In terms of practicality and cost, liquid fuel boilers are somewhere between solid fuel and gas. They still require space to store fuel and tanks for it, and are still not completely autonomous due to the need for regular maintenance. At the same time, liquid fuel boilers do not require a large number of documents and, on average, have a higher efficiency than their gas counterparts.

However, liquid fuel boilers are chosen mainly due to the availability of a stable source for purchasing this fuel at a lower price. In the article we will look at liquid fuel options, what their consumption is, how economically profitable they are and where to get them, and also give an example of the most successful boiler models.

Types of liquid fuel for boilers

In domestic conditions, in more than 80% of cases, diesel fuel (diesel fuel) is used as liquid fuel. Accordingly, it is burned by universal gas-diesel boilers or specialized diesel boiler units. In addition to wholesale purchases, you can find diesel fuel at a lower price from agricultural enterprises, tractor drivers, truck or bus drivers.

In almost all instructions for boiler units, the manufacturer indicates fuel requirements; for 2022, the standard is fuel with a viscosity of up to 6 mm2/s at 20°C. In Europe, this is a common fuel for heating private houses under the marking EL DIN 51603; in Russia, its closest analogue is the Euro-4 standard.

From the instructions for De Dietrich NeOvo EcoNox liquid fuel.

It is easiest to determine the approximate consumption of diesel fuel by a boiler, since it is known that 1 liter of Euro-4 fuel, when burned in a modern boiler with an efficiency of 90-95%, produces 1 kW of thermal energy (+-5%). As a result, the consumption of diesel fuel by the boiler = Nominal power of the boiler (kW) / 10 is the hourly consumption when operating at maximum power; in practice, the boiler is active for an average of 1/3 of the day.

For example, with a power of 24 kW, the maximum consumption is 24/10 = 2.4 l/h. In practice, this will be about 0.8 l/h - this is the most accurate generalized calculation method. Calculate the real indicator without individual initial data such as the degree of insulation of the house, temperature requirements, weather conditions, fuel quality, etc. impossible. However, it will differ slightly from the theoretical one.

Less common diesel alternatives are:

- Used oil . Much cheaper, but almost equally calorific fuel. It can be purchased for a completely symbolic price from service stations and auto repair shops, agricultural enterprises, any type of vehicle fleets, factories, and railway depots. However, the initial cost of household boilers that burn waste is extremely high (usually from 100 and even 150 thousand rubles), and due to the low environmental friendliness of the raw materials, the boilers require regular maintenance.

- Fuel oil . A more expensive analogue of mining, fuel oil of the M100 and M40 grades is most often used as fuel for heating. It is burned in heating boilers running on waste oil; it is not economically justified on a domestic scale.

- Light heating oil . Similar to diesel fuel, but since heating oil is not used in cars, requirements such as cloud point, cetane number, etc. are not observed during its production. In view of this, the price for it is on average 5% lower - 43-46 thousand rubles / ton, when diesel fuel is 45-49 thousand rubles / ton.

- Kerosene . Boilers capable of burning it are extremely rare; usually these are models that run on waste and fuel oil. It has only 5-8% higher calorific value, but costs on average 75-95 thousand rubles/t.

- Rapeseed oil . An alternative to diesel fuel, several times cheaper in cost. However, there are very few diesel boilers running on rapeseed oil, and it is extremely difficult to obtain raw materials, unless you own a rapeseed field.

Selection of fuel storage containers

Organization of the boiler room space with a plastic container for storing fuel indoors.

To store liquid fuel, even with a boiler of the lowest power, special containers are needed. They can be made of steel, stainless steel or aluminum, but today plastic is most often used - durable, lightweight and resistant to temperature changes on average from -50°C to +50°C. According to SNiP, in the boiler room it is permissible to place a container with a volume of up to 0.8 m3 (800 l), at a distance of more than 1 m from the burner. If the volume is larger, the tank must be placed behind a blank wall or outside.

When storing outdoors, it is worth considering the need for an additional pump; the characteristics of the standard pump are usually indicated in the instructions, and you should rely on them. Also, the external part of the pipeline must be insulated in accordance with the type of fuel used. For example, the viscosity of diesel fuel changes significantly at +5°C and below, and fuel oil solidifies on average at +10°C.

It is advisable to store fuel for no more than a year, and it is most profitable to stock up for the entire heating season, so for the first time you need to calculate the approximate consumption for the entire season. Further, the amount of fuel consumed will be known thanks to the practice of the past heating season.

How to fill the heating system in an apartment building

Scheme of water heating with associated movement of water: 1 – boiler; 2 – main riser; 3 – expansion tank; 4 – air collector; 5 – supply risers; 6 – return risers; 7 – return line; 8 – expansion pipe; 9 – pump; 10 – direction of pipe slope.

