Types of connection

Autonomous heating can be implemented using:

- Wall-mounted single-circuit boiler with electronic ignition, providing forced circulation in the radiator system.

- Non-volatile wall or any floor equipment.

- A non-volatile boiler installed in an open circuit with natural circulation.

- Heating circuit modifications for heated floors. This is characterized by a low coolant temperature.

- A single-circuit boiler connected to a hot water supply system. We are talking about a wiring diagram for a gas heating boiler with a boiler

- Double-circuit boiler providing heating and hot water supply. In this way, a double-circuit gas boiler with a boiler is connected, which is quite popular.

- When the DHW circuit has water recirculation. Thanks to the constant movement of water in the circuit, heated towel rails connected to the hot water supply are kept hot. It also ensures high-speed hot water supply to the mixers.

If a hot water supply of considerable length does not have water recirculation, it will require prolonged draining before heating. In addition to the known inconveniences, this also entails financial losses. The same applies to dead-end DHW distribution without recirculation. In this case, heating of heated towel rails connected to the wiring occurs exclusively during water intake.

Harness complete set

The harness includes the following elements:

- Diaphragm expansion tank . Designed to compensate for surges in coolant volume during heating. This need arises in closed heating systems. Inside the container there is an elastic membrane that divides it in half. One half contains air or nitrogen (in this case, the walls of the tank do not corrode). When the volume of coolant increases, this provokes compression of the gas: as a result, the total pressure in the system remains almost at the same level. The standard volume of the expansion tank is 10% of the amount of coolant. For a rough calculation, a ratio of 15 l/kilowatt of heating boiler power is usually used.

- Safety valve . Resets excess coolant when the pressure in the circuit rises to dangerous levels. As a result, pipes and radiators are protected from rupture. A drainage pipe is provided to drain water into the sewer. If this valve operates regularly, this indicates insufficient capacity of the expansion tank.

- Air vent . If air pockets occur, they are removed automatically. We are talking about air accumulations formed in the system as a result of draining the coolant. Because of them, hydraulic noise arises and additional obstacles to normal circulation in the mode of low hydraulic pressure.

- Pressure gauge . Controls the operating pressure in the circuit. It is sometimes replaced with a thermomanometer, which additionally records the temperature. The scale of the device must have a marking of up to 4 atmospheres.

- Open expansion tank . Replaces the expansion tank, air vent and safety valve in an open circuit. In this case, the system does not face the problem of excess pressure. A tap is used to connect a tank communicating with the atmosphere to the DHW system: this ensures recharge of the circuit.

- Indirect heating boiler . Inside this heat-insulated container with a heat exchanger, hot water is prepared. Heat is supplied by means of coolant flowing through the heat exchanger from the heating system. This element is included in the piping diagram of a gas single-circuit heating boiler; the connection of an indirect heating boiler must be carried out by specialists.

- Circulation pump . Thanks to it, forced circulation of coolant is carried out through the heating circuit. When selecting a suitable pump, pay attention to the level of pressure it creates and productivity. The power consumption indicator in modern models is regulated within the range of 50-200 W. Thanks to this, the speed of movement of the coolant can be changed depending on the situation.

- Hydroarrow . Several heating circuits can be connected to this container with pipes. Its task is to combine the supply and return pipes. As a result, it becomes possible to bring together systems with different temperatures and coolant speeds, smoothing out their mutual influence.

- Coarse filter . Inside the settling tank with a filter mesh, large particles in the water are retained. Most often we are talking about sand and scale. As a result, the thin heat exchanger tubes in the gas boiler are prevented from clogging.

- Two- and three-pass thermostatic mixers . Thanks to them, it becomes possible to create coolant recirculation, the temperature of which is an order of magnitude lower than that in the main circuit. A thermal head is used to control the mixer shutter. The valve changes its position in response to the temperature of the sensing element.

Installation

High-quality piping of a boiler connected to a double-circuit boiler involves connecting the water heater to one of the heat exchangers. A ring system is formed when the boiler inlet pipe communicates with the initial link of the heat exchanger. Everything is designed in such a way that the water coming from the water supply bypasses the boiler heat exchanger. It will go straight into the boiler, and from there it will penetrate into the hot water supply line. You can connect an electric boiler using approximately the same scheme, but the water supply is connected to the first pipe of the second unit that exchanges heat, and the second pipe is already connected to the boiler.

