The long-burning industrial solid fuel boiler came to our homes not so long ago, although humanity has known about the principle of this kind, slow burning, since medieval times. And the technology of a “smoldering fire” enclosed in a stone vice will be demonstrated in practice by any professional forester or hunter. There are a great many modifications, and almost every seller offers a long-burning solid fuel boiler.

Choosing the optimal and reliable long-burning boiler for a private home can only be done after a thorough assessment of the characteristics of the presented devices. In addition, it will be necessary to coordinate them with the characteristics of the heated room.

A solid knowledge of the range and classification of devices will help you choose a long-burning solid fuel boiler. Let's take a look at their varieties together and see what makes up the price of such an interesting and attractive product.

The demand among the population to buy long-burning solid fuel boilers is based on the constant need to save money, as well as the time spent on adding fuel and regularly cleaning equipment.

Description of design

As a rule, long-burning boilers are not used for heating water , that is, they are mainly made single-circuit. They are used in systems with forced circulation of water media. Even if heating the water is possible, its temperature is no more than 80 degrees. The design is equipped with a control unit that allows you to regulate the intensity and performance of room heating. If an emergency occurs, the regulator will signal about it.

Advantages and disadvantages

Among the main advantages are the following:

- ease of maintenance;

- affordable cost of equipment and fuel;

- positive reviews;

- autonomy;

- possibility of choosing different types of fuel;

- environmental cleanliness;

- excellent efficiency;

- intuitive controls;

- safety.

Heating a private house with a solid fuel heater, especially an automatic one, does not require large amounts of time spent servicing the equipment. It is enough to add fuel once every couple of hours (and probably even a day).

The disadvantages can probably be attributed to the fact that the entire heating procedure is a kind of vicious circle: loading fuel, ignition, combustion, extinction, cleaning.

We also note that most models are very sensitive to the quality of fuel and barely regulate the temperature.

Due to the fact that solid fuel devices have recently gone through many stages of improvement, they have become very economical and quite effective, which is the reason for their increase in popularity. There are also automatic long-burning boilers. Modern equipment can operate with a one-time load from 5 to 36 hours. The size of the firewood used has also changed. Now it is possible to load firewood up to 1 meter long and up to 20 cm thick. Such a large fuel size saves material and time costs during procurement.

In order to most accurately understand what we are talking about, we will describe the technical data of one of the devices - KT-2E (made in Ukraine):

- heating area - 250 sq. m;

- power - 25 kW;

- loading chamber volume - 62 cubic meters. m;

- fuel capacity - 56 kg;

- burning time on one tab is around 8-46 hours (this depends on the type of fuel);

- firewood size - 46 cm;

- dimensions of the loading opening - 230x370 mm;

- water in the boiler - 117 l;

- Efficiency - 83%;

- chimney size - 170 x 170 mm;

- water pressure - no more than 3 bar;

Known analogues

In addition to the previously listed “Nedelka”, LIEPSNELĖ, Stropuva, “Stimul”, the most often mentioned in comparison are the “Peresvet” boilers, which are sold at approximately the same prices.

In terms of fuel combustion efficiency, they are almost identical, however, they have much smaller fireboxes (and this means a shorter burning time of one load), as well as a less practical combustion shaft design, which implies the use of much more fragmented logs 36-42 cm long. Otherwise, it is worth noting that that Peresvet mine boilers are much more efficient when burning pellets, and also have a maximum permissible operating pressure of 1.5 bar.

BoilersReviewBoiler ManufacturersSolid Fuel Boilers

Principle of operation

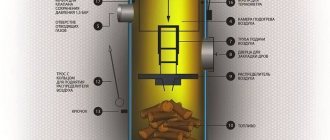

Solid fuel boilers consist of the following parts:

- heat exchanger;

- fan;

- fuel bunker;

- combustion chambers;

- smoke exhauster.

Solid fuel is placed inside the bunker and set on fire.

