There are boilers that run not only on solid fuel, but your “house in the village” may end up in a place where gas is not supplied, and there are power outages. In such a situation, a wood-burning boiler for heating is a real panacea. The main thing is to prepare firewood in advance - and you will be able to heat not only the house, but also the bathhouse or greenhouse. What are the advantages of such equipment and does it have any disadvantages, by what principle is the choice made, and what are the connection diagrams? Answers to these questions will be given throughout the article.

Organization of heating from a wood boiler

Review of long-burning boiler models

There are boilers from different manufacturers on the market, and their declared characteristics are similar, so making a choice is sometimes difficult. Below is an overview of the most popular models.

Boilers Liepsnele, Lithuania

The design of the boilers is of the classic shaft type with top combustion. Liepsnele boilers are energy independent and have high efficiency - it is at least 90% in any operating mode and with any fuel.

Brief technical specifications:

| power, kWt | from 10 to 40 |

| Heated area, m² | from 70 to 400 |

| Time of continuous operation on wood | up to 48 hours |

| Continuous operation time on coal | up to 7 days |

| Firewood loading volume, kg | from 25 to 75, depending on the model |

| Firewood length, cm | from 25 to 55 |

| Coal loading volume, kg | from 75 to 220 |

| Price, rub | 102 000-123 000 |

Video: installation and connection of Liepsnele heating equipment

Boilers SWaG, Ukraine

Brief technical specifications:

| power, kWt | from 10 to 50 |

| Heated area, m² | from 120 to 550 |

| Time of continuous operation on wood | from 12 to 36 hours |

| Continuous operation time on coal | from 3 to 6 days |

| Fuel loading volume, kg | from 70 to 400, depending on the model |

| Electricity consumption per hour, W | from 83 to 100 |

| Price, rub | 27 000-110 000 |

In SWaG boilers, along with the main fuel, you can burn sawdust, straw, wood chips and other waste, mixing them with coal or firewood. Do not use dusty fine coal that is prone to caking and coking - the operation of the boiler will be unstable and ineffective.

Video: description of SwaG boilers

Boilers Stropuva, Bulgaria

Classic top-burning, shaft-type units for heating residential and industrial facilities.

Equipped with a bimetallic traction regulator, which eliminates the need to connect to the electrical network. The range of universal boilers is represented by models from 8 to 40 kW. Brief technical specifications:

| power, kWt | from 8 to 40 |

| Heated area, m² | from 30 to 400 |

| Time of continuous operation on wood | from 18 to 31 hours |

| Continuous operation time on coal | from 3 to 5 days |

| Firewood loading volume, kg | from 30 to 80 |

| Firewood length, cm | from 45 to 55 |

| Coal loading volume, kg | from 70 to 180 |

| Price, rub | 54 000-110 000 |

Stropuva boilers are distinguished by increased safety and resistance to water hammer - in case of sudden overheating, the walls of the housing are not damaged, the deformation is directed inward.

Video: Stropuva long-burning models

Boilers Nedelka, Russia

Domestic-made boilers capable of operating on one load of coal for 6-7 days. They have high efficiency - up to 92%, the boiler automation allows you to accurately regulate the temperature of the network water and the microclimate in the premises of the house.

The boiler has a rectangular shape with a loading door in the upper plane. The type of combustion in the boiler is top; for more complete heat removal, smoke circulation is provided - channels through which heated flue gases pass.

The heat exchanger of the Nedelka boiler is multi-pass, which ensures maximum heat removal from the most heated surfaces. The firebox is equipped with a grate and two cleaning doors: through one, located in the fuel chamber, combustion products are removed from the firebox, and through the second - from the ash pan.

The fuel quality requirements for Nedelka units are low: they can burn coal and firewood, pellets, wood chips, and construction waste. The greatest efficiency and duration of combustion is achieved when working on coal, the quality of which does not have any special requirements - effective pressurization can ignite any fraction of coal.

Three models of boilers are recommended for private houses: KO-60 - for a house with an area of 100 to 300 square meters, KO-90 - from 200 to 400 square meters and KO-110 - from 250 to 600 square meters. Moreover, the larger the area, the shorter the boiler’s burning time at one load, so it is better to choose a more powerful boiler.

Prices for Nedelka boilers, depending on the modification, range from 110 to 220 thousand rubles.

Nedelka boilers do not require maintenance between loads. The entire combustion process is controlled by a microprocessor unit.

Why do I choose the solid fuel boiler “Nedelka” KO-60 - Video

The correct choice of the appropriate model of solid fuel equipment will allow you to forget about daily loading, cleaning and maintenance of heating equipment. Modern boilers are reliable, safe and do not require monitoring. It is enough to clean the unit from ash and ashes once every few days and load a new batch of fuel, after which the house will be warm and comfortable all week.

Types of wood boilers

A wood-burning boiler is a highly efficient heating equipment installed as a source of heat supply in autonomous systems in order to maintain sanitary and hygienic living conditions in houses of medium and small size.

These installations are equipped with special safety components to ensure safe operation. The units operate in the efficiency range from 70 to 80%.

There are quite a few modifications of boilers. Photo source: remoo.ru

Classification of solid fuel boilers:

- Classic direct combustion boilers. Despite the fact that they are significantly inferior to the latest devices in terms of operating time from 1 load, they are still popular due to their low price.

- Top combustion boilers are cylindrical in shape and equipped with a specialized telescopic air tube. Due to the fact that the combustion process also occurs at the top of the combustion chamber, a new portion of fuel can be added after the combustion of the previous layer.

- Bottom combustion boilers have a particularly well-thought-out and efficient design of mine boiler units with long-term combustion of the bottom layer. This makes it possible to fill the firebox with firewood at any time during operation.

- The pyrolysis device is a gas-generating wood-fired boiler with 2 combustion chambers. In the first, primary combustion takes place with a deficiency of oxygen, which triggers the process of pyrolysis and gas generation. The second is for complete combustion of synthesis gas. This design makes it possible to increase the operating time of the boiler with one filling of firewood.

- Pellet boilers are produced to operate on pressed or granulated wood waste and are equipped with a special hopper, from which fuel enters the combustion chamber using an auger.

Combination boilers: installation step by step

Prices

The cost of combined thermal equipment starts from $300. But these are the lowest-power and most unreliable boilers of Russian and Ukrainian production. Domestic units costing from $700 are considered optimal in terms of price/quality ratio.

For example, this is a modification of AOTVK-0-14-3, capable of efficiently heating a building with an area of up to 110 square meters. The boiler power is 14 kW when using solid fuel and 3 kW when powered from the mains. The cost of a more powerful and larger boiler from the same manufacturer (22 and 6 kW, respectively) can reach $1000.

Imported units from European manufacturers are much more expensive.

Installation cost

The cost of installation and connection of combined heating boilers depends on many factors:

- dimensions and weight of equipment;

- the complexity of the piping - shut-off valves, pump, expansion tank and other elements of the system;

- the need to prepare the foundation;

- difficulties in installing a chimney.

The minimum cost of all operations for installing and connecting hybrid heating equipment is 4,500 rubles.

Summarizing this article, we should highlight the main advantages and disadvantages of combined boilers of the “electricity - wood” type.

