The best gas boilers for heating a private house of 200 sq.m. according to user reviews: summary technical characteristics of boilers with prices for them in online stores in your city.

| Number | Name | Rating |

| Baxi gas boilers for 200 sq.m. | ||

| 1 | Baxi ECO Four 24 F | |

| 2 | Baxi LUNA-3 COMFORT 240 i | |

| 3 | Baxi MAIN 5 24 F | |

| 4 | Baxi ECO-4s 24 | |

| 5 | Baxi ECO-5 Compact 24F | |

| 6 | Baxi ECO-4s 24F | |

| 7 | Baxi MAIN Four 240 F | |

| Protherm gas boilers for 200 sq.m. | ||

| 1 | Protherm Wolf 16 KSO | |

| 2 | Protherm Cheetah 23 MTV (2010) | |

| 3 | Protherm Cheetah 23 MOV (2010) | |

| 4 | Protherm Jaguar 24 JTV | |

| Conord gas boilers for 200 sq.m. | ||

| 1 | Conord KSts-G-16S | |

| Viessmann gas boilers for 200 sq.m. | ||

| 1 | Viessmann Vitopend 100-W A1JB010 | |

| Oasis gas boilers for 200 sq.m. | ||

| 1 | Oasis BM-20 | |

| 2 | Oasis RT-20 | |

| 3 | Oasis BM-18 | |

| 4 | Oasis RT-16 | |

| 5 | Oasis BM-16 | |

| 6 | Oasis RT-24 | |

| Gas boilers Buderus for 200 sq.m. | ||

| 1 | Buderus Logamax U072-24 | |

| 2 | Buderus Logamax U072-24K | |

| Bosch gas boilers for 200 sq.m. | ||

| 1 | Bosch Gaz 6000 W WBN 6000- 12 C | |

| 2 | Bosch Gaz 6000 W WBN 6000-18 C | |

| 3 | Bosch Gaz 6000 W WBN 6000-24 C | |

| Lemax gas boilers for 200 sq.m. | ||

| 1 | Lemax Wise 16 | |

| 2 | Lemax Patriot-20 | |

| 3 | Lemax Premium-12.5N | |

| 4 | Lemax Premium-20 | |

| 5 | Lemax Premium-12.5 | |

| 6 | Lemax Premium-10N | |

| 7 | Lemax Patriot-16 | |

| 8 | Lemax PRIME-V24 | |

| 9 | Lemax Premium-16N | |

| 10 | Lemax Premium-16 | |

| 11 | Lemax Premium-10 | |

| Gas boilers Rostovgazoapparat for 200 sq.m. | ||

| 1 | Rostovgazoapparat AOGV 11.6 | |

| Vaillant gas boilers for 200 sq.m. | ||

| 1 | Vaillant atmoTEC pro VUW 240/5-3 | |

| 2 | Vaillant turboTEC pro VUW 242/5-3 | |

| Navien gas boilers for 200 sq.m. | ||

| 1 | Navien DELUXE 24K | |

| 2 | Navien SMART TOK 24K | |

| 3 | Navien DELUXE 13K | |

| Leberg gas boilers for 200 sq.m. | ||

| 1 | Leberg Flamme 24 ASD | |

| Kentatsu gas boilers for 200 sq.m. | ||

| 1 | Kentatsu Nobby Smart 24–2CS | |

| Gas boilers MORA-TOP for 200 sq.m. | ||

| 1 | MORA-TOP Meteor Plus PK24SK | |

| 2 | MORA-TOP Meteor Plus PK24KT | |

| 3 | MORA-TOP Meteor Plus PK18SK | |

| 4 | MORA-TOP Meteor Plus PK18ST | |

| 5 | MORA-TOP Meteor PK18ST | |

| 6 | MORA-TOP SA 20 | |

| 7 | MORA-TOP Meteor Plus PK24ST | |

| 8 | MORA-TOP SA 20 G | |

| 9 | MORA-TOP Meteor PK24KT | |

Large area heating options

The energy efficiency of boiler equipment affects the cost of money. To heat a private house with an area of 200 square meters, you will need a powerful and economical boiler.

Depending on the design, gas heat generators can be divided into several types:

In order to determine which gas unit to choose for heating a house of 200 square meters, you should take into account the features of its design.

Heating options

Electric boilers are compact in size, require a minimum of wiring and have a modern design, which allows them to be installed anywhere.

It is most profitable and justified from an economic point of view to use an electric boiler when living in a house temporarily, for example, upon arrival only for weekends, vacations or holidays. In this case, even high temporary electricity costs can be covered for a long time by a 1.5-2 times lower initial cost of the electric boiler, minimal costs for its installation and organization of the heating system.

