by a conventional thermostat. Such a convector first overheats the air by several degrees above the set value, wasting more energy, then turns off, giving time for the temperature to drop by several degrees. A new heating cycle follows, and so on. In such cycles, excess electricity is wasted and the electronics of the device wear out faster.

Control unit with digital INVERTER technology

A convector with an inverter control unit and a highly sensitive temperature sensor does not have this drawback. To maintain the set temperature, the heating element of the inverter convector does not need to be constantly turned on, using maximum power, and then turned off to cool. The inverter control unit smoothly reduces the power of the heating element as the current temperature approaches the set one and then works to accurately maintain the temperature with a constant minimum electricity consumption.

If we compare inverter heating with a boiler, then the system based on an electric boiler and radiators is much more inert, it reacts more slowly to changes in internal temperature and therefore consumes more electricity than is necessary to maintain a comfortable temperature.

Inverter heating boilers working principle, pros and cons

Using electricity for heating has many good qualities. So, if we compare a system of this kind with gas heating, it is noteworthy that there is electricity in any home. An electric boiler does not require a permit; such boilers are small and their price is lower. Of course, the cost of electricity for some customers may eliminate the benefits entirely. However, currently developments are aimed at increasing the efficiency of boilers and reducing heat loss. And the most promising system in this case is inverter heating boilers.

Inverter heating boiler

Basically, if we consider traditional electric boilers, then the working principle is that energy transfer to the heat carrier is carried out using a tubular heater

So, if the design has a tubular-type heating element, then it is also necessary to take into account the individual location in order to heat the water, the protection of the tubular heater from the rust process, and also take into account heat loss

Inverter (or electromechanical) heating boilers operate on the principle of electromagnetic induction.

Thus, with the help of an alternating magnetic field, an induction current is generated. In order for this process to be implemented, it is necessary to convert direct current from the electrical network into electric current. This is what a voltage converter does - it will work both from the mains and from batteries.

Working diagram of an induction heating boiler

So, an inverter heating boiler has 2 circuits:

- Magnetic. Will generate an alternating magnetic field.

- Pipe coil. Heats up the coolant.

When electric current is applied, the coil produces a magnetic field, which heats the water in the pipe system.

What is good and what is bad about an inverter boiler

An inverter heating boiler has a couple of positive qualities:

- Since there are no TENS, the operating characteristics become greater.

- The heating inertia is small. So, if the system has a centrifugal pump, then the heating rate of the coolant will be higher.

- Reduced requirements for the chemical properties of the coolant. After all, the TEN, in this case the winding, does not come into direct contact with water. Thanks to this, the composition of the coolant will be determined only by the characteristics of heating devices and pipes.

Inverter boiler design

Of the minuses it is necessary to note:

- First of all, the cost. Compared to boilers using tubular heaters, inverter boilers will be more expensive.

- Quite impressive dimensions and weight. To organize a heating system in large rooms, you will need a volumetric heat transfer chamber, due to this a decent number of turns in the coil.

- Power regulation requires a complex electronic control system.

Despite the presence of these shortcomings, the number of objects heated by boilers that use voltage converters for heating boilers is growing.

Organization of the heating system

Depending on the power, all inverter boilers can be divided into these types:

- Industrial. They are large in size, have a very complex system for changing the current (performed by a voltage converter for a heating boiler), and large-volume heat exchangers.

- Homemade. This version of the model is characterized by fairly small dimensions, and also the ability to work from the network and from batteries.

To organize an inverter-type heating system, it is necessary to design it very carefully in advance.

When the boiler does not stop operating, the total load in the electrical network of the premises will increase, due to which the wiring will need to be laid with a larger cross-section.

An important nuance is the safety of the boiler. And this nuance must be properly guaranteed. So, you will need to install a protective electrical unit that will automatically de-energize the boiler if power surges are observed in the network.

Simple and accessible information about the types of voltage converters

The type of inverter is the main criterion when choosing, which you need to decide on first. Each type has certain properties, operating algorithm and characteristics.

Off-line

Off-line inverters are also called backup inverters; they have the simplest design and operating algorithm:

- At normal voltage in the electrical network, the inverter is inactive, and the boiler operates in normal mode, exclusively from the electrical network.

- As soon as the voltage in the electrical network drops below a critical level (usually 175-190 V) or disappears altogether, the inverter instantly switches the power to the boiler to the battery connected to the converter. The switching occurs imperceptibly, in modern models it takes 4-8 ms, which is enough for the uninterrupted operation of the boiler unit.

- As soon as the voltage in the electrical network is restored, the inverter switches power to the main network and goes into standby mode.

