Do-it-yourself waste oil burner manufacturing features

The easiest way to make a burner is using a small gas cylinder or a blowtorch. To work you need to prepare:

- the above container;

- welding machine;

- grinder;

- a piece of 1.5-inch pipe;

- a round plate equal to the inner diameter of the pipe;

- a piece of wire 6 - 8 mm;

- bolt with a through internal hole for the oil supply nozzle;

- a thick round blank for the lid.

Beginning of work

- Two holes are drilled tangentially in the cylinder: from the bottom (for the mixture of air and oil to enter), and from the top for the flame to exit. Tubes with a diameter of 1.5 inches are welded. One is a continuation of the other, only a little higher; so that the fire swirls inside and does not immediately fly out into the street.

- An ignition hatch is made on top and equipped with a heavy lid so that it does not open during operation due to the pressure of incoming air.

Air flow control

The pressure and amount of air supplied for combustion is regulated by a homemade damper (it is made according to the throttle principle, like in a carburetor).

The flap is installed in the supply pipe upstream of the fuel injector as follows:

- A hole for the rotary axis is drilled strictly according to the diameter of the existing workpiece.

- A round plate is cut along the inner diameter of the pipe, which in the closed position can completely block the hole.

- A rotary axis is made in the shape of the letter “L” and a damper is mounted on it with small bolts.

- In front of the damper, a hole is drilled or a slot is cut in the supply pipe to remove “excess” air (in case there is a lot of it for the burner).

The principle of feeding waste into the burner itself

To supply oil, a diffuser is installed in the intake pipe immediately behind the damper. The diffuser is a chiseled ring insert that slightly narrows the flow area. Thanks to it, a vacuum is created and oil (or other liquid fuel) flows through the nozzle and mixes with air.

For the supply pipeline, it is preferable to use metal pipes. A freon tank is well suited for the fuel tank, and the needle valve allows you to precisely regulate the oil supply.

Simple homemade burner

The oil must be separated from water and filtered.

Principle of operation

The fuel is supplied by gravity to the nozzle and is sucked in by air passing through the diffuser. The resulting mixture ignites inside the cylinder, and the torch is blown outside. Thus, the source of heat is the burner itself (heats up to a crimson glow) and the torch.

The flame can even be used to melt some metals such as copper, aluminum and others that have a lower melting point.

Burner design

A standard homemade burner functions this way. Gas is supplied under pressure through a special hose from the cylinder. Most often, propane is used as such gas. The volume of gas supplied is changed by a regulating operating valve located on the cylinder. Therefore, installation of an additional reduction gearbox is not required.

The shut-off valve is located behind the main valve and is mounted on the gas cylinder. It is used to open or close the gas supply. All other adjustments (length and intensity of the flame) of the burner itself are carried out using the so-called working tap. The gas supply hose through which gas is supplied is connected to a special nozzle. It ends with a nipple. It allows you to set the size (length) and intensity (speed) of the flame. The nipple together with the tube is placed in a special liner (metal cup). It is in it that the creation of a combustible mixture occurs, that is, the enrichment of propane with atmospheric oxygen. The created combustible mixture under pressure flows through the nozzle into the combustion area. To ensure a continuous combustion process, special holes are structurally provided in the nozzle. They perform the function of additional ventilation.

Based on this standard design, you can develop your own design. It will consist of the following elements:

- housing (usually made of metal);

- a reducer, which is attached to the cylinder (use a ready-made device);

- nozzles (made independently);

- fuel supply regulator (optional);

- head (the shape is selected based on the tasks being solved).

The burner body is made in the shape of a glass. The material used is ordinary steel. This shape allows for reliable protection against possible blowing out of the working flame. A handle is attached to the body. It can be made of various materials. The most important thing is that it provides convenience when working. Previous experience shows that the most optimal length of such a handle is in the range from 70 to 80 centimeters.

Gas burner device

A wooden holder is attached to the top. A gas supply hose is placed in its body. This allows you to give the structure a certain strength. The flame length can be adjusted in two ways. Using a reducer located on the gas cylinder and a valve installed on the tube. The gas mixture is ignited using a special nozzle.

Drilling holes

In order for the air flow to atomize the fuel as efficiently as possible, the hole should be as small in diameter as possible. The priority is 0.010 inches. Although holes up to 0.020 in size are also considered acceptable. To obtain them, special thin drills are used. If you look at them from the side, they will seem intermittent. In any case, the drilling process should be done slowly and carefully. Compressed air will flow through these holes.

As for spraying using air, this option is more preferable than gas. This is due to the low cost of the resource. While you have to pay for gas, you don’t have to pay for air. In addition, you need very little of it, so you can use ordinary compressors, such as those used on aquariums. In principle, the Babington burner, the drawings of which you can find in this article, is almost ready for use. There are a few small parts left.

Burner classification

The device of a gas burner is quite simple. Modern gas burners are divided as follows:

- Pre-mix. A gas mixture is formed immediately before entering the outlet.

- Injection burners. The air required for combustion is spontaneously sucked in (as they say, injected) by the gas jet itself.

- Regenerative. The essence of their work lies in the preheating of gas and air. This happens before mixing. The heating itself is carried out by a special device - a recuperator.

- Regenerative. Preheating in burners of this type is carried out in a regenerator.

- Pressurized (supercharged gas burners). In them, air is forced into the firebox by a special fan. This happens after mixing the combustible mixture.

- Diffusion. By design, these are the simplest burners. They consist of a regular tube with holes drilled in it. Gas is supplied through these holes. To ensure constant and reliable combustion, the necessary air comes from the environment.

- Gas atmospheric burners for boilers. The principle of their operation is very similar to the principle of injection burners. The main difference is that oxygen enrichment is not carried out completely, but partially.

- Gas burners for stoves, fireplaces, heating systems.

Homemade gas burner at work

The power of any gas burner is determined by the volume of gas consumed per unit of time. It can differ quite significantly for different burners.

Do it yourself

The process of making a Babington burner is not very complicated and, if you have all the necessary materials and tools, it will only take a few days, depending on the skills of the person.

To manufacture this unit you will need the following materials:

- steel tube DN10,

- metal tee with a diameter of 50 millimeters with internal thread;

- a metal sphere (or hemisphere) with a diameter of less than 50 millimeters;

- copper tube DN10 at least one meter long;

- metal elbow DN10 with external thread;

- a bend with a diameter of 50 millimeters with an external thread, a length of at least 10 centimeters;

You will also need a minimum set of tools:

- angle grinder (grinder) or hacksaw for metal;

- perforator;

- special chuck for thin drills;

- drill;

- drill with a diameter of 0.1–0.3 millimeters;

- soldering iron;

Preparatory stage

Before starting assembly, you need to make a hole in the sphere (hemisphere). This is one of the most difficult and critical stages, since the hole must be made exactly in the middle. Otherwise, the burner torch will be directed to the side, which in turn can negatively affect the quality of the product and its efficiency.

In addition, drilling holes of this diameter is a difficult task, since thin drills can break. Therefore, this process must be carried out carefully and slowly.

Step-by-step instruction

Once the sphere or hemisphere is ready, you can begin assembly. It is very simple and consists of several simple manipulations:

- The metal squeegee will act as a nozzle. It is cut to the required length and screwed into the tee. After this, a hole is drilled in the side of the burner, large enough so that the jet can be ignited through it.

- On top of the tee, closer to the nozzle, a hole is made for a copper tube through which fuel will be supplied to the device.

- An elbow is attached to the copper tube to connect the fuel line.

- A copper tube makes several turns (2-3 will be enough) around the nozzle. They must be done at some distance from the drive. This will allow the oil to be heated to the desired temperature before it hits the sphere.