Advantages:

- ability to burn any type of solid fuel;

- possibility of simultaneous operation of the combustion chamber and heating elements;

- independence from the availability of power supply;

- the ability to maintain a minimum temperature to avoid freezing of the house in the absence of the owners.

Flaws:

Among the shortcomings, only one can be highlighted - the small volume of the combustion chamber, which will require frequent addition of solid fuel in the absence of power supply. Otherwise, hybrid heating units have absorbed all the advantages of gas and solid fuel boilers.

Criterias of choice

The Kupper boiler is characterized by an optimal price/quality ratio.

When choosing a boiler, it is worth considering the following indicators:

- Heated area. Approximate efficiency calculations are performed using the formula 1 kW = 10 sq.m. For example, in the central part of Russia, heating a house with an area of 150 sq.m requires a device with a power of 15 kW. For colder regions, a more powerful unit is needed. To heat a similar house in Siberia, it is worth taking a device with 30 percent more power. When connecting a second water circuit for DHW, you need to add another 15–20 percent to the final value.

- Material. Cast iron equipment can last 35 years and has the best thermal and technical performance. But such units are unstable to mechanical damage and weigh a lot. Steel devices are cheaper, they are not afraid of shocks, but their service life is on average 10–15 years less.

- Firewood loading type. More often, devices are manufactured that provide for lateral fuel supply. But there are also top-loading models. A similar design is used in gas generator boilers. The main advantage of the solution is the ability to pre-dry the firewood, which increases the heating efficiency.

- The ratio of the volume of the combustion chamber and the power indicators of the boiler - how many times during the day it is necessary to load fuel. For steel devices this value is on average 1.5–2.5 l/kW versus 1.1–1.4 l/kW for cast iron ones.

- Burn protection. An important characteristic, especially with open access to the boiler room. It is achieved through thermal insulation of the combustion chamber handles, other highly heated elements, protecting cases and grates.

- Additional functionality - automatic sensors, built-in storage boiler, remote control system. All this makes the operation of the heater more convenient. But some options require connection to an electrical power source, which deprives the unit of autonomy.

In addition to technical indicators, you will need to decide on the brand of wood-burning boiler and the cost. A good option in terms of price and functionality would be one of the modifications of the Kupper boiler. Their advantage is also their compactness, which allows the device to be placed in a small area.

Self-assembly of a wood-burning boiler

The instructions for assembling it will help you understand the process of how to make a wood-burning boiler.

You should start with the manufacture of an element designed to supply air, for which you need:

- Take a pipe with thick walls, the length of which is equal to the height of the combustion chamber, and weld a bolt to it.

- Cut a circle from a sheet of metal with a diameter slightly larger than the cross-section of the pipe.

- Drill a hole in it for the bolt.

- Connect the pipe and the bolt together, and then tighten the nut. In this case, the air duct must be freely covered with a sheet of metal so that it is possible to change the size of the clearance and thereby adjust the intensity of fuel combustion.

Next, when making a wood-burning boiler with your own hands, you should do the following:

- Using a grinder, make vertical cuts 1 centimeter wide in the air duct pipe, through which air will penetrate into the combustion chamber.

- Cut a circle from a sheet of metal with a diameter slightly smaller than the same parameter for the firebox.

- Create a hole inside the circle for mounting the air duct.

- Insert an air pipe into it, first retreating 20–30 centimeters from its edge, and then weld it.

Then you need to make the body of a homemade wood-burning boiler:

- when using an old gas cylinder, you need to cut off its top part;

- if metal sheets are selected, they must be twisted into a cylinder, fastened and welded to the bottom.

The chimney is made like this: a hole is made in the side of the cylinder and a pipe with a minimum diameter of 10 centimeters is welded to it.

Then you need to insert an air supply pipe into the unit body, for which you need to make a hole in the bottom of the firebox. It is necessary that the blower protrudes beyond the unit. The air supply pipe should be located below the location of the chimney.

At the next stage, when you make a wood-burning boiler for heating your house yourself, you need to make a heat-dissipating disk. To do this, a pancake with a diameter slightly smaller than the body is cut out of a sheet of metal 10 millimeters thick. Using steel wire or reinforcement, a handle is made that is attached to the disk.

The most reliable and economical wood boilers

Firewood burns out pretty quickly. To prolong this process as long as possible, they achieve the process of smoldering fuel. For this purpose, special combustion structures have been made that allow working on one load for 4 hours or more.

The result was very inexpensive, popular boiler designs: Evan WARMOS-TK-12.0 and Lemax Forward-12.5.

Main characteristics of Evan WARMOS-TK-12.0:

- Brand country: Russia.

- Production - Russia.

- Heating capacity using wood is 9 kW.

- Boiler type: non-volatile.

- Number of circuits: single-circuit, heating.

- The firebox is open.

- Automation - by air.

- The metal of the heat exchanger is steel.

- Firewood burning time is 5 hours.

- Chimney – 114 mm.

- Dimensions – 620x440x930 mm.

- Weight – 250 kg.

- Warranty – 1 year.

- Price – 20,500 rub.

Main characteristics of Lemax Forward-12.5:

- Brand country: Russia.

- Production - Russia.

- Heating capacity using wood is 12 kW.

- Boiler type: non-volatile.

- Number of circuits: single-circuit, heating.

- The firebox is open.

- Automation - adjusting the level of air supply to the burner.

- The metal of the heat exchanger is steel.

- Firewood burning time is 4 hours.

- Chimney – 140 mm.

- Dimensions – 121x109x917 mm.

- Weight – 70 kg.

- Warranty – 3 years.

- Price – 16,500 rub.

Design features and device

The chamber for storing fuel in any long-burning boiler is impressive in size. This parameter directly affects the burnout time of the fuel filler. Currently, there are two successfully competing technologies implemented in TT boilers: we are talking about Buleryan and Stropuva devices. The high cost and complexity of making a drawing of a long-burning boiler with your own hands poses certain obstacles to the spread of the last of them in our country. In contrast, the Buleryan method is widely used by craftsmen for independently organizing heating of country houses.

The drawing of a long-burning solid fuel boiler Buleryan consists of the following components:

- A metal case covering the internal chambers.

- Lower chamber for burning fuel.

- Upper chamber for gas combustion.

- Doors for storing firewood. It is located in the upper part of the structure due to the large size of the lower compartment for storing the resource.

- Smoke pipe. It is located at the top of the boiler and is connected to the chimney.

- Ash chamber. It is located at the bottom of the boiler and is intended for cleaning it.

There is also another interesting detail. As you know, in conventional furnaces the function of the ash pan is performed by the ash pan: it is through it that the air necessary for combustion flows. In the case of Buleryan, the ash compartment is made completely sealed: the air supply channel here is the upper air chamber. To regulate the oxygen supply, there is a damper at the top of this chamber. As combustion progresses, the wood in the firebox gradually settles, which causes the distributor to lower. This ensures a continuous supply of fresh air.

To carry out a new load, the distributor can easily be returned to its original position by pulling it up. The position of this lever serves as a kind of reference point for the level of remaining fuel: in this way you can determine how long it will take to load the next portion of firewood. Buleryan boilers are highly environmentally friendly, which is explained by the complete burnout of fuel and gas: virtually no carbon dioxide enters the atmosphere. “How to make a wood-burning boiler with your own hands - step-by-step instructions.”

