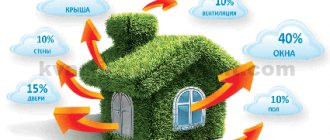

When building a private cottage, country house or any public building, the main task is to minimize the heat loss of the facade. This leads to lower costs for various fuels, be it gas or wood. To achieve this, various types of insulation are used. The most affordable option is to insulate various walls with expanded clay.

Expanded clay in bulk

Choice of material and which fraction is better

To understand how to retain heat and insulate walls with expanded clay, it is necessary to understand the very understanding of this material.

The concept of “expanded clay” is a collective term and implies the presence of insulation in several varieties. But they are all united by some common points. First of all, these are raw materials for production. It is represented by gravel in three fractions, sand and crushed stone.

Gravel

It looks like round or oval granules. It is obtained by firing clay, and the place of production is rotary kilns. Gravel has various uses, which is determined by the diameter of its fraction:

- 20-40 mm. In this form it has the lowest bulk density. It is used where a thick layer of thermal insulation is required. It is mainly used for filling foundations, attic floors, and cellars.

- 10-20 mm. This insulation is used for floors, roofs, and walls if they are made using the well masonry method.

- 5-10 mm. It is mainly used as a base for “warm” floors. In addition, they insulate exterior facades. A mixture of cement and expanded clay is poured between the masonry and the cladding.

Varieties of expanded clay

Sand

It is obtained by sifting out fine clay. In addition, large pieces of expanded clay are crushed in shaft furnaces. The scope of application depends on the size of the fraction:

- Expanded clay sand with a fraction of up to 5 mm is used to make a cement floor screed, where the layer thickness can reach up to 20 cm;

- sand with a fraction of up to 3 mm is used to obtain “warm” masonry mortar.

Crushed stone

It is obtained by crushing large pieces of baked clay. It is used as a thermal insulation filler when producing concrete structures that have a lower specific density.

Expanded clay of different fractions

*

To choose the right expanded clay, you need to pay attention to the following characteristics:

- Ability to insulate heat and sound. What matters is the thermal conductivity coefficient that the granules have. Heat is best retained in the presence of granules with low thermal conductivity. Expanded clay granules with a diameter of 10-20 mm are the best option when bulk heat-insulating materials are used. With their use, the amount of heat loss is significantly reduced.

- Bulk density value. If it is necessary to equip the foundation, then the density of the granules is of great importance. It depends on many factors. The most significant of them is the quality of the raw materials. The rules for observing the technological process during heat treatment of granules in ovens are important. Various additives can be used to enhance strength.

- Ability to absorb moisture. The material must have a correlation coefficient of at least 0.46. If the indicator is lower, then the granules absorb and retain moisture. This is evidence of poor product quality.

- Resistance to putrefactive processes and fungal infection. If the material is affected by fungus and rot, this indicates that low-quality additives were used in production. Such expanded clay cannot be used for wall insulation.

- Resistant to fire. The use of expanded clay not only insulates the house, but also increases its fire safety.

Based on these data, you can choose the ideal option for a certain type of work related to insulating the walls of a building.

How to insulate a foam block house from the outside

By choosing to insulate a cinder block house from the outside, the homeowner receives the following benefits:

- The rooms retain usable space. If decorative finishing has already been done in the premises, then it is even more impractical to insulate the building from the inside.

- There are no obstacles to warming up the house from the inside.

- With internal thermal insulation, foam concrete blocks heat and freeze cyclically, which negatively affects the integrity of their internal structure.

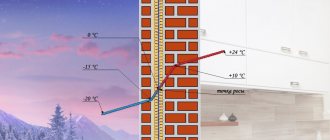

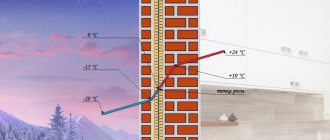

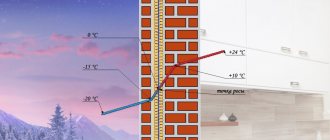

- The presence of insulation inside living rooms shifts the dew point towards the rooms, which causes moisture to condense in the thickness of the wall. This provokes the development of mold fungi and destruction of the material.