To prevent freezing of the heating system, the boiler must maintain a positive temperature even during the absence of the owners. It is important to choose a model with the largest possible amplitude of power changes so that the operating mode is as economical as possible. For example, models with 3-stage power control are a bad option, since there will be too much heat output when operating even at the first power stage, and this is an unjustified expense.

It’s great if the model is equipped with a GSM module or has the ability to connect it, so you can control the operation of the electric boiler remotely and be sure that everything is in order with the heating system, otherwise a notification will be sent to your phone.

This is what a compact and economical full-fledged heating system with an inexpensive electrode boiler looks like.

It is still justified to use an electric boiler as an additional heating equipment with a main solid fuel, liquid fuel or gas boiler. An effective option is to operate at maximum load only at night (when electricity tariffs are minimal) and accumulate excess heat in a buffer tank. In any case, when used as additional heating equipment, low-power models, sometimes even single-phase (up to 6 kW), are sufficient.

It is completely unjustified from an economic point of view to heat a house with an area of 200 m2 with an electric boiler for permanent residence, since electricity costs can reach 35,000-45,000 rubles per month. In addition, it is worth ensuring a connection to the electrical network through a voltage stabilizer, purchasing and connecting a generator in case of a temporary power outage.

How to choose an external thermostat for an electric boiler and save up to 30% on heating every month

Calculation of the minimum required power for a house with an area of 200 square meters

When choosing a heat generator for heating a private home, it is necessary to determine the power of the boiler. If you use a device with insufficient power, normal heating of the room will not be possible.

The small power of the unit for a house of 200 sq. m will lead to rapid wear of the product. Excess power will lead to unnecessary fuel consumption.

The power calculation is carried out based on the fact that on average 41 watts of thermal energy per hour are consumed per cubic meter of free space in the room.

To calculate the volume of housing, the total area is multiplied by the ceiling height in meters. As a rule, it is about 3 m. Thus, the volume of a house of 200 square meters is approximately 600 m3.

What to look for when choosing

Depending on the manufacturer, the design of boilers and their technical characteristics may vary. When selecting a product, a number of factors must be taken into account. This will allow you to choose an installation with high efficiency and cost-effectiveness.

Type of fuel

Modern boiler systems can operate either from a centralized gas supply system or from cylinders. In the second case, liquefied propane-butane is used. Connecting heating from cylinders is possible at facilities where there is no centralized gas supply system.

It should be taken into account that boilers designed for connection to gas pipelines and cylinders differ in their design. Some manufacturers produce models that, if necessary, can be converted from gaseous fuel to liquefied fuel and vice versa.

Power

Before choosing a unit for heating a private house of 200 square meters. m, it is necessary to correctly calculate its power characteristics.

After determining the minimum permissible power of the installation, a number of factors must be taken into account:

Correct calculation of the power of a gas boiler for 200 sq. m will provide a comfortable room temperature regardless of weather conditions.

Price

The price of a boiler for a house of 200 square meters differs depending on the design of the product, manufacturer, number of circuits and degree of automation.

The choice of model is made based on the personal preferences of the owners of the premises. Products from foreign manufacturers have a higher price. Domestic boilers have a low cost.

Taking into account the technical characteristics of the boiler installation, it will be possible to choose a gas boiler with a good price-quality ratio.

Economical

To reduce fuel consumption, products with a high efficiency are selected. Such models make it possible to make maximum use of the thermal energy generated as a result of gas combustion. Depending on the design and equipment, boilers heat the coolant in different ways.

Some property owners, in order to save money, install two low-power boiler systems simultaneously in a cascade.

One boiler is constantly used for preparing hot water and heating the premises. The second one is connected when the ambient temperature drops significantly. The simultaneous inclusion of two models with low power indicators in the system allows you to save fuel consumption.

Durability

The service life of the product is affected by the scope of use and the quality of the materials from which the parts are made. Using an installation with insufficient power to heat a private house with an area of 200 square meters will lead to wear and tear on the components. When choosing, it is better to give preference to boilers made from corrosion-resistant materials. This will ensure uninterrupted operation of the installation and increase its service life.

Safety

There are models on the market with varying degrees of automation. This minimizes human participation in the operation of boiler equipment. When selecting an installation, it is necessary to take into account the design features and purchase additional equipment that meets the manufacturer’s requirements.

Installation of gas boiler equipment is carried out by highly qualified specialists and requires permitting documentation. Connection and further use of boilers is possible only in strict accordance with the operating instructions provided by the manufacturer.

Which brand of floor-standing gas boiler is better to choose?

On the consumer market you can find domestic and foreign models from different manufacturers. Russian companies produce simple floor-standing gas boilers for the home. Products from foreign suppliers are convenient, but their prices are higher. The review covers the products of the following companies:

- Lemax - the products of this company are in great demand due to their quality. Modern Italian and German equipment is used in production.