The design of a long-burning solid fuel boiler is as follows:

- Firebox. The main structural element of any boiler or furnace. Designed to burn fuel in it.

- Gas afterburning section. Here the gases coming from the furnace burn out.

- Ash pit. Compartment for collecting ash. It needs regular cleaning.

- Chimney. A channel for discharging combustion products outside the home.

Advantages and disadvantages

This type of heating has a significant list of advantages, in the first place of which is the economy of the heating option, which is caused not only by the lowest prices for wood fuel, but also by the low costs of installing and operating heating equipment.

The main advantages of boilers for heating with wood:

- Environmental Safety. Due to low emissions of harmful substances into the atmosphere.

- The technological simplicity of the boiler using wood and coal guarantees a long period of operation.

- The variability of the stove device, the possibility of using all types of solid fuel, for any premises, for example, for a wood-burning bathhouse.

- Energy independence.

- Possibility of heating large areas of 1000-1500 m2.

- Wide selection of types of units with a water circuit.

- The ability to create a water heating circuit with your own hands.

Disadvantages of solid fuel boilers:

- Need for additional fuel storage space.

- Low comfort levels and the need for constant care.

- High download frequency.

- Low level of automation and regulation.

Characteristics

Most wood-burning hot water boilers on the market today have the following performance characteristics:

- Power. This indicator depends on the volume of the heat exchanger, the volume of the combustion chamber and the material from which the furnace walls are made. Also, the boiler power indicators are directly affected by the consumption of fuel material. The more firewood is loaded, the more thermal energy will be released during its combustion. How many kilowatts do you need to heat a private home? To find out how much power is required to heat a particular room, you need to use the following ratio: to heat 10 m² of space, 1 kW of thermal energy is required.

- Efficiency. To calculate the efficiency of the device, you need to know the circulation rate of the coolant, the amount of heat given off by the wood during combustion, and also take into account the method of burning the fuel. The efficiency of long-burning heating equipment and pyrolysis systems can reach up to 85-95%.

- Coolant. Water is used as a coolant in wood heating systems. As an alternative, the use of any non-freezing liquids is allowed.

- Purpose. In winter, the boiler can be used for both heating and water heating. In summer, the main purpose of a wood-burning boiler is to prepare hot water.

Advantages and disadvantages

Heating with wood is characterized by a number of undeniable advantages, the main of which are the following indicators:

- Low weight of heating equipment. Wood-burning boilers, unlike their counterparts operating on other types of fuel, are not subject to any strict requirements regarding their design and installation location. Therefore, a self-made boiler can be installed in any part of a country house, although allocating a separate room for the furnace would be the most correct solution.

- Automatic control system. The minimum number of components for the ACS of an industrially manufactured boiler allows not only to efficiently consume fuel material, but also reduces the likelihood of failure in operation if one of the control devices fails.

- Versatility. In wood heating boilers, not only wood, but also any other type of solid fuel can be used as fuel.

- Long service life. A wood-burning boiler will serve its owner for many winters. How many years will an industrial boiler last? Manufacturers of this type of heating equipment guarantee at least 15 years of trouble-free operation.

- Easy to maintain. When performing work related to the maintenance of a heating boiler in a private home, you only need to clean the ash pan and chimney once a year.

- Acceptable price. How much do you need to pay when buying a boiler? The price of each specific model depends on the number of options present in this equipment. It can be noted with complete confidence that every owner of a private home can purchase a wood-burning heating boiler without serious damage to the family budget.

Unfortunately, wood-burning hot water boilers are not without certain disadvantages. These disadvantages apply only to wood-burning boilers made by hand. One of them is that in a homemade wood boiler it is impossible to automate the control process, so the owner of such equipment needs to load fuel into the combustion chamber manually.

The second drawback is the “gluttony” of a self-made water boiler. In order for the operation of this equipment in winter to provide comfortable living conditions, it is necessary to create a large supply of firewood. How much firewood do you need to last all winter? Fuel consumption for each specific case is individual. The amount of stored firewood depends on the power of the heating device and the area of the heated premises of a private house.

How to choose the right model

When purchasing, you should be guided by all the information about the features of the models that will be important during operation. From the ability to install in a prepared room to the quality of the wood burned. The choice of a specific model is determined by the following economic and technical characteristics:

- Price. The cheapest are classic designs. They are 2-4 times cheaper than pyrolysis analogues.

- Boiler weight. Steel construction is lighter than cast iron. The heaviest models are some types of pyrolysis boilers. Weight can reach 500 kg. This factor should be taken into account when purchasing. The floor in the boiler room must be sufficiently reinforced.

- Power. It is generally accepted that 1 kilowatt is needed per 10 m2 of area with average energy efficiency of housing. In regions with harsh climates, a correction factor is used. Sometimes it can be up to 2 units. A high level of thermal protection, on the contrary, will reduce the average value. For a “smart home” you can apply a coefficient of 0.5-0.7.

- Material of manufacture. Steel boilers are noticeably cheaper. The metal burns out faster, and the service life of such a device is about 20 years. Cast iron is more resistant to high temperatures and will withstand 35 years of regular use, and it is also more inertial. It warms up slower, but cools down longer, which in some cases is very beneficial.

Domestic wood boilers Source criptopia.ru

Connecting boilers using wood and electricity

Without a doubt, purchasing, installing and wiring two separate units will cost you more than one combined heat generator. But by implementing this option, you get full heating with two energy carriers, operating effectively in automatic mode.

Reference. In non-gasified private houses in the Russian Federation, the combined operation of a solid fuel and electric boiler is used quite often, since this is the most convenient way to heat a home with wood. The combination of gas and wood is no less common, and the third place is occupied by the so-called multi-fuel boilers, which we will discuss in a separate article.

In our pair of heat sources, the wood (coal) boiler is the main one, and the electric one is the auxiliary unit. As the latter, you can use any of the three types of electric boilers offered on the market:

- traditional heating element with built-in circulation pump and control unit;

- electrode with remote control panel;

- induction with separate remote control.

We will not analyze the advantages and disadvantages of each type of electric boilers; this is the topic of another article. Here we will show in diagrams how to connect boilers using wood and electricity, so that the second one supports the first one automatically. Let's start with the joint piping of a wood-burning and heating element heating unit:

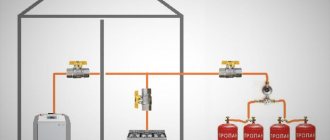

Piping diagram for joint operation of boilers

Reference. The presented circuit can be used for joint connection with a gas wall-mounted boiler, which is installed in place of the heating element.

The system operation algorithm looks like this:

- The TT boiler is inactive and its circulation pump is switched off. Heating devices receive heat from an electric boiler, which is guided by a room thermostat, where you have set the desired temperature. To prevent the coolant from moving in a circle through a parallel ring, the circuit uses 2 check valves.

- You have melted a solid fuel unit. For some time it will begin to gain temperature, and the water will circulate in a small circle, directed by a three-way valve with a thermal head. The pump will turn on at the command of the overhead thermostat installed on the supply pipeline.

- When the coolant in the small ring heats up to 55 °C, the temperature sensor of the thermal head located on the return line will operate. The three-way valve will open slightly and heat will flow into the heating system.

- The electric boiler will turn off the heating based on the signal from the room thermostat and go into standby mode.