- When performing external insulation, the dew point moves closer to the outer surface of the building. So the blocks do not accumulate moisture - on the contrary, it constantly evaporates due to the ventilation gap.

How to insulate a foam block with polystyrene foam from the outside

To externally insulate a façade with polystyrene foam, the following steps must be completed:

- Remove all contaminants and uneven surfaces from the wall.

- We apply a layer of primer, which will prevent the glue from penetrating into the thickness of the wall. The primer layer is a significant consumption of glue, which ultimately has a positive effect on the cost of work.

- Attach a metal profile to the wall on which the first row of foam will be mounted.

- In accordance with the instructions, you need to prepare a homogeneous glue - it is best to use a regular drill with attachments for mixing.

- We glue the insulation, laying out the slabs in a checkerboard pattern.

- We secure the foam sheets with disc-type dowels. Each plate must be secured at the edges and central part

- We fix the reinforcing network - this layer will increase the strength of the insulating material.

- The wall is covered with plaster, the finishing is facade putty, as an option, you can choose siding or other finishing

Insulation of house walls with foam plastic

Insulation of a foam block with penoplex from the outside

To insulate a foam block house from the outside with penoplex, you should follow these steps:

- Cleaning the walls of the house - we get rid of dirt, dust, old mortar.

- Apply a layer of primer to increase glue adhesion.

- We fix the base profile located at the bottom of the wall - it will act as a support for the insulation, and will also become a barrier for rodents.

- Mixing glue with a drill

- The glue is applied to the insulation boards, which are glued to the wall from bottom to top. Each subsequent layer is shifted relative to the previous one by half the length of the insulation board.

- Additionally, we attach the insulation with fungi - dowels are installed in the corners and in the center.

- Bonding a reinforcing mesh that provides the necessary rigidity to the insulating layer.

- Finishing stage - we cover the mesh with plaster, and then paint the facade.

Insulation of foam block with mineral wool

Mineral insulation materials have shown themselves to be good for improving the thermal insulation of a house made of foam blocks. All this can be done with your own hands:

- The preparatory stage, at which the wall is cleaned of all unnecessary elements, be it dust, dirt, mortar drips, and so on. If necessary, the walls are leveled.

- A waterproofing film that protects mineral wool from moisture.

- Fastening the starting profile at the bottom of the wall - it is necessary to support the thermal insulation material.

- Mounting wooden guides to the façade, between which mineral wool will be placed.

- We insert the cut pieces of mineral wool into the crate.

- Laying a vapor barrier membrane; as an option, the membrane can be superdiffusion.

- We attach wooden strips 20-30 mm thick over the membrane - they are necessary to form a ventilation gap.

- We cover the wall with siding on top of the sheathing; you can use PVC panels.

How much material will be needed: how to calculate

Building a house involves large financial costs, and naturally, if there is an opportunity to save money, it is worth taking advantage of. To do this, you will need to correctly calculate the required volume of insulation so as not to overpay for what is unnecessary.

When making calculations, the thickness of the expanded clay should be taken into account. The thermal conductivity coefficient depends on this. On average, for effective insulation, the layer thickness should be 10 cm. Then you will need 1/3 of the cube. You can see how many kilograms of expanded clay are included in one cube on the packaging, approximately from 15 to 800 kg, depending on the type. If your expanded clay weighs 300 kg, then 1 cubic meter will require 60 kg.

Expanded clay is packaged and sold in bags

The cost of expanded clay also depends on its type. The smaller the fraction, the higher the price. On average, the cost varies from 1700 to 2800 rubles. For the bag.

Expanded clay block wall brick cladding

Laying expanded clay block in Ufa

When ordering expanded clay concrete masonry, our company recommends a thorough approach to choosing a company that will carry out the stages of work. Only choosing a professional team will be your guarantee of obtaining the desired and expected result that will satisfy the needs of your entire family. Call us right now!

