In search of a more efficient heating system, people have tried many options, of which underfloor heating has become the most successful. Warm floors are usually installed during housing construction or renovation, since its installation requires a complete change in the heating system and floor structure. The advantage of this heating system is the large heat-transferring surface area. Let us examine in detail the delights of heating a house with warm floors.

Electric heated floor

Installation of electric heated floors can begin at any time during repair work. According to the type of heating, electric heated floors are divided into cable, thermomats (heating mats) and film. Heating occurs using a cable or any other heating device by supplying electricity.

The underfloor heating cable can be considered as the main heating system. But due to the high cost of electricity, it is most often used in small areas (bathtub, corridor), where it serves as the main heating.

Sensors

The sensors are designed to monitor pressure and temperature indoors, outdoors and coolant in the pipelines of the heating system.

Temperature sensors are:

- Submersible . Designed to take readings about water heating in pipes. Their installation is carried out in certain areas of the system. These sensors are bimetallic and alcohol

- Remote . This type of sensor is installed outside the heating system. Recently, wireless models have become popular, which transmit information using auxiliary electronics, which makes it possible to install them almost anywhere - in a separate room or outdoors.

- Pressure sensors can be mechanical - pressure switches (mechanical measurement of pressure difference and electrical conversion) and analog pressure sensors (conversion of pressure directly into an electrical signal, for example, using piezo elements).

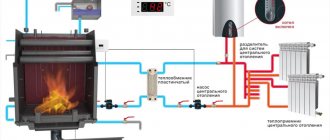

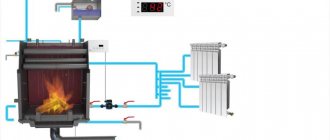

Water heated floor

A type of underfloor heating that can be equipped with an autonomous water boiler or central heating (using a special heat exchanger). Does not work without a pump and requires one.

In addition to pipes, a water heated floor includes: thermal insulation (expanded polystyrene), damper tape, fasteners, special accessories for making expansion joints, as well as the manifolds with fittings necessary to connect the underfloor heating system to the heating system.

Thanks to its water component, it can operate from any boiler and does not depend strictly on electricity. Not counting the operation of the pumps themselves. An excellent solid heating system for your home.

Thermostats

Thermostats are a control element of the system and can be mechanical or electronic.

- Mechanical thermostats consist of a thermal head (sensing element) and a valve. The working fluid of the sensitive element is a liquid, gas or elastic element that changes its shape depending on temperature. When the air temperature in a heated room changes, the volume of the working fluid changes. The sensing element reacts to this and moves the regulator valve stem. This changes the flow area in the channel.

- Electronic thermostats (ET) . This is an automatic device consisting of several devices that ensure the maintenance of a given temperature in thermal installations. In the heating system, they automatically control the operating modes of equipment and actuators (boilers, mixers, pumps, valves, etc.), and the result of their operation is the creation of a temperature regime specified by the user in the room.

- Digital thermostats come with “open” and “closed logic”. Closed logic implies strict control algorithms and a certain set of external devices connected to the system (sensors, actuators). Only limited parameters can be changed; the user cannot program control algorithms.

In large systems, thermostats with open logic are used - these are freely programmable controllers with a wide range of settings and functions. They can be integrated into a centralized building management system. Mounted in automation panels. Installation and configuration of such thermostats requires certain qualifications.

Myths about heated floors

Is underfloor heating harmful to health? The peculiarity of heating a house with heated floors is that it is picky about installation technology. Failure to comply with the technology significantly affects the performance of the system. This is where myths regarding the dangers of heated floors are born.

If you install the floors correctly, then you don’t have to worry about any consequences.

Regarding electromagnetic radiation when installing an electric heated floor, many myths have also been born about it. Yes, indeed, like any electrical device, radiation occurs, but the intensity is so low that even insects will not notice your heated floor.

First launch of TP

Warm floors are very convenient.

All that remains is to figure out how to turn on the heated floor. The first start can be carried out only after the screed has completely dried - this is about a month. First, the system is filled with water. This is done manually using a pressure test pump or through a pre-installed connection to the water supply circuit.

The technique is as follows:

- all air vents and all shut-off valves open;

- the circuit is filled with coolant;

- when water begins to ooze from the air valves, they close;

- the temperature regime is set at the mixing unit;

- then the boiler turns on.

As the coolant heats up, air will come out of it, so it will need to be vented. After several cycles of heating the coolant, the system will stabilize and you will only have to adjust the hydraulic resistance on different TP circuits using flow meters. As you use it, you will make adjustments to the coolant temperature.

Heating a house with a warm water floor

When discussing the features of heating a house with a water floor, many developers are interested in factors that we will explain below.

System life

Manufacturers like to mention that underfloor heating can last at least 50 years. Underfloor heating pipes are designed for this period. Regarding external parts: manifold, taps, etc., most likely they will fail sooner. But changing them won't be a big problem.