Limited air and high temperature create the formation of pyrolysis gas. The resulting gas enters the combustion chamber of the boiler through ceramic nozzles, where it interacts with secondary air. In the chamber, the gas burns completely, and CO2 is formed. High-temperature gases that exit the combustion chamber enter the heat exchanger and then into the chimney. In this case, the fan creates an air flow that blows across the heat exchanger. Then the heated air enters the grilles, which are located inside the heat generator or through a ventilation duct system connected to it. According to this scheme, the air in the room is heated. With the help of an electronic unit, the air temperature at the exit is in the region of 50-110 degrees. With approximately one load, a heat generator can operate for 6-9 hours, but these figures can vary significantly depending on the manufacturer. We must not forget, in order to preserve the walls of the combustion chamber, it is not advisable to allow the device to operate in critical mode if the temperature is more than 110 degrees.

General information

Scheme of a pyrolysis boiler. (Click to enlarge)

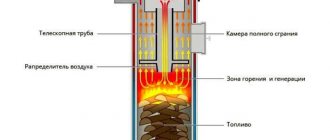

A pyrolysis or gas generator boiler is one of the types of solid fuel boilers, the peculiarity of which is the separate combustion of fuel and gases released from it.

The best fuel for such a boiler is wood and brown coal; in some models it is possible to use coal or coke. These types of fuel have a large amount of volatile substances, which are the main ones in heat generation.

The whole process begins with igniting dry solid fuel and further limiting access to air. When there is a deficiency of oxygen, the volatile substances released from the firewood (hydrogen, carbon monoxide, hydrocarbons) do not ignite, but enter another chamber where air is supplied. There they burn.

An important point: it is recommended to install a pyrolysis boiler in a separate room with direct access to the street - this will help keep other rooms clean and prevent unpleasant odors and smoke from entering them.

The advantages of gas generator boilers are:

- high efficiency (85 – 92%). This is 4–7% higher than modern ones with undivided combustion of fuel;

- one stack of firewood is enough for 12 hours of operation (conventional boilers “require” wood every 3 – 4 hours);

- the combustion process is easily automated and regulated;

- less emissions of harmful gases into the environment;

- possibility of using large firewood.

You should also point out the weaknesses of pyrolysis boilers:

- are not able to operate on raw fuel;

- high cost of the unit (almost 2 times more expensive than “regular” ones);

- dependent on electricity, which drives the fan to generate thrust in the desired direction;

- It is impossible to automate fuel supply.

Types of solid fuel boilers

Solid fuel boilers can use various substances. By type of fuel they are divided into:

- who use firewood - any trees will do (birch, oak, maple, alder, ash). In this case, it is necessary to take into account the calorie content , since the higher it is, the longer the wood burns. For combustion, it is best to use wood with a moisture content of no higher than 25%;

- who use coal - coal of any fraction and class is suitable. It is advisable to choose coal with a calorie content of no more than 7000 kcal per kilogram. Burning a kilogram of coal with a calorific value of 7000 kcal, the result is 8.15 kW/h, and this figure is close to what natural gas creates;

- pyrolysis - work on wood, molecularly decomposing the wood during combustion at elevated temperatures. The wood must be dried for at least a year before burning;

- that use pellets - you can use any pellets (straw, sunflower husk, wood). This is the most profitable type of fuel. Pellets are characterized by low ash content and high calorie content. Devices that run on pellets are, according to reviews, some of the most popular today due to their advantages;

- universal - used on all different types of fuel.

In addition, depending on the type of fuel, they can be divided into those where manual loading and automatic feeding are carried out using a piston or auger.

What to look for when choosing?

When choosing a TKDG, the main attention should be paid to the following characteristics:

- Type of fuel . The units can be designed for a specific fuel or be universal. Main options: coal, firewood, peat, pellets.

- Boiler power . It determines the heated area. For domestic needs, usually does not exceed 100 kW.

- Number of circuits : single-circuit or double-circuit.

- Loading chamber volume . The duration of operation without new fuel loading depends on it.

- Cost-effectiveness , i.e. fuel consumption. The main indicator is efficiency.