- Protherm - equipment is assembled at factories in Slovakia and Turkey. The first boilers of this company were imported to Russia in 1996.

- Siberia – the brand presents a line of devices with different characteristics. The boilers are made using basalt fiber, which is used to insulate spacecraft.

- Borinskoe - the company supplies heating equipment to regions of Russia and neighboring countries. The range includes more than 30 models of gas equipment for home heating.

- Baxi - today the Italian brand is owned by the BDR Thermea Group corporation. The company produces non-standard heating and hot water supply systems. The quality of the products is confirmed by certificates.

- Ferroli is an Italian company that has been producing heating and air conditioning equipment since 1955. Products are supplied to dozens of European countries. The boilers of this company are durable, reliable and safe.

- Viessmann is a large international concern that supplies equipment for heating and cooling of premises. The main priority is the technological development of the industry and concern for the environment. Products are supplied to 74 countries around the world.

- Buderus , a European manufacturer of heating equipment, began producing the first boilers in 1731. The trademark belongs to Bosch Thermotechnik GmbH. German technology is reliable and efficient.

- Alpenhoff is a German company that produces heating equipment. Production and research centers are located in Germany and Slovakia. The products of this company are imported to 30 countries around the world.

- Atem - the first equipment of this company was released in 1988. Since then, the brand’s products have become popular in Ukraine and other countries. Heating appliances are included in the IQenergy energy saving program.

- Termomax is a Ukrainian company that produces more than 100 thousand products for space heating every year. Simple equipment is in demand among Russian buyers.

- Navien , a Korean brand, has been providing comfort and coziness for 40 years, producing high-quality heating equipment. The main goal of the company is to create favorable conditions for the environment. Products are supplied to 35 countries around the world.

Review of the best models 2022

The final cost of the boiler differs depending on the technical characteristics and design. The market offers a large selection of models from Russian and foreign manufacturers

The manufacturer produces models that differ in their design and technical characteristics. When choosing a boiler for heating a private house with an area of 200 square meters, it is necessary to take into account a number of factors, such as power rating, technical characteristics of the product, type of construction, etc.

A properly selected boiler will allow you to maintain the desired temperature in the room regardless of weather conditions.

Source

Wall-mounted or floor-standing gas boiler

According to the installation method, gas boilers are of two types:

The first type provides for mounting to the wall, so it has a small weight - no more than 80 kg. The power of such units can reach 35 kW (more powerful ones are rare), and the capacity of the built-in boiler does not exceed 40 liters. Wall-mounted models are an excellent solution for small private houses with an area of about 100 m2 - 120 m2.

Although these devices have low power and low heating capabilities, they have their advantages:

- for a wall-mounted boiler you do not need to allocate a special room - just place the device in the bathroom or kitchen;

- Most wall-mounted units are equipped with a closed combustion chamber, and the chimney can be removed through a hole in the wall.

Floor-standing boilers are larger and heavier: the mass of such units can exceed 100 kg. Installation of such equipment implies the creation of a boiler room in compliance with the requirements of specialized SNiPs.

The rules regulate important parameters of room equipment: ceiling height, dimensions of the podium for boiler equipment, air exchange rates. The combustion chamber of floor-standing units is predominantly open. This means that a constant flow of air is required for normal operation. However, floor-standing boilers have more power than wall-mounted ones.

Wall-mounted units have a weak point - the heat exchanger. This part is often made of steel to reduce the cost of the boiler and reduce its weight. Condensate, which has acidic properties, forms on the walls of the heat exchanger, which leads to the destruction of the steel part. The cost of replacing a heat exchanger reaches 50% of the price of the boiler itself. Copper is more resistant to corrosion, so copper heat exchangers have a long service life, but the price of copper elements is higher.

When producing floor-standing devices, there is no need to reduce weight, so heat exchangers for such units are often made of cast iron. The main advantages of this material are heat capacity and durability. The service life of cast iron reaches 50 years. However, such a heat exchanger has a drawback - fragility. In addition, sudden temperature changes in the supply and return pipes negatively affect cast iron.

When choosing between a floor-standing and wall-mounted gas boiler, it is necessary to take into account that wall-mounted units are often cheaper, since they are equipped with an expansion tank and a circulation pump. For floor-standing equipment, these parts must be purchased separately, which results in additional costs.

Wall-mounted gas boiler equipped with a tank and circulation pump.

In some cases, a heating system with a single-circuit boiler is filled not with water, but with a special antifreeze. This liquid does not lead to corrosion of metal parts and allows you to increase the service life of the boiler and pipeline. Unlike water, antifreeze does not freeze at subzero temperatures, so in winter a heating system with antifreeze does not fail (and water can freeze and damage pipes).