Our experience suggests that buildings from 1996 to this day are doing quite well and the underfloor heating system works without problems.

System efficiency

Manufacturers often like to mention that heating a house with underfloor heating as the main source of heat is more economical than many other heating systems. As practice shows, in most cases you do not get significant savings. But condensing boilers, heat pumps and solar collectors (for additional heating) can be connected to heated floors. In these cases, flooring can be significantly more economical.

Comfort

Many developers are confused by the fact that the floor will be uncomfortable to walk on. It will also be uncomfortable to sleep at night. The surface temperature of the heated floor is only 28 degrees. You will practically not feel it. For the bedroom, you need to provide a room thermostat so that you can set a comfortable temperature.

Which system is better

Any choice should be based on knowledge, so let’s make a small comparison.

- The battery sections practically do not fit into the interior.

- They heat the walls, while the heated floor is exclusively the air in the room.

- The installation of heated floors requires significant costs, both labor and financial.

- In rooms heated by underfloor heating, you can lower the temperature a couple of degrees without reducing the level of comfort.

- These floors are distinguished by increased thermal inertia. It takes from a couple to 24 hours to warm them up, however, the cooling cycle takes no less time.

- Operating heated floors is overall cheaper than operating radiators.

On a note

Thus, the conclusion suggests itself - in the future, in most cases, heated floors will be installed instead of radiators. And don’t let the initial costs scare you – they will definitely pay off over time.

Warm floor or radiators. What's better?

Radiator heating has a number of advantages and disadvantages. The advantages of radiators are an affordable price for all segments of the population, a large selection, and widespread availability.

The disadvantages of radiator heating include the strictly horizontal installation of radiators, which contributes to irrational heat distribution. Warm floors warm a house much more evenly than radiators.

In terms of consumption, both systems will be comparable, but water heated floors are more expensive to install.

Having analyzed the advantages and disadvantages of both heating systems, we can conclude that the optimal option for heating a room is to combine radiator heating with a heated floor system. In this case, the advantages of both systems are combined, and their disadvantages are eliminated. The main advantage of using both heating systems is that they work autonomously from each other, and if one of the systems breaks down, you can use the second.

Automation boards

Heating automation panels are used to control the heating system. They are used to control circulation pumps, control valves with pulse or analogue control, gate valves and solenoid make-up valves.

The automation panel can be equipped with temperature, pressure and differential pressure sensors, or the manufacturer indicates a list of compatible equipment.

Functions implemented in automation panels:

- Regulation of supply and return coolant temperatures for heating systems;

- Maintaining the specified value of the selected parameter, regulating the parameter according to the network diagram;

- Enabling energy saving modes at night, on holidays and weekends, controlling circulation pumps, lowering the temperature of hot water in the circulation circuit;

- Protection against valve sticking (periodic run);

- Control of the operation of the main and backup pumps with the organization of their alternating operation, automatic transfer switch and protection against “dry running”;

- Automatic restart of pumps in case of power failure;

- Other functions.

When connecting sensors to a heating automation panel, take into account the type of signal transmitted by the converter - analog, discrete or threshold - open/closed. Expansion modules that control device drives are selected based on the same principles, taking into account the type of control signal and control protocol.

Underfloor heating scheme.

There are three main types of water floor installation.

Snail or spiral

The most popular, economical and energy efficient method of laying water heated floor pipes. The snail-shaped pipe laying scheme first describes the perimeter of the room, starting from the edge, and tends to the center of the room, constantly reducing the radius, and then in the opposite direction.

The advantage of this method is the step length - the snail can be mounted in steps from 10 mm to any convenient size. There is also an even distribution of heat. This method of laying a water heated floor pipe is the least labor-intensive due to the slight bending of the pipe. If you really want to, even one builder can handle the installation and you won’t have to spend money on additional labor. The method of laying pipes in the form of a snail allows you to install a heating system in rooms of any size and various shapes.

What criteria do you use to choose boilers?

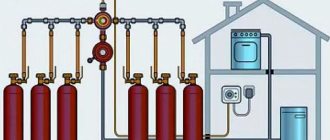

This is a rather complex question; to make the right decision, you need to look at it in more detail. From the point of view of installing additional heating systems, the technical indicators of the boilers are not of great importance; they all generate thermal energy in sufficient quantities, which makes it possible to connect the systems. But in practice, not everything is so simple. What types of heating boilers are there?