- In the sphere, at the opposite end of the small hole, another hole is drilled along the outer diameter of the steel tube. The tube is hermetically inserted into the sphere. This is necessary so that the air exits only through a small hole, and pressure is created inside it. If a hemisphere is used instead of a sphere, then the tube is soldered at the small hole and sealed.

- From the opposite end from the nozzle, a metal tube with a sphere is inserted into the tee. She is fixed in it.

- Thus, the burner is ready for use. All that remains is to connect a compressor to the tube with the sphere, which will pump air into it and a fuel line to the copper tube.

- If desired, this system can be improved by connecting a pump to supply oil. You can also install a control unit with control sensors. This will make this system automatic and more secure.

Operating rules

In order for the burner to be safe to operate, it is necessary that all parts associated with the supply of air and waste oil are sealed. In addition, it is necessary to protect the mining storage from accidental exposure to fire. To do this, you need to make a metal screen. It can also be made from other non-combustible materials.

For safety, it is also important that the torch burns strictly straight (this depends on the accuracy of the center of the drilled small hole). Equally important is the correct adjustment of the oil supply to the burner. It can be carried out due to the longitudinal displacement of the tube with a sphere (hemisphere) inside the tee.

If you comply with all fire safety standards and correctly adjust the fuel supply, then your homemade Babington burner will be reliable, burn cleanly, will not smoke and will last for many years.

Fuel supply

Amateur craftsmen often supply drip furnaces with single-stage fuel: an oil tank, a ball valve, and a supply tube. Firstly, this is dangerous: for convenience and safety of starting the stove, the valve must be placed closer to it. The supply tube gets quite hot when fuel is supplied from the bottom. If the heating passes through the pipe past the valve, up to which there is a solid column of fuel in the pipe, this could lead to disaster. Secondly, the fuel supply to the furnace is unstable: as the tube warms up, the drops become more frequent, because the oil thins out. If it flows in a trickle, then it is again dangerous.

The drip supply of oil to the furnace during processing should be organized according to a 2-stage scheme: main (storage) oil tank - valve - supply dropper - supply tank (tank) - free flow from it at least 60 mm from the bottom (for additional sedimentation of sludge) - working dropper. The fuel supply is opened when the kindling in the bowl (see below) is lit. While the oil drips into the tank to the level of the drain, you can slowly adjust its flow, and then it drips into the bowl drop by drop.

Scheme of safe power supply of a drip furnace from a supply tank with a safety valve and capillary

This system, however, is not completely safe. If in a hurry, out of ignorance, or simply trying to quickly warm up from the cold, open the valve too much, the consumables will immediately fill, fuel will rush into the stove, and it will throw out a tongue of fire and start spitting burning spray. It would be correct to build a drip oil supply system into the furnace with a safety float valve and a metering capillary (see figure on the right).

Since different metals are wetted by waste in different ways, and its properties vary significantly from batch to batch, the length of the capillary will need to be selected: the oil is fed under a gravitational pressure of 120-150 mm (from a suspended container) at room temperature, and the capillary is selected so that it drips more often, but with drops clearly visible to the eye. A diesel fuel drip furnace can be used from the same feeder, but the capillary will need to be taken with a clearance of 0.6-1 mm and a length 2.5-3 times longer than for mining. There is only one drawback to this scheme for supplying fuel to a drip furnace: the exhaust is dirty fuel, and the capillary will have to be cleaned periodically.

What can it be made from?

Thanks to its simple design, an oil-drip furnace can be made with your own hands from almost any material: sheet iron, an old barrel, a gas cylinder. The only condition is that the walls should not be thinner than 4 mm , otherwise the body will move when fired.

A simple and reliable way is to make your own oven from a gas cylinder. Its body is durable and can withstand high pressure and heat, and its dimensions are just right for a stove that can heat a garage, workshop or small private house. When used carefully, such a stove is safe, easy to clean and light. The operation of the furnace is shown in the video.

Watch video: furnace in operation

Necessary materials

- To assemble a drip-type furnace operating on waste oil, you will need:

- gas cylinder 50 liters - used, but without damage to the body;

- metal pipe Ø100, with a wall thickness of at least 3.5 m - about two meters;

- scraps of metal equal-angle corner 40-50 mm for the heat exchanger, stand and other small parts;

- sheet steel 4 mm, you can also use scraps of a suitable size;

- cast iron brake disc from a passenger car;

- a standard size used freon cylinder with a working needle valve;

- metal pipe ½ inch - about half a meter;

- a hose of a suitable diameter that can be put on a ½-inch pipe and clamps;

- ½ inch ball valve;

- door hinges and latch for the firebox door.

An air heat exchanger will also require a duct fan and pipes of a suitable diameter. You can use a corrugated pipe or components for a chimney.

Preparing the balloon

The gas cylinder, even after prolonged ventilation, contains gas condensate.

To remove it, you need to remove the gearbox and valve from it and expose it to fresh air for a couple of days. After this, a hole is very carefully drilled in the bottom of the cylinder. To avoid sparks, the drill must be moistened with oil. Drilling a hole in thick metal is difficult, so it is better to start with a drill of a smaller diameter, and then drill it out to the required size. The result should be a hole with a diameter of 10-16 mm.

The drilled container is filled with water and, after standing for 24 hours, it is drained. Condensate has a pungent and extremely unpleasant odor, so it must be drained carefully and away from residential areas. You can repeat the procedure to rinse the balloon properly.

Furnace body

The balloon is conventionally divided into two unequal parts: the lower - 1/3 of the height, and the upper - 2/3. Openings are cut out in both parts, approximately a quarter of the circle in width. The execution of the openings is shown in the photo.

Cut out the holes using a grinder, trying to make an even cut - the cut pieces of metal will then be used to make doors.

The interior of the cylinder is washed again with water under pressure from a hose. This will help completely wash away any remaining gas condensate.

The oven compartments must be separated by a metal insert. It is cut out with your own hands from 4 mm sheet metal to the size of the cylinder.

This circle forms the bottom of the oil vapor combustion chamber. The resulting chamber is quite large in size, which allows you to use the stove for burning wood or briquettes, as well as burn garbage in it. Try the bottom in place and adjust it if necessary.

The burner is made with your own hands from a piece of pipe Ø100 mm, length - 20 cm. using a drill and a metal drill bit. make holes with a diameter of 10 mm.

The holes are placed around the circumference in a checkerboard pattern until approximately the middle of the burner. After drilling the holes, the inside of the pipe is carefully ground so that there are no burrs left. Soot and soot will settle on them during the operation of the stove.

The burner is installed in the previous part - the bottom of the upper chamber, after which the joint is welded using a welding machine.

The resulting part is installed in place - in the furnace body between the chambers. Place it with the perforated part down. The holes are designed for free air suction.

working tray You can take a used disk. Cast iron is a heat-resistant material; in addition, the design of the disk makes the lower part of the stove heavier and makes it more stable.

A plug is welded to the bottom of the disk to close the holes. It is cut out of 4 mm sheet metal.

The top cover is also made from it . The shape of the opening should allow the counter part of the burner to be welded and allow free access to air.

The bottom of the burner is welded to the lid - a piece of pipe Ø100 mm, length - 10 cm.

A coupling is used to connect the burner parts. You can make it yourself from a Ø100 mm pipe, cut lengthwise and slightly bent. The coupling is necessary to make the burner design detachable. By lifting it, you can remove the oil pan and clean it, as well as remove soot from the top of the chamber and burner.

Oil supply system

In do-it-yourself drip-type furnaces, oil is supplied from an external tank using an adjustable dropper. In the furnace design under consideration, a used freon cylinder is used as a dropper. The main condition is the serviceability of its needle valve.