It is recommended to install the water heater as close as possible to the energy source in order to simplify their connection using automation. When the device is mounted, it is time for docking. Important: a properly installed and connected water heater must only take a certain amount of heat. Excessively high consumption can paralyze the heating system. This problem can most often be solved by installing an automatically controlled circulation pump with your own hands or with the help of professionals.

Only the very last step is to install the thermal block. It is almost always recommended to have the circuit assembled by a professional. The nuance is that indirect heating boilers with a control unit must be connected exclusively to heating systems that receive water from uncontrolled boilers.

All you need is:

- tighten up the serving and taking moves;

- connect the storage tank to the water supply;

- place a comb distributing hot water on the upper outlet;

- Fill the reservoir and begin warming up immediately.

The simplest boilers interact mainly with automated heat sources. During installation, you will have to take care of connecting a sensor that measures the heating force. This sensor is supposed to be connected to a strictly defined input into the boiler. It is possible to connect boilers independent of the electrical network to autonomous boilers, but this immediately complicates the work and requires a special circuit. It should be borne in mind that it is possible to heat the water inside the boiler a little lower than the heated liquid in the coil.

Therefore, when the boiler is switched to low heating mode and can supply coolant heated to 40 degrees, only combined type heaters can raise the temperature higher. They always include an electric heating element to help add heat. If, when setting up a system that controls recirculation, priority is given to heating hot water in the tap, the movement of the entire coolant is directed through the storage exchange unit. As a result, the total time spent on obtaining liquid at the required temperature is noticeably reduced.

As practice shows, if boiler room designers and installers give preference to the option with priority, it is possible to provide comfortable conditions for residents. To warm up the entire volume of liquid in the tank, it should take from 20 to 40 minutes.

And if we talk about stabilizing the temperature against the background of coolant consumption, this time is reduced several times more. Even a small dwelling is unlikely to have time to cool down enough for it to be detected by those in it. But a lot depends on the installed boiler and boiler: their power must match, and ideally it is recommended to install a boiler with a power reserve of 25%.

To ensure stable operation of devices connected to combs that distribute hot water, it is necessary to supplement the outlet from the boiler with a special expansion tank. The recommended value is 10% of the main tank, helping to absorb the effects of thermal expansion. All connected branches must be equipped with ball-type shut-off valves. With their help, any node can be disconnected from the main line at the right time and checked or repaired.

The pipelines through which the liquid is supplied are usually equipped with check valves. With their help, the opposite flow of the coolant is prevented, and the convenience and safety of installation is increased. It may be necessary to place a boiler near the boiler, on the supply side of which a pump is mounted to provide circulation. In this option, it is very important to provide a separate circuit through which water will flow into the heater from the boiler. Essentially, a parallel type of connection is created.

If there is a pump in both the boiler and the boiler, a three-way valve must be mounted immediately behind the circulation pump; one channel is connected to the water heater pipe. This ensures normal heating operation. A tee must be installed on the return pipe up to the point where it enters the boiler. And this tee is connected to a pipe that draws liquid from the heat exchanger. Such a simple system easily and elegantly solves the problems.

As soon as the sensor signals that the coolant temperature has dropped below the set point, the valve transfers fresh flow to the boiler. The heating system stops. When the normal value is restored, the same valve switches back. The minimum number of components reduces the risk of breakdown. And the simplicity of execution allows you to quickly find a problem if it does appear.

When a grid-independent boiler is used, ensuring boiler priority is not as easy to achieve as in other options. It is recommended to install the water heater higher in relation to the floor of the room than the radiators. It is advisable that the lowest point of the wall model is also raised above the boiler. But it is possible to strictly comply with such a requirement only in individual cases. When it is partially executed, it is still worth raising the drive to as high a height as possible.

