A circulation pump is most often installed in autonomous heating systems to ensure constant circulation of coolant through the pipes. This allows thermal energy to be evenly distributed throughout all rooms and used efficiently. Using a circulation pump in a private home allows you to warm up all the rooms in a short time, and then constantly maintain a comfortable temperature by adjusting the performance.

The correct choice of a circulation pump allows you to reduce energy costs by almost a third. Therefore, when purchasing equipment, you should either pre-calculate the required operating parameters or seek help from specialists.

- Design and operating principle

- Types of circulation pumps

- How to choose the right pump

- Marking of circulation pumps

Basic parameters of heating pumps

There are not many parameters that you should pay attention to when choosing a device. In fact, there are only two of them - pressure and productivity (flow)

Pressure is the hydraulic resistance of the system that the pump is able to overcome. This value is measured in meters of water column. As a rule, the hydraulic resistance of the entire system is set by the highest point of the pipeline through which water circulates.

The pump's performance, measured in m³/h, shows how much liquid it can move through the pipeline per unit of time. Therefore, before choosing the required model, you need to know the exact volume of coolant in the system.

Important! Pressure and productivity are inversely proportional to each other. That is, the maximum pressure is achieved at zero supply

And, conversely, the maximum flow rate is possible at zero pipeline height.

It is the pressure-flow characteristic of the device that allows us to determine the model with optimal parameters for a specific system. At the same time, the standard formula - the more powerful, the better - is not entirely suitable for this case. Because this means purchasing a more expensive unit and increasing energy consumption.

Grundfos ups pump technical specifications

Technical characteristics of the grundfos UPS pump are presented in the catalog in the documentation section. Below we propose to consider a summary field of hydraulic characteristics.

We would like to give fairly banal advice that it is better to buy a Grundfos UPS pump in a specialized store from an official dealer. There are many fakes on the markets where Grundfos is easily confused with low-quality manufacturers. Counterfeits of Grundfos UPS pumps are indistinguishable to non-specialists, so be wise and do not fall for the tricks of scammers. The video highlights the typical differences between the original and the fake:

Grundfos not only takes care of promoting products on the market by expanding the dealer network, but also creates conditions for warranty support. When purchasing a Grundfos UPS pump, the buyer can always count on technical support.

Summing up

The Danes have set a high quality trend; the Grundfos pump has occupied the leading steps of the pedestal for many years. The scope of Grundfos equipment is extremely wide. Today we looked at a household pump UPS, installed to increase the flow rate of coolant and faster delivery of hot media to heating radiators.

However, do not forget about the optimal ratio of the coolant speed and the diameter of the pipeline system. High speed will cause a hum, insufficient speed will cause your household to freeze. If you are not sure that you can choose the right Grundfos pump, it is better to use the help of a specialist.

In addition, Grundfos pumping equipment is effectively used in organizing the supply of hot water. The Grundfos pump will become an indispensable tool in the installation of water-filled underfloor heating systems. Grundfos pumps can often be found as part of finished boiler equipment; BAXI gas boilers are a prime example. It is difficult to imagine the functioning of central air conditioning and ventilation systems without a Grundfos pump.

As a piece of advice, we would add that it is better to piping a double-circuit boiler using a Grundfos pump from the Alpha family. The demand for Grundfos Alpha pumps during installation of underfloor heating is growing significantly. The Grundfos UPS household series is less powerful; the circulation pump pushes the water column only 80 meters. For higher needs there is the Grundfos MAGNA 3 range.

Putting the pump into operation

Before connecting, the device is filled with water and air is pumped out. To release air, a bolt located on the rear of the motor is rotated. The air will begin to bleed. If water begins to flow out, it means the air has been released. The bolt returns to its original position. The valves on the suction and discharge sides open.

To switch the speed, use a speed switch located on the capacitor box.

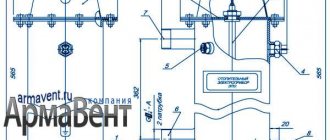

Installation rules

- Installation is carried out in a ventilated, warm room.