A hole is cut in the lower part of the cylinder of such a size that it is convenient to fill the waste from a canister or other container.

You can install a mesh on the filler hole; it will serve as a coarse filter. The oil tank should be located above the level of the furnace, so hanging brackets can be welded to the body.

A hose is connected to the cylinder valve using a clamp. A hole is made in the furnace body, positioning it on the installation side of the oil tank. The diameter of the hole should allow the installation of a half-inch oil supply pipe.

A piece of the required length is cut from the pipe and a thread is cut at one end, and the other is cut at an angle so as to direct the stream of oil exactly into the opening in the pan.

The pipe is welded to the body. The seam is cleaned.

A ball valve is screwed onto the other threaded end of the pipe . During assembly, a squeegee with the free end of the oil hose is connected to the valve.

Heat exchanger

In this furnace, the heat exchanger is an optional element. If you need to heat a small room without partitions, the heat from the walls of the stove will be enough. But for greater efficiency, it is recommended to make an air or water heat exchanger located in the upper chamber.

As a heat exchanger, use a piece of pipe Ø100 mm of such length that its ends extend beyond the body by 10-20 cm on both sides. Two holes are made in the housing on opposite sides through which this pipe is passed. It is secured by welding.

A flame divider made of sheet iron is welded above the heat exchanger. It will break the flame into tongues, due to which the heat transfer to the walls and pipe of the heat exchanger will increase.

A swirler is installed inside the air heat exchanger. It is necessary to accelerate air flows and better heat removal. It is made from a steel strip or angle, divided into bent blades.

Air ducts are connected to the heat exchanger pipe. They can be made from an uninsulated chimney pipe and corresponding corner elements. On one side, a duct fan is installed into the air duct. The fan can be connected to the network directly or through the contacts of a thermal relay, installing it on the fan housing and adjusting the temperature experimentally.

Doors and shut-off valves

Doors are made from the cylinder fragments cut off at the first stage, with hinges and a valve welded to them.

A hole is made on the bottom door to improve air supply. It is more convenient to do it at the bottom.

To seal the top door, stop plates are made from a steel strip. They are mounted on rivets.

The door lock can have absolutely any design; you can make it yourself, since the door is opened infrequently, only to remove soot or when burning the stove with solid fuel.

Smoke pipe and chimney

A smoke pipe from a piece of pipe Ø100 mm is welded to the top of the gas cylinder, having previously cut a hole of a suitable diameter. The inner surface of the smoke pipe is cleaned of scale to avoid soot deposition.

The chimney is made from a stainless sandwich pipe, assembled from the necessary elements. It can be brought out both through the ceilings and through the wall.

The flue gases in the exhaust furnace have a high temperature, which is why the chimney pipe can burn out! Do not use uninsulated pipes or wall penetrations to avoid fire!

Video: drip-type mini-oven

Video: Inferno oven, part 1 and part 2

Nozzle

First you need to make a spherical nozzle; fuel will flow through it in the future. Make a hole in the sphere, the diameter should be approximately 0.25 mm

Please note that the power of a homemade burner depends on the diameter. The smaller the diameter, the lower the power and vice versa

All difficulties await you in the manufacture of the nozzle. The channel for air passage must be made perfectly smooth. It is necessary that the air hits forward and not against the walls of the nozzle. The best option is to make a hole on a special machine.

But if luck smiles on you and you find a jet with the desired diameter, then do not miss the opportunity and place it in the center of the spherical element. If you can’t find a hemisphere, you can use a small piece of sheet metal with a jet attached inside. As a result, you will receive an oil spray nozzle. Heated fuel will flow into it, and atomization occurs due to the incoming air. When installing such a device in a universal boiler, you get an effective and cheap heat source.

Alternative heating devices: secondary oil burner

Thermal energy generation is an important process for some types of production. In addition, thermal energy is a basic element for heating premises for various purposes.

articles:

To supply heat to their homes, homeowners use different types of fuel: natural gas, electricity or solid fuel. The choice of fuel is determined by its availability or availability in a certain region.

Today, high-quality fuel is an expensive “product”, so many are busy looking for alternative sources of thermal energy.

The most popular is used motor oil, which, when reused, allows you to obtain a sufficient amount of heat. Let's look at how to make a waste oil burner with your own hands.

Savings and safety

In Russia, the recycling of used oil (machine, transmission, vegetable or generator) is one of the main areas of waste processing.

Today, oil that has spent its service life is often used as an alternative source of thermal energy; in addition, the use of heating systems that operate on waste oil allows great savings.

The cost of the equipment pays off very quickly - this allows us to speak with confidence about the economic feasibility and profitability of using such systems for space heating.

The equipment is popular, especially among owners of private residential buildings. A self-installed waste oil burner is easy to operate and maintain. It can be used to supply heat to an extension, garage, bathhouse and other rooms in the house.

Most functioning models require scheduled maintenance no more than once a year, but this period depends on the quality of the recyclable materials. Such equipment is safe for the environment: the burner is mounted in such a way that during fuel combustion there is practically no release of harmful combustion products into the environment.

The fuel combustion process is not accompanied by gas or smoke, and the “working off” burns completely.

Advantages of heating equipment

Self-assembled waste oil burners are convenient to use in places where it is impossible to connect to a centralized heating system, there is no natural gas, or there is no chance of using solid fuel to heat a private home. Compared to other heating methods, the use of “working off” has a number of advantages:

- • quick heating of the room and maintaining optimal temperature;

- • compactness of equipment;

- • ease of operation and installation;

- • accessibility, since “waste oil” is on the list of the cheapest types of fuel, and equipment, in particular a waste oil burner, can be assembled with your own hands;

- • safety and environmental friendliness: by using “recycling” you are doing your bit to protect the environment. In the process of oil recycling, combustion is not accompanied by fumes and soot, and the fuel burns 100%.

What does a secondary oil burner consist of?

In appearance, the design resembles a small gas cylinder with two steel pipes on the sides. To assemble a heating device, you will need a welding machine, as well as some skills and abilities to handle it. When carrying out work, it is important to remember safety precautions.

The main element of a self-assembled waste oil burner is the body, for the manufacture of which a metal sphere (ball) is suitable. The structure is sold at any hardware store. You can use an empty gas cylinder as a base, after making sure that the tank is empty. When working with a welding machine, you should remember safety: in order not to harm your eyesight, you must wear safety glasses or a special mask.

Initially, the housing must be prepared for installation by removing excess handles, taps, etc., using an angle grinder. Next you need to make holes for the steel pipes. In order not to make a mistake with the drilling location and not to break the body of the waste oil burner with your own hands, it is recommended to first mark its position using a bright marker.

Rods are screwed into the prepared holes to supply the “working”. Using turning equipment, the ends of steel pipes are pre-cut to fit the hole. The main element of the air supply system, which is a round object with a large nozzle for taking in air masses, is also made on a lathe. If you do not know how to use such equipment, you can seek the help of professionals or purchase ready-made parts for the heating structure in the store.

In a self-assembled waste oil burner, the air intake is installed at the outlet of the housing. Screws and other additional parts are used to regulate the flow of air masses. After assembling the heating structure, you need to make sure it is working.

Advantages and disadvantages of a liquid fuel burner

This equipment has a lot of advantages, the main ones are:

- Easy to make with your own hands and use.

- Wide distribution of drawings for the manufacture of fixtures.

- Cheapness of used oil used as fuel. These devices are perfect for transport organizations and companies where there is a lot of waste. In this way, waste can be disposed of and space heating can be carried out.

- Efficiency and functionality of devices.