Expanded clay blocks for wall masonry - advantageous offers from our company will help you save an impressive amount and build a house from expanded clay blocks quickly, cheaply and with high quality. Work only with trusted companies, and then you are guaranteed to have the most luxurious and beautiful dream home. We are waiting for you by phone!

Price list for masonry work in Ufa

Laying expanded clay blocks price

The cost of laying expanded clay concrete blocks varies and depends on the complexity of the project, the size of the materials, and the amount of work. Do not rush to choose employees at a low cost, because this does not mean that you will be provided with high service and quality. Too low prices always alarm a smart customer, and if you decide to make a profitable deal, our company is at your disposal.

1 m2 of expanded clay block masonry

The cost of the work depends on the selected types of services that you want to order from our company. If you only need to lay expanded clay concrete, the price will be the same. If, in addition to masonry, you want to decorate the house with a ventilated façade or plaster, the cost of the work will be completely different. Find out the details right now by calling us by phone.

Laying expanded clay blocks price for work

Our masons will perform a complex of actions and lay expanded clay concrete at a high-quality professional level. We will help you purchase material at a favorable price, organize delivery, unload it and build durable housing for many years. A country house, built with love and warmth, will certainly become your family’s favorite place. And we will do our best to achieve this!

Our works

Two-story house made of expanded clay block, lined with brick. Total area - 100 sq.m. We conclude an agreement, payment in stages! Weekly report, guaranteed!

We will select a project to suit your budget. For any questions, call: +7 (917) 411-5296

Two-storey house made of expanded clay block, lined with brick 140 m² Total area - 140 sq.m We conclude an agreement, payment in stages! Weekly report, guaranteed!

We will select a project to suit your budget. For any questions, call: +7 (917) 411-5296

Advantages of expanded clay as insulation

*

This material has a number of positive qualities that contribute to its active use in the construction industry:

- Environmentally friendly. It is made from natural raw materials, so its use is considered safe.

- Affordability. The low cost makes this material very popular and profitable in home construction.

- Convenient to use. Due to their small size, the granules can fill any gaps.

- Light weight does not put a load on the foundation.

- Due to its good technical characteristics, it is able to withstand temperature changes, thanks to which it is used in different climatic zones.

The advantages also include the material’s resistance to rotting and does not attract rodents and insects. Its use will allow you to keep heat in the house for a long time and reliably.

Pros and cons of using wall insulation

In terms of popularity as a material for insulating the external walls of a brick house, expanded clay is inferior to a number of modern insulators. This phenomenon is explained by the economic profitability and efficiency of use due to the competitive advantages of the material.

The advantages of using expanded clay for insulating external walls:

- Due to its impeccable resistance to heat transfer characteristics, bulk insulation represents a reliable barrier against heat loss during the cold season. In summer, a comfortable microclimate in the house is also maintained, since the expanded clay insulator does not allow the street heat to pass through;

- bulk material can be used in concrete mixtures, which has a positive effect on the thermal insulation properties of the structure;

- the natural composition is characterized by environmental friendliness, resistance to chemicals, and inertness to biological threats;

- expanded clay granules are unattractive to rodents and insects;

- the porosity of the structure determines the effectiveness of the solution as sound insulation of the facade.

Expanded clay granules are unattractive to rodents and insects.

Among the advantages of using expanded clay for insulating the external walls of a brick or frame house, they also note its non-flammability, resistance to temperature changes, ease of self-installation and the availability of the solution.

The downside is that the granules absorb moisture; protection is required in the form of concrete pouring, wall plaster or other moisture-resistant material.

Preparatory work

Before installing the insulation, it is necessary to lay waterproofing. It will protect expanded clay from excess moisture. To do this, you can use regular plastic film. After laying it, the edges are fixed with construction tape.