- After the solid fuel burns out, the water in the system, followed by the air in the rooms, will begin to cool. The overhead thermostat of the TT boiler will “see” that the coolant has cooled down and will stop the pump.

- When the temperature in the house drops to the value you set, the room thermostat will turn on the electric boiler again.

Important! Since the internal circulation pump of a wall-mounted heat generator cannot be turned off, a more powerful unit must be selected for a solid fuel heat source. As a rule, a pump with a pressure of 0.6 Bar is sufficient (in an electric boiler it is usually set at 0.5 Bar)

Point two: install all overhead sensors and thermostats on metal pipes; they will lie on metal-plastic or polypropylene.

Our expert Vladimir Sukhorukov will tell you in detail about how to properly connect an electric and solid fuel boiler in his video:

Induction and electrode heat generators are not equipped with their own filter and circulation pump, so the latter will have to be purchased and installed separately. This is all the difference in the connection diagram for heaters of this type, only the pump unit needs to be connected to the network through the control cabinet so that the room thermostat turns it off together with the electric boiler, as shown in the diagram:

In this scheme, the circulation pump of the electric boiler will be turned off along with it thanks to a separate control cabinet

If the heating system of a private house consists of several circuits (radiators on different floors, heated floors and an indirect heating boiler), then to work together, the wood-burning and electric boiler are connected using the method of primary and secondary rings. The operating principle of this type of harness is described here.

Connecting an electric and solid fuel boiler to the heating system using the primary and secondary ring method

Calorific value of firewood: comparison table of different species

Calorific value of firewood

The combustion process itself is a chemical reaction that involves the interaction of wood and oxygen, resulting in the release of byproducts. The chemical composition and characteristics of each type of wood determines the amount of heat given off.

Wood is based on compounds such as cellulose and lignin. Together they form containers in the form of cells where air and water accumulate. In addition, wood contains various resins, tannins and proteins. A comparative table of the calorific value of various types of wood is presented below.

Open circuit with gravity circulation

This option is easy to perform even for a beginner. Here water circulates in the system due to the difference in density of cold and hot liquid. According to the laws of physics, hot water begins to flow upward (since its density is less), and then it cools down and returns to its starting point.

Despite the fact that this type of strapping is quite simple, it requires compliance with a number of requirements. Firstly, in order for water to circulate freely in the system, you need to install the heating equipment half a meter lower than the radiators are located in the house. Secondly, in order to minimize the manifestation of hydraulic resistance, pipes with a cross-section of up to 5 cm are needed, while distribution pipes on batteries can have a value of 2.5 cm. Thirdly, locking devices and fittings directly affect the free circulation of water in the system, therefore, there should be a minimum of such elements.

But for the sake of fairness, it is worth saying that an open system with natural circulation also has a number of its advantages. In addition to the fact that it is the easiest to set up, the financial costs for it are not so great. True, the owner will not be able to constantly control the temperature of the coolant at the outlet, which is why the heating of the circuit is somewhat reduced. Also, the expansion tank occasionally remains open, which means that oxygen has contact with the coolant, which gradually increases the risk of corrosion.

To summarize, it is worth saying that experts recommend this type of heating scheme only for those private houses where people live from time to time, and not on an ongoing basis, for example, for a summer house.

Rules for cleaning and maintaining the boiler and chimney

If the heat transfer of the TTK decreases, its condition should be checked. Perhaps the cause was contamination with soot. To clean, you need to wait until the entire structure has cooled completely, open the grates and the ash pan, and use a metal poker to clean off any buildup from the walls.

The soot settles on the remaining fuel, which must also be removed to reload the chamber. Cleaning a chimney yourself is difficult, especially if there are several bends. Soot and condensation accumulate on its walls, resulting in worse traction and an increased risk of fire.

Depending on the operating mode and the fuel used, cleaning is carried out 1 or 2 times a year. It is better to entrust the work to professionals, which will avoid injuries and other problems. A cleaned boiler and chimney will ensure high heat transfer and long service life of the entire system. Study liquid thermal insulation at the link.

liquid thermal insulation

Pyrolysis boiler

The operating principle of solid fuel pyrolysis boilers operating on wood is based on the destruction of wood under the influence of high temperature and low oxygen content. They are used for long-term heating of premises for various purposes.

Such a boiler consists of two chambers. The first is used to load fuel. The second one receives exhaust gases and secondary air for long-term combustion. Making such a unit with your own hands is more difficult than a regular one, but it is possible.

Main elements of the device

A wood-burning boiler is made from a metal barrel. Preferably with a capacity of 200 liters. The lid of the barrel is cut off and the side is welded to it. A round piston is made from a massive billet or any other weighting material. Its diameter should be slightly smaller than the internal diameter of the barrel.

A hole is cut in the cover to install an air duct pipe with a diameter of 100 mm. The height of the pipe should be at least 20 cm higher than the barrel. A chimney pipe is welded into the side of the barrel. It also uses rolled steel with a diameter of 100 mm.

The air pipe is welded to the piston. A damper is provided at the upper end of the pipe to regulate the amount of incoming air. Ribs are welded to the bottom of the piston and are used to compact the fuel mass.

Principle of operation

During operation of the boiler, firewood is loaded directly into the firebox and ignited. A cap with a piston is installed on top. As the fuel burns, the piston will move down, increasing pressure in the lower chamber. Due to this and the minimal amount of oxygen, the firewood will begin to slowly smolder.

The gas released during pyrolysis will enter the upper chamber, the temperature in which can reach 900C. Through the chimney, the remaining combustion products are removed into the atmosphere.

First heating of the boiler

After checking the heat generator and all valves for leaks, you can begin using the unit for its intended purpose.

It is recommended to carry out the first heating with an open door or window in the room where the TTK is located. During operation, an unpleasant odor may be released due to the combustion of a small layer of industrial oil or other components remaining on the device.

The minimum burning time for the first time is 60 minutes, the firebox must be fully loaded. Before setting fire, it is worth checking the chimney.

Connecting a solid fuel boiler to the system

After the installation of the solid fuel boiler with your own hands is completed and the chimney is in its place, you can proceed directly to connecting the equipment to the general system. The main thing to remember is that cold water should not be supplied to a working boiler, especially if it has a cast iron heat exchanger. Otherwise, due to the temperature difference, sticky condensation will form on the walls of the firebox, which will mix with soot. It will reduce the efficiency of the boiler, and it is quite difficult to clean it.

In this regard, the requirements for installing a solid fuel boiler provide a standard piping scheme with a bypass and a three-way valve. It is set to a fixed temperature of 50-55º, so that the coolant will move in a small circle until its temperature reaches the required values, after which the valve will begin to gradually dilute it with a cold flow from the heating circuit.

It is worth noting that when piping pellet boilers, special attention should be paid to connecting the burner and automation. Often, products of European brands are equipped with automatic fire extinguishing systems connected to a central water supply

Therefore, in order to figure out how to properly install a solid fuel pellet boiler, you should consult with a representative of the manufacturer.

To connect the boiler, you will also need to install an expansion tank, shut-off valves and a circulation pump. After this, the circuit is filled with water and a pressure of 1 bar is pumped into it. Upon completion of work, a test run of the system is performed to check the functionality.

Step-by-step boiler installation instructions

The selection and arrangement of equipment is not yet a guarantee of trouble-free operation of the system, because its elements still need to be installed correctly. And you should start with the arrangement of the boiler room, in which all this should be located. A short instruction in pictures will tell you what you need to pay special attention to.