- Mobility of the device.

Despite the listed advantages, the burner also has a drawback. It is quite demanding on the quality of used oil.

Video on the topic

The idea of using waste oil as an energy carrier to heat buildings is not new. Due to the large amount of waste at vehicle service stations, especially trucks, a problem arose with its disposal. It is not surprising that various units, both factory-made and home-made, have appeared that make it possible to effectively burn this substance and receive thermal energy from it. One of such devices is a Babington waste oil burner, we will look at it in this material, and also tell you how you can make it yourself.

Principle of operation

In most known oil burners, the oil-air mixture is supplied through a nozzle under pressure. In contrast, in the Babington system, oil is supplied by a low-pressure pump and flows freely over a surface shaped like a sphere or close to it. The fuel forms a thin film and evaporates, carried away by a stream of air supplied under pressure into a small (up to 0.3 millimeter) hole in the center of the sphere. Oil vapor and air mix, forming a torch of the fuel mixture. This torch is ignited and heats what needs to be heated - the walls of the furnace or the liquid heat exchanger of the boiler.

Operating principle

Some of the oil does not have time to evaporate and burn and flows below the hole, ending up in the fuel collection pan. The waste then flows from the sump into the fuel tank and is reused.

To increase the fluidity and volatility of the mining, it is heated. The heated waste is sprayed into droplets of a smaller volume, which also improves the quality of the fuel mixture and the overall efficiency of the device.

Is it possible to make a blowtorch work during mining?

The principle of operation of a conventional blowtorch is to ignite gasoline vapors, which are pushed out under the action of compressed air.

This effect is achieved by forcing air into the burner fuel tank. What happens if you pour used oil into a blowtorch?

Oil itself, even under pressure, does not evaporate well - it needs to be heated. Due to poor atomization, the flame will be uneven and it will be difficult to ignite the burner. The oil burns with the formation of a large amount of soot and soot, so the jet will quickly coke, its cross-section will decrease, and the lamp will fail. Increasing the cross-section of the nozzle will also not give the expected effect - the oil will be sprayed in large drops, which will not allow obtaining a uniform flame of the torch.

In addition, used oil often contains impurities: diesel fuel, gasoline, antifreeze and even water, which can lead to flashes inside the lamp. To use waste as fuel for a blowtorch, you will have to install a filtration system, which will further complicate the task.

Considering all the difficulties, using a gasoline blowtorch as a burner during mining is difficult and unsafe. Therefore, it is necessary to modify or completely change its design.

This article talks about the types of wood-burning stoves and how to make them yourself. Read about the advantages and design features of a brick kiln with a water circuit here:

Finished equipment

HVAC and heating equipment stores sell burners using waste fuel (oil). An analogue of real stores are online portals for selling equipment. The list of available burners in terms of power and capabilities is extremely wide, as is the price range. The majority of the market is occupied by the following manufacturers:

- The stove is a “Gnome” class burner. Price niche from 40 thousand rubles. up to 450 thousand. Power range 35 - 1000 kW. Comparable to Amalthea burners.

- NORTEC is the most popular Chinese manufacturer. Budget options for 60 kW cost 75 thousand rubles. There are universal models of 1500 kW and costing more than 570 thousand rubles.

- Euronord is another Chinese company, the range of burners is 40 - 236 kW, priced at 90 - 150 thousand rubles. respectively.

- The domestic company Olympia has the highest price, up to 780 thousand rubles. for 500 kW, but the manufacturer has a RosTest certificate.

For the most part, store burners are ejection devices equipped with automatic systems, fuel heating and safety sensors. All control is carried out from an electronic remote control. There is also equipment for attachment to a boiler or heater. As you can see, even the most budget options have a decent price.

Furnace manufacturing procedure

Let’s say right away that it is advisable to adhere to the above dimensions as accurately as possible, since all of them are calculated from considerations of the greatest efficiency of the device and the maximum degree of fuel combustion.

- A mining tank is made, for which a bottom made of steel sheet is welded to a piece of 344 mm pipe. The legs are immediately welded to the “pan”.

- A lid for the tank is being made. A hole with a diameter of 60 mm is made in it, which simultaneously serves to fill the mining and to regulate the draft during operation of the furnace, so the hole is equipped with a gate. Through it, ignition will also be carried out using rolled paper, wood chips, etc.

- A combustion chamber is made, for which 48 holes of 9 mm in diameter are evenly drilled in a long 100 mm pipe. The chamber is welded to the lid of the oil reservoir.

- The afterburner chamber is made from a 352 mm pipe. Don’t forget to weld the partition; the reason for its necessity was described above.

- Weld the structure to the perforated combustion chamber.

steam heating

Starting the furnace

It has already been said implicitly that you need to start the drip furnace slowly and smoothly. Usually, for this they use a torch made from a knitting needle with a piece of foam rubber or a rag: let some drops in and place the torch. When it gets wet, they wait until a puddle drips into the bowl, light a torch, and pour oil into it.

There is a much more convenient and safer way to start a drip stove: a wad of toilet paper soaked in the same oil. They put it in a bowl, set it on fire and slowly regulate the drips, no longer worrying about kindling. Toilet paper is almost pure cellulose; it burns without leaving a residue. Tourists have been warming themselves in tents this way for a long time: the roll is inserted into a wood chip stove, poured with half a glass of alcohol (which also burns without a trace), or the whole thing, darling, and set on fire from above. A lot of heat is generated, and an insignificant amount of fluffy ash can simply be blown out. In the oven it will fly out into the chimney.

Let's start making our own

- welding machine;

- Bulgarian;

- lathe.

In appearance, the burner looks like a small empty gas cylinder, with oppositely directed steel pipe sections welded on the top and bottom sides of it. The inside of the burner measures only 1 inch (2.54 cm) and its walls are quite large.

A piece of pipe at the bottom is required to supply oil and air to the part where combustion occurs. The short pipe at the top is used as the burner mouth from which the flame will erupt.

Expert tip: To set the air flow into the oven, a regular high-power household vacuum cleaner can be used.

Additional Tips

When using a homemade burner, there are usually increased requirements for compliance with fire safety rules

Important to remember:

- Do not leave a working nozzle unattended.

- It is prohibited to install the equipment in a residential area.

- To heat the heating main boiler, a special room is usually made without flammable coating on the walls, ceiling and floor.

- To increase operating efficiency, heavily contaminated waste is enriched with clean oil.

- Reliable ventilation is built in the boiler room to remove gases and smoke after fuel combustion.

- Carry out regular maintenance and equipment reliability checks.

If used correctly, a homemade burner will last for many years. The savings from using this type of heating are obvious, because the used oil has already been paid for, and if not for the homemade firebox, it would have to be disposed of.

Operating principle and types of structures

Since any oil contains flammable substances, they can be burned. People have long been trying to make the most of this for their own benefit, but solving this problem is not so easy, especially if they try to burn used oil, which contains many additional components. There are three types of devices for this purpose:

- Ejection. Very effective system. Excellent fuel combustion, high temperature, low emissions, but it is almost impossible to do at home. In addition, not all fuels can be used without pre-treatment.

- Evaporative. The easiest to assemble from scrap material, but its effectiveness is low, there is a lot of waste and pollution. Additional equipment is required for ignition and smooth operation.

- Injection. The most acceptable option for making an oil burner with your own hands. Relatively simple design, easy to maintain, unpretentious to fuel. The main disadvantage is the inability to use in residential premises.

In this video you will learn how the burner works during mining:

Some craftsmen try to adapt blowtorches for heating by working off, but most often such endeavors result in complex alterations and a complete abandonment of the original burner design. The Babington oil burner has become most popular in recent years.

