Types of heated towel rails

The modern market offers a wide range of different models of devices for drying towels. According to the type of energy consumed, heated towel rails are divided into three main types:

- Water. In private homes, the device is connected to the heating circuit and functions only while the boiler is being used to heat the room. Water is used as a coolant. In apartments, it is possible to connect this type of heated towel rail to hot water supply.

- Electric. This model operates independently of the heating system. The device is heated by a heating element. To connect such a heated towel rail, an electrical outlet is required. You can use the device for drying things and additional heating of the room for any room in the house.

- Combined. The design of the heated towel rail combines a water circuit and electrical energy. The heating element heats the coolant liquid, which is the heat source in the device.

Based on the meter of location, a distinction is made between horizontal and vertical types of heated towel rails. On the modern market you can find corner and floor designs, which are especially relevant for small bathrooms.

The materials for making towel dryers can be:

- Steel. Devices made from this material have a low cost and many disadvantages - low wear resistance, susceptibility to corrosion, and the possibility of peeling off the chrome coating. The best option is stainless steel. Its cost is an order of magnitude higher, but at the same time the technical parameters of the product increase.

- Copper. Such heated towel rails are considered durable. The only drawback is the high price of copper products.

- Aluminum. This material has good thermal conductivity. Aluminum dryers are relatively inexpensive universal products.

- Brass. This material, like copper, is endowed with high wear resistance and resistance to corrosion. Due to the high thermal conductivity of drying towels made of brass, you can choose small sizes.

Copper heated towel rail

Heated towel rails are produced in various sizes. Standard devices are shaped like a snake or ladder. The variety of modern models allows you to choose a towel dryer of the most unusual design.

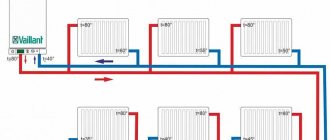

Upper and lower wiring of a two-pipe network

At the moment, wiring installation is done in two ways:

- Top

: the distribution pipeline is laid from above, an expansion tank is installed at the highest point of the heating circuit (insulated attic). This option is suitable for private houses and cottages with a hollow roof; - Bottom

: The “hot line” is installed in the basement or under-floor space. The return pipe for cooled water to the boiler should be located lower than the direct pipe. An upper air line is used to remove excess air from the network. In this case, the device itself must be mounted in a recess, because for uniform heat distribution, the batteries must be located above the boiler.

Both schemes are relevant for any type of arrangement of supply pipes. At the same time, the lower wiring is used mainly in multi-storey residential buildings, while the first is relevant for private houses and cottages.

There are several ways to connect water dryers: bottom, top, corner and side.

The most acceptable option is a side connection.

Such models can be adjusted to different installation locations. Also, such a connection will have a more aesthetic appearance, due to the fact that it will be almost invisible.

Before purchasing a device, you should find out the distance between the hot water supply outlets. Almost always it is 50 cm.

Requirements for connection diagrams

The installation of a heated towel rail is carried out according to a specific scheme, which is selected taking into account the characteristics of the model and the location of the pipeline in the room. The most common and effective is the side and bottom insert. Each option has its own connection features.

When using a towel dryer using the bottom cut-in method, the following must be taken into account:

- the heated towel rail should be located above the level of the lower outlet from the riser;

- along the straight sections of the heated towel rail pipes, the presence of depressions and protrusions, which can cause air accumulation in the system, is excluded;

- when using a bypass of an offset or narrowed type, the upper supply to the riser must be placed below the drying device;

- pipe sections hidden in the walls must be protected with heat-resistant insulation.

The lower connection diagram ensures the working process regardless of the direction of the water flow.

Installing a heated towel rail using a diagonal or side connection is more practical. The main condition for this type of connection is:

- no bends in the supply pipeline;

- the slope of the supplied pipeline must be at least 3 millimeters per meter of connection;

- when installing a heated towel rail at a short distance from the riser and using a pipe with a cross-section of 32 millimeters, a horizontal pipe connection is possible;

- The connection points for the towel dryer must be located between the upper and lower outlets of the vertical pipeline.

With a diagonal connection, air bleed is not required and any distance of the device to the riser is allowed.

With or without bypass

Let's start with what a bypass is. This is a jumper between the input and output of the device, which ensures water circulation when the device fails or is turned off.

The jumper between the input and output of the heated towel rail is the bypass

If the circuit has a bypass, shut-off ball valves can be installed at the inlet and outlet of the device. This is convenient - you can turn it off if necessary (during repair or replacement) and not block the entire riser.