Table 2. Correct step-by-step installation.

| Steps, photo | Description |

| Step 1. Arrangement of the boiler room | The boiler is installed after repairs have been completed in the room where it will be installed. It is important that: non-combustible materials are used in the finishing; the foundation for the boiler was prepared; there must be an air flow in the room; An exit for the chimney pipe must be provided in advance in the wall or ceiling. |

| Step 2. Choosing a location for the boiler | When choosing a place for installation, you need to keep in mind that there must be a minimum of 700 mm between the walls and the rear and side surfaces of the boiler body. On the front side, this distance must be at least 1250 mm (if the unit is top-loading). If loading is done from the front, you must also add the width of the door to this distance. |

| Step 3. Aligning the body position | It is very important that the position of the boiler does not deviate from the vertical, so during installation you need to use a level. Place it on the firebox with the lid folded back. |

| Step 4. Preparing components | According to the boiler passport, check its equipment, which may vary depending on the manufacturer. Purchase all other elements necessary for installation in advance in accordance with the selected scheme. |

| Step 5. Preparing tools | Naturally, you will need tools: adjustable, gas, socket and open-end wrenches, as well as screwdrivers of different sizes, a square and an angle grinder. |

| Step 6. Installing the combustion regulator | FUM tape is wound onto the regulator rod, and it is installed in its regular place. Tighten the nut, set the desired temperature and fix it in this position with a screw. |

| Step 7. Installation of the heating element thermostat | A little further than the combustion regulator there is a hole for installing the heating element regulator. If you don’t plan to install it, then simply screw a plug in there. |

| Step 8. Installation of the heating element | Next, the heating element itself is mounted - or a plug instead. |

| Step 9. Install the faucet | For ease of operation or routine maintenance of the system, taps are installed at the inlet and outlet of the coolant from the boiler. |

| Step 10. Assembling the security group | You assemble a pressure gauge, an air valve and a safety valve into one unit, which ensure the safe operation of the boiler and come with it. The group is placed in front of the shut-off valves. |

| Step 11. Pipeline connection to the boiler | To connect the supply and discharge pipelines to the boiler, you need to make rotary pipes. It is better if the connections are welded rather than detachable. |

| Step 12. Sealing the chimney landing site | To ensure that the chimney pipe fits tightly and does not allow combustion products to enter the room, its landing site and all other connections are treated with sealant. |

| Step 13. Water connection | Install a flexible tube onto the faucet installed at the very beginning, through which the hydraulic part of the boiler will be filled with water. Open all taps, raise the pressure to 1.3 atm, and check the tightness of the system. There shouldn't be any leaks anywhere. |

| Step 14. Heat the boiler | Now, in accordance with the instructions, you can load the firebox with wood and light it. |

The installation process is presented only in general terms, since each boiler model has its own nuances, and the connection diagram may be different.

Prices for angle grinders (grinders)

Angle grinders (grinders)

Video - Heating boiler connection diagram

Some tips for proper boiler operation

In order for your boiler to be as efficient as possible, it must be operated correctly. Here are the points you need to pay attention to so that the firewood burns longer:

- When igniting the fuel, the damper on the boiler must be completely open;

- The long burning mode is set only after heating to +600 degrees ;

- The coolant at the outlet must have a temperature of 65 degrees or more;

- If the boiler design does not provide for the laying of raw firewood, its humidity should not exceed 20%;

Dependence of heat production on wood type

- To avoid resin settling on the walls of the firebox and chimney, heat the boiler with hardwood firewood - acacia, birch, alder, aspen. And, by the way, the breed has a great influence on the amount of heat received;

- Do not chop the firewood - the larger the pieces, and the closer to each other they are laid in the firebox, the longer they will burn;

- To prevent logs from hanging, they should not be too long. The ideal size is the length of the combustion chamber minus 5 cm .

Advice! You should not use flammable liquids for ignition - a dry splinter will be enough for this.

Two examples of wood heating boilers

How to make a wood-burning boiler for water heating with your own hands

- Tools and materials:

- Welding.

- Grinder, grinding and cutting discs, glasses.

- Drill, metal drill bits.

- Gas keys with numbers 1 and 2.

- Hammer.

- Set of keys and screwdrivers.

- Pliers.

- Square.

Boiler manufacturing, drawings

Basically it can be divided into three stages:

- Manufacturing of the body.

- Assembly.

- Painting.

Photo 1. Drawing of a wood-burning heating boiler indicating the dimensions of the device. Front and side views.

Step-by-step production of a wood-burning boiler:

- Preparation of material. The simplest option is a thick-walled two-hundred-liter barrel. Another suitable material is sheet steel and a pipe with a diameter of 80 cm and a length of 1 m. It is not advisable to use stainless steel, since due to low thermal conductivity, heating the room will require more firewood.

- Preparation of the bottom - the optimal thickness of the bottom is 50 mm.

- Preparing the support - use reinforcement with a diameter of 14 mm.

- Grate - a thick metal circle, at least 50 mm thick, is suitable. Slots are made in it through which ash from the firewood will flow into the ash pan.

- Preparing a metal sheet for a box with a partition.

- Preparing a sheet for a water tank (factory one will do).

- Welding reinforcement inside the housing. Fixing it on three levels parallel to each other. The first is the bottom of the boiler, the second is above the ash door, the third is 200-220 mm under the upper edge of the body.

Photo 2. Drawing of a wood-burning heating boiler made of metal. The device is shown in cross-section from the side and from the front.

- Construction of the box and dividing it into two compartments: for the firebox and for the ash. The box is inserted through the hole in the body and fixed by welding.

- Making a blower. You can simply cut a hole in the body, or you can make it in the form of a box - there will be no need to attach a door and it will become more convenient to remove accumulated ash.

- The bottom is welded not far from the bottom of the body, and a grate is welded above it. The installation level of the latter must coincide with the internal partition of the box.

- A slot is made for the pipe, the door and chimney are welded.

- A water tank is mounted above the boiler at a height of 250-300 mm. It is attached to the wall and placed so that the chimney passes through it. The heat from the pipe will heat the water.

Preparation for use

A solid fuel boiler (SFC) is a type of heating equipment that runs on wood, coal or pellets, providing room heating. Regardless of the chosen model and the principles of its operation, there are certain installation rules that must be followed.

How to protect the premises and where is the best place to put them?

To date, there are no specific requirements for placing a structure in a private or apartment building. Some experts recommend that during installation, take into account the rules set out in SNiP in the section “Boiler installations”. However, the information in the document rather refers to powerful units.

It is strongly recommended that you consider the following requirements when choosing a location:

- All heating system pipes must freely exit from the selected room and be distributed throughout the entire house or apartment;

- the room should be well ventilated and insulated;

- It is prohibited to install models in bedrooms, especially in children's bedrooms;

- installation in the corridor, kitchen is allowed;

- the device must be freely accessible from any side;

- the ideal option is to build a separate extension from foam blocks;

- it is allowed to install boilers in an outbuilding or a separate boiler room;

- the structure is mounted closer to the outer wall;

- There must be at least 100 cm of free space in front of the unit, at least 60 cm in the back and sides.

If you follow the recommendations, the operation of the device becomes easier and safer.