Robert Babington patented his invention at the end of the last century using one of Murphy's laws - to do everything in reverse. Robert did not spray the fuel by blowing it out of the nozzle, but simply tried to force air through the oil film. It produces an oily aerosol that burns beautifully. It’s not for nothing that they say that everything ingenious is simple.

DIY Babington burner

A worthy alternative to store-bought burners would be to make your own waste oil burner. First you need to decide on the type of device. Ejection circuits are difficult for home production, and evaporation circuits have a limited scope of application. This means that the best option would be the Babington device, which was originally intended to run on diesel fuel.

The key operating principle of this burner is that a stream of compressed air is supplied directly through the waste layer. Also, the device does not have bottlenecks that could become clogged with dirt. To create burner units you will need the following materials:

- The fuel unit is a tank with a heating element with a power of up to 1 kW made of stainless metal. A sump with a pipe, a drain with an inch thread and a 2/1-inch adapter for draining excess waste oil into the tank. Copper tube with a diameter of 1 cm and a thickness of up to 0.15 cm. An oil pump with an electric motor, equipped with an oil filter with a large mesh (can be removed from a car or motorcycle).

- Pneumatic unit - a compressor with a permissible pressure of 2-4 atm., a tube for an air stream with a diameter of 1-1.5 cm.

- The fuel-air mixing chamber is an empty metal ball or hemisphere with sufficient thickness for a 0.3 mm hole (nut with a plug, brass door handle, etc.).

- A nozzle that directs the flame in the desired direction. Length 20-40 cm, external thread with a diameter of 2 inches.

- Connecting parts (fittings) and transition parts (adapters) allowing you to assemble the entire unit into a single burner.

Preparing burner modules for assembly

The role of the key part is given to the hemisphere in which the used oil is mixed with oxygen. You need to drill a hole in it, which affects the power of the future burner. For a 15 kW heating boiler, a nozzle with a single hole of 0.2 mm is suitable. Greater burner power can be achieved with 3-4 holes of 0.1-0.25 mm, with a mandatory distance of 0.8-1 cm (so the torches from each hole will not extinguish each other). One quarter-centimeter hole consumes 2 liters of waste oil per hour of operation.

The fuel tank is made of corrosion-resistant metal, as is the fuel sump. The latter is equipped with a tube through which waste oil flows back into the tank. A plug is made at the bottom of the sump to drain the dirty residue. A heating element equipped with a regulator is built into the tank, which will turn it off at 70°C.

The role of the body is played by a cross or tee, to which the nozzle and adapters are mounted. At the top there is an oil supply, at the rear there is a compressed air supply, at the bottom there is an adapter for draining excess fuel. The role of adapters is played by plugs with holes for air and oil supply pipes.

The pump motor for supplying waste is connected to a network with a voltage of 220V. Oil (waste) from the tank flows through a copper tube, on the one hand, wound three times around the nozzle, and on the other, led into the tank through an oil filter.

The air tube is attached to a hemisphere with a drilled nozzle and a plug adapter is installed. The hemisphere itself is positioned in such a way that the fuel from the copper fuel tube completely covers the nozzle, and the remainder flows into the sump. The duct compressor is also connected to the household network.

Preparing fuel for the burner

A device operating on waste oil consumes any type of waste. Motor oils with high water content are mixed with diesel fuel (or clean oil) before filling. Mining with moderate contamination can be poured immediately.

It is advisable to let edible oils stand before use, then drain the remainder. Fuel oil and viscous fuels and lubricants need to be heated to 70-80°C. For greater efficiency, 10% diesel fuel is added to synthetic and mineral oils when filling.

Safety precautions

- There must be fire extinguishers in the room where the device is used.

- If the floor and walls of the room are made of flammable material, they are sheathed with asbestos or metal.

- Fuel is stored at a distance insufficient for ignition from burner operation.

- Oily stains are removed in a timely manner.

- A working burner must not be left unattended.

The Babington burner is a reliable device with an extended service life and is designed to bring savings to the owner.

How to choose a burner for mining

When choosing this boiler module, the determining factor is power. The fuel preheating mechanism and injector design are important.

Power

It determines the performance characteristics of the burner. Installing a 30 kW device in a 15 kW boiler is unacceptable and will lead to melting of the structure. The data sheets of store products indicate the heat transfer and the dimensions of the recommended and maximum heated areas.

Number of steps

Heat transfer power is regulated in 2 ways:

- Single-stage burners heat the coolant to a given temperature. Next, the fuel supply is blocked, the boiler cools down to the set value, and the cycle repeats.

- Two-stage designs operate without shutting down in 2 modes: at full power - when the system warms up to the planned levels (after which it begins switching to economical oil consumption), half or two-thirds less.

Power control is carried out by the burner.

This method of adjustment requires equipment with automation, which increases the cost of the design, but reduces operating costs by 15-20%.

If the supply of fuel and air is fully automated and is guided by the readings of temperature sensors of the coolant, heated and burned oil, the volume of incoming air and fuel, then such units are called smooth two-stage and modulating.

Size and volume

The burners are compact, their performance does not directly depend on the size of the heating devices and is determined by design solutions at the planning stage.

Burner material

Its body is made of corrosion-resistant steel parts, fuel lines are made of soft non-ferrous metals (copper) and their alloys.

Oil consumption

The amount of fuel for heating the room depends on:

- heat loss of serviced areas;

- territorial affiliation with climatic zones (in the Arctic region winter is colder and longer);

- the amount of impurities and their effect on the caloric content of the combustible mixture;

- unit efficiency;

- settings of the heating device and its power;

- number of working hours and temperature conditions of the heated room.

Oil consumption depends on the heat loss of the serviced areas.

The approximate figure for the middle zone of the country is 2.5-4 tons with a round-the-clock consumption of 3 liters per hour.

Burner features

In order to burn the oil effectively, it will need to be heated first and then sprayed. For this purpose, an electric heating element is installed. But the energy consumption will be quite large. And the main thing for you in manufacturing is to achieve minimal losses when using the device. The burner must be a source of very cheap heat, which cannot be realized when using heating elements.

If you can’t warm up the oil first, you need to try to atomize it. The simplest burners made according to the Babington scheme can be successfully used in boilers. The design is extremely simple - fuel flows over a spherical surface. A thin hole is made in the latter; compressed air is supplied through it. It turns out that the oil is blown away from the sphere, small drops are formed, which can be ignited.

The principle of operation of a homemade stove during testing

My working stove works on a very simple principle. Ignition is in progress. The fuel begins to burn on the surface of the body and heats up the stove. As the process progresses, oil vapors are removed through the chimney under the influence of draft.

The stove design includes a part of the chimney with many holes (usually up to 50). This part of the unit is called the burner. In such a burner, oil vapors are mixed with oxygen entering the smoke exhaust pipe under the influence of draft. As a result of their mixing, the combustion process begins to be much cleaner and more intense, releasing a huge amount of heat.

The principle of operation of a homemade stove during testing

Kinds

These devices may differ from one another in several ways. First of all, if possible, regulate the power. There are three varieties:

Single stage

These are the simplest burners, the thermal output of which, also known as power, is always constant.

The amount of incoming heat is regulated by periodically turning on/off the burner.

The advantage of this device is its low cost.

The disadvantage is that all elements of the boiler, and especially the heat exchanger, operate with maximum thermal load and under conditions of sudden temperature changes. And this negatively affects the durability of the heat generator.

Two-stage

Such devices can operate in two modes: with maximum performance and half. Half mode is used as an intermediate mode for smoothly reaching maximum power, or as the main mode in relatively warm weather.

