Read in the article:

- When should utility networks be laid?

- Connecting water supply and sewerage pipes to the building

- Laying communications inside the house

- How to safely lay communications in a wooden house?

- How to connect a house to a centralized water supply?

- Construction of an individual well

- Water purification system

- Is it possible to do without shut-off valves on the water supply?

- Laying cold water pipes

- Hot water preparation

- How to dispose of domestic wastewater?

- Layout of sewer pipes

- Organization of the heating system

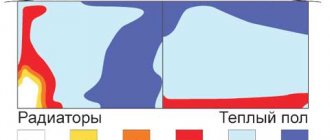

- Radiator connection diagrams

Laying and wiring communications in a house is one of the most critical stages of construction. How to properly organize electricity and water supply, heating and sewerage?

1

When should utility networks be laid?

The best option is when, in parallel with the architectural design, an engineering design of the building is also developed, which contains, in particular, diagrams for installing equipment and laying highways. Then, at the stage of constructing the frame of the house, communications will be installed without problems. If you are installing them in an already built house, you will have to make holes and channels in ready-made structures - foundations, floors, walls, which will result in additional labor and financial costs.

Engineering design of the first floor of the house

2

Design:

The design phase cannot be underestimated. Without a well-designed project that takes into account all the initial information, it is impossible to carry out high-quality work. The material of construction of the house, location, and the nearest accessible points for connecting external communications directly affect the final project. The skill and experience of the chief design engineer determines how harmoniously the elements of engineering communications will be combined, their interaction and ease of management. Entrust the design only to an experienced specialist who can foresee all the nuances of operating the systems. The cost of an engineering complex project per square meter in our company is 320 rubles.

Important. When ordering a project, be sure to make sure that the work and materials are listed in as much detail as possible. If the project includes the item “installation of a shower,” then all the work and materials must be listed, down to the smallest screw. Detailed designs are a hallmark of the professionalism and experience of the designer.

Connecting water supply and sewerage pipes to the building

For this purpose, they mainly use pipes made of polymeric materials - polypropylene (PP), polyvinyl chloride (PVC), low-density polyethylene (HDPE), metal-plastic, etc., laying pipelines underground.

To avoid water freezing in winter, the water pipe is laid 30 cm below the so-called penetration depth of 0°C temperature into the soil (for central Russia this value is 210–220 cm), that is, at a distance of 240–250 cm from the surface of the earth. If the depth is shallower, the pipe will have to be heated with an electric cable. There is no need to slope the water main.

HDPE and PVC pipes are characterized by increased mechanical strength, as well as resistance to low temperatures and aggressive substances contained in the soil

Polypropylene pipes

HDPE pipes

PVC sewer pipes

Since the contents of the sewer pipe are practically not at risk of freezing, it is usually located 30 cm above the soil freezing level (in central Russia - at a distance of 130–140 cm from the ground surface). In this case, the pipe requires a slope of 2 cm per 1 linear. m. With a smaller slope, drainage will be difficult, and with a larger slope, there will be a risk of blockages.

3

Possible problems

What problems may you encounter:

With instantaneous water heater

Each chosen method of providing a home with hot water has its own weaknesses.

Electric flow heaters often fail due to burnout of heating elements , which become covered with scale and cannot withstand the load.

The same applies to the heat exchanger - poor water quality clogs the coil or honeycomb, which leads to excess pressure, and possibly even rupture and leakage of the equipment.

Therefore, maintenance consists of organizing proper filtration of the hot water supply, replacing heating elements and ensuring correct connection from an electrical point of view.

High power electrical appliances must be equipped with individual electrical protective equipment . As for geysers and boilers, they need periodic cleaning of excess combustion products.

With storage water heater

The main problems remain the same - the performance of the heating elements, the quality of the incoming water and electrical safety.

It is electrical safety that many users neglect, not realizing that this is not only protection against electric shock, but protection of the most expensive equipment.

All models of storage heating tanks are made of metal, which means that without proper grounding, they are subject to accelerated corrosion. If the tank leaks, then in most cases, such equipment cannot be repaired. This is why it is so important to check the ground circuit .

As for heating elements, in these models they are even more susceptible to burnout than in flow-through ones.

Everything you need to know about hot water is presented in this section of the site.

Laying communications inside the house

When constructing building structures (in particular, when concreting a shallow slab foundation), sleeves are placed in them - passage elements made, as a rule, from sections of steel pipe. They protect the pipeline from damage during building settlement and do not interfere with its temperature deformations. The inner diameter of the sleeve must be at least twice the outer diameter of the pipe. The gap between the sleeve and the pipe is filled with a soft waterproof material (oiled or bitumen-impregnated rope, silicone sealant, polyurethane foam, etc.), which does not prevent the pipe from making slight movements along the longitudinal axis. When the main passes through the foundation at a level below the groundwater level, special measures are taken to seal this gap.