Preparing the room is no less important. It is necessary to pour the concrete base for the installation of the TT in advance, punch a hole for the chimney and ventilation. The walls in the room must be protected from fire. You can trim them with thin sheets of metal, asbestos cement or other non-combustible material.

If the room is decorated with wooden slabs, you are allowed not to remove them, but simply protect them with metal sheets. It is also required to place metal protruding 80 cm on all sides of the boiler. This will prevent the floor from catching fire when particles of burning fuel fly out of the boiler. If additional electrical equipment will be installed in the room, it is necessary to make a common concrete screed on the floor to protect against accidental fire.

How to make ventilation

After preparing the room and choosing a location for installing the heating device, you can begin installing ventilation equipment. The use of firewood or coal involves the generation of a large amount of dust and smoke, so this stage cannot be excluded.

For unhindered access of cold air and outflow of hot air, it is necessary to make two windows with bars. The exhaust is located in the upper part of one of the walls of the room and is small in size. The supply window is slightly larger and is located at the bottom of the adjacent or opposite wall.

Sometimes a ventilation window is mounted above the boiler, which is not recommended. The gap under the door leading to the living rooms can act as a supply opening.

Reviews about wood heating

One of the ways to choose a wood-burning stove or boiler for a summer house is a detailed analysis of reviews. They talk about the advantages and disadvantages of each of these components. However, it is worth knowing that reviews of wood-burning stoves and boilers are almost always subjective:

- Until recently, there was an old stove at our dacha. We were already thinking of replacing it with a boiler, but we did not have enough funds for this. On the advice of a specialist, a new chimney was installed - a sandwich. And what a surprise it was when the traction increased and the wood consumption became less. Conclusion - you need to first check the remaining components of the furnace, and then think about replacing it;

- After installing a long-burning boiler, the consumption of firewood decreased significantly. The only thing that was not taken into account was the mandatory insulation of the entire house. We had to urgently replace the windows with new ones;

- For the dacha we decided to use a wood stove for heating. After much deliberation, we installed a homemade heat exchanger and connected it to the pipes. The result was even better than expected. Now the house heats up much faster.

When organizing wood heating, you need to arrange a place to store fuel. This should be a room with normal room temperature and humidity. Otherwise, damp firewood will have less heat transfer.

The video talks about the basic rules of wood heating at home:

TOP 10 best solid fuel boilers

There are many models of solid fuel heating units. Depending on the manufacturer and price, the equipment has different technical parameters, design specifics, and operating features.

After analyzing reviews from owners of private houses, we identified the ten best models and collected them into a separate rating. Places in it are distributed based on user ratings and performance demonstrated in practice. We invite you to get to know each of the participants in more detail.

Place #1 – Protherm Beaver 20 DLO

The easy-to-maintain and efficient boiler from the Slovak manufacturer Protherm can be combined with electric and gas appliances. High efficiency and low heat loss allow the use of this model in buildings up to 500 m². The average price of a boiler is about 55 thousand rubles.

Main operating parameters:

- boiler type – single-circuit;

- unit power – 18-19 kW;

- efficiency rate – 90.2%;

- combustion chamber design is open;

- installation – floor;

- heat exchanger – cast iron;

- maximum temperature – 85 °C;

- maximum liquid pressure – 4 bar;

- the diameter of the hole for the chimney is 15 cm;

- device weight – 230 kg.

Wood with a moisture content of no more than 20% and fine-grained coal are used as fuel for the device.

The enlarged chamber allows you to make large gaps between adding firewood and not having to thoroughly chop it before loading. Thanks to the large ash compartment, the equipment does not need to be cleaned too often.

The combustion intensity is controlled using a control valve. Additionally, the unit is equipped with a thermomechanical power regulator and a built-in thermomanometer.

A special feature of the model is a two-pass cast iron heat exchanger in 4 sections. The device is made using a special casting technology, which promotes uniform heating of the coolant.

After complete combustion of the fuel, the cast iron slowly cools, maintaining heat in the room. However, this material also has a disadvantage - it will take a lot of time to heat up a cast iron boiler. In addition, the device is very heavy: it is impossible to install it yourself.

Place #2 - Teplodar Cupper PRO 22

The boiler of the Russian brand Teplodar is universal equipment for arranging open and closed heating systems in private homes, at technical and industrial facilities. The model serves up to 220 m² of area.

It is a combined option and can operate on different types of coal, wood/charcoal briquettes, firewood, and gas fuel. At the same time, the price of the model is quite acceptable - about 25 thousand rubles.

Main operating parameters:

- boiler type – single-circuit;

- unit power – 22 kW;

- efficiency rate – 90%;

- combustion chamber design is open;

- installation – floor;

- heat exchanger – steel;

- maximum temperature – 95 °C;

- maximum liquid pressure – 2 bar;

- the diameter of the hole for the chimney is 15 cm;

- device weight – 115 kg.

The excellent efficiency of the unit is due to a high-quality heat exchanger, as well as a number of successful design solutions. In the center of the firebox there is a special structure - a water jacket, consisting of 27 tubes placed in a chaotic checkerboard pattern.

The equipment has several compartments. Sealed doors do not allow smoke to escape and prolong the fuel combustion process. When fully loaded, the device can operate autonomously for up to 8 hours.

The model is supplemented with a small thermometer. One of the main advantages of the boiler is the built-in heating element, which maintains the optimal temperature during the combustion of the main fuel material.

The device does not cause problems in maintenance: the retractable ash pan and removable heat exchanger are easily removed and cleaned of accumulated soot.

Among the disadvantages of the boiler is the small firebox and, accordingly, the need to frequently add firewood. And also a minus is the high cost of components. To heat a small area, it is better to choose devices with lower power.

Place #3 – Lemax Forward-20

The unit from the Russian company Lemax costs about 19 thousand rubles, therefore it belongs to the budget category of heating equipment. It has an extremely simple design, so owners do not have any difficulties in operation.

This is a good option for installing autonomous heating in a house or country house with an area of up to 200 m².

Main operating parameters:

- boiler type – single-circuit;

- unit power – 20 kW;

- efficiency rate – 75%;

- combustion chamber design is open;

- installation – floor;

- heat exchanger – steel;

- maximum temperature – 95 °C;

- maximum liquid pressure – 2 bar;

- the diameter of the hole for the chimney is 15 cm;

- device weight – 78 kg.

The non-volatile boiler operates on wood, coal fuel, and wood waste. It provides sufficient heat transfer, rapid ignition of fuel materials, and cools slowly, maintaining heat.

The likelihood of harmful particles generated during the combustion process entering the room is almost completely eliminated.

Thanks to the well-thought-out vertical loading type, loading and distributing firewood in the chamber is easy and simple. The loading door is equipped with a convenient handle.

The reinforced heat exchanger with a heat-resistant coating and the boiler body itself are made of high-quality thick special steel, guaranteeing long service life of the equipment.

The floor-mounted installation model is relatively compact and has an aesthetic design. Since it does not require additional space for maintenance, it can be installed in small boiler rooms without problems.

Disadvantages include weak efficiency and fairly rapid fuel burnout, which significantly reduces loading intervals.

Place #4 - Bosch Solid 2000 B SFU 12

The classic solid fuel boiler of the German brand Bosch stands out for its stylish design and good technical characteristics. The device, which costs about 50 thousand rubles, is designed for heating various types of premises with an area of about 130 m².