A two-stage burner is more expensive than a single-stage burner, but the boiler equipped with it operates in a gentle mode, and therefore lasts longer.

Modulated

The most expensive type of diesel burner, which is characterized by the ability to smoothly regulate power over a wide range - from 10% to maximum. Such burners do not turn off, but operate constantly - with the productivity that is required at the moment. This not only reduces the thermal load on the heat exchanger and furnace, but also eliminates temperature changes.

Diesel burner M 302

In addition, fuel consumption is reduced. After all, the operating scheme of one- and two-stage burners assumes some overheating of the coolant, as a result of which the amount of heat loss increases (it is proportional to the difference in temperature inside the room and outside).

If the boiler is equipped with a modulating burner, no overheating occurs (the temperature is maintained at the set point all the time), so heat loss, and therefore fuel consumption, becomes minimal.

Other types

Diesel burners also differ in the method of supplying primary air, which is used to prepare the fuel-air mixture. On this basis they are divided into two types:

- Diffusion (atmospheric): the simplest burners in which air is sucked in due to the pressure drop in a moving liquid stream. But with this method it is not always possible to ensure the supply of a sufficient amount of oxygen, so the fuel may not burn completely. The consequences are a drop in the efficiency of the installation and the formation of a large amount of soot.

- Pressurized or blown burners: Equipped with a fan that provides forced air supply in any volume. They cost a little more, but the fuel burns completely under any conditions.

Particularly powerful heat generators are equipped only with forced-air burners.

Technological features

Car oil is a good fuel for heating rooms

It is important to create the necessary conditions for the combustion of this material:

- at the time of arson, the oil must be heated to a temperature of +300°C, which transforms it into a gaseous state;

- it can be atomized and enriched with a simultaneous supply of air.

Due to its viscosity, the waste must go through the stages of heating, atomization and air enrichment. This will allow efficient use of combustible material and increase its efficiency.

https://youtube.com/watch?v=G_Xkkh6-W0E

https://youtube.com/watch?v=AZWiw-6Gpoc

Manufacturing recommendations

There are several useful recommendations that will help in making a burner:

- The hole should be exactly in the center of the sphere, and its axis should coincide with the axis of the air duct. Otherwise, the torch will hit to the side, and this creates additional danger.

- Instead of drilling a hole, you can use a ready-made jet. To do this, a hole slightly smaller than the outer diameter of the nozzle is drilled with a conventional drill, then it is modified manually, and the nozzle is simply hammered inside.

- If there is more than one hole, the distance between them should not be less than 7 mm.

- To ignite, you need to make a hole in the side of the nozzle.

- In the simplest case, fuel should be supplied to the burner by gravity, but a fuel pump can also be used.

- Even a low-power compressor (for example, from a refrigerator) can cope with air injection. The working pressure inside the sphere does not exceed 4 Bar (4 * 105 Pa).

It is not necessary to use a heating element in the design. When starting the burner, you can use a propane torch, hot water, or even an old coffee maker to preheat the oil.

Advantages and disadvantages

The main advantage due to which the homemade burner at the Babington mine has gained wide popularity is its omnivorous nature, as mentioned above. In fact, you can pour any heated oil of a reasonable degree of contamination onto a spherical surface, and a properly made burner will still operate stably. It is not afraid of gasoline or antifreeze impurities, unless their ratio with oil is one to one, then problems will inevitably arise. And then, this is not at all a reason to get rid of such a mixture; for the burner to function normally using waste oil, it will need to be well diluted with the “correct” treatment, and then put into use.

Another advantage is the simplicity of the design, which is why craftsmen quickly mastered this product. Indeed, making the “heart” of the device from a ball or hemisphere placed in a body is quite simple. It is somewhat more difficult to organize the fuel supply and air injection, and even to configure the entire system so that the DIY Babington burner operates stably and safely. But there is wide scope for the implementation of various technical solutions.

Of the serious shortcomings of the unit, only one is striking. This is the constant presence of dirt in the room where the liquid fuel burner operates. Unfortunately, it is impossible to completely eliminate accidental spills or seepage of contaminated machine oil through leaks, even if all connections are sealed and an automatic Babington burner is installed. To one degree or another, the room will be dirty, you will have to come to terms with it.

Due to its popularity and simplicity, the burner for the waste boiler is made by craftsmen in different variations, but we will undertake to describe the simplest design, which will be available for repetition at home. First you need to select the necessary materials, here is their list:

- Steel tee with internal threads with a diameter of 50 mm - for the body.

- Squeegee with external thread with a diameter of 50 mm - for the nozzle. Its length is optional, but not less than 100 mm for the nozzle.

- Metal elbow DN10 with external threads - for connecting the fuel line.

- Copper tube DU10 of the required length, but not less than 1 m - to the fuel line.

- A metal ball or hemisphere that fits freely into the tee is for the working part.

- A steel tube of at least DN10 is used to connect the air duct.

To make a burner for testing with your own hands, you need to perform one precise operation - make a hole in the center of the sphere. The hole diameter is from 0.1 to 0.4 mm, ideally 0.25 mm. It can be done in 2 ways: drill with a tool of the appropriate diameter or install a ready-made jet at 0.25 mm.

It is not easy to accurately make such a small hole; thin drills easily break. Instructions on how to do this correctly are shown below:

Another way to make a calibrated hole in the spherical part of an autonomous burner is to insert a nozzle of the required diameter there. To do this, a hole is drilled, the diameter of which is slightly less than the outer diameter of the nozzle, and processed with a reamer. The jet is pressed inside and polished, as described in the video:

When this operation is completed, we assemble the burner based on the drawing:

A hole must be made on the side of the nozzle wide enough to ignite the unit. A large fuel heating spiral is not needed, 2-3 turns are enough. The finished product can be mounted on a mounting plate and built into any boiler, including a homemade one. At the end of the work, you need to connect the air and fuel lines, and then organize the supply of oil and air. The simplest method of fuel supply is by gravity; for this purpose, the waste container is suspended from the wall above the burner device and a tube is laid from it.

If you use a pump to pump oil, you can subsequently use control sensors and a control unit, then you will have an automatic burner that will be safer to operate. Detailed instructions for selecting materials and assembling the device are shown in the video:

If everything is done correctly and the diameter of the air hole is 0.25 mm, then the fuel consumption of the burner should not exceed 1 liter per hour. There should be no black soot during combustion; you need to achieve even burning of the torch. The adjustment is carried out by moving the sphere back and forth or changing the air pressure. Any compressor can cope with its injection, even from a refrigerator, since the operating pressure does not exceed 4 Bar.

How to make a burner yourself

The simplicity of the burner design allows it to be easily manufactured in a home workshop or garage. Let's look at how to make a burner of the simplest design.

First of all, you should select materials:

- The body of the future burner is a steel tee with internal thread. Inner diameter – 50 mm.

- The nozzle is made from a squeegee (a piece of threaded pipe). The outer diameter must be 50mm to fit the body. The nozzle length is not less than 100 mm.

- Connection to the fuel line is made through elbow DN 10.

- The fuel line is a copper pipe DN 10, at least a meter long.

- The air duct is a steel tube of the same diameter.

- A metal sphere or hemisphere that can fit freely into a tee.

- Fuel tank and settling tank.

- Heating element for fuel.

The fuel tank should not be located in close proximity to the flare. Otherwise, a fire will occur.

Advantages and disadvantages

The main advantage due to which the homemade burner at the Babington mine has gained wide popularity is its omnivorous nature, as mentioned above. In fact, you can pour any heated oil of a reasonable degree of contamination onto a spherical surface, and a properly made burner will still operate stably. It is not afraid of gasoline or antifreeze impurities, unless their ratio with oil is one to one, then problems will inevitably arise. And then, this is not at all a reason to get rid of such a mixture; for the burner to function normally using waste oil, it will need to be well diluted with the “correct” treatment, and then put into use.