The water supply line passing under the wall of the strip foundation should also be inside the sleeve, which will protect it from damage due to the compressive influence of the soil

To prevent leaks, the sleeve installed in the interfloor ceiling should protrude 30–50 mm above it.

Water supply and heating pipes with a small diameter, as well as electrical cables, can be laid in the thickness of walls and ceilings (in channels sealed with screed or plaster) or in the substructure of the floor (usually inside the insulation layer). In the case of external installation, the pipes are secured to the walls with clamps with vibration-isolating gaskets.

4

What type of heating to choose

Naturally, the starting point for planning a heating scheme is the selection and purchase of a boiler.

Heating boilers

Now we will not consider non-standard devices that can run on wood or any solid fuel, diesel fuel or waste oil, etc. Because, as a rule, using them to organize hot water supply and heating at the same time is difficult and expensive.

Advice: if your area does not have gas supply, and there are frequent interruptions in electricity, then perhaps you should still consider the option of installing boilers that also run on alternative fuel as a heating source. Otherwise, there is a big risk that in winter, from time to time, the house will be left without heat.

As illustrative examples, let’s take a closer look at the more familiar systems that run on gas or electricity. We will also consider how to best organize the supply of hot water based on such boilers.

So, an overview of the two “classic” types of boilers.

Gas boilers

These devices can be divided into several of the most common types.

- AOGV. Floor-standing boilers with an expansion tank are designed for completely autonomous operation. Most often, it is impossible to heat water for domestic needs with their help. The obvious advantage of the AOGV is, naturally, its autonomy, since the operation of the device does not require the supply of electricity to the automation.

The disadvantages include not very economical gas consumption and not very good build quality and automation in inexpensive models.

AOGV

- Wall-mounted chimney boilers with electronic control. As a rule, these are very economical and efficient devices with a high level of efficiency. Water enters the radiators using either an external or built-in pump.

But this is both a plus and a minus - because in most cases such boilers cannot operate without electricity. Hot water for the bath, shower and kitchen is supplied through a second circuit.

Chimney boiler

- Wall-mounted turbocharged boilers. Also an excellent option with a high level of efficiency, and thanks to the turbine, such boilers can be installed almost anywhere in the room, since there is no connection to the chimney. The disadvantage is the same as in the previous case - in the absence of electricity, the automation and the turbine itself do not work.

Turbocharged boiler

Advice: if you want to purchase an energy-dependent, but very economical gas boiler and there are usually no power outages, still play it safe - purchase at least such an additional accessory as an uninterruptible power supply for gas boilers. Essentially, this is a battery that will keep the automation operating while there is no electricity in the house.

Uninterruptable power source

We looked at gas boilers as a heating source, but what about hot water in this case?

Well, everything is simple in principle - either a double-circuit boiler or an additional gas water heater. As a rule, its price is several times lower than the cost of boilers, so in this case, when purchasing a column, you will not overpay much in total.

Standard geyser

Now let's touch on electrical appliances.

Electric boilers

There are many electric boilers on sale today that are capable of heating even very large areas.

However, how effectively they can do this and at what cost is a big question.

Probably, boilers of this type are worth buying when there is no alternative - that is, gas. Or as a backup option - in case the main gas boiler suddenly breaks down in the middle of winter.

Electric boiler

Why this particular recommendation?

- Firstly, because whatever one may say, such a device “eats” a lot of electricity - and this, accordingly, will significantly hit your pocket.

- Secondly, even very expensive electric boilers, as a rule, have a rather low level of efficiency - in practice, this means that during severe cold weather, if the house is not well insulated, it will be very difficult for the boiler to quickly warm up all the water in the system. A gas boiler is much better in this regard - since it will reheat the cold water coming from the system in a matter of seconds.

Insulation scheme for the facade of a country house

No, of course, electric boilers also have a right to life, but if we are talking about large heating areas, then it is important to understand several points:

- The house must be well insulated.

- Heating with electricity is more expensive than gas - so if the situation is, as they say, “without options,” then maybe it’s worth trying to get some kind of subsidies or discounts on electricity.

- If there is no gas in the house, and suddenly the electricity is turned off, what to do, how to heat the house? Perhaps it makes sense to purchase a combination boiler that can run on solid or liquid fuel.

And of course, electric boilers have an undoubted big advantage - unlike gas appliances, you can easily connect them yourself, without any permits.

Note! Connecting an electric boiler is a simple matter, but just be sure to make sure that the wiring, circuit breakers and meter can withstand the load. Because if all this is old and bad, then there will be constant malfunctions in the operation of the boiler. And in this case, trouble is not far away.

As for what is needed for hot water supply and heating at the same time, there are not many options. Water for domestic needs will be heated either by the second circuit of the boiler (if available), or you will have to additionally purchase and connect a boiler or instantaneous electric heater.

Electric boiler

Now let's look at an equally important point - what radiators are on the market and what is best to buy. And then we’ll figure out the principles of installing the entire system as a whole.

Which radiators to choose

There can be no universal recommendation here! Because you need to choose one or another type of radiator based on the capabilities of a specific budget, the area and volume of the premises, the number and size of windows, as well as the type of boiler. And, of course, it is important to focus on the surrounding design, the concept of the environment.

Therefore, just take note of the characteristics of each type of radiator and make a decision based on the characteristics of your specific situation.

Radiators are like this:

- Aluminum heating radiators. As a rule, these are cast products that are lightweight, relatively low cost and have a high heating rate. The disadvantages include the not very chic appearance, as well as the rapid cooling of the water in the system;

Aluminum radiator

- Bimetallic heating radiators. These devices are very resistant to hard water and are more suitable for central heating systems. But of course, bimetal can also be used to heat a private home - the design of such batteries is, in principle, not bad, but the price in this case is also rather high. Another feature of these products is the ability to add or reduce the number of sections;

Bimetallic radiators

- Steel radiators. These are efficient heating devices, quite beautiful, durable and “average” in price. They heat up quickly, but cool down just as quickly. The main advantage is that to heat such a radiator you need a very small amount of water - and this directly saves gas or electricity;

Steel radiators

- Cast iron batteries. The main advantages are durability, interesting design, slow cooling of the metal and resistance to corrosion. The disadvantages include the heavy weight and rather high cost of the products.

Cast iron radiators

So what should you choose?

Probably due to the large amount of water in bimetallic, aluminum and cast iron products, they are unlikely to be suitable for an electric boiler that heats a large area. In this case, the optimal solution would be to purchase steel radiators.

And for gas boilers, in terms of efficiency, in principle, any of the listed radiators are suitable.

But of course, if you buy a product made of metal that cools quickly, remember that in this case it is highly desirable to insulate the house well. Otherwise, the consumption of gas or electricity will be high.

Now let's look at how to assemble a system for hot water supply and heating - what is important to pay attention to and what is needed to carry out the work.

How to safely lay communications in a wooden house?

Pipelines should be fixed to wooden walls and ceilings using fasteners designed to prevent their deformation and damage when the building settles. Compensation gaps left where pipes pass through the roof, walls or partitions serve the same purpose.

Electrical wiring in wooden houses can be laid in both open and hidden ways. The option of wiring over the walls (in plastic boxes or corrugated sleeves) is safer, but is not always acceptable from the point of view of interior design. In the second case, wires are allowed to be enclosed only in metal pipes and ducts, which are laid inside walls and ceilings.

5

Features of the device and operation

The core of almost any electric boiler is the heating element circuit. It consists of internal heating elements to which automatic units are switched. With their help, the coolant is heated, transporting heat into the heating circuit. Electricity is supplied from single-phase and three-phase electrical networks. The efficiency of electric boilers is such that they almost completely convert electrical energy into heat: the efficiency of the devices approaches 99%.

Classic boilers are characterized by small dimensions, which avoids cluttering the living space. However, in this case, the problem of lack of hot water is not solved. As you know, only city apartments in multi-storey buildings can boast of centralized hot water supply.

For residents of country cottages, the option remains to heat the water manually or use an electric instantaneous and storage water heater. Double-circuit electric boilers for heating a home are not much more complicated than their single-circuit counterparts. At the same time, they are able to heat the water with an additional heat exchanger with a heating element.

This design consists of the following elements:

- Two heating elements.

- Expansion tank.

- Safety group (sometimes replaced by a safety valve).

- Circulation pump.

The supply heating circuit of the main heating element is switched on according to the set temperature indicators. In this case, the heating element for the DHW circuit starts only after opening the hot water tap. As for other types of internal structure of double-circuit heating boilers, they have not taken root in the plumbing equipment market due to an imperfect design and a number of weak points. One of these options involves heating water in the DHW circuit from the heating circuit.

Electric double-circuit boilers for heating and water supply are divided into two groups according to the type of installation:

- Wall-mounted.

- Floor-standing.