Power calculation for 200 square meters

A simplified scheme for determining energy costs is based on knowledge of the total area and specific heat loss coefficient. In the central zone of the Russian Federation, each square meter of a building loses 100 W, with a ceiling height of up to 270 cm. By multiplying the area of the building by the specific value of heat losses, 200 m² × 100 W/m² = 20,000 W, we obtain the power required to heat it.

A similar calculation can be made if you know the volume of a residential building. This method is convenient in cases where the height of the ceilings in the rooms is not the same and differs from 270 cm. The specific heat loss per cubic meter is taken to be 40 W/m³. Let’s assume the ceiling height is the same everywhere, 325 cm, then to heat the house you will need 200 m² × 3.25 m × 40 W/m³ = 26,000 W.

However, simplified calculations poorly take into account factors such as:

When building a new house, the latter can be compiled. But when buying a home on the secondary market, this will be difficult.

Dependence on the features of the house

In the absence of design documentation, it is difficult to take into account its specifics in calculations. However, based on information from modern SNiP (building codes and regulations), as well as information available to the owner, it is possible to estimate the level of heat loss.

House parameters that can be obtained:

Power reserve for water heating

This factor significantly influences the choice of the number of kilowatts of the boiler.

For correct calculation you will need to decide on the following parameters:

According to SNiP 2.04.01-85, in houses with a shower and a bathtub (up to 170 cm long), the average daily rate of hot water per resident is 115 liters. That is, for a family of 3 people, the DHW system should supply about 350 liters. If a double-circuit boiler with heating of running water is used, then the heating power should be increased by 30%. We get (20000 - 26000) W × 1.3 = (26000 - 33800) W for one bathroom.

It is customary to have 3 water points in the house (bath, washbasin, kitchen). And then the boiler power needs to be increased by 50%, which will give new values of 30,000-39,000 W.

It is possible to reduce the requirements for the unit by installing a boiler or geyser, but in the first case you will not be able to obtain the required volume of water in a short time. A 3000 W electric heater will take 40-50 minutes to raise the temperature of 100 liters of water to +55°C. In the second, you will need to spend money on the purchase and installation of equipment, look for free space in the house and the possibility of organizing a separate smoke removal channel.

In case of severe frosts

Features of the regional climate also influence the choice of heating equipment power. Most calculations are based on average values, without taking into account short-term deviations. However, if frosts set at 10-20°C below normal for 1-1.5 months or even a week, in this case it will be necessary to make provisions for such anomalies.

Up to 20% of the design capacity is allocated to compensate for extreme events, which is reflected in the value of climate coefficients:

Continuing the estimation calculations for a private house, we arrive at (30-38)×1.2=(36-46) kW.

2. What parameters, besides volume and area, influence the choice of boiler? And why is this important?

A simplified calculation formula often leads to the purchase of an unsuitable boiler. Each house is individual, and heat loss percentage cannot be equal for all houses. Before calculating power, consider the data of a specific house:

1) Measure the area of walls, windows, doors;

2) Specify the thickness of the walls, indicate the type of finishing and material, the height of the ceilings;

3) Observe the minimum temperature of the house in cold weather;

4) Determine the desired temperature as a result of installing the boiler;

5) Write down the thermal conductivity values for the materials from which the house was built.

Wall material

Wall thickness and material thermal resistance

Required thickness for home

510 mm (if laying two bricks), R=0.73 °C m²/W

Wooden panel (inside filled with mineral wool + 25 mm layer of inner and outer cladding)

Thermal resistance of materials

Why is this necessary? The key parameter influencing the choice of boiler is the heat loss of the house. Houses with the same area and volume, but different degrees of insulation, will require equipment of different power.

Surface

Heat loss in%

Roof and ventilation

Foundation, if it is adjacent to the ground

Walls, windows and doors

Ground floor and unheated rooms, basement, for example

It also matters: how different the outside temperature is from the inside, the climatic region, the strength and direction of the wind, how the house stands relative to parts of the world.

| Heat loss |

Is it worth taking more power than required?

Only a specialist can indicate the exact amount of heat loss. It will take into account the properties of the building materials of the foundation, floor, walls, ceilings and ceilings. It will even take into account the heat generated by household appliances if there is a need for high accuracy of calculations. The other extreme is to neglect calculations and install equipment with multiple power reserves. This way the heating issue can be solved, but the problem of excessive fuel consumption will arise.

A gas boiler will often turn on and off, while a solid fuel boiler will release energy into the atmosphere. In addition, a powerful installation becomes more expensive disproportionately quickly, and its efficiency decreases when operating in less than optimal mode. Sometimes they offer cascade connection of equipment. This solves specific issues, but does not in any way affect the basics of low-speed operation. It will simply be a system with a backup boiler.