Another advantage is the simplicity of the design, which is why craftsmen quickly mastered this product. Indeed, making the “heart” of the device from a ball or hemisphere placed in a body is quite simple. It is somewhat more difficult to organize the fuel supply and air injection, and even to configure the entire system so that the DIY Babington burner operates stably and safely. But there is wide scope for the implementation of various technical solutions.

Of the serious shortcomings of the unit, only one is striking. This is the constant presence of dirt in the room where the liquid fuel burner operates. Unfortunately, it is impossible to completely eliminate accidental spills or seepage of contaminated machine oil through leaks, even if all connections are sealed and an automatic Babington burner is installed. To one degree or another, the room will be dirty, you will have to come to terms with it.

Due to its popularity and simplicity, the burner for the waste boiler is made by craftsmen in different variations, but we will undertake to describe the simplest design, which will be available for repetition at home. First you need to select the necessary materials, here is their list:

- Steel tee with internal threads with a diameter of 50 mm - for the body.

- Squeegee with external thread with a diameter of 50 mm - for the nozzle. Its length is optional, but not less than 100 mm for the nozzle.

- Metal elbow DN10 with external threads - for connecting the fuel line.

- Copper tube DU10 of the required length, but not less than 1 m - to the fuel line.

- A metal ball or hemisphere that fits freely into the tee is for the working part.

- A steel tube of at least DN10 is used to connect the air duct.

To make a burner for testing with your own hands, you need to perform one precise operation - make a hole in the center of the sphere. The hole diameter is from 0.1 to 0.4 mm, ideally 0.25 mm. It can be done in 2 ways: drill with a tool of the appropriate diameter or install a ready-made jet at 0.25 mm.

It is not easy to accurately make such a small hole; thin drills easily break. Instructions on how to do this correctly are shown below:

Another way to make a calibrated hole in the spherical part of an autonomous burner is to insert a nozzle of the required diameter there. To do this, a hole is drilled, the diameter of which is slightly less than the outer diameter of the nozzle, and processed with a reamer. The jet is pressed inside and polished, as described in the video:

When this operation is completed, we assemble the burner based on the drawing:

A hole must be made on the side of the nozzle wide enough to ignite the unit. A large fuel heating spiral is not needed, 2-3 turns are enough. The finished product can be mounted on a mounting plate and built into any boiler, including a homemade one. At the end of the work, you need to connect the air and fuel lines, and then organize the supply of oil and air. The simplest method of fuel supply is by gravity; for this purpose, the waste container is suspended from the wall above the burner device and a tube is laid from it.

If you use a pump to pump oil, you can subsequently use control sensors and a control unit, then you will have an automatic burner that will be safer to operate. Detailed instructions for selecting materials and assembling the device are shown in the video:

If everything is done correctly and the diameter of the air hole is 0.25 mm, then the fuel consumption of the burner should not exceed 1 liter per hour. There should be no black soot during combustion; you need to achieve even burning of the torch. The adjustment is carried out by moving the sphere back and forth or changing the air pressure. Any compressor can cope with its injection, even from a refrigerator, since the operating pressure does not exceed 4 Bar.

How the burner came to be

Back in 1969, inventor Robert Babington was awarded a patent for this burner. True, today its term has long expired. In 1979, Babington proposed a new burner design. It was fundamentally different in that it had a double air spray. This invention was very similar to the Airtonic burner, which was also made using the technology of this inventor. It was used for military purposes in a field kitchen. Naturally, the burner was powered by diesel fuel and was irreplaceable. The final version was proposed by John Archibald. Many people call this man the inventor of the Babington burner. But it is impossible to give a definite answer. And it is unlikely that this plays a significant role for us. The most important thing is to be able to create such a unit with your own hands and ensure its efficient operation. Fortunately, doing this is not as difficult as it might seem at first glance.

General information

Autonomous heating boilers operating on heavy fuel appeared in the middle of the last century. In 1969, engineer Robert Babington patented a unique burner design, which was equipped with an air atomizer, which ensured the most complete combustion of fuel, excellent heater efficiency and device safety. The first modifications of Babington boilers were used for military purposes and were intended to run on diesel fuel.

The operating principle of the Babington burner differs from classical oil boilers. Fuel, that is, waste or other oil and an air mixture, is supplied using nozzles and low-power pumps. A hemisphere is used as a working surface, onto which diesel or waste flows, forming a thin film. In the center of the nozzle there is a small hole with a diameter of no more than 0.3 millimeters. Compressed air is supplied through the existing hole, which makes it possible to tear off part of the surface from the oil film, resulting in a saturated air-fuel jet.

The saturated air-fuel mixture is ignited, forming a powerful and stable flame. The fire is directed into the boiler or furnace firebox, where through the walls or directly it heats the water jacket with the coolant circulating inside. Directly under the hemisphere there is one or several containers for expiring fuel, which allows you to select excess waste, directing it through the pump back into the combustion chamber.

To improve burner efficiency while reducing fuel consumption, the used waste oil is additionally heated, which allows for the following:

- The heated fuel forms a thin film on the working surface, which is better atomized by a saturated air stream.

- The smallest drops in the air stream are easily ignited, which subsequently improves the combustion performance of the stove.

- Fuel consumption is reduced and at the same time the efficiency of the heating system is increased.

Fuel heating can be done either using electric heating elements or through additional heat removal from the burner itself. In the first case, the boiler is energy dependent, and its maximum efficiency and fuel efficiency are achieved only when connected to electricity.

How to make a diesel burner with your own hands

Security measures

- A burner using oils and other GSPs can be dangerous if installed and operated incorrectly. To avoid a fire, a number of measures must be observed:

floors and walls made of flammable materials are sheathed with metal or asbestos sheets; fuel reserves are stored at a safe distance; oil leaks must be removed in a timely manner; electrical elements of the installation must be carefully insulated to avoid sparking in the oil spray area; The burner must be placed out of reach of air currents and drafts.

A burner with an open nozzle must not be left running unattended!

The Babington burner, unlike a blowtorch converted for working in mining, is a reliable and durable unit that does not require complex maintenance. It is enough to periodically clean the fuel system, tank and sump, blow out the air duct in idle mode, and also monitor the serviceability of the compressor and oil pump. A working burner is a reliable and economical unit with a long service life.

The idea of using used machine oil as burner fuel is not new. There are many different schemes for making such a device on the Internet. And the popularity of such products is only growing. This is understandable, because such a device will be very useful in everyday life, heating a country house or utility room.

In addition, it has a number of advantages:

- Most of the proposed schemes are simple, and anyone with a minimum of necessary skills and tools can assemble it.

- The fuel for this burner is very affordable. It can mainly be found in auto repair shops, where there is simply an overabundance of it. Thus, used oil can be obtained for free or for a minimal amount.

- The question of recycling used oil often arises, and such a burner will help dispose of it without harming the environment.

- This device is multifunctional and can be used as a regular burner or an oil heating system.

- Such a device, as a rule, is mobile, as it is light in weight and size.

- This burner is universal in the type of fuel used. In fact, it can operate on any combustible fuel, be it used engine oil, gasoline, kerosene or any other.

Among the many schemes, one is the most interesting in terms of simplicity, functionality and unpretentiousness. This miracle unit is called a Babington burner. It is named after its creator and its device was unavailable for a long time due to a patent. But the patent has expired and now anyone can bring the scheme to life.