We recommend: Do-it-yourself insulation of the ceiling in a bathhouse - several affordable methods

Also, most devices are designed for overvoltage, usually they operate at values above 260-300 V. Off-line inverters are the simplest and most inexpensive, their prices start from 4 thousand rubles .

However, it is better not to use them if the power supply voltage fluctuates too often or constantly. With such instability, the converter switches from the main power source to the backup one too often, which leads to very rapid wear of the batteries.

Line-interactive

Line-interactive voltage converters are the most optimal and universal for a modern heating boiler. In addition to the converter and switching relay, as in Off-line devices, linear-interactive models use a voltage stabilizer.

In standard mode, the boiler still consumes electricity from the main network, but the voltage is equalized by a built-in stabilizer; some more technologically advanced models are equipped with additional filters that smooth out noise, eliminate interference in the network, etc. With this type of operation, the battery is used less frequently and the energy efficiency (efficiency) is much higher.

Linear-interactive models often have a built-in battery that can ensure the boiler operates for 20-120 minutes, while it is also possible to connect external additional batteries that can extend autonomy to several days.

A Line-interactive inverter will always be sufficient for any gas, solid fuel or low-power electric boiler. However, such equipment also has disadvantages - poor smoothing of the sinusoid during interference, disruption of its uniformity during deep drawdowns or drops (switching time of 4-6 ms does not protect overly sensitive modules).

On-line

The most technologically advanced and expensive double conversion inverters. A simplified operating algorithm looks like this:

- At the input, the inverter converts the alternating voltage of the electrical network into a constant voltage of 12 V.

- At the output, the inverter converts 12 V to 220 V with a perfectly pure sine wave with a frequency of 50 Hz.

The batteries in such a device act as a buffer capacity necessary to equalize the current parameters. The advantage of the technology is that the boiler does not contact the electrical network directly and, at any current parameters in the network, receives an ideal, pure sine wave produced by the inverter. However, due to double conversion, the efficiency of such equipment is lower, up to 90%.

Why do you need an inverter?

Many people still remember color tube televisions, which weighed up to 60 kilograms. It was possible to reduce their dimensions and weight thanks to the use of inverters in power supplies. The inverter converted the network voltage with a frequency of 50 hertz into a high frequency voltage of several tens of kilohertz. This voltage was supplied to a transformer, the distinctive feature of which was a core made of a special ferromagnetic alloy. The physical properties of the ferromagnetic material used made it possible to significantly reduce the dimensions and weight of the power transformer. The conversion of the mains voltage of 50 hertz to high frequency is used in vortex induction boilers - these are new generation induction boilers for heating homes. The voltage is supplied to them from the inverter, the transformer coil is a winding on the central pipe made of a ferromagnetic alloy, and the secondary short-circuited winding is the pipe and the body of the induction boiler. This technical solution made it possible to make the boiler compact, reliable and economical. But on the other hand, the use of expensive copper for winding and special alloys for heat exchangers, the automation unit and the inverter made the cost of the product high. Therefore, the price for any induction boiler will be significantly higher than for an electric heating element boiler.

High-quality uninterruptible power supplies for gas boilers

Gas and electric boilers, which serve as an important element of the autonomous heating system, are particularly sensitive to voltage changes in the network. When electricity consumption increases (in extreme cold), they are especially often automatically turned off, due to which the efficiency of their use is noticeably reduced.

However, buy and use more expensive and powerful voltage inverters for the home as a backup power supply for boilers

not rational. In addition, for the normal functioning of such a device, you may have to change the wiring.

Therefore, it is more profitable and easier to buy and install an inverter for the boiler. Unlike such powerful household appliances as an electric kettle, boiler, fan heater, etc., gas boilers, as a rule, have low power (up to 600 W). When purchasing inverters for a boiler

All you have to do is choose a less powerful and more budget-friendly device.

If you want to provide long-term backup power, then inverters for boilers

specialists select an additional set of batteries. Based on the average hourly load, they calculate the maximum battery life of the UPS for the boiler and the required battery power.

Prices: summary table

| Model | View | Available nominal powers, W | Input voltage range, V | price, rub. |

| CyberPower SMP550EI | Off-line | 200, 300, 375 | Advanced: 100-280 Normal: 190-260 | 6 200-7 900 |

| Exmork NB-Y300W LCD DC12V | Line-interactive | 300, 600, 800, 1000 | 140-280 | 6 100-6 500 |

| POWERMAN ONLINE 1000 | On-Line | 900, 1800, 2700 | 115-295 | 12 900-15 500 |

| SibKontakt IS2-12-300 | Off-line | 300 | 220-300 | 3 900-5 000 |