Ideal models

The main part of any boiler is the internal heat exchanger. The efficiency of the device, its performance, and safety factor depend on the selected properties of the material. The best choice would be stainless steel, copper, cast iron. The greatest reliability is provided by single-circuit heat exchangers, an open type of burner that does not require the creation of a 5-7-meter chimney with natural draft.

When choosing which gas boiler is better, inexpensive models can be considered in this order:

Heating with solid fuel

The choice of boiler type in the absence of a gas pipeline is obvious and depends on the existing infrastructure. Heating a 200 m² house with solid fuel is provided by the PROTHERM BOBER 40 DLO model. It is built according to a single-circuit scheme with the possibility of connecting a hot water supply or a heat accumulator.

Wood or coal can be used as fuel. The combustion time for a full load of firewood is at least 2 hours, and for coal - up to 4. It is more efficient to heat and collect water in a heat accumulator.

Additional characteristics of the model:

The market offers a wide range of equipment from which you can choose the best option for a particular case, from the simplest boilers to systems with turbocharged combustion chambers from brand manufacturers.

Source

Gas, firewood, coal, electricity – which is cheaper?

In the medium term, the cheapest boiler fuel is natural gas . To generate 30 kW, only 2.75 cubic meters of such fuel is sufficient (taking into account 91 percent efficiency and the calorific value of a cubic meter of fuel at 43,000 kJ). In 2015, one thousand cubic meters of gas in the European part of Russia cost about 5,000 rubles. As a result, “production” of 30 kW using a gas boiler costs no more than 13.75 rubles.

Heating with coal burned in the firebox of a solid fuel boiler will cost a little more. To generate 30 kW, 8 kilograms of coal are required (taking into account 80 percent efficiency and the calorific value of a kilogram of fuel at 17,000 kJ). In 2015, a ton of ordinary coal cost about 4,000 rubles. Generating 30 kW using a coal boiler will cost 32 rubles. But coal will have to be stored somewhere. And the delivery of such fuel is not cheap.

Heating a house with wood alone will cost much more. If you load dry wood into a solid fuel boiler with a calorific value of 14,000 kJ per kilogram of fuel, then to generate 30 kW, taking into account the 80 percent efficiency of the boiler, you will have to spend almost 10 kilograms of firewood. In 2015, the cost of a cube of firewood (650 kilograms) delivered to your home in the form of a packaged woodpile reached 3,000 rubles. As a result, generating 30 kW using a wood-burning boiler will cost 46-47 rubles.

Electric boiler for a house of 200 sq.m. - this is a direct path to ruin, even taking into account the 99 percent efficiency of such a heating device. After all, the cost of a kilowatt with electric heating reaches 2.4 rubles. As a result, generating 30 kW will cost 73 rubles!

Popular models of gas boilers for a house with an area of 200 square meters. m.

BOSCH ZW 30-2AE

Double-circuit gas boiler for a 200 sq.m. home, compatible with programmable thermostats. This heating device is equipped with a 10-liter hydraulic accumulator, a three-way valve and its own pressure unit - a three-speed pump.

Other characteristics of the model:

PROTHERM PANTHER 30 KTV

Turbocharged gas boiler with heat exchanger for heating hot water. In the body of this model there was room for a pump, an expansion tank, and even a bypass. The burner and heat exchangers of the boiler are made of stainless steel.

FERROLI DIVAtop 60 C32

Wall-mounted chimney gas boiler, equipped with a hot water supply circuit and a 60-liter boiler. The pressure unit of this boiler consists of two units - one pump serves the heating system, the second - the hot water supply system.

Other characteristics of the boiler:

Solid fuel boilers for a home with a capacity of 200 square meters - an overview of popular models

PROTHERM BEAVER 40 DLO

Single-circuit solid fuel boiler for a house of 200 sq.m., with the ability to connect a heat accumulator and an indirect hot water heating circuit. The boiler uses the energy of wood and coal. Moreover, a full load of firewood burns for at least 2 hours, and coal will last twice as long – up to 4 hours.

Other characteristics of the model:

KOTEKO GEYZER 30

Pellet boiler for a house of 200 sq.m. with the ability to connect to a hot water supply system. In addition, this heating device is equipped with a hopper with automatic supply of granulated wood (pellets) or fine coal. The capacity of the bunker is enough for 3 days of work.

Other characteristics of the boiler:

Source

Which gas boiler is best for heating a house of 200 sq. m

If you want to know which gas boiler is best for a private house of 200 sq. m., then “you are welcome to our hut” - we will examine this question below.

In particular, we will consider what power of the heating unit we need to include in the calculations, whether it is necessary to reserve power for the production of hot water in the domestic hot water supply, and whether it is worth using a cascade scheme for installing heat generators with such a house area.

Reserve for heating tap water

If you want to use your gas boiler for hot water supply, then you should decide how exactly you will prepare hot water for the water supply. This determines what reserve for hot water supply you will need to include in your calculations.