The principle of its operation is very simple and includes the following stages and parts:

- Preheated fuel falls on the sphere, spreading over it evenly, forming a thin film.

- A compressor is connected to the sphere itself, pumping air. A very small hole is made in the sphere, with a diameter of 0.1-0.3 mm. Air under pressure exits the sphere through this hole. Passing through the fuel, the air disperses it, forming something like an aerosol.

- Next, this jet is ignited and a burning torch is obtained.

- The rest of the unused waste flows into the settling tank and can be reused.

- In order for unused waste oil to be automatically supplied to the sphere again, it is necessary to connect a pump to the system, which will supply fuel from the sump.

Preheating the fuel solves 2 problems at once:

- Increased fluidity. The heated waste oil spreads better over the surface of the sphere and is atomized much more easily by the supplied air.

- Facilitates the process of igniting the torch. At the same time, it is not only easier to launch the device, so to speak, but the efficiency also increases.

The advantages of this scheme include:

- Versatility in fuel use. Such a burner is practically independent of the degree of contamination of the liquid energy carrier.

- No filtering required. Due to the fact that there are no narrow passages in the system, except for the air hole, it does not require filtration, unlike factory analogues.

What is Babington's famous invention?

Every invention has its own author, even if his name is undeservedly forgotten by his descendants. For example, in 1969, British inventor Robert Babington received a patent for a stove running on diesel fuel, which was reminiscent of lighting kerosene gas operating on kerosene vapor. Robert Babington's design was originally designed for kerosene, then it was adapted for diesel fuel. When the number of cars increased disproportionately, the used oil had to be disposed of somehow. Therefore, innovators were looking for devices suitable for these purposes.

First, based on the patented invention of R. Babington, a do-it-yourself diesel burner appeared, then it was adapted for burning oil and other types of fuel. The testing device appeared much later than the diesel design, but it surpassed its predecessor in popularity and safety.

After some time, a similar device was proposed again, since the first patent had expired, and the liquid fuel stove had not lost its relevance. Similar devices were repeated in different versions, and not only self-taught craftsmen, but also design bureaus of reputable enterprises tried to assemble the Babington burner with their own hands.

By design, the burner is a simple device, so it can be successfully manufactured at home. It is characterized by fairly high efficiency in terms of obtaining the heat necessary for heating:

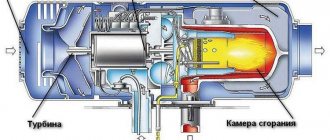

Burner diagram based on the Babington principle, where 1 – heating sensor; 2 – casing; 3 – heat exchanger; 4 – fuel sprayer; 5 – glow plug; 6 – supercharger; 7 – fuel pump; 8 – friction clutch; 9 – electric motor; 10 – lever for switching operating modes; 11 – fan; 12 – skeleton; 13 – fuel pipe; 14 – combustion chamber.

- technological installations;

- small workshops;

- workshops;

- garages;

- warehouse and utility rooms.

On a note! You should not adapt a homemade burner with your own hands for heating your home, since burnt oil has a specific smell.

Why work off

Drip fuel supply is widely used in heating engineering when a heat output of approx. up to 15 kW. The principle of operation of a drip furnace is simple: liquid fuel drips into a heated evaporator, into which primary air is supplied. Each drop evaporates and partially burns immediately, maintaining the temperature of the evaporator. The remaining fuel vapors enter the combustion chamber with the influx of secondary air, where they burn completely. Thus, in drip furnaces, 2-stage fuel combustion is carried out. Unlike stoves with non-pressure burners, where the fuel heats only itself until it evaporates, in drip stoves part of the heat from the combustion of each drop is spent on heating a rather massive evaporator, which determines their lower efficiency. But there are ways to minimize this disadvantage, see below.

The maximum power of a drip furnace is largely determined by the properties of the fuel: if, in order to obtain a given amount of heat, the fuel must be released in a trickle, the furnace becomes fire and explosive. Mining in this regard is good because its viscosity and surface tension are high, i.e. It is possible to obtain frequent and large drops of waste. Diesel fuel is significantly worse in these parameters, although it is still possible to make a stove using waste fuel and diesel, see below. Drip stoves are not made with light liquid fuel - it is dangerous. Fuel oil and oil sludge are too valuable as fuel, and industrial-scale sources of heavy fuels are too stable to be burned haphazardly.

Blitz tips

- If the fuel supply is adjusted correctly , the Babington burner is very economical and consumes only 0.5–1 liters of waste per hour. And air consumption will be only a few liters per hour.

- If you additionally add a chimney and a combustion chamber with a water jacket to the circuit, then such a burner can be used as a full-fledged boiler for heating a private house.

- You can use a compressor from an old refrigerator as an air pump

- Such a system works stably even on a mixture of various used oils containing gasoline , diesel fuel, various additives and even antifreeze, which undoubtedly gives it an advantage over its factory counterparts.

- The heat from such a burner is very strong , and the power, depending on the configuration, is more than 10 kW.

Requirements for the operation of oil boilers during development

Oil boilers are considered simple and convenient equipment, but only if used correctly.

There are few requirements, however, they will increase the service life of the flawless operation of the units:

- The boiler room should be equipped with good ventilation. Sometimes combustion product vapors enter the air, poisoning it. To prevent leaks in residential premises, the boiler room is organized outside the residential building or in a separate isolated and ventilated room.

- The cleaner the waste, the longer the injectors will work, and the combustion process will be more efficient. Any oil can be used, including waste oil from household appliances. Equipment manufacturers indicate energy requirements in the technical data sheet; they should be adhered to.

- Install an additional filter system. Oil filtration devices will help further purify the energy carrier.

- Connect the boiler to the chimney with a damper. The pipe passage area in the roof should be supplemented with a protective casing.

- Provide a separate room for storing waste. You cannot store supplies in the boiler room.

- Before adding oil, turn off the unit from operation. The first portion can be mixed with kerosene at the rate of 10 parts oil to 1 part kerosene.

- The heat exchanger must be cleaned regularly. Factory boilers are equipped with a removable back panel. In self-produced boilers, provide access to the heat exchanger for cleaning soot and combustion products. Cleaning is carried out in stages - first brush dry, then after removing the layers, it is permissible to wipe the parts with a damp cloth.

- Change injectors at least once per season. Even if the nozzles are visually clean, the boiler has not been operating for long, replace the parts as they become clogged inside. Timely replacement will double the service life of the equipment.

- Oil filters are changed at least once a season, but it is better to do it more often. Especially if you use oil with poor filtration. It is more practical to install two filters - coarse and fine. In this case, the nozzle receives a purified mixture, it clogs the structure less, and combustion will be efficient and fast.

Features of ignition of the furnace during mining

To light a stove of this design, you need to know some nuances, which are due to the complexity of igniting mineral oils:

Ignition of the furnace

- Before each use of the stove, it is necessary to carry out an external inspection of the structure, make sure that it is in good condition, and check the condition of the chimney (if necessary, clean it).

- Inspect the lower container (oil reservoir), make sure that no water has entered it.

- The usual fuel supply should be 2-3 liters of oil; if necessary, add it.

- The stove is ignited through the filling hole using a burning oiled wick, which can be twisted from an ordinary rag. It may take up to 5 minutes for the main volume of oil to ignite (to speed up ignition, you can add 100 grams of kerosene to the container).

- After stable flame combustion appears, it is necessary to set the required furnace draft. Usually the damper is left slightly open by 1-2 cm. If necessary, the combustion intensity is adjusted using the same damper.

Devices of this type are characterized by a simple design, while the heat transfer of such a furnace is quite high. Therefore, if you have unlimited waste reserves, install heating of this type, you will not regret it, and you will also save a lot.