Floor-mounted models are more powerful: for this reason, they are used for heating large households. There is no need to worry about the loss of living space, because... They take up little space and are compact. In a small home, it is recommended to use miniature wall-mounted electric boilers for heating and hot water. Some models of this type are distinguished by good power, which is enough to heat large areas.

How to connect a house to a centralized water supply?

In most cases, cottage communities are connected to a centralized network or have their own well, so it will not be difficult to supply water to the house on a general basis. If there is a need to connect directly to the central main line, then you should contact the local Vodokanal service for technical conditions for such a connection. In accordance with this document, you need to prepare a design for the cottage water supply system (connection point, pipe laying diagram, etc.) and coordinate it with the same service, after which you can make an insertion with shut-off valves into the pipeline and pull the pipes to the house.

6

Recommended manufacturers of home heating equipment

Vaillant is a German manufacturer of heating equipment, whose history dates back to 1974.

The choice of equipment begins with determining the available fuel for the boiler: gas, electricity, solid or liquid. Then they study the proposed models based on power, equipment reliability and cost.

The list of manufacturers of heating equipment and water heaters is almost limitless, about 500 brands from different countries. In Russia alone there are more than 150 companies whose models have been serving in private homes for many years. Almost every region has its own manufacturer or its representative office.

It is impossible to choose the best manufacturer (the undisputed leader). But you can consider the products of such world-famous companies (if the financial side of the issue is not of interest) such as Vaillant, Viessmann, Buderus, Bosch, Ferroli, Ferroli, Ariston. When time is of the essence, you can spend several months monitoring offers and purchase a boiler or water heater from one of the well-known manufacturers at a good discount.

Among the most popular Russian manufacturers are the Zhukovsky Machine-Building Plant, the Conord plant, Signal-Teplotekhnika LLC and some others. In terms of reliability and durability, this equipment is not inferior to foreign analogues, but costs significantly less. In addition, maintenance is easier due to an extensive network of service centers.

When the heating system and hot water supply need to be installed urgently, it is wiser to contact a trusted regional company for the installation of heating equipment, where it is easy to order not only a boiler from the currently available range, but also turnkey installation.

Construction of an individual well

Scheme of constructing a well “on sand”

On the lands near Moscow, in order to reach the aquifer, wells with a depth of no more than 30 m (“on sand”) are often constructed. The work is carried out using a self-propelled unit. A steel or plastic casing pipe is placed into the drilled hole, the diameter of which is determined based on the need for water. For example, for a house with 4–6 water points and a water flow rate of 1.5–2 m³/h, a pipe with a diameter of 115–133 mm is sufficient.

A mesh or gravel filter (or a combination of both) is placed at the bottom of the pipe and a submersible pump is lowered into the well. The system is equipped with a hydraulic accumulator (expansion tank) and a pressure switch.

In the case of a large cottage with a daily water consumption of 3–4 m³/h, it is advisable to drill an artesian well with a depth of 40 m and equip it with a caisson with a pumping complex. A permit is required to drill such a well and a tax is charged for its use.

7

Water and air heating

Heating can be water (using water or antifreeze as a coolant) and air (heat is carried throughout the house by air currents). Which option is more practical?

The author votes with both hands for traditional water heating. The only convincing advantage of air as a coolant is that it is not afraid of freezing when the boiler is stopped.

The problem of water heating freezing is eliminated by filling the heating circuit with antifreeze

There are many more disadvantages:

- Air heating is noticeably more expensive (it requires laying large cross-section air ducts throughout the house and installing a heat recuperator in the ventilation);

- It is installed only at the construction stage: the notorious air ducts are laid in the walls or above suspended ceilings;

- It forces you to sacrifice the usable area of the house, precisely because of the large diameter of the air ducts, which compensate for the low heat capacity of the air.

Boiler and air heating lines

Water purification system

Water from a well or village water supply needs to be purified, as it may contain mechanical particles (sand, iron, etc.) and solutions of organic and inorganic compounds. To do this, at the point where the pipe enters the house (after the shut-off valves), special equipment is connected to it, the choice of which depends on the chemical and bacteriological composition of the water, as well as on its purpose - only technical or also drinking.

Process water must be mechanically purified from suspended particles, for which cartridge-type filters are used. And to prepare drinking water, additional filtration stages are required. It is necessary to remove iron, manganese, hydrogen sulfide, etc. from it (reagent or non-reagent filters), soften it, that is, remove calcium and magnesium salts (ion exchange devices), and disinfect it - kill microorganisms - under the influence of ultraviolet radiation. At the final stage of filtration, installations with a reverse osmosis membrane work most effectively, trapping almost all impurities, including metal salts, many bacteria and viruses, etc., and allowing only water molecules to pass through.