If there is no such jumper, no taps can be installed. In this case, the heated towel rail is part of the riser; by closing the taps, you completely shut off the riser.

When connected without bypass, no taps

The bypass can be direct (as in the first photo in the chapter) or offset (in the photo below). An offset jumper is installed at the top supply of coolant for better performance (circulation improves). With bottom feed, the offset only gets in the way. If you don't know where the water is coming from, it's better to do a direct bypass.

Offset bypass with upper coolant supply improves circulation

Bypasses (straight or offset) are also made narrower. Tapering, as well as displacement, improves circulation, but only in the case of top feed. The narrowing is made with a pipe that is one step smaller than the main one (if the riser is inch, the bottleneck is made 3/4″). You can't do less. The insert size is at least 10 cm.

It is strictly forbidden to install taps on the bypass. Each tap is a loss of pressure, which means it worsens the circulation of the entire riser, the water flows no longer so hot. For all neighbors above or below (depending on the direction of supply), the pressure deteriorates noticeably. Sometimes it also falls on the owner of the bypass with the tap. In addition, this is an absolutely unnecessary detail that only causes harm, and no noticeable improvement in circulation in the heated towel rail is observed. Well, and besides, this is a violation of SNiP 01/31/2003 (clause 10.6) - interference with public communications, for which a (considerable) fine may be issued.

Options for technical solutions

Installation of a heated towel rail in a private home can be carried out in several ways - connecting to the main heating system, installing on a separate circuit or connecting to a hot water supply. Each option has its advantages and disadvantages.

Heated towel rail on a separate heating circuit

This installation option is suitable for any model of water heated towel rails. The device is connected on a separate closed circuit together with the pumping group.

The advantage of using this installation method is:

- providing heating of the bathroom without the use of radiators;

- convenient use regardless of the time of year;

- the ability to install any design of a water heated towel rail, which allows you to implement any design solutions.

Heated towel rail on a separate heating circuit

The disadvantages of connecting a device for drying towels to a separate heating branch often include the complexity of installation work. To install the device, additional equipment is required, which includes a pump, a separate collector outlet and automation.

Connecting the structure to the main heating circuit

This method of connecting a heated towel rail to the heating system is less expensive. But for convenient use of the device, it is recommended to additionally install a temperature limiter. This is due to the strong heating of the coolant in the supply circuit, which often causes discomfort when touching the dryer with your hands.

Using the option of connecting a heated towel rail to the main heating circuit has its advantages:

- the ability to use the device as the main heating of the bathroom;

- low installation costs;

- Application for any models with liquid coolant.

The disadvantage of this installation is that the device is turned off in the summer along with the heating system.

Hot water connection

This type of installation involves connecting a heated towel rail to a central hot water supply. The option is quite economical, since it does not require the installation of additional devices and is successfully used in apartments.

The advantages of this type of connection include:

- uninterrupted use with year-round supply of hot water;

- simplicity of installation work, no additional costs.

Connecting a heated towel rail to hot water has its disadvantages:

- for installation, it is allowed to use only certain models of dryers made of standard stainless steel;

- limited possibility of use as the main heating of the bathroom.

The power of dryer models that are designed to be connected to hot water supply is no more than 200 watts, so installation in a room without radiators or heated floors is impractical.

Typical mistakes of independent craftsmen

When, with a side or bottom connection, the lower outlet is located above the extreme point of the PS, a stagnation zone is formed between the bottom of the device and the connection point of the lower outlet.

This is a consequence of the fact that the cooled liquid, having dropped down, cannot get back into the riser due to the pressure on it from a column of hot water with a lower specific gravity. As long as the permissible height difference between the bottom outlet and the bottom of the heated towel rail is not exceeded, the device works, and after that the circulation in it stops.

Circulation will also stop if there is a bend formed by the upper pipe. The only way to make such a scheme work is by inserting a Mayevsky tap to periodically bleed off the accumulated air. Sometimes a loop is made in the upper pipe, laying it behind the ceiling trim, and the lower pipe is walled into the floor.

Air will accumulate at the top, and the cooled water in the unit will be blocked in the lower loop located in the floor. The movement of the coolant will stop completely.

Materials for work

In private homes, water heated towel rails are mainly installed, which are connected directly to the heating system.

When connecting the device, you must use the following materials:

- shut-off valves;

- fittings – couplings, bends, bends;

- air vent valve;

- mounting tow or tape;

- fastening elements - dowels, brackets, bolts, screws.

To connect a heated towel rail in a private house, you will need an installation tow.

Experts recommend installing a bypass on the heated towel rail, which is a piece of pipe with tees at the edges. In this case, ball valves are mounted at the ends of the dryer.