If you use a double-circuit boiler, then to reliably heat tap water in instantaneous heater mode, you need to set at least 30 percent of the power.

That is, for our case this is a minimum of 6 kW, and the total power is at least 26 kW. And that is not all.

If you use two water points in the bathrooms, one point in the kitchen, a bath, a shower, and also heat water for the bath with a boiler, then you will have to spend not 30, but 50 percent on hot water.

That is, at the output we already have 10 kW for DHW or 30 kW of total power.

However, if you decide to use a single-circuit boiler and an indirect heating boiler, then you should set the minimum power for hot water supply in the region of 2-3 kW.

Of course, if you install a standard 100 liter 24 kW boiler, then for quick heating it can take on all 20 kW.

But in the case of using only 3 kW of reserve, it will also heat the water. Only it will take about 4 times longer to do this.

Although, with a reserve of 3 kW, water in the BKN of 100 liters is heated to +55 degrees Celsius in just 40-50 minutes.

Reserve for severe frosts

When thinking about which gas boiler to choose for heating a house of 200 square meters, you should not forget about the climatic features of your area.

How cold is the weather in winter? How strong do the winds blow in winter?

How many kilowatts should be put into reserve “just in case” - taking into account extremely low temperatures and strong winds? It depends on the characteristics of your place of residence.

The standard “reserve” is approximately 20 percent of the required minimum power of the heat generator. If our minimum power is 20 kW, then the reserve will be 4 kW.

So, we end up with a minimum required power of 20 kW, a DHW reserve of 3 or 6 kW (depending on the DHW scheme) and a cold reserve of 4 kW. The final power is around 27-29 kW.

Should we install a cascade of boilers?

Or maybe install a cascade of two gas boilers? What advantages does this scheme have in our case? For example, you can put 2 gas boilers in a cascade, each with a power of 15 kW.

It will be possible to use 1 boiler in a cascade in the off-season, and in winter connect both boilers.

If one boiler fails, the second heat generator will be able to maintain an acceptable temperature in the house during repairs.

Is it necessary to put 2 gas boilers of 20 or 30 kW in a cascade? No. In this case, the whole point of such a scheme is lost; we will simply have 1 backup boiler “just in case.”

Source

Types of boilers for warm water floors

There is a wide range of boiler equipment on the market. Boilers differ in the type of fuel they operate on - gas, diesel, electric and solid fuel. They are made of various materials, there are: cast iron and steel.

They also differ in the installation method:

In addition, heating boilers have a different number of circuits; they are single-circuit and double-circuit.

Single-circuit - designed only to heat the coolant for heating the house. To increase the scope of their application, additional elements (boiler, heat exchanger, etc.) are required.

Double-circuit - multi-tasking devices, they provide simultaneous heating of water for the heating system and hot water supply. The last function is performed by a built-in storage boiler and a flow-through heat exchanger.

Gas

For gas boilers, the body is made of cast iron or steel. The weight of cast iron devices, with the same power, is 2 times more than steel ones. They are voluminous and have a high cost. Steel products are light in weight and small in size. They are distinguished by their suitability for repair.

Modern floor-standing gas units operate on mainline and liquefied fuel. However, suspended mini-models are more convenient to connect; they do not take up space, and their power (7 - 30 kW) is enough to heat a small private house.

Standard gas boilers can operate with full efficiency only at maximum water heating - 70 - 90 degrees, which is not permissible for a water floor.

If gas equipment operates at low temperatures, this provokes the formation of condensation, and this affects its service life. These boilers have the opportunity to be converted to a water floor by carrying out work to improve the design.

The most suitable gas boilers are condensing boilers, designed for warm water floors. They have additional recharge from the resulting condensate. Even when operating at low temperatures, their efficiency is close to 100%.

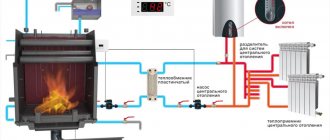

Gas units come in single and double circuit types. The floor heating is connected to the double-circuit boiler via a hydraulic arrow.

Solid fuel

Heating boilers with solid fuel operate on the same principle as a wood or coal stove. But in a boiler, wood is burned without air access, and wood gas is released, which heats the coolant. Such generators are problematic when connected to warm water floors; they require constant attention and maintenance.

An exception is pellet boilers with automation, since they have a long burning period. But they also require more attention compared to gas or electric installations.

To maintain the coolant temperature at the required level, the automation has to periodically “switch off” the firebox, and this leads to a loss of boiler efficiency. Installing a buffer tank will help avoid this.

Then, the device will be able to fully use its potential, transferring heated water to the buffer, and the floor will take it from there in the required volume. This will lead to savings, since the pause between fuel supply to the firebox will increase.