The more polluted the water from the well, the more justified is the use of a reverse osmosis stage in the filter. However, it must be taken into account that the volume of water discharged into the sewer in the form of filtration waste is 3 times greater than the volume of purified water, and the degree of its purification is so high that it can cause an imbalance in the salt balance in the human body

8

Equipment and materials

Many people wonder how to make plumbing with their own hands. This is quite within the capabilities of anyone who has a desire to understand its structure.

The selection of equipment is carried out after determining the source. To connect to the central water supply, pipes and shut-off taps are sufficient. It is advisable to install a well at the connection point, but you can do without it. This is determined by the technical conditions issued by the water utility.

In the case of an autonomous option, the water supply scheme becomes significantly more complicated. Various equipment will be required for lifting and cleaning.

Pump equipment

A submersible or surface pump is used to supply water. Surface pumps are much cheaper than submersible pumps and can be purchased immediately with a hydraulic accumulator; this installation is called a pumping station. They are easy to maintain, and the well casing can be of small diameter, sufficient for the passage of a water intake hose with a filter tip.

Pumping stations are suitable for drawing water from surface sources. They are also installed if the pressure in the central water supply is very low and does not suit the consumer.

If the depth to the surface of the water in the well (well) is more than 5 meters, then the choice clearly remains with a submersible (deep) pump.

When choosing a pump, take into account:

- height of water rise (pressure) from the depth of the pump to the highest point of water collection in the house;

- required hourly flow rate (liter/min.), taking into account the number of users;

- pump diameter, taking into account the diameter of the well casing:

- pump type: vibration, vortex, borehole, centrifugal (the last 3 pumps are a type of centrifugal).

Vibration pumps are inexpensive, but they are not recommended for use in wells, due to the vibration created in the environment; they are only suitable for wells. The most reliable choice is a vortex pump. It has the lowest requirements for water purity.

Important: in each specific case, taking into account the type of well, water purity, and lifting depth, the right choice can only be made by a specialist with experience in operating pumps in a given area.

Hydraulic accumulator

For every electric motor, the hardest moment is starting up. Increased currents by 7 times, low torque, starting under load, all this significantly reduces its service life. To prevent the pump from starting frequently, due to a glass of water, a minute of hand washing, flushing the toilet, leaks in the network and other little things, a hydraulic accumulator must be installed.

And the larger the tank volume, the better for the pump. As well as for users, in case of a power outage

Its installation is mandatory, and its good condition is very important.

The volume of the hydraulic accumulator for water supply is determined by a special calculation. Simplified, you can select by pump output per minute, if the pump was selected taking into account the number of users. The result obtained is the minimum volume. If space allows for a larger tank, consider going a couple sizes larger. Each manufacturer has its own tank size. This row serves as an example, the volume is indicated in liters: 8, 10, 12, 18, 25, 30, 35, 40, 50, 60, 80, 100 and more.

It must be borne in mind that the useful volume of the tank, that is, the volume of water that it will give up when the power is turned off, is only 1/3 of its volume. This is provided that the air chamber has a free pressure of 0.2 bar lower than the pump shutdown pressure. Owners pump air above this value, therefore, the tank will give even less.

Storage tanks for water

Essentially, this is the same hydraulic accumulator, only much larger in size. If the hydraulic accumulator serves to protect the pump from frequent starts, then the accumulator tank also serves to create a reserve supply of water. But do not delude yourself, a tank of 500 liters will be able to release no more than 225 liters of useful water, with the correct pressure in the air chamber.

Therefore, it is easier and cheaper to install a simple tank of the required volume, but you will have to take water from it in a bucket. It can be installed in the attic, but the pressure will not be enough, and in winter you will need to take care to ensure that the water does not freeze.

Tip: by installing a system for automatically replenishing the storage tank, you can ensure uninterrupted water supply to your home.

Is it possible to do without shut-off valves on the water supply?

Definitely not possible. To shut off the water in an emergency or in case of plumbing repairs, shut-off valves at the pipe entry into the house are necessary. It is installed in front of the water meter, if the water supply is drawn from a centralized main, or in front of the hydraulic accumulator, if from a well. In addition, it is recommended to install shut-off valves on the risers going to the upper floors - then when replacing the mixer at the top, you will not have to “dehydrate” the entire house.

9

Option 2. Electric water heater

My neighbors have a separate electric water heater - storage, 50 liters, not connected in any way with the heating boiler. That is, the boiler is not used at all to prepare hot water. With three people permanently living in the house (kitchen, shower, two toilets, washbasin), this system has fully justified itself. Yes, probably, the cost of electricity is slightly higher than if there was a gas hot water supply, but not so significant. And there are also monetary benefits.