By placing the boiler on the floor, the rate of heating of the liquid is immediately reduced. What’s even worse is that the lower part of the container is basically unable to warm up normally in this mode. If you connect the boiler using the classical system, then any power outage will deprive you of access to hot water. The problem can be solved by using a larger pipe for the circuit connected to the water heater than on the heating link. Immediately at the beginning of the heating branch, a thermostat head is placed and a sensor is applied. Energy is provided by batteries.

Without constant recirculation, systems that contain a water heated towel rail cannot operate. The benefit of such a circuit is that water flows instantly when you open a hot tap. But the total consumption increases, and the efficiency of the system comes into question. To make matters worse, recirculation creates the problem of mixing dissimilar layers of liquid. However, since it has been decided to use a heated towel rail on water, this is the only possible choice.

By choosing Protherm indirect type boilers, you can combine them into one system with gas or electric-powered single-circuit boilers of the Skat models. The popularity of water heaters connected to a solar collector is also growing. This solution allows you to provide yourself with both heat and hot water at minimal cost even in winter. The single-circuit option involves placing the collector under the tank, and the tank itself communicates hydraulically with the lower branch pipe of the collector and with the upper outlet from it.

Video - How to connect a KN boiler to a single-circuit boiler

Pipes

Using pipes, the gas boiler is connected to the heating system, and the coolant is distributed in the required directions.

If the design of an autonomous heating system is done correctly, its parameters are absolutely stable and controllable:

- Temperature inside convection circuits (equipped with radiators or convectors). Should not be more than + 75-80 degrees. Heating of heated floors does not exceed + 25-35 degrees.

- Pressure. Permissible limits: 1 -2.5 kgf/cm2.

If the circulation pump fails, the thermostat will almost instantly stop the combustion process. This will protect the coolant from overheating and boiling. For this reason, the switching of the boiler and heating distribution is often carried out using polymer and metal-polymer pipes, which allows you to save on the purchase of expensive metal products.

A few recommendations:

- To implement sequential wiring of radiators and boiler switching, metal-plastic pipes with press fittings are most often used. Another common option is polypropylene products with aluminum reinforcement.

- When installing threaded fittings for metal-plastic, special care must be taken: if the O-rings move even slightly, this will lead to a leak. As a rule, such a nuisance should be expected after several heating-cooling cycles.

- Unreinforced polypropylene (or glass fiber reinforced) has a very high elongation coefficient. An increase in temperature by 50 degrees provokes an elongation of each meter of pipe by approximately 6.5 and 3.1 mm, respectively. This option is also unsuitable.

- To organize radiant wiring or underfloor heating, metal-plastic pipes with press fittings, pipes made of cross-linked polyethylene or thermally modified polyethylene are also used.

Varieties of heating schemes for a private house

In the simplest version of the boiler diagram, there is no piping at all. In the vast majority of cases, the factory equipment of boilers with electronic ignition consists of the following elements: a pump, an expansion tank, an automatic vent and a valve (with a pressure setting of 2.5 kgf/cm2). The location of all piping units is the building: as a result, the complex is transformed into a mini-boiler room.

As additional elements, the system can be equipped with:

- Filter. Its installation location is the inlet pipe. As a result, the heat exchanger receives protection from contamination while increasing the hydraulic resistance of the circuit. This leads to a decrease in the speed of movement of the coolant, and the pump itself experiences additional load.

- Ball valves. They are installed at the inlet and outlet sections. This makes it possible to dismantle the heat exchanger or boiler while maintaining the heating circuit.

Making a boiler yourself

Due to the rather simple principle of operation, such a device can be made independently. Now let's look at how to make an indirect heating boiler with your own hands.

All work on the manufacture of a water heater consists of assembling the component parts of the structure:

Tank

A tank is used as a boiler capacity. Its volume depends on the needs of the home owners for hot water and is calculated from the amount of 50–70 liters per person daily. Approximately, a 200-liter boiler is suitable for a family of 4 people.

For the heating device, the tank must be made of stainless steel, aluminum alloys or other corrosion-resistant material. An alternative is a gas cylinder, but its walls must first be cleaned and primed. Without this action, the hot water will smell like gas.

5 holes are made in the tank: 2 on the side for mounting the coil, one at the bottom for the inlet pipe, one at the top for water intake and one at the bottom for the drain valve. To use the boiler outside the heating season, it is necessary to install a heating element. The bottom hole is also drilled for it. Shut-off elements or ball valves are attached to the holes made.

Coil

A copper or brass tube is suitable for this element, the diameter and length of which depend on the volume of the tank. On average, for every 10 liters, 1.5 kW of thermal power of the serpentine tube is calculated. You can use a tube made of metal-plastic or other metal with good heat transfer.

The tube is wound in a spiral onto a cylindrical mandrel. To do this, you can take a log or a large diameter pipe.

When winding the coil, it is important to monitor the turns:

- in order to ensure the best contact of the heating surface of the tube with the heated water, the turns should not come into contact with each other;

- You should not wind it with excessive force, otherwise it will not be easy to remove the coil from the mandrel.

- The number of turns on the coil is calculated from the volume and height of the tank.

Thermal insulation

The outside of the tank must be covered with a layer of insulation. It is necessary to increase efficiency and reduce heat losses. To insulate the container, polyurethane foam, mineral wool or any other heat-insulating material that is attached to the base with wire, glue or strip ties is suitable. For a neat appearance, it is better to cover the tank body with thin sheet metal or foil insulation.

You can also insulate the tank using another container of larger diameter. To do this, a do-it-yourself boiler is inserted into a large tank, and the wall is filled with insulating material or foam plastic, using the principle of a thermos.

Heating element for combined BKN

Tubular heaters are sold in assortment in hardware stores. The following formula will help you calculate the performance of the heating element:

P= 0.0011*m*(tk-tн)/T

The following values are considered calculated:

- P is the power of the heating element;

- M is the mass of heated water;

- tk is the desired water temperature;

- tн - initial water temperature;

- T is the water heating time.

In a combined indirect heating boiler, the coil is placed throughout the water heating tank from bottom to top - the scheme ensures maximum efficiency and uniform heating of water. The heating element is installed at the bottom of the tank.

Installation

Assembly of a self-made boiler is carried out after preparing all the components:

- the coil is mounted in the center or along the walls inside the tank, and pipes are soldered to its inlet and outlet pipes;

- for a vertically standing boiler, supports are welded to the bottom, for a mounted device - “ear” loops;

- the heating element is installed;

- the boiler is tightly closed with a lid;

- connecting the coil according to the diagram for making an indirect heating boiler with your own hands to the heating system circuit;

- connecting the inlet/outlet pipe for water;

- pipe distribution to the kitchen or bathroom at the water collection point.

Floor-standing gas boilers with piezo ignition

Boilers with piezo ignition and floor-standing equipment do not belong to mini-boiler rooms: we are talking about heating devices that require external piping.

It includes:

- Pump. To select the pump performance, the formula Q = 0.86R/Dt is used (Q is the performance in m3/hour, R is the thermal power of the boiler or a separate circuit, Dt is the temperature difference between the supply and return). In order for a convection heating system with gas boilers to work normally, the temperature difference must be 20 degrees (+75-80 degrees on the supply pipeline, and +55-60 on the return pipeline). A boiler power of 36 kW assumes the following reasonable minimum pump performance - 0.86x36/20 = 1.548 m3/h.

- Membrane expansion tank.

- Safety valve.

- Automatic air vent.

- Pressure gauge.

The optimal location for the safety group is the boiler outlet: it is here that the temperature and pressure indicators reach their maximum values. The pump is placed in front of the boiler, in an area with the lowest coolant temperature (this allows you to significantly extend the service life of the impeller and rubber seals). The expansion tank can be mounted anywhere in the system: the main thing is that the distance to the pump impeller is no more than two diameters (if it is installed in front of the pump).

When installed after the pump, this distance is increased to eight diameters. This distance is necessary to ensure that pressure surges that occur during pump operation do not reduce the life of the tank membrane. To prevent condensation from appearing, the heat exchanger is often equipped with an additional small circulation circuit. If the return pipe is cooled, it is possible to add hotter coolant inside it (it is taken from the supply pipe through a mixing unit).

Natural circulation

The gravity system is characterized by complete energy independence: its operation is ensured by atmospheric pressure. Instead of a bulky safety group in the piping of a single-circuit boiler, an expansion tank is sufficient. For bottling, it is advisable to install a vent in front of the boiler heat exchanger: this will make it possible to completely drain the water into the sewer or drainage well. Typically, such a need arises in the event of a long departure, or when the gas supply is cut off. As a result, the system is protected from defrosting.

The individual components of the system are located as follows:

- It is recommended to install the tank above all other elements.

- The bottling located immediately after the boiler is positioned in the vertical direction (a small angle is allowed). Thanks to the acceleration section, the water heated in the heat exchanger rises to the top filling point.

- It is important to maintain a constant slope when laying the bottling after the tank. As a result, the cooling water will return by gravity: in this case, air bubbles will be able to escape inside the expansion tank.

- The boiler must be lowered as low as possible. The best place to place the heater is in a pit, basement or basement. Due to the difference in height between the heat exchanger and heating devices, the proper level of hydraulic pressure is ensured, ensuring water circulation in the circuit.

Some features of arranging an inertial heating system:

- For the internal filling diameter, an indicator of 32 mm is selected. If plastic or metal-plastic pipes are used, then the outer diameter is 40 mm. Thanks to the large cross-section, compensation is achieved for the minimum hydraulic pressure due to which the coolant moves.

- The gravity system sometimes includes a pump: however, this does not mean that the circuit loses its energy independence. In this case, the pump is mounted not in the filling gap, but parallel to it. To connect individual taps, a ball-type check valve is used, which is characterized by very low hydraulic resistance. A ball valve is also installed. If the pump stops, the bypass is shut off, which preserves the functionality of the natural circulation circuit.

Hydroarrow

This node includes both circuits:

- The first uses the movement of coolant between the hydraulic arrow and the boiler heat exchanger.

- In the second, one or more heating circuits with different heating levels are switched to it.

The operating principles are as follows:

- The vertical hydraulic arrow makes it possible to select coolant at different temperatures. The top section will be hot and the bottom section will be cold.

- When water is taken from the upper pair of taps, switching of convection heating is allowed. The lower pair is used in an intra-field circuit.

- The coolant temperature below the switching level of the return pipe of the circuit at the junction of the water gun and the boiler may drop noticeably.

Set for work

- Level.

- Roulette or ruler.

- Hammer. Can be replaced with an impact drill.

- Pliers.

- Adjustable wrench.

- Tees-fittings. They will allow you to insert into water pipes.

- Stopcocks.

- Sealing tape. Necessary for sealing connecting elements. You can replace it with tow or a special paste.

- Flexible connecting hoses. Water will be taken in and discharged through them.

- Additional pipes. Buy as needed. Be sure to check with the seller whether the pipes you choose can withstand use in the upcoming conditions.

Recycling

In a parallel position to the main radiator heating circuit or a small circuit in the area from the boiler to the hydraulic switch, a low-temperature circuit is installed. It contains a bypass and a three-way thermostatic valve. Thanks to the pump, water constantly circulates inside the underfloor heating pipes.

To select new portions of hot coolant from the supply pipe when the temperature inside the return pipe drops, a three-way mixer is used. It can be replaced with a simple thermostatic valve equipped with a remote capillary-type temperature sensor or an electric thermocouple. The sensor is installed in a niche on the return line of the heated floor. The valve is activated when the coolant temperature drops.

Radiator connection of serial type

This option is possible if a condensing gas boiler is used, because The operation of classical equipment is difficult at return temperatures below +55 degrees. The fact is that a cooled heat exchanger collects condensate on its surface. Gas combustion products contain, along with water and carbon dioxide, aggressive acids. In this case, there is a real threat of destruction of steel or copper heat exchangers.

Condensing boilers have a different operating principle. A special stainless steel heat exchanger (economizer) is used to collect combustion products. As a result, additional heat transfer occurs and equipment efficiency increases. Because of this, the return pipe temperature level of +30-40 degrees is optimal. The heating system consists of two series-connected circuits - radiator and in-floor. The return pipe of the first is the supply pipe of the second.

Water intake when the supply is turned off

Most storage water heaters are closed-type and do not drain water by gravity. However, there are a number of piping additions that make it possible to draw water in the absence of pressure. These same additions make it easier to empty the tank if it is removed for maintenance.