- Installation is carried out after completion of welding and cleaning of the system.

- Closing valves are mounted at the inlet and outlet to the pump; this will prevent leaks and water from draining from the system when repairing the unit.

- To prevent breakdowns, the device is installed above or near the pipes.

- The device is connected to the pipeline so that the axis of the incoming and outgoing pipes coincide.

- To ensure quiet operation and absence of vibration, the unit is not installed close to the knee.

- The diameter of the pipe must match the diameter of the unit;

- Installation is carried out so that the direction of the arrow on the device coincides with the direction of the working fluid;

- The unit is installed taking into account accessibility if necessary.

Safety precautions

Before dismantling or installing the unit, it is disconnected from the network. Before dismantling the device, wait until it cools down.

When bleeding air, electrical parts are protected. To avoid damage, the pump is installed in a dry place.

Characteristics and installation diagram of the Gilex Compass pump

The temperature range of the room is from minus ten to plus fifty degrees Celsius.

Problems with Gilex and how to fix them

Circulators are reliable, but minor problems occur. To eliminate them you need to know the cause.

List of problems:

- When starting, the unit stops immediately. The reason is plaque between the impeller and the housing. The problem can be resolved by removing the plaque and unlocking the shaft;

- high noise level. The reason is air in the system or high water pressure. Fix the problem by bleeding air from the system and reducing the fluid speed;

- the unit does not start. The reason is that there is no voltage in the network, the capacitor has broken, deposits on the bearings have blocked the shaft. It is necessary to check the integrity of the cable and unblock the shaft;

If the operating rules are followed, the compass will serve for many years and does not require repair work.

Gilex Compasses are distinguished by their reliability and quality. Positive reviews confirm the quality of the devices.

What is a BP/BP connection?

The detachable connection BP/BP of the heating system is a set of adapters that allows you to connect the pipe to the pump body.

- BP/BP means nut/nut;

- BP/HP means nut/thread.

BP/BP adapters are used to connect circulation pumps. Here is an example: Photo of an adapter for connecting a BP/BP pump (1 1/2″ - 1″). This means that the pump nut has a diameter of one and a half inches (32 mm), and the pipe connection nut has an inch (25 mm) diameter.

On the nameplate of the pump and in its description, the diameter G is often indicated; this is the diameter of the union nut for the pump. Pumps are sold complete with connection adapters.

Note: Threaded connection of circulation pumps is typical for low-power household pumps. More powerful pumps are connected via flange connections.

Common labeling

When choosing a Wilo brand pump, you should pay attention to the letter and number designations that come after the main part of the name. Each of the letter designations indicates the type of product, and the numbers in the product labeling indicate its most important characteristics.

Drain TMW 32/11

This Wilo pump model is a vortex drainer made from various materials. The device is capable of pumping slightly polluted water (meaning those in which the diameter of the pollution particles does not exceed 1 cm).

Brief technical characteristics of the circulation pump Vilo Drain TMW 32/11:

- The maximum depth at which it can be used is 3 m.

- This device has overheat protection. In 60 minutes of operation it will be able to pump 15 cubic meters. meters of water.

- As the name implies, the head height of this device is 11 m, cross-section is 165 mm.

Its average cost is 10,500 rubles.

How to choose the right pump

Equipment installed in the heating system must comply with its operating characteristics. If the model is selected incorrectly, the room temperature will be uncomfortable - too high or too low.

The main selection parameters are:

- connection diameter. To determine it, it is enough to measure the pipes in the heating system. Standard connection diameters are 1” (25 mm) and 1¼” (32 mm);

- installation length. It is indicated in the marking of the circulation pump and can be 130 or 180 mm. Selected in accordance with the location and features of equipment installation;

- pressure To determine it, you need to know the total length of the heating circuit. For every 10 m of the system there should be about 0.6 m of head water column. If the circuit length does not exceed 80 m, one pump will usually be sufficient;

- equipment performance. It is calculated using the formula Q = N/(T2-T1). Q - productivity, N - power (kW), T2 - outlet temperature (+90...+95 oC) and T1 (+60...+70 oