An autonomous water supply system, which independently supplies water to distribution points as in a city apartment, has long ceased to be a curiosity. This is the norm of country life, which just needs to be properly designed, assembled and equipped with equipment capable of starting and stopping the system as the taps are used.

Stable operation of an independent network will be ensured by an expansion tank for water supply. It will protect against water hammer, significantly extend the service life of pumping equipment, guarantee regular filling of the system with water, and eliminate the need to carry it in buckets.

We are pleased to introduce you to the features of the device and the operating principle of the hydraulic accumulator. We carefully describe the rules for choosing a membrane tank, the specifics of installation and connection. We have supplemented the information offered for consideration with useful illustrations, diagrams and video tutorials.

Connection diagrams for hydraulic tanks

For a hot water supply system, the expansion tank is installed in the section of the circulation line, the suction line of the pump, closer to the water heater.

The tank is equipped with:

- pressure gauge, safety valve, air vent - safety group;

- shut-off valve with a device that prevents accidental shut-off.

In a water supply system where water heating equipment is present, the device takes on the functions of an expansion tank.

Installation diagram in the hot water system: 1 – hydraulic tank; 2 – safety valve; 3 – pumping equipment; 4 – filtration element; 5 – check valve; 6 – shut-off valve

In the cold water system, the main rule when installing a hydraulic accumulator is installation at the beginning of the piping, closer to the pump.

The connection diagram must include:

- check valve and shut-off valve;

- security group.

Connection schemes can be very different. The connected hydraulic tank normalizes the operation of the equipment, reducing the number of pump starts per unit of time and thereby extending its service life.

Installation diagram in a cold water system with a well: 1 – tank; 2 – check valve; 3 – shut-off valve; 4 – relay for pressure regulation; 5 – pumping equipment control device; 6 – security group

In a scheme with a booster pumping station, one of the pumps runs constantly. This system is installed for houses or buildings with high water consumption. The hydraulic tank here serves to neutralize pressure surges, and to accumulate water, a container of as large a volume as possible is installed.

Technical recommendations

Diagram of installation of a membrane tank

installation of a membrane tank

Before you begin connecting the accumulator to the water supply system, you should:

- Carefully study the instructions supplied with the equipment.

- Carry out technical pressure calculations and compare them with those specified in the standard operating manual.

- To carry out a quality installation, you need a wrench for detachable connections and plastic pipes and a wrench of the right size.

- To mount large-volume equipment, special brackets will be needed.

Mounting on brackets

Please note! Measurements and calculations of the equipment in use must be carried out by a highly qualified specialist. The quality of the water supply system depends on the accuracy of the calculations and measurements performed.

Many years of experience in using membrane tanks for water supply have shown that horizontal models are the best option. If you have a submersible pump connected, purchase and install vertical accumulators.

Features of adjusting the hydraulic accumulator

Expansion tanks for water supply are sold with standard manufacturer settings - often the pressure in the air compartment is already set at 1.5 bar. The permissible pressure is always indicated on the label and the manufacturer does not recommend deviating from the specified parameters, especially in the direction of increasing it.

Before proceeding with the adjustment, the system is disconnected from the power supply and the shut-off valves are closed. The membrane tank is completely emptied by draining the water - an accurate pressure indicator can only be measured when the water compartment is empty.

Next, pressure readings are taken using an accurate pressure gauge. To do this, remove the decorative cap from the spool and bring the device. If the pressure differs from the required one, it is brought into compliance by pumping or bleeding excess air.

Considering that the manufacturer is against deviations from the recommended pressure values, it is necessary to select suitable equipment at the design stage, the parameters of which will not conflict with each other

When adjusting the pressure in the gas compartment of the tank, the manufacturer fills it with an inert gas, for example, dry nitrogen. This prevents corrosion of the inner surface. Therefore, users are also recommended to use technical nitrogen to increase pressure.

Setting the tank pressure in the water supply system

The pressure in a closed tank is always set slightly lower (by 10%) than the pressure level when starting the pump. By adjusting the pressure in the device, you can adjust the water pressure. The lower the gas pressure in the hydraulic tank (but not less than 1 bar), the more water it will hold.

In this case, the pressure will become uneven - strong when the tank is full and increasingly weak when it is empty. To ensure a strong and even flow of water, set the pressure in the chamber with air or gas to within 1.5 bar.

The water pressure in the water supply is set using a relay. When setting the pressure in the expansion chamber, these values must be taken into account

Adjusting the hydraulic tank in the water heater trim

The expansion tank, which is used for hot water supply, should initially not contain water. The pressure in the device is set at a value that is 0.2 greater than the upper pump shutdown threshold.