First of all, the theory: the hot pipe of the tank reaches the very top of the container, the cold pipe is located below under the diffuser cap. The water is drained through the cold pipe, and air is sucked into the container through the long hot outlet pipe.

The simplest solution is to cut a tee into the hot outlet to the location where the ball valve is installed. Using these two taps, you can provide air to the tank and use hot water from the “cold” pipeline. But this approach is not entirely safe: if you forget to turn off the air intake valve, you risk flooding your home when pressure appears in the cold water supply system.

The problem is solved in two ways. The first is to install a check valve on the air suction valve at the hot inlet. The problem is that there is almost always a small amount of water in the high tube of a filled tank, so the system does not work very stably - the water column prevents the valve from opening even if there is a relative vacuum in the tank. You have to bleed water from the tube manually when you first open the system.

1 - tee; 2 - check valve; 3 - valve for air intake

It is also possible to install a check valve bypassing the cold supply shut-off valve. In this case, the valve is installed opposite the normal flow of water, blocking its flow into the tank when pressure is applied. As before, this task can be solved with even fewer three-way valves.

Single-circuit boilers with DHW supply

To provide hot water supply, along with a safety group, a pump and an expansion tank, the piping of a single-circuit gas boiler must include an indirect heating boiler. A connection diagram for an indirect heating boiler with recirculation is possible. In this case, water is heated thanks to the coolant from the heating circuit. This leads to the appearance of two circulation circuits - a large one (through the heating system) and a small one (through the boiler). Each of them has shut-off valves, which allows you to turn them on separately. To break the supply bottling, a piping scheme is used for a single-circuit boiler with a boiler, immediately behind which a bypass with a tap is installed.

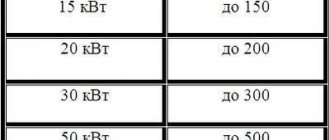

Boiler selection

The volume of the boiler is determined by the power of the heating network in the house. Because it will take the main load while the device is operating. If the heater volume is larger than the system volume, the boiler may malfunction. Also, the temperature level in the heating equipment will be too low to warm the house. The volume of the indirect heater should not exceed forty percent of the total volume of liquid in the heating system so that performance does not suffer.

You need to consider the number of people in the family. A person needs up to eighty liters of water to take a shower. And two hundred liters of water are heated by a boiler in about six hours. Knowing these values, you should calculate the volume of the device so that it is enough for the needs of the family until new heating occurs.

Selection by material

It is important to pay attention to the material of the coil. Inexpensive models are equipped with a steel coil welded to the tank. In expensive devices, the tube is brass and removable

Brass is much higher quality than steel. Removable coil is easy to remove to clean out deposits

In expensive devices, the tube is brass and removable. Brass is much higher quality than steel. The removable coil is easy to remove to clean out deposits.

Tanks often develop leaks. Inexpensive boilers are enameled inside, but the material, due to the rapid formation of cracks due to temperature changes, can leak because the metal corrodes. The best option is to purchase a stainless steel tank. This option will cost more over a longer service life, because the magnesium anode can be replaced.

The material from which the insulation is made also affects the efficiency of the system. Foam rubber is often used, which is inferior in many positions. It is good to use polyurethane or other insulation materials as insulation.

Select by additional parameters

The boiler can be equipped with two heating sources, or have a heating element. From them it will heat the water when the heating in the house does not work. These devices are expensive, but practical.

Boilers can be wall-mounted or floor-mounted. It is selected according to the type of heating system. With a wall-mounted system, a wall-mounted boiler is chosen. Tanks with a volume of less than two hundred liters can be mounted on the wall.

Pros of boilers

The advantages of boilers of this type include:

1.Hot water obtained in this way has a low cost. No need to pay for electricity or gas. The load on the heating source is small. In winter, this type of boiler is considered relevant.

2. During the heating season, the load on the electrical network is reduced, since the operation is based on the energy of the boiler.

3.Can heat a large volume of water.

4. The boiler can provide water to several units at once.

5. Alternative heating sources can be used for heating.

6. The coolant does not interact with water, which is heated; liquid almost free of salt enters the coil.