- Durability or service life.

- Control systems : electronic or mechanical.

- Safety . Critical protection systems must be provided.

- Price.

You should also pay attention to the material of the body and combustion chamber, loading method (manual, automatic, semi-automatic), volatility, weight and dimensions.

Reviews of solid fuel boilers

Many people have been using these devices for years and they know exactly about all the advantages and disadvantages.

Therefore, before buying a solid fuel boiler, it would be good to consult with someone just to find out consumer feedback. According to our statistics, the owners of these boilers say that it is necessary to carefully select fuel, find out what kind of fuel is available in your case, determine how much it burns and how much energy it produces, and then compare it with the cost of them and select the most profitable type of equipment . In this case, you need to carefully take care of the exhaust system, because sometimes some of the heat simply flies into the air. The overall result suits everyone. Users in our country, as a rule, burn wood; they are harvested from the beginning of summer and sometimes until the end of autumn. Many of the consumers in their reviews recommend choosing birch , because when it burns, the largest amount of heat is generated, which is the advantage. Here are reviews on whether it is worth buying a solid fuel boiler.

Is it worth buying a solid fuel boiler?

If it is not possible to connect gas, yes.

Is a solid fuel boiler profitable?

Much cheaper than electric.

How often do you need to add firewood to a solid fuel boiler?

Maximum twice a day.

How effective is pyrolysis technology from direct combustion?

In direct combustion boilers, the efficiency is rarely higher than 75-80%, and this is under ideal combustion conditions of high-quality fuel. For example, 1 kg of wood with a moisture content of 20% can produce 3.9 * 0.75 = 2.925 kW of thermal energy (specific calorific value of wood - 3.9 kW/kg). Coal with a moisture content of 10% produces 7.5 * 0.75 = 5.625 kW (specific calorific value of coal is 7.5 kW/kg).

With pyrolysis combustion technology, the efficiency today often reaches 92% and from the same fuel the unit will produce:

- 1 kg of wood – 3.9*0.92 = 3.588 kW (+22.7%);

- 1 kg of coal – 7.5*0.92 = 6.9 kW (+22.7%).

A significant difference shows how much heat is lost by emitting rather than burning associated gases (accordingly, with different differences in efficiency, the results will be different).

The use of effective combustion control during pyrolysis can significantly increase the operating time of the boiler in the mode of maintaining the coolant temperature, which further enhances the accumulation of thermal energy. The combustion temperature of pyrolysis gases is higher than with the classical method, so reaching the desired mode occurs much faster.

How and what kind of coal is best to heat a household solid fuel boiler

A question of cost

The cost range for solid fuel boilers is very large. The cost depends on how much area will need to be heated, but the manufacturer is even more important.

So we can buy a domestically produced Ogonyok KOTV device for 15 thousand rubles, while the Polish SAS ECO will cost much more, about 160 thousand rubles. Boilers made in Turkey by Caldera and Germany by Roda are in excellent demand, the cost of which will also not greatly please the consumer. But, not forgetting about saving in the future, you need to think carefully.

Exploitation

Judging by the reviews, operation does not create any issues. Apart from downloading after a certain time, the rest does not require much labor. Due to the well-thought-out design, cleaning from combustion products and raw materials is quite simple. The owner of the house only needs to load fuel into the fuel container, light it and set the desired temperature (when installing a temperature control device). Then you can enjoy the comfort and warmth of your home , only breaking away from time to time to refuel.

How to choose a solid fuel boiler?

Most people associate solid fuel devices with the stoves that once heated the entire country. With the creation of electric and gas boilers, the popularity of solid fuel heating systems has greatly decreased. It was believed that a heating boiler using solid fuel - peat, coal or wood - was more difficult to operate and needed constant monitoring. In some ways this was true. A classic solid fuel boiler has a small firebox and to heat your home you need to add fuel 6-8 times.