Rules and procedures for connecting a heated towel rail

Installation of the device in the heating circuit is carried out by inserting a pipeline. Before installation work, the water supply is turned off and the coolant is drained from the system.

Connecting the water towel dryer is carried out in the following sequence:

- the location of the device is determined and appropriate measurements are taken;

- threads are cut at the ends of the pipeline;

- The bypass is assembled, tees and a shut-off valve are fixed on the pipe;

- to ensure complete tightness of the connections, tow or a special thread is used;

- Ball shut-off valves are installed on the taps, to which the device inputs are connected.

The valves connected to the heated towel rail are left in the open position, and the shut-off mechanism on the bypass is closed. After connecting the dryer, it is necessary to fill the system with water and check the joints under pressure for leaks.

Recommendations for installation work

The efficiency of a heated towel rail depends on its correct installation. To avoid future problems with the operation of the device, it is recommended to take into account the following recommendations during the installation process:

- The diameter of the pipeline should not exceed the cross-section of the heated towel rail itself. Compliance with this requirement helps prevent an increase in pressure in narrowing areas.

- Installation of adapters in the presence of different sections of pipelines and pipes is allowed if the diameter of the towel dryer is smaller than the pipes. Violation of this installation procedure can cause a significant increase in pressure in the device, which will lead to an emergency.

- To remove air from the device, ensure normal operating process, as well as the possibility of repair, it is recommended to install a bypass. In order not to disrupt the good circulation of the coolant, shut-off valves should not be installed on the jumper.

- A distance of 4 centimeters must be maintained from the wall surface to the heated towel rail. If the diameter of the device pipes exceeds 25 millimeters, then it should be increased to 7 centimeters.

- The location of the bottom of the dryer from the floor should be 90 centimeters. The optimal height is considered to be 120 centimeters.

Experts recommend using materials of the same origin when installing a heated towel rail. The combination of different metals can lead to the process of structural destruction. Teflon gaskets will help eliminate problems with corrosion at joints.

The method of installing a heated towel rail in a private home depends on the type of device chosen and the complexity of its design. Taking into account all the installation requirements, you can connect the towel dryer yourself.

What not to do

All the above schemes work stably. As you noticed, all bends go straight, without bends in the form of an arc or rings. This is not accidental - air accumulates in all irregularities, which interferes with, and sometimes completely blocks, circulation.

This scheme doesn't work

The installation of the heated towel rail in the photo is incorrect. At least two mistakes were made:

- the bends are made narrower than the center distance of the heated towel rail;

- They are made with a metal-plastic pipe with loops.

This connection simply cannot work. Metal-plastic pipes are an excellent material, but not for connecting heated towel rails. Their fittings have a very narrow lumen, which has a bad effect on circulation. Plus, air accumulates in the loops, and the flow along the upper loop, even when supplied from above, will not flow - too much hydraulic resistance to the water must be overcome.

Unstable circuits

The following two schemes may work, but not always. At the bottom of the heated towel rail, the water stagnates and, given any difference in height, cannot rise. No one can say specifically when it will work and when it won’t. Depends on the pressure in the riser, the diameter of the pipes and the design of the dryer itself.

Unstable connection schemes

With such a connection, even a working connection may suddenly (usually after stopping) stop working. Everything is simple: the pressure has changed, the pipes are clogged, the water from below is not “pressed”, the heated towel rail does not heat.

Another option for an unstable circuit is with a loop on top. Again, it will work under certain conditions. But sooner or later the highest point will become airy and block the circulation. The problem can be helped by installing an automatic air vent at the highest point, but if the pressure drops, it will not save you.

With loop on top

Not true at all

The photo below shows examples of what not to do. Schemes without a tap on the bypass are inoperative. What this threatens is known. In addition, after several years of use, they will stop functioning altogether. Most likely this will happen after the next shutdown - the system will become clogged with dirt. This is because the entire flow of hot water is directed through the heated towel rail. After repairs, the water carries a huge amount of dirt, which safely settles in the bends (in the lowest areas first). Within a few years everything becomes completely clogged. Fortunately, everything needs to be redone and connected correctly, but only flushing can help the fire.

Very bad idea

It is necessary to wash both the heated towel rail and the connections to it. To do this, remove the dryer and wash it in the bathroom, and wash the outlets one by one by connecting a hose to the free outlets, the other end of which is taken to the sewer. By manipulating the taps, pass a flow of hot water through one outlet, then through the other. After washing everything is put back in place. It may be possible to start the system after this.