It is better to use expanded clay when insulating a new building, when its construction is just underway. In this case, three-layer masonry is used. Each layer is associated with certain characteristics. The load-bearing layer is made using expanded clay concrete blocks with a thickness of 20 to 40 cm. For the main layer, granulated expanded clay and cement laitance are used. The last layer is represented by wooden, panel or brick protection.

Before laying the heat insulator, it is doused with cement laitance. At the same time, individual fractions set faster, and as a result, the entire layer as a whole hardens faster. Installation requires many tools. The work is carried out using a trowel, which is used by masons, a mortar shovel, a hammer, and a chisel. When performing work, you cannot do without levels and plumb lines, and a measuring tape. In addition, it is necessary to prepare a container in which the solution is mixed.

Useful video

In the video we will look at an example of insulating the ceiling of an extension of a private wooden house with expanded clay backfill:

You can cope with this work yourself at some stages of the preparatory work. Laying utility networks: ventilation, electrical wiring, plumbing - trust the builders who perform a range of construction and installation works.

(2 ratings, average: 5.00 out of 5)

- Features of thermal insulation

- Advantages and disadvantages

- Insulation technology

- Preparatory work

- Installation instructions

- Surface finishing

Ceiling insulation with expanded clay is an excellent alternative to using traditional thermal insulators like foam plastic or mineral wool. It makes it possible to provide high-quality heat conservation in any type of room. In addition, this method does not require significant costs.

Techniques for insulating a mill with expanded clay

The following materials are required for the work: sand, cement, expanded clay screenings and reinforcing mesh.

Fine-fraction expanded clay for wall insulation

As soon as the method by which the heat insulation will be laid is chosen, the thickness of the backfill is determined. Professionals recommend having some reserve. This achieves an increase in the sound and heat insulation that the wall will have.

When building a private house, well masonry is mainly used. With it, a layer of insulation is located between the inner and outer walls in the middle part of the masonry.

Using expanded clay for wall insulation

*

With this type of insulation of the walls of a brick house with expanded clay, the masonry is not thick, but has good performance related to thermal conductivity. In this case, less materials are consumed for construction. But this requires accurate calculations of the work in which diaphragms are performed.

Condensate liquid may accumulate inside the well. To prevent this, the inner surface is covered with a vapor barrier layer. Assembled when performing such work, the entire wall can have a thickness of 30 to 60 cm.

The masonry is simple and is carried out according to the following algorithm:

- the foundation is completed. These are the two bottom rows of bricks. Before laying them on the foundation, a horizontal layer of waterproofing is performed;

- carry out the construction of external parallel walls and partitions for their connection (diaphragm);

- When 5-6 rows have been completed, insulation is poured into the well. After this, it must be compacted thoroughly. Filling is carried out exclusively with dry gravel and is done in layers. The insulation is poured on top with a cement-based solution;

- Before backfilling, a sheet of foam plastic with any waterproofing is placed down. This will not allow the material to absorb moisture from the surface of the earth and remain dry from the inside;

- then a concrete screed is performed. It serves to give greater rigidity;

- then carry out the execution of horizontal diaphragms;

- The construction of the wall continues in this manner until the end.

We also recommend that you read the link svetokna.ru. The company produces PVC windows, doors, balconies and loggias.

Features of use

In order for sheets of material to be securely held on a vertical surface, it is imperative to install a sheathing made of wooden beams and a special frame system. According to the standards, the width of the installed sheathing should be 2-3 centimeters less than the width of the sheet of cotton wool. You also need to install anchors into the wall - sheets of mineral wool will subsequently be placed on them.

If you are insulating a building with uneven expanded clay concrete walls, it is advisable to use mineral wool, which has two layers of different densities. In this case, the material is attached to the wall with a soft layer so that it adheres better to the surface.

Finishing

After completing the insulation work, the wall will dry within a few days. The final strength gain will be completed in a month. Then finishing and cladding are performed. For finishing you can use brick or wood. Before this, the walls are plastered. This is done both externally and internally. This achieves additional insulation from steam and moisture. The outer plaster layer will protect the building from precipitation. In addition, the structure is given greater rigidity.