The water valve located in the house should be closed, and the water discharge on the coolant supply pipeline is gradually opened. At this time, the discharge on the return line is blocked. Then you need to very slowly open the valve on the return line until it is completely open

Caution must be exercised because if the high-pressure water supply of a general heating system is suddenly opened, this can lead to sudden changes in pressure, causing water hammer. The push can be so powerful that one will be enough to break the system in the most vulnerable places. It will take some time for the heating system to fill

Reset should be monitored continuously. When water flows without any admixture of air bubbles, and this can be understood by the cessation of the characteristic hissing sound, close the discharge valve. Now it’s time to open the water supply valve to a specific room. At the final stage, all that remains is to bleed the air from all heating circuits. This method of filling the system with water is intended for heating with bottom wiring

It will take some time for the heating system to fill. Reset should be monitored continuously. When water flows without any admixture of air bubbles, and this can be understood by the cessation of the characteristic hissing sound, close the discharge valve. Now it’s time to open the water supply valve to a specific room. At the final stage, all that remains is to bleed the air from all heating circuits. This method of filling the system with water is intended for heating with bottom wiring.

A system with top piping looks much easier to use

In this case, you should simultaneously, with the same caution, open both dampers at once, while the discharge should be closed. To bleed air, go up to the attic of the building and open the air valves provided by the design

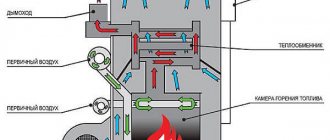

Design and principle of operation

Liquid fuel boilers are both single-circuit and double-circuit, but exclusively energy-dependent models, the operation of which requires a connection to the electrical network. In fact, liquid fuel models differ from gas models only in the burner, which is adapted to the characteristics of a particular type of fuel and is equipped with a turbocharger necessary to spray the fuel throughout the combustion chamber. Any type of liquid fuel requires preheating, which is also carried out in the burner, all this makes it so massive and large-sized.

The rest of the operating principle is standard:

- Fuel from the reservoir is supplied to the burner heating chamber, then atomized using a nozzle and ignited in the combustion chamber.

- Above the combustion chamber there is a heat exchanger, which heats up and transfers thermal energy to the coolant located inside (often all the walls of the combustion chamber are a heat exchanger).

- The coolant (usually water) circulates through the system giving off heat to the heating radiators.

There are also models with a different structure and operating principle; we have already described them in a more detailed analysis of diesel boilers and boiler units that burn waste oil:

All the details you need to know about diesel boilers for heating a private home

All the details you need to know about waste oil boilers for a private home

Classification

Depending on the capabilities of water heating, diesel fuel heating boilers are divided into

- single-circuit, which are not intended for heating water;

- double-circuit with heating element or storage boiler.

Diesel boilers can have natural draft, when gases are removed through a chimney, or forced draft.

Forced draft is provided by blower fans and requires the installation of a coaxial chimney (it is built on the principle of “pipe in pipe” - combustion products are discharged through the inner pipe, and combustion air through the outer one).

A special feature of oil boilers is the presence of an oil heating system.

Almost all modern models have automatic control, a built-in thermostat, operation control sensors, and forced removal of combustion products.

Reviews of household liquid fuel boilers: advantages and disadvantages

| Advantages | Flaws |

| Reliability - liquid fuel boilers, especially if they are expensive European models, are durable and trouble-free | The use is not always justified in economic terms. Diesel models have high fuel costs, and used oil models themselves are extremely expensive. To obtain benefits, you need to comply with many conventions. |

| Operating costs – almost any type of fuel can be obtained at a fairly low cost, especially used oil | Energy dependence - due to forced-air burners, all liquid fuel models require connection to the electrical network |

| Autonomy - after starting and setting up the boilers practically do not require human intervention throughout the entire season | The operation of burners and boilers in general is quite noisy, but the owners note that the noise is not audible even behind the thin walls of the boiler room |

| Availability of both single-circuit and double-circuit models | The need for good ventilation, according to reviews from the owners - forced, natural - does not relieve the room from the constant smell of fuel |

| Almost all models are equipped with a standard list of protection systems | |

| No permission required for connection and installation |

User reviews

Vasily, 41 years old, Tver region:

“I was choosing between a long-burning solid fuel boiler and an oil boiler. I leaned towards the second option, since such equipment, if there is a supply of fuel, operates without human intervention. At first the coaxial chimney was simply brought out through the wall, but then they built a tall one: the unpleasant smell from the exhaust bothered me.”

Grigory, 54 years old, Ivanovo region:

“We haven’t installed gas yet, so we installed an oil boiler. I recommend choosing clean fuel, otherwise the injector will quickly clog. In winter, due to strong winds, there are problems with electricity, so I bought a diesel generator.”

Minimum required power

An accurate calculation of the boiler's heating output is carried out by a heating engineer based on SNiP 2.04.01-85. However, in domestic conditions, for an average uninsulated or weakly insulated house with a masonry of 2 bricks and a ceiling height of 2.7 m, the minimum required power is calculated from the rule of 1 kW per 10 m2, we also recommend laying a 20% reserve.

For example, for the house described above with an area of 150 m2, the minimum required power of an oil-fuel boiler will be (150/10) * 1.2 = 18 kW.