Firstly, in this option your boiler operates with less load and in a more gentle mode. This means we can hope for greater durability.

Secondly, we can pay less attention to water treatment (which, in theory, needs to be done if we want to extend the life of the equipment) - but the cost of a good water treatment system will be 50-60 thousand plus regular maintenance.

The price of an electric water heater with a volume of fifty liters today ranges from 11 to 14-15 thousand rubles. (depending on the manufacturer).

As I already said, my neighbors have had this heater working for several years without requiring any cleaning or replacement. And without special water treatment - only one main filter for mechanical cleaning at the entrance of the water supply to the house.

Laying cold water pipes

Wiring diagrams

At the entrance to the house of the water supply coming from the centralized main, a cold water meter is installed. When supplying water from a well, the system is equipped with a hydraulic accumulator. Next, a shut-off valve, filter units, and a tee with separation into cold water and water for heating are installed.

There are two schemes for connecting pipes to water collection points: with a serial connection and with a collector connection.

The first of them involves laying one main line with branches to each consumer, and the second provides for a common collector with pipes diverging from it. In the case of sequential wiring, if several taps are opened at the same time, the most distant one may not have enough pressure. But for a small house with only two or three water collection points, such a scheme is quite suitable, and it will cost significantly less than a collector one.

The diameter of the main water pipe and risers depends on the water needs of the house and is determined by calculation. On average, this is 20–25 mm (outer Ø), and if there is a pool, it can be as much as 50 mm. Bends are made from pipes of smaller diameter.

Manifold layout of water supply pipes

In the cold water supply system, pipes made of polypropylene, metal-plastic, metal (steel, copper, stainless steel), polyethylene, PVC are used for internal wiring

10

Operating principle of an autonomous water supply system

The water supply system is one of the most important elements in home improvement. The essence of its work is the automated supply of the required volume of water, for which the user now only needs to start the equipment and then simply periodically monitor it.

An autonomous network independent of the central water supply must be properly designed and calculated in order for the house to be fully provided with water according to the needs of the owners. The system must be organized so that water flows freely to all water intake points.

For normal operation, the water supply system is equipped with devices and technical devices that provide automatic or partially automatic operation.

To automate the process, a hydraulic accumulator is used. It is used as a buffer tank for storing water and as a device for maintaining stable pressure.

The membrane tank has two compartments - for air and water, they are separated by a rubber membrane. When the container is filled with water, the air chamber is compressed more and more, causing the pressure to increase.

Autonomous water supply systems consist of internal and external parts. Includes pipeline branches of the same name, laid from the source of water intake to water collection points, fittings, plumbing, pump, storage tank or hydraulic accumulator

Reacting to an increase in pressure, the electric relay turns off the pump. As soon as one of the owners opens the tap, the pressure in the system begins to drop. The relay again reacts to a decrease in pressure and turns on the pump unit to replenish the consumed water.

The use of a hydraulic accumulator in a water supply system allows not only to automate the process of water intake and ensure its supply. The service life of pumping equipment is significantly extended due to the reduction of on/off cycles.

Water supply is the life support of a home. It depends on how comfortable a person will live in his home.

To select the correct system parameters, you must:

- Formulate requirements for the intensity and regularity of water supply. It is possible that in a small country house you can get by with a system with a regular storage tank and a minimum of plumbing fixtures.

- Determine possible sources, feasibility and cost of their construction, water quality.

- Select equipment and calculate options for laying utility networks.

A well-designed system requires professional installation and the use of high-quality components.

Hot water preparation

Typically, a heat generator working for the heating system also provides hot water supply to the cottage. The DHW capacity of wall-mounted double-circuit boilers is a maximum of 15 l/min. So, if you need a large amount of hot water, it is advisable to install a single-circuit gas boiler with a storage tank - a boiler that can hold up to 260 liters of water (the volume of mounted models is up to 100 liters).

For the hot water system, pipes made of reinforced polypropylene with a welded joint are mainly used, capable of withstanding the maximum permissible temperature of hot water. It can also be products made of metal or cross-linked polyethylene. The wiring is carried out according to the same scheme as chosen for the cold line: with serial or collector connection of consumers.

11

What you need to know about collectors?

This design ensures a uniform supply of liquid to several simultaneously switched on water taps while maintaining the required pressure. When selecting equipment, you should remember that there are manifolds for distributing cold and hot water.

To make the device body, brass or stainless steel is used; there are devices made of impact-resistant plastic that can withstand heating to temperatures of more than 100°C. Metal products are attached to pipelines using threaded bushings. To connect plastic pipelines, manifolds with compression transition elements or with special bushings (fittings) are used that allow plastic pipes to be soldered.