Main operating parameters:

- boiler type – single-circuit;

- unit power – 13.5 kW;

- efficiency rate – 84%;

- chamber design – open;

- installation – floor;

- heat exchanger – steel;

- maximum temperature – 95 °C;

- maximum liquid pressure – 2 bar;

- the diameter of the hole for the chimney is 14.5 cm;

- device weight – 155 kg.

The model runs on wood, fine-grained brown coal, and coke. It is equipped with a vertical loading chamber, which is much more convenient to fill through the lid located in the upper part of the structure.

The cast iron grate, installed at the bottom of the chamber, is easily shaken using a side lever. For the purpose of more productive combustion of fuel materials, the main part of the firebox is lined with high-quality refractory bricks.

The boiler has the ability to adjust power. To do this, you need to use a mechanical draft regulator. The thermometer and pressure gauge built into the front panel help control pressure and temperature.

The Bosch boiler is completely energy independent, but does not have the highest power and efficiency. You also need to take into account that it does not accept excessively wet fuel. The firewood in it burns out quite quickly, so to maintain constant heat you need to be prepared for frequent refills.

Place #5 – Stropuva S40

The Stropuva S40 model is one of the most “long-lasting” wood-burning boilers. When fully loaded, it can work up to 70 hours without requiring much outside participation. The power of the device allows you to heat 400-500 m² of area. Of course, the cost of this product is appropriate - up to 100 thousand rubles.

Main operating parameters:

- boiler type – single-circuit;

- unit power – 40 kW;

- efficiency rate – 85%;

- chamber design – open;

- installation – floor;

- heat exchanger – steel;

- maximum temperature – 95 °C;

- maximum liquid pressure – 1.5 bar;

- the diameter of the hole for the chimney is 20 cm;

- device weight – 291 kg.

The boiler is installed in a water heating system and can work in conjunction with a boiler, heated floors, and radiators.

The cylindrical firebox can hold up to 50 kg of wood. Long-term combustion in it is ensured by a special surface technology: thanks to the special distribution of air flows, layers of fuel are burned in stages.

Due to uneven heating, condensation does not form on the walls of the device.

The combustion process is controlled by an automated control system operating on a thermomechanical principle: when the desired temperature is reached, the position of the damper changes. The model has an additional protective mechanism - a safety valve.

Due to its high cost, impressive power and rather complicated installation due to its heavy weight, this boiler is more often used in industrial buildings. However, sometimes it is also purchased for large private houses.

Place #6 – Kiturami KRM 30R

The Korean biofuel boiler is an excellent solution for arranging a heating system for large industrial, commercial and industrial buildings, warehouses, and private homes. It can efficiently serve up to 700 m² of area. The average price of a device on the market is 108 thousand rubles.

Main operating parameters:

- boiler type – double-circuit;

- unit power – 35 kW;

- efficiency rate – 92.7%;

- chamber design is closed;

- installation – floor;

- heat exchanger – steel;

- maximum temperature – 85 °C;

- maximum liquid pressure – 1.96 bar;

- the diameter of the hole for the chimney is 19.5 cm;

- device weight – 170 kg.

The main advantage of the model is that it operates on solid and diesel fuels with automatic switching from one to the other. For this purpose, the design provides two separate combustion chambers.

In addition to heating, the unit can provide hot water supply without additional equipment.

The boiler is equipped with an electronic control unit, sensors that monitor pressure indicators, temperature marks, and coolant level. The model has special overheating protection.

The kit includes a thermostat regulator, thanks to which you can set the optimal temperature conditions. Among the additional functions, it is worth noting automatic ignition.

The main disadvantage of this boiler is, of course, its high cost.

Place #7 - Burzhuy-K STANDARD-20

The pyrolysis boiler of the Bourgeois brand is capable of efficiently heating residential premises, utility and administrative buildings. The maximum service area is 200 m². You can purchase the unit at a price of 55 thousand rubles.

Main operating parameters:

- boiler type – single-circuit;

- unit power – 20 kW;

- efficiency rate – 85%;

- chamber design – open;

- installation – floor;

- heat exchanger – steel;

- maximum temperature – 90 °C;

- maximum liquid pressure – 4.5 bar;

- the diameter of the hole for the chimney is 15 cm;

- device weight – 270 kg.

The equipment operates on wood waste, coal, and wood materials. The duration of combustion depends on the specific type of fuel, its moisture content, the weather in the region, and the quality of the room insulation.

A deep firebox, draft regulator and pyrolysis combustion method extend this period to an average of 8-10 hours.

The body and heat exchanger of the unit are made of thickened durable steel. The design has a place for heating elements. If you connect it, the device will be able to maintain heat after the base material burns out.

As negative nuances of this model, they mention the lack of ability to adjust the temperature, as well as restrictions on the humidity of fuel materials - the pyrolysis mode only works when using firewood with a moisture content of less than 12%.

Place #8 – Viadrus Hercules U22 D-4

The universal combi boiler of Czech production is distinguished by decent power, robust and durable design, and relaxed requirements regarding smoke draft.

Its performance is sufficient for high-quality heating of objects with a total area of up to 240 m². The approximate cost is 69 thousand rubles.

Main operating parameters:

- boiler type – single-circuit;

- unit power – 23.3 kW;

- efficiency rate – 80%;

- chamber design – open;

- installation – floor;

- heat exchanger – cast iron;

- maximum temperature – 90 °C;

- maximum liquid pressure – 4 bar;

- the diameter of the hole for the chimney is 15.6 cm;

- device weight – 247 kg.

The unit accepts different types of fuel - coal, wood, gas and even waste oil. Wood shavings, pellets, chips and sawdust can be used as additional fuel materials.

The peculiarity of this model is that it can work with wood with high humidity (up to 25%). However, you need to take into account: the higher the fuel moisture, the lower the boiler power.

Thanks to the enlarged firebox opening, the device can accommodate large pieces of wood with a diameter of up to 22 cm. Power adjustment is carried out by a thermomechanical regulator. A thermomanometer is provided to monitor pressure and temperature.

The special design of the chamber ensures high fuel combustion efficiency. A single-pass cast iron heat exchanger with 4 sections promotes long-term heat retention. The boiler body is covered with an insulating layer that reduces heat loss.

Among the disadvantages of the device is the lack of a burner included, labor-intensive cleaning of ash and soot.

Place #9 – Buderus Logano S111-2-20

A good solid fuel boiler from a brand owned by Bosch is reliable and safe. It is installed in heating systems of houses whose area is no more than 200 m².

The unit can be combined with equipment operating on liquid fuels and gas. The average price of the model is 66 thousand rubles.

Main operating parameters:

- boiler type – single-circuit;

- unit power – 20 kW;

- efficiency rate – 76%;

- chamber design – open;

- installation – floor;

- heat exchanger – steel;

- maximum temperature – 95 °C;

- maximum liquid pressure – 3 bar;

- the diameter of the hole for the chimney is 14.5 cm;

- device weight – 200 kg.

The body of the device is made of stamped stainless steel. Thanks to its compact dimensions, it can easily be placed in narrow spaces. In addition to generating heat, the boiler can heat water for domestic hot water systems.