In order to prepare the solution, river sand and cement (M400) are mixed in a ratio of 4:1. The final finishing can be done with decorative stone. This is a pretty good solution. They can perform work not only outside, but also inside the building. This is a good interior solution without putting significant additional pressure on the structure. Such material should be free of visible stains and growths. It will be even better if the outer surface is coated with a water-repellent composition.

Insulation of brickwork with expanded clay

At a relatively low cost, expanded clay is very popular as insulation. Having completed such work, the house will be warm and comfortable. But at the same time, it is necessary to control the load indicators on the foundation and the structure as a whole. Otherwise, insulating a house with expanded clay is considered a profitable option. This serves as one of the indicators of its wide popularity. It should also be said that the work associated with insulating a private house with expanded clay is not particularly difficult.

What is the best way to insulate?

Any insulation from the following list will be good thermal insulation for expanded clay blocks:

- glass wool;

- mineral wool;

- Styrofoam;

- expanded polystyrene (penoplex);

- polyurethane foam;

- liquid materials.

Glass wool is one of the most traditional and cheapest insulation materials . Its advantages are frost resistance and air non-conductivity. The disadvantages are low environmental friendliness and the risk of injury if installed incorrectly.

Mineral wool made from basalt or slag does not have these disadvantages: it is more environmentally friendly, is not flammable and retains heat better. However, it costs more than glass wool and is susceptible to moisture stagnation.

Polystyrene foam as insulation is relatively cheap , it is lightweight and very easy to attach to walls. Its disadvantage is rapid deterioration under the influence of moisture, insects, rodents and birds (to avoid this, it must be reinforced with mesh).

Expanded polystyrene is similar to polystyrene foam in terms of thermal protection, but this material is not susceptible to rodents, so it is more expensive. It is considered one of the most suitable materials for thermal insulation of expanded clay walls. It minimizes the number of cold bridges between blocks and is also easy to install. The material is dense and durable, not afraid of moisture.

Polyurethane foam copes well with protection from dampness , since it has a high degree of water resistance and retains heat well. However, it is quite expensive and requires special equipment and tools for installation.

Liquid insulation consists of two components - polyurethane foam and penoizol. This composition retains moisture and air and is easily applied by spraying onto a special sheathing. The downside is the cost, as well as the inability to immediately begin plastering work - after all, the finish must be fixed with a frame.

Accessories

Those who grow indoor flowers have probably noticed that some pots have no drainage holes at all. Experts note that this is even very good. Such a pot can be safely called universal, because the number and size of holes can be controlled independently. To make holes for draining water, you need to use the following tools:

- Carefully heat an iron object (for example, a thick nail, awl or knife) over the fire and make all the necessary holes with it.

- Using a conventional drill, drill holes of the required diameter.

Advice from the experts

Let's consider some recommendations that experienced builders give when working with expanded clay:

- When working with insulation, it is better to use a respirator, as the material is very dusty.

- Buy expanded clay in bags. This will not increase its cost much, but will simplify installation.

- Work in warm weather. Expanded clay quickly absorbs moisture. It is better to store it under a canopy, in a ventilated place.

- One of the cheapest insulation options: a combination of coarse expanded clay with foam chips.

Use insulation from one manufacturer. It is better to take insulation with a small reserve than to later buy additional insulation from an untested place.

Calculation of the required layer thickness

It is quite problematic to make an accurate calculation of an expanded clay wall. Thermal conductivity indicators depend on: fraction, density, raw materials used in production, precise technology. Two identical building materials may differ in this indicator from different manufacturers.

You can take a simpler calculation based on the experience of many installers. A minimum layer of 20 mm of expanded clay retains heat, approximately as much as a 50 mm mineral wool slab. When insulating, it is better to pour a layer of pellets up to 25 cm.

S x R = V , where S is the area, R is the consumption of heat insulation per 1 m², V is the total volume of material.