Electrical

Electric boilers are the most efficient water heaters for warm water floors; there are: heating element, ion and induction. In them, electrical energy is converted into thermal energy. They are fully automated, easy to install and adjust, and can be configured remotely. The devices maintain heating of the coolant at a given level without losing its efficiency.

Wall-mounted heating elements are often used because they are simple in design and easy to install. They are equipped with an expansion tank and pump.

If the room area is not large, then the TP circuits can be connected directly to the heat generator.

When constructing a warm water floor from a heating boiler in a large private house, you will need to install a mixing and distribution unit.

The disadvantages include the high price of energy resources. To reduce the cost of heat, it is recommended to use a scheme with an external water storage tank and a two-tariff energy meter.

Diesel

The principle of operation of diesel boilers, the fuel for which is diesel fuel, is similar to the operation of gas boilers. Their combustion process is completely automated. They have high productivity, low fuel consumption, are easy to install and easy to maintain. It is worth noting their environmental suitability and cost-effectiveness.

The disadvantage of such models is the smell of diesel fuel, so they are installed in a separate room (boiler room). In addition, you also need a container for fuel and a pump to supply it.

How to choose a boiler for heating a private house?

Today the market is filled with various heating boilers, each with its own advantages and disadvantages. You need to explore all the options to make the right choice.

Choosing a boiler for heating a house - basic steps

How to make the right choice and where to start? The boiler is the heating heart of your future home, which will help you not freeze even in the most severe winter.

Its main task is to heat the coolant, which will move through the pipes and transfer heat through radiators. The entire heating system depends on the correct operation of the boiler, this also applies to hot water.

The main selection criteria that will help divide heating boilers into groups:

- Type of fuel;

- Power;

- Installation method and location;

- Kind of work;

- Price.

Types of fuel in heating boilers

There are four main types of fuel that are used to heat a home.

- A gas boiler. Can be natural or liquefied and is the cheapest option. All you need is to install the main gas and you’re done, you can buy a gas boiler. Each model can operate without a main gas source using cylinders;

- Wood and coal boiler. Wood, variations of coal, coke, briquettes or wood chips are used for heating. The disadvantage of such a boiler is that you constantly need to monitor it and replenish fuel, that is, add firewood. As a result, we get a non-automated heating option that does not depend on electricity;

- Electric boiler. Such a boiler will be the cheapest, although the fuel source itself is expensive. To install such a system, electrical power must be nearby. This variation of the boiler is the most neutral, having no pronounced disadvantages or advantages;

- Diesel boiler. The liquid fuel boiler is fully automated, which is a huge plus for any owner. Diesel is not a cheap option, but costs less electricity. Boilers of this group are universal, they can become gas at any time and do not depend on the main line. Another advantage is the absence of odor or noise when operating a modern diesel boiler.

Choosing the power of a heating boiler for a home

The power of the future heating boiler must be selected according to one criterion - the future area of the room in which it will be installed. The larger it is, the more powerful the boiler is needed. It is also worth remembering about heat leakage, the so-called heat loss effect. Heat always escapes through open windows or doors; this factor depends on the insulation of the building itself. It is for this reason that the boiler must have a power reserve.

The power parameter is measured in kilowatts; 1 kW can heat approximately 10 square meters. Let's make an approximate calculation, imagine that your house has 200 square meters. We get:

200 m2 = 20 kW boiler power + 15%, which gives an approximate power reserve of 23 kilowatts.

| House area, m2 | Boiler power, kW | Maximum fuel consumption, kg/h |

| 100 | 5-12 | 3,2 |

| 130 | 6-16 | 4,7 |

| 160 | 6-20 | 6 |

| 200 | 7-24 | 7,6 |

| 220 | 8-25 | 7,9 |

| 270 | 10-32 | 8,9 |

| 370 | 18 and over | from 14 |

The purchased heating boiler must have a power of at least 23 kW. Keep in mind that this does not affect fuel consumption as such; the boiler always uses only the required amount of energy. But in winter you will get maximum warmth and will not freeze. The boiler will not operate at maximum power, since it has a reserve, which means that its service life will increase by several years.

Selecting a boiler based on installation method and location

- Floor-standing version. Such a boiler is always placed in a separate room due to several requirements for its installation. This also concerns several nuances and the location of necessary things, for example, an expansion tank, pump, pipes, various taps and fittings. This option requires a boiler room;

- Wall-mounted version. Most often it is a ready-made mini-boiler room. The body is pre-equipped with all the necessary elements so that the boiler can operate. This applies to the expansion tank, pumps, thermometer and pressure gauge, as well as additional components. The wall-mounted boiler has been very popular in recent years, it can help you save space in your home and does not require a separate room. It is also worth highlighting their favorable price; their service life does not exceed ten years.