The non-volatile model is equipped with a volumetric loading chamber that accepts wooden blocks up to half a meter long. Firewood can be placed on top. The unit also works great on coal.

The water temperature, combustion intensity and air flow are controlled using a regulator, damper and a special lever. Pressure and temperature parameters are measured with a thermomanometer.

To achieve the declared maximum power of the boiler, you need to spend quite a lot of fuel, since its efficiency is not very high. This is the main drawback of the model.

Place #10 – ZOTA Master 20

An economical boiler from ZOTA is a cost-effective solution for houses up to 200 m². It sells for about 26 thousand rubles.

Main operating parameters:

- boiler type – single-circuit;

- unit power – 20 kW;

- efficiency rate – 75%;

- chamber design – open;

- installation – floor;

- heat exchanger – steel;

- maximum temperature – 95 °C;

- maximum liquid pressure – 3 bar;

- the diameter of the hole for the chimney is 15 cm;

- device weight – 128 kg.

A special feature of the model is a removable hob that serves as a regular household stove for cooking.

This heating boiler runs on wood and coal. However, due to the insufficient depth of the firebox, only finely chopped wood will have to be used in it.

The unit is equipped with good thermal insulation and an efficient heat exchanger design. The operation of the device is automated by a mechanical draft regulator. To control the temperature, a thermometer is built into the panel, but there is no pressure gauge in the equipment.

In general, the device copes well with its tasks, but, judging by user reviews, it is not entirely easy to maintain.

We install the heat generator and chimney

As such, installing a heating boiler on the floor or foundation is not difficult - the unit must be placed in the design position and aligned vertically using adjustable legs or metal pads. It is not necessary to scrupulously maintain the alignment of the chimney pipe and the hole in the wall: they can be combined without problems by turning the knees.

Important point. To avoid problems with the formation of condensation during operation, it is strongly recommended that the chimney of a wood-burning heater be assembled from insulated pipes - sandwiches. The second option is to make a chimney with your own hands: take an ordinary pipe and cover it with basalt fiber.

Factory-made and home-made sandwich pipes for chimneys

The easiest way is to install an external chimney duct of an attached type. That is, attach the pipe vertically to the wall and connect the gas duct from the TT boiler through a tee. In a wooden house, the passage through the outer wall or ceiling for access to the roof is carried out in compliance with fire safety rules using the following technology:

- Cut a square opening in the partition, the dimensions of which are 38 cm larger than the internal chimney pipe in each direction. For example, if the diameter of the channel is 100 mm, and the thickness of the sandwich insulation is 5 cm, then the size of the opening will be 100 + 380 x 2 = 860 mm.

- Install a pass-through unit made of galvanized steel in the form of a box.

- Pass a sandwich pipe through it, and fill the void with basalt wool.

- Secure the outer assembly cover.

Note. A chimney is laid through a wall made of brick or foam block using a steel liner and seal.

Scheme of assembly and connection of an attached chimney from a sandwich

Next, we list the requirements that must be met when installing a chimney duct:

- number of pipe turns – no more than three, minimum height (calculated from the boiler grate) – 5 m;

- sections (modules) are joined together in such a way that condensate can drain inside the pipe, and rain can drain outside;

- mount the horizontal part with a slight slope towards the heat generator;

- install an inspection hatch and a condensate collector in the lower part;

- To avoid having to cross the roof eaves, go around it with a pipe using two 30° elbows; Drawing of a gas duct laid from the boiler inside the house with exit through the roof

- wall brackets should not coincide with the joints of the chimney sections;

- Place a cap in the form of a cone or a rotating weather vane on the head of the chimney.

The correct installation and assembly of a modular chimney is reflected in two connection diagrams, which show external and internal installation through the ceiling.

Minimum pipe head height depending on the distance to the roof ridge

Important note. Make sure that the head of the chimney duct does not end up in the area of wind support on the roof of your or a neighboring house. To ensure stable traction, raise the pipe to the mark shown in the diagram above.

Rules for choosing a heating boiler

Before you start choosing a specific heating boiler model, you need to study the criteria that you should focus on. By understanding the operating features and basic parameters of the equipment, you can choose a device that can satisfy all your needs.

First of all, consider these nuances:

- boiler type and efficiency;

- camera design;

- device power and room area;

- combustion time and supported fuel types;

- heat exchanger material;

- additional functions and protection systems.

Boilers are single-circuit and double-circuit . The first option is connected to an autonomous heating system and is intended exclusively for heating. Some models work in conjunction with a boiler.

The second option replaces the water heater and boiler, providing not only heating, but also hot water supply.

The boiler efficiency indicator, expressed in the efficiency parameter, shows how productive the device is. The higher it is, the less volume of fuel materials will be needed to heat the room

One of the main indicators of equipment is the output thermal power. This parameter must be selected based on the area that is supposed to be heated.

It is highly desirable that the model has the ability to adjust the power, allowing you to achieve the optimal comfortable temperature.

Boilers with an open chamber design take oxygen from the room and remove combustion products through the chimney. They should be installed in areas with good ventilation. Units with a closed chamber type can be placed in almost any room

The frequency of loading depends on the combustion time of the fuel in the boiler. Pyrolysis boilers and long-burning appliances retain heat the longest. The best option would be units that run not only on wood, but also on alternative fuels.

Also, when choosing, it is important to pay special attention to the heat exchanger:

Image gallery

Photo from

Heat exchanger in a heating boiler

Solid fuel boiler with steel heat exchanger

Cast iron model of heating boiler heat exchanger

Boiler with copper heat exchanger

Operational safety and equipment efficiency are enhanced by additional built-in mechanisms and functions. It’s good if the selected model has overheating protection, devices for regulating traction, measuring current pressure and temperature.

Wood heating schemes for a house

Connection diagram for a boiler with a heat accumulator

The key point in designing wood heating is the choice of circuit. It depends on it whether a wood-burning heating boiler will be installed with your own hands or whether its functions will be performed by a stove or fireplace. To determine the optimal option, it is necessary to take into account all possible factors.

First of all, the area of the building and the number of rooms are taken into account. Most often, wood-burning heating stoves for summer cottages are installed if there are a maximum of two rooms. In this case, there is no need to create a water heating system.

Let's consider the main factors influencing the choice of heating type:

- Vodyanoye . It consists of a boiler (stove, fireplace) connected to a pipeline. The transfer of thermal energy occurs due to installed radiators. The best option for a house with an area of 80 m² or more;

- Pechnoye . Wood heating stoves are used to heat the air in the room. They are characterized by low efficiency and small heating area. However, their arrangement requires the least amount of effort. The exception is structures made of fireclay bricks. This type is used to heat houses with an area of less than 60 m²;

- Fireplace . Analogue to furnace heat supply. The difference will be in the size of the combustion chamber - in a fireplace it is much larger. In addition, heating a private house with a wood-burning boiler sometimes implies the presence of a hob in the design.

Heat exchanger in the furnace

As you can see, the choice of option directly depends on the area of the house. It must be taken into account that the wood heating circuit can be modernized. It is enough to install a heat exchanger in the furnace to make it possible to provide a full water heat supply.

But the most common option is to install a wood-burning boiler for heating the house. It is much more practical and easier to use than a fireplace or stove.

For normal operation of wood heating in a country house, it is necessary to think through the chimney system in advance. The optimal diameter of the pipe and its height are taken into account.