Safety regulations

The basic requirements are indicated by manufacturers in the technical documentation and are as follows:

- Safety of operation depends on compliance with the manufacturer's requirements.

- Independent repair or modernization of the burner or furnace is not allowed.

- Electrical circuits must be grounded in accordance with the “Rules for Installing Electrical Appliances”.

- A packet switch should be provided in the power circuit.

- It is prohibited to operate the equipment in rooms with high humidity or dust.

- No flammable materials should be stored in the room in which the boiler is located.

- Coolants approved by the equipment manufacturer can be used to charge the circuit.

- If you do not plan to operate the boiler in winter, then you should drain the water from the heating and hot water supply lines.

- When refilling tanks, do not leave the equipment turned on.

The best known manufacturers and models: characteristics and prices

Kiturami Turbo 13R

The most common and one of the best liquid fuel boilers for heating a private home in the budget price category. This is a diesel double-circuit model, the primary heat exchanger is steel, the secondary (for hot water supply) is copper. The fuel consumption of the 13 kW model is 1.97 kg/hour (2.25 l/hour), quite average, but sufficient. In general, the model is characterized by the minimum required set of components and the minimum required operating efficiency, due to which it is possible to maintain one of the lowest prices on the market.

At the same time, the boiler is known for its reliability and trouble-free operation. Separately, it is worth noting the functionality; for this price, the basic package includes a room thermostat - an extremely useful device that affects not only comfort, but also savings. There are all the minimum necessary protective systems and auto-diagnostics. Available in 13, 17, 21 and 30 kW versions.

Ferroli ATLAS 32

Universal Italian boiler with replaceable burner (diesel gas). Known for its high reliability, cast iron heat exchanger and efficiency of 94.3%. Users like to note the extremely quiet operation of an oil-fired boiler. There is protection against overheating and freezing, it is possible to connect an external thermostat, but it is not included with the boiler.

The only drawback is the lack of low-power models. Available in versions with heating outputs of 32, 47, 62, 78 and 95 kW. Please note that it is usually sold without a burner, which must be purchased separately. Diesel fuel – SUN G burner, gas – SUN M burner.

ACV N3

Another universal gas-diesel model made in Belgium. A diesel burner here also needs to be purchased separately; burners BMR 31, BMV 1FV, BMV 2FV can be installed on this model. Unlike the previous Ferroli, here the heat exchanger is made of furnace steel, however, based on the experience of other models, even steel heat exchangers from ACV have never had any questions, as with all boilers in general. The manufacturer is known for the practicality and absolutely trouble-free boiler units. However, the price is corresponding, in our opinion, too high; if the budget is strictly limited, this model is not the best choice.

There are protections against overheating, lack of traction, low-temperature corrosion, there is a connector for external control, but the thermostat itself is not included in the basic configuration. The body is thermally insulated; owners note the low noise level of the burners.

NORTEC B70 (WB 40)

Domestic model that burns waste oil. Despite the low cost for boilers of this type, the amount is still significant and will only pay off when used in a large private house (from 300-400 m2) with permanent residence; purchasing such equipment for a summer residence with temporary residence is irrational. In addition to mining, it is capable of burning fuel oil, heating oil and even crude oil. The 40 kW model consumes up to 4 l/hour of fuel.

From the factory, the boiler is already equipped with all the necessary components of the fuel unit - a transfer pump, a disposable fuel filter and a fuel intake. Equipment of this type uses extremely wear-resistant and durable materials that do not raise questions about reliability. In this model, the automation is equipped with the minimum necessary functionality: a basic set of protection systems and the ability to set the temperature in the system. Due to its simplicity, there are also no problems with it.

Cost: 146,000-175,000 rubles.

How to reduce diesel consumption

Let's look at how to reduce diesel consumption. First of all, you should pay attention to the thermal insulation of the house. Modern materials and methods of heat conservation will reduce the number of days when it is necessary to heat and retain the heat produced.

Increasing the sections in the radiators will also increase the efficiency. Thus, the required coolant temperature is reduced, saving diesel fuel. High-quality burner adjustment using software adds 10% savings. By installing a thermostat in the room, you will avoid excessive heating of the room and automate the control of the device.

To get the maximum benefit from using a diesel boiler, you should approach its installation in a comprehensive manner. By insulating the house, designing the heating system and setting up the automation properly, you will heat the room at minimal cost.

Prices: summary table

| Model | Available power, kW | Number of circuits | Efficiency, % | Cost, rub. |

| Kiturami Turbo 13R | 13, 17, 21, 30 | double-circuit | 86 | 43 000 |

| Ferroli ATLAS 32 | 32, 47, 62, 78, 95 | single-circuit | 64,3 | 63 000 |

| ACV N3 | 16, 25, 30, 51 | single-circuit | 90 | 93 000 |

| NORTEC B70 (WB 40) | 40, 59, 147, 197 | single-circuit | — | 159 000 |

DieselLiquid fuel BoilersWaste oil