Selecting a boiler by type of operation

The main criterion is the differences in working type. You should not add fuel or location to this characteristic; it does not matter in this case. You can purchase a boiler with the following type of operation:

- Single-circuit boiler. This boiler is intended only for heating a private home. It can heat water for a shower, washing dishes or a car, that is, it completely supplies all rooms with hot water. This requires several additional components and the connection of various devices, for example, an indirect heating boiler and a pair of pumps. Such a boiler needs a separate room, since it has an impressive size;

- Double-circuit boiler. Recently, this type of boiler has become one of the most popular; it can both heat a house and provide the owner with hot water. A unit is pre-placed inside the housing; it, in turn, can heat water for domestic needs. This fact will help save a lot of space since it does not require any additional hardware. Such a boiler is suitable for a small country house or private apartment where no more than three people live;

- Chimney boiler. Such a boiler always has an open combustion chamber, through which, when fuel is burned, the house is sold, that is, the main combustion product. It must be discharged through a chimney, which must be located separately, always above the roof of the house itself. Such a boiler requires natural draft and a chimney, or it simply will not work. It is also worth remembering to install ventilation, because such a boiler will take atmospheric air for operation directly from the room. Almost always installed in a separate boiler room;

- Flueless boiler. Such a boiler has a closed combustion chamber, to which a special fan or forced-air burner is always attached. This excludes the construction of a chimney, although according to the rules of use it is still needed. The difference lies in its installation; it can be installed horizontally and be routed through the wall. The main advantage of such boilers is the absence of forced ventilation as such. If you have not provided for a chimney in advance, then choosing this particular type will allow you to save on the construction of a separate stationary chimney.

Bottom line

In conclusion, I would like to say that price is too individual an indicator to list possible options. Boilers can be arranged according to fuel type, where the first option is the cheapest:

- Electric boiler;

- Solid fuel boiler;

- A gas boiler;

- Liquid fuel boiler;

- Combined, that is, a universal boiler.

The given sequence is not always true, because the cost may depend on the performance of the model, material, automation and service life.

www.mastergrad.com

Boiler selection

There are no water heaters that are specifically designed for warm water floors. A number of manufacturers produce devices that have a “warm floor” function, but this mode only limits the level of water heating. In addition, you need to take into account what type of coolant is allowed for this model. There are devices that do not work with antifreeze; this is indicated in the instructions for the equipment.

In principle, any model of water heater can service a heated floor, the main thing is to properly wire and connect it.

What are the features of choosing a water heater, and what should you pay attention to:

In addition, heat generators must be selected depending on the area and operating conditions, with attention paid to:

Everyone determines the cost of a heater for themselves, based on the cheapest energy source. For some it is gas, for others it is wood. If there is a multi-tariff meter in the house, electricity will be profitable.

An electric boiler is most suitable for hydrofloors, as it is able to maintain the temperature at a given level with low power consumption. 1 kW of electricity is converted into kW of heat. If the heating area is not significant, then it can be connected directly.

To connect a cottage of an impressive area, you will need a mixing unit. When installing gas equipment, you cannot do without a distribution unit, since direct connection is not recommended. And feeding a heated floor from a solid fuel boiler leads to increased costs due to the purchase of additional components.

In addition, installation of gas or solid fuel boilers requires the installation of a boiler room.

Boiler power: 7 customer questions

Weak boiler power will ruin everything, including the standard of living. Due to excess power, the system will operate in impulses: fuel consumption will increase, and the service life of the equipment will be shortened. The boiler may boil. Or brains. How to calculate correctly, what parameters to take into account, what heat loss is and other customer questions about boiler power can be read here.

How to calculate power

What kind of boiler is needed for warm water floors - an economical one, so we choose it taking into account its performance. To select a suitable model, you need to calculate the power.

The average unit indicator for a suburban building is 1 kW of power required per 10 m2, that is, the specific productivity is 100 W per m2. But this is a fairly rough calculation, which is suitable for a brick building with minimal heat loss.

When installing gas equipment, it is necessary to prepare and coordinate the project with government agencies, and obtain permission from the gas inspectorate. The project has a section that indicates the calculation of the power of the device.

If you plan to place an electric or pyrolysis boiler, then a form is used to calculate the load of the house. The formula is suitable for midland regions; if the apartment is located in the northern regions, a correction factor of 1.2 or 1.3 is used. In case of poor insulation or DHW provision, a coefficient of 1.2 is also applied.

Using an example, we calculate the productivity of a generator for a house of 250 m2 in the northern region, with poor insulation and hot water supply:

If the premises are located in the central area, then the calculation indicator looks like this:

If the room is well insulated and hot water supply is not required, then:

It is not recommended to make a large reserve of power; in addition to increasing the cost of thermal energy, this will lead to overheating of the transformer unit and failure.