| Boiler type | Technical specifications |

| Gas | The optimal choice for combined heating systems. It can operate fully automatically and has excellent efficiency indicators. There are products on sale that differ in size, installation method (floor and wall), thermal power, number of circuits (single and double circuit), installed electrical equipment and fittings. A wide range of technical parameters and costs allows all buyers to choose the option that suits them. The only problem is that not all regions of our country have gas pipelines. |

| Electric | A modern boiler that fully meets stringent safety requirements, degree of automation and efficiency. It can connect to “smart home” systems, which significantly improves the microclimate parameters in the premises and saves energy. It has two drawbacks. The first is known to everyone - high power puts forward special requirements for electrical wiring; approvals from regulatory organizations are required. The second drawback is known only to practitioners. The water is heated by a special heat element, its surface area is insignificant. In many regions, the water is very hard, and solid salts are deposited on the heating element. A deposit thickness of just one millimeter reduces the efficiency by approximately 5–10%. In addition, because of them, the heat exchange process between the heater and water deteriorates; its heating temperature exceeds the critical one, which causes rapid failure of the device. As for various filters for purifying water from salt solutions, their actual capabilities are very far from those advertised. |

| Solid fuel | Most often used in dachas or suburban villages where there is no natural gas. Modern models increase the fuel burning time, which simplifies the operation of the boiler. But connecting them to combined heating systems is not recommended due to the difficulty of adjusting the temperature of the coolant. |

All modern solid fuel boilers have one more significant drawback; manufacturers do not mention it.

Problems of solid fuel boilers

Why do professionals strongly discourage connecting solid fuel boilers to combined heating systems? We will not dwell on the fact that the heating temperature of the coolant does not depend on the wishes of the residents, but on the physical characteristics and parameters of fuel combustion; most consumers understand this. Solid fuel boilers have another unpleasant drawback.

An increase in efficiency can be achieved in one way - by increasing the amount of transferred fuel energy (fire and smoke) to a water container. This is achieved by increasing the contact surface area and the duration of energy transfer. The dimensions of the container have a direct impact on the dimensions of the boiler; this parameter cannot be abused. To increase heat transfer, designers additionally slow down the combustion process by limiting the supply of oxygen to the fuel, so it burns for a long period of time. But reducing oxygen automatically reduces draft and smoke temperature.

Long burning solid fuel boiler

As a result of combustion, all types of solid fuel produce a lot of ash and soot; with a lack of oxygen, their amount increases even more. The fuel has a certain moisture content and steam is released during combustion. The steam condenses on the walls of the chimney, soot sticks to it and over time the draft completely disappears. This situation can lead to tragic situations.

Accumulation of soot on the internal walls of the chimney

In houses with ordinary stove heating, chimneys are periodically cleaned with strong combustion; in modern closed heating systems this cannot be done. The water may boil, but the installed expanders are of a closed type. The result is a rupture of plastic pipes, a boiler, or a violation of the sealing of fittings.

Method of laying pipes in the form of a snake

This scheme for laying water heated floor pipes has large heat losses due to the fact that hot water is supplied only from one side and loses all energy when reaching the end of the scheme. Thus, we get a warm floor at one end of the room and a gradual decrease in temperature as we move away from the coolant mixing unit. Another disadvantage of laying with a snake is the difficulty of installation. The pipe bends 180 degrees. Very often you have to take a step of 200 mm versus 10 for the snail.

In order to reduce the temperature difference in the snake system, you can make a double snake. However, this will not completely solve the problem of labor-intensive installation of water-heated floor pipes.

The best option for using a snake is to combine one method with the second. Or first you need to cut off the outer walls, then lay the snake in the middle of the room. This results in an optimal temperature distribution. A combined scheme involves mixing methods for laying heated floors or duplicating them. For example, two turns of a snail or several snakes in a row. If the layout of the room allows, then you can mix methods for laying out a warm water floor. For example, at the entrance, where heating is not particularly needed, put a snake, and in the center of the room, in order to concentrate useful energy, spread a snail. Before starting work, it is best to draw a diagram of the water heated floor on the plan. Thanks to this, future work on installing a water heated floor will become much easier.

Actuator drives

Valve drives can be threshold (two or three position) and analog, with the possibility of smooth regulation.

The most famous and common method of regulation in a pumping system is regulation by a damper when the engine is running at full speed, and pressure regulation in the system is carried out using shut-off valves (gate valves, taps, bends, ball valves, etc.). The operation of the pump is ensured by a constant supply of energy to it from an electric motor, and it is controlled by a pressure control device.

Regulating the throttle can be compared to driving a car: when the gas pedal is pressed all the way, the speed of movement is regulated by the brake pedal.

A more economical way to control coolant flow is to use frequency converters to regulate the rotation speed of heating system pump motors.

With this method of regulation, up to 50% savings in energy consumption are achieved, and if we take into account that during its service life the engine consumes electricity in an amount that far exceeds its cost, then this indicator turns out to be extremely relevant. For example, an 11 kW engine operating for 8 hours a day throughout the year will consume electricity in the amount of about 145 thousand rubles. (at a tariff of 4.5 rubles/kWh).