When selecting a collector, you should take into account the number of outputs intended for switching external equipment. Standard products provide up to 6 channels, but manufacturers allow 2-3 collector modules to be connected in series. For coupling, couplings are provided at the nodes; the method of connection depends on the design features of the collector. If switching of the additional unit is not required, the collector is closed with an end cap.

Recommendations for the buyer

Basic recommendations for selecting a collector:

- Before purchasing a collector, you should decide on the type of material of the water pipes. It is recommended to use products made of polymers (for example, cross-linked polyethylene) that are not destroyed by water and do not have threaded connections.

- During the installation process, it is necessary to provide for the installation of a tap for the side lines. There are manifold blocks with integrated valves; the installer needs to connect the pipes and the manifold itself to the central riser. Please note that if the locking mechanism is damaged, the entire manifold block will need to be replaced. When using brass or stainless steel products, the taps must be installed separately.

- A block of additional devices is installed in front of the manifold (for example, meters, filters or a check valve).

How to dispose of domestic wastewater?

If there is a common village sewer system, the issue is resolved simply - you just need to get permission to connect your own pipe to it. If there is no such option, there is only one way out - to create a local treatment system, that is, to acquire a septic tank or a deep biological treatment plant. They are located underground (at a depth of up to 2.5 m) at a distance of at least 3 m from the house and no closer than 20 m from the water well.

Septic tank

is a storage container made of polymer material that is resistant to low temperatures and aggressive chemicals contained in the soil. Here, wastewater is settled and preliminarily mechanically purified (clarified), and then it is either removed by a sewage disposal machine or subjected to further purification using a filter well, trenches or underground filtration fields.

Deep biotreatment unit

(or local treatment plant - VOC) can consist of a single container divided into chambers (polymer, metal, concrete) or a system of separate modules, where step-by-step water purification occurs using anaerobic and aerobic bacteria, and sometimes with the use of special chemicals. As a result, the wastewater is purified by 95–98% and can be discharged into a drainage well, roadside ditch, etc.

When connecting to the village network, an inspection well should be installed at least 3 m from the house. Moreover, from the well to the main line there is usually a pipe with a diameter of 150 cm, and from the house to the well (and also, in the case of an autonomous sewer system, to a septic tank or biological treatment plant) - with a diameter of 100–110 cm

Septic tank

Deep biotreatment unit

12

Connection diagrams

What schemes can be used:

Instantaneous water heater

A scheme using a flow-through heater involves heating water in a specially designated tank or device at a time when water passes through it under pressure.

There are a huge variety of ways to provide flow-through heating by using:

- geyser;

- electric flow heater;

- water supply systems with heating system;

- double-circuit boiler.

In each case, one principle is involved - instant heating of water from heating elements. To make the water hot enough, it is necessary to install very powerful electrical devices or consume a large amount of gas, otherwise the water at the outlet will not reach an acceptable temperature.

The same applies to the number of water distribution points; for example, taking a shower and washing dishes at the same time will be difficult, since not every device can heat a large amount of water at once.

Storage heater

The second method is to install a water heating tank . Cold water flows into it, after which it is heated by the built-in heating element to a specified level. Such a water heating system is superior in price, but guarantees uninterrupted access to water until it runs out in the tank.

The user can choose the tank volume at his own discretion, based on his needs.

You can find two versions of such tanks on sale: with indirect heating and layered. Stratified tanks are also often used in conjunction with instantaneous heaters, while indirect tanks are a completely autonomous water heating system.

Layout of sewer pipes

Horizontal sections of the main line are laid in the underground space (basement, ground floor) or in the floor structure.

Toilets and bidets are supplied with pipes with a diameter of 100–110 mm (with a slope towards the drain of 2–3 cm/linear m), and to sinks, showers and bathtubs - 50 mm (at least 3 cm/linear m). If the bathroom is located close to the riser, the drainage from it will move by gravity.

Bathrooms on the upper floors of the building are recommended to be located above the same bathrooms. It is necessary to provide for the possibility of cleaning and inspecting the pipeline, and in order to reduce the likelihood of blockages, when installing pipes, their sharp bends and turns should be avoided.

To ensure that the air necessary for the normal operation of the drain enters the sewer - without air locks and ejection - the risers are brought to the roof (always in separate channels, and not through the ventilation shaft) or special valves are installed on them.

13

What are the advantages of hot water supply to a private home with water circulation in the system?

By using a storage water heater in the domestic hot water system, hot water is circulated in the pipes. Each water intake point is connected to a ring pipeline through which hot water circulates.

The section of pipe from each water intake point to the ring pipeline should be no longer than two meters.