This is actually quite a big drawback, in contrast to gas devices running on liquefied or main gas. Another disadvantage is the need for high-quality fuel. This was especially true for gas generator or pyrolysis boilers, which are quite sensitive to fuel moisture. Such disadvantages, or more specifically features, must be taken into account when choosing a heating boiler.

And now about the advantages of solid fuel boilers.

Solid fuel boilers are safer, unlike electric and gas ones, since there is always a danger of gas explosion and leaks, not even in the boilers themselves, which have an increased degree of protection, but usual in the gas supply system.

These boilers are economical - you can buy firewood in places far from the city quite cheaply, and the design of today's devices is such that they have a fairly good efficiency.

Environmental friendliness - today in solid fuel boilers the fuel burns completely , leaving a little ash, which, as a rule, serves as fertilizer, although little of it is obtained.

We mentioned above that heating requires 6-8 refuelings daily. In fact, modern boilers now operate on one refill for up to 36 hours, which significantly increases their attractiveness to buyers.

And the main thing is convenience, durability and unpretentiousness - it is now quite expensive to install gas into a house, and using electricity for heating is also not cheap. Choosing liquefied gas can be inconvenient and it may not be easily and quickly delivered to every area. Often a solid fuel boiler is the best option , and sometimes the only one. As already described, you can choose any fuel for heating - coal, firewood, briquettes, coke, European firewood, and so on.

Design features

The latest developments in the field of thermal energy have been introduced into the designs of such solid fuel boilers. They significantly increase the operating efficiency of heating devices, increase periodic maintenance time, have high efficiency and allow operation with various types of solid fuels.

They are made from high-strength steel or ductile iron, ensuring long-term use without the need for repair or replacement. The level of automation of such boilers ensures regulation of combustion modes without human intervention and complete safety during operation.

The main thing !, the use of long-burning technologies allows you to increase the periodic loading time to 48 hours, and in some models even up to 10 days. As a result, the operation of the heating boiler becomes very simple and not burdensome for its owner.

Types of heating boilers

There are two types of boilers:

- with manual loading;

- with automatic loading.

Manual loading boilers

As a rule, long-burning boilers from BuderusLogano are recommended.

The choice of this particular brand is due to the excellent quality of production, ease of operation and reliability. Long-burning boilers BuderusLogano G221 are manufactured in a number of modifications with a power of 25-50 kW. This is the best option for heating a country house or a small industrial premises. This boiler runs on briquettes, wood or coal. This is a traditional cast-iron heating boiler, the combustion duration of which is ensured by the volumetric loading chamber and modern technologies used in the manufacture of this device.

Automatic pellet boilers

This is a type of boiler that runs on granular fuel - pellets. These devices are absolutely unpretentious in operation , but they are energy dependent and need to be connected to electricity for the device’s automation to operate.

Installation and connection

The efficiency and safety of Cooper boilers can only be achieved if they are correctly installed and connected to the heating system and chimney. We list the main requirements that must be strictly observed:

- The boiler room in which the installation is carried out must have a good flow of fresh air, good natural and artificial lighting.

- When using pellet equipment, as well as for a solid fuel pellet heating boiler “Zota”, a power supply is required in the boiler room.

- The floor on which the heating boiler is mounted must be durable, not smooth and made of non-combustible materials. When installed on a wooden floor, there must be a protective screen in the form of a steel sheet between it and the boiler.

- The distances from the solid fuel boiler to the walls of the boiler room must be at least 2 m from the front and at least 1 m from the sides.

- The premises must be equipped with water drainage into the sewer system.

- In conjunction with Kupper boilers, it is recommended to use sandwich chimneys, also produced by the Teplodar plant. The chimney must be insulated from wooden ceilings, have a length of at least 5 meters, and rise 50 cm above the ridge of the roof.

You can see more details about installing a pellet burner on a Cooper boiler in the following video:

We introduced you to the line of solid fuel boilers of the Kupper series from Teplodar. In addition to heating devices, the plant produces a wide range of related equipment for them, such as control panels, chimneys, hydraulic separators, etc. Using Teplodar products you can create the most efficient heating system in your home.