For example, if the relay is configured to turn off the equipment at a pressure of 4 bar, then the pressure in the gas compartment of the expansion tank should be set to 4.2 bar.

Installed in the water heater piping, the tank does not serve to maintain pressure. It is designed to compensate for expansion when water is heated. If you set the pressure in it to a lower value, then there will always be water in the tank.

Types of membrane tanks

There are two types of expansion membrane tanks:

- With a replaceable membrane - models that imply the ability to change the rubber membrane. At the first need, it can be removed through the flange by unscrewing its bolts. In large tanks, the membrane is additionally fixed to the nipple, which allows you to stabilize the device, but even in this case it can be easily removed from the mounts on the back.

Membrane for hydraulic accumulator

- With a stationary membrane - tanks in which the separation membrane is fixed as rigidly as possible and cannot be replaced. If it fails, the entire device will have to be replaced. The price of such expansion tanks is lower than the cost of models of the previous type, but there is no need to talk about complete ease of use.

Advice. When choosing between a replaceable and stationary membrane, consider one important factor: in the first case, the water is completely contained in the membrane and does not come into contact with the inner surface of the tank, which eliminates corrosion processes, and in the second case, the contact is maintained, so it is impossible to achieve maximum protection against corrosion.

Hydraulic tank maintenance rules

A routine inspection of the expansion tank consists of checking the pressure in the gas compartment. It is also necessary to inspect the valves, shut-off valves, air vent, check the operation of the pressure gauge and water pressure switch. To ensure the integrity of the tank, an external inspection is carried out.

During preventive maintenance, the pressure in the hydraulic tank should be measured and adjusted if necessary.

Despite the simplicity of the device, expansion tanks for water supply still do not last forever and can break. Typical causes are rupture of the membrane or loss of air through the nipple. Signs of breakdowns can be determined by the frequent operation of the pump and the appearance of noise in the water supply system. Understanding how your accumulator works is the first step to proper maintenance and troubleshooting.

Down with confusion

In plumbing stores you can find two types of these devices, differing in color:

| Image | Description |

| 1. Expansion tanks installed for heating - water supply are usually red and, in full accordance with the name, are designed to compensate for the thermal expansion of water or coolant liquid when heated. Liquids practically do not compress, and when they expand, the pressure in a closed circuit begins to increase at a catastrophic rate; the air cushion inhibits its growth. |

| 2. Hydraulic accumulators - blue (see Hydraulic accumulators for water supply). They allow you to create an autonomous supply of cold water and act as a damper. That is, they dampen pressure surges when opening/closing shut-off valves and turning on/off the water supply pump. |

The video in this article will help you learn more about membrane tanks.

Installation of an open type hydraulic tank

An open-type device is used less and less often, as it requires constant user intervention in its operation. An open expansion tank is an unsealed container that serves to generate pressure in the water supply system, accumulate water, and also serves as an expansion chamber.

The tank is connected to: a drain tap, pipes for the recirculation and supply pipes, a control and overflow pipe

The tank is installed above the highest plumbing point, for example, in the attic, water enters the system by gravity. Every meter the device rises increases the pressure in the water supply by 0.1 atmospheres.

To automate the process of providing water, the tank is equipped with a float switch and an automatic relay is installed that will turn the pump on and off.

The container is mounted in a frost-free room, covered with a lid to prevent dust and debris, and the walls are wrapped in mineral wool or other insulation.

This method of organizing water supply requires regular monitoring by the user, otherwise the water may freeze at subzero temperatures (if the room is not heated). The liquid will evaporate, so you will have to constantly add it.

In addition, such a container is bulky and not aesthetically pleasing; it requires an attic space in the house. But the main drawback of the device is that the tank is not designed to work under conditions of high water pressure in the system.

Choosing the right device

When choosing a model with the necessary functions and volume, take into account the fact that the frequency of pump operation depends on the total volume of the tank.

The leading characteristic for any tank is not its functionality, but its volume.

At the same time, for each water supply system there are criteria that cannot be neglected, namely:

- Number of regular water users. (Daily use).

- Number of points for water intake. (Appliances, taps and other plumbing fixtures).

- Approximate frequency of using water intake points at the same time.

- The “on-off” cycle. You need to know exactly the limit of this cycle per hour for your pump.

Approximate calculation:

When calculating for three regular consumers, install a tank with a total volume of 20-24 liters. However, the pumping equipment should produce approximately 2 cubic meters per hour.

When calculating for four regular users with a reserve, it is better to install equipment of 50 liters or more. The pump productivity in this case is approximately 3.5-3.7 cubic meters per hour.

If there are more than 10 consumers, then a tank of at least 100 liters is required, and pumping equipment with an indicator of more than 5 cubic meters per hour.