Water circulation in the domestic hot water system of a private house is ensured by the operation of a circulation pump with low power (up to several tens of watts).

In domestic hot water systems equipped with a storage heater, the warm water supply mode has the following characteristics:

- hot water is always available at water points;

- you can turn on the water at several points at once, while the temperature and water pressure levels do not change significantly;

- the ability to collect any amount of heated water, even the smallest.

In a domestic hot water system with water circulation, energy is regularly consumed to operate the pump and compensate for heat losses in the boiler and pipes. In order to reduce energy consumption, an automatic program is used that turns off water circulation during periods of time when it is not in demand. Insulation of the boiler and water supply will also help reduce energy costs.

Organization of the heating system

The most common option is a heating system based on a boiler with a coolant in the form of purified water. Coolant circulation can be natural or forced. There are boilers that run on natural and liquefied gas, liquid (diesel) and solid fuels (coal, firewood, pellets), as well as combined boilers that use different types of fuel, and electric ones.

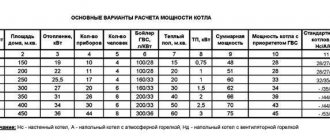

Due to the availability of fuel and high performance, consumers most often choose gas boilers. To determine the required boiler power, a thermal engineering calculation is needed, but for a general idea you can use a simple ratio: 0.1 kW per 1 m² of area.

For a small house, a compact wall-mounted boiler is suitable, which, with a power of up to 35 kW, can be installed in the kitchen or in the hallway. Massive floor-standing units capable of serving large areas require a specially equipped boiler room. Gas, liquid and solid fuel boilers must be equipped with a chimney and safety devices (pressure gauge, safety valve, air vent, etc.).

14

The procedure for calculating water heating schemes with your own hands

Calculations of thermal installations require a serious level of preparation from the designer. However, as an amateur method, we can recommend the following rough methods:

- to determine the boiler power: calculate the total volume of a private house by summing the volumes of each room. The cubic capacity of all rooms should be taken into account, regardless of the presence or absence of radiators in them. For example, let the volume of the house be 300 m3. The amount of energy required to heat 1 m3 depends on the region. For buildings in the European part of the Russian Federation, 40 W/m3 is required, in the south - 25 W/m3, in the north - 45 W/m3. Therefore, for a private house with a volume of 300 m3 in the Moscow region, you will need a boiler with a capacity of 12,000 W. Adding a margin of 20% and converting W to kW, we get 14.4 kW;

- To calculate the number of battery sections, the area of the room and the power (heat transfer) of one section are taken into account. The power depends on the material of the heating device (indicated in its passport). Next, you should divide the square footage of each room by the value of the rated heat transfer. By summing up the number of sections, a small margin of thermal performance is also added to them;

- the pump for systems with forced circulation is selected taking into account the length of the pipeline and the cross-section of the pipes. The algorithm for their calculation is described in detail in the story on the video:

What is required for installation

In a private house, do-it-yourself heating installation begins with drawing up a working diagram of the entire heating system with the exact linear dimensions of each section of the pipeline and the area of the premises. The drawing data is necessary to visualize the overall heating scheme and to calculate the required number of pipes.

In order to draw up an as-built diagram, you do not need to be a professional draftsman. It is enough to draw an arbitrary simple drawing, arrange the heating radiators on it and count the number of pipes for the combined circuit.

Based on the initial data and preliminary calculation of the required amount of thermal energy to heat the house, you can begin selecting materials for constructing a home autonomous system.

Selecting a Heat Source

The boiler is the main element of thermal energy generation. The main criterion for choosing a heat generator depends on the type of fuel as the source of its operation. Boiler power is calculated based on several factors:

- Volume of heated premises.

- Climatic features of the region.

- Thickness of external walls.

- Availability of thermal insulation of the main structural elements of the building.

- Availability of basement and attic space.

When choosing a heating boiler, it is important to pay attention to the adaptation of the selected model to domestic conditions and the presence of a certificate of quality conformity

Pipes

A correctly selected type of heating pipe eliminates technical operational problems and guarantees a high degree of reliability of the heating line. More recently, steel pipes with a diameter of up to 108 mm were used for laying heating pipelines. It was difficult to assemble such a heating network; individual pipes had to be welded together.

Currently, piping is best done from the following materials:

- polypropylene with internal reinforcement of aluminum or fiberglass;

- metal-plastic;

- cross-linked polyethylene;

- polyethylene with PE-RT additives;

- copper.

From the above list, the most popular are polypropylene pipes, which are characterized by strength, flexibility, resistance to temperature changes and corrosion. This material is easy to install and connect to heating radiators.