To avoid breakdowns and expensive repairs, you need to carefully familiarize yourself with the manufacturer.

In this choice, there is no need to chase a cheaper and dubious brand. Improper savings can lead to breakdowns in the future.

Models with a low retail price inside are made, as a rule, without defects. But consumable parts are always made from the cheapest materials.

It is better to inquire about the material from which the membrane is made. Its environmental friendliness and stability will improve comfort as well as the service life of the system.

How to choose tank volume

You can choose the tank volume arbitrarily. There are no requirements or restrictions. The larger the volume of the tank, the greater the supply of water you will have in case of a shutdown and the less often the pump will turn on.

When choosing a volume, it is worth remembering that the volume that appears in the passport is the size of the entire container. There will be almost half as much water in it. The second thing to keep in mind is the overall dimensions of the container. A 100 liter tank is a decent-sized barrel - about 850 mm high and 450 mm in diameter. You will need to find a place somewhere for it and the harness. Somewhere - this is in the room where the pipe from the pump comes. This is where all the equipment is usually installed.

The volume is selected based on the average flow rate

If you need at least some guidelines to select the volume of a hydraulic accumulator, calculate the average flow rate from each water intake point (there are special tables or you can look at the data sheet for household appliances). Sum up all this data. Get the possible consumption if all consumers work simultaneously. Then figure out how many and which devices can work at the same time, calculate how much water will be consumed in a minute in this case. Most likely by this time you will have already come to some decision.

To make it a little easier, let’s say that the hydraulic tank volume of 25 liters is enough to meet the needs of two people. It will ensure the normal functioning of a very small system: faucet, toilet, sink and small water heater. If you have other household appliances, the capacity must be increased. The good news is that if you decide that the current tank is not enough for you, you can always install an additional one.

How to install correctly

Based on the installation methods, the device can be either vertical or horizontal. As for technical differences, most models do not have them. This must be taken into account when choosing a method for installing one of the membrane tanks for water supply. The installation process itself should not cause any special difficulties, so all the necessary work can be done independently, without involving third parties. But at the same time, you must have at least minimal experience in installing water supply networks.

Basic rules to follow:

- in order to avoid an increase in hydraulic resistance, no additional devices should be installed between the pump device and the tank;

- the case itself needs high-quality grounding, which will help avoid electrocorrosion in the future;

- the cross-section of the pipe used must be equal to or greater than the pipeline being connected;

- It is recommended that the connection be made using American quick-release fittings, which are used to connect to pipelines. They will make it possible to disconnect the device from all networks in case of emergency;

- installation should be carried out in a place where it would be convenient to carry out repairs and other types of maintenance work. It is necessary to take into account the size of the room in which the installation will be carried out.

Installing a device such as a membrane-type expansion tank will significantly increase the efficiency of the entire water supply device. An important role here will be played by the chosen type of installation of the main equipment and compliance with all technologies and requirements. If, for any reason, you doubt your abilities, you should entrust all the necessary work to specialists who will be able to make correct calculations and pay attention to all the nuances regarding the technological features and installation location of the expansion tank. There is no place for savings here, since certified and truly high-quality products will be expensive, but will also serve well, avoiding expensive repair work.

Functions and operating principle

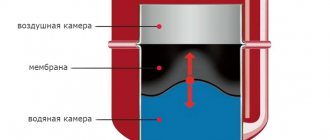

A membrane tank is a sealed, predominantly metal tank, consisting of two separated chambers: air and water.

The separator is a special rubber membrane - it is usually made of strong butyl, which is resistant to the development of bacterial microorganisms. The water chamber is equipped with a pipe through which water is directly supplied. The main task of the expansion membrane tank is to accumulate a certain volume of water and supply it at the user’s request under the required pressure. But the functions of the device are not limited to this - it also:

- protects the pump from premature deformation: thanks to the water reserve, the pump does not turn on every time the tap is opened, but only when the tank is empty;

- protects against changes in water pressure when using several taps in parallel;

- protects against water hammer that could potentially occur when the pumping unit is turned on.

Operation of the device

The principle of operation of the tank is as follows. When the pump turns on, water begins to be pumped into the water chamber under pressure, and the volume of the air chamber decreases at this time. When the pressure reaches the maximum allowable level, the pump turns off and the water supply stops. Then, as water is drawn from the tank, the pressure decreases and, when it decreases to the minimum allowable level, the pump turns on again and resumes pumping water.

Advice. During operation of the tank, air can accumulate in the water chamber, which causes a decrease in the efficiency of the equipment, so at least once every 3 months it is necessary to carry out maintenance of the compartment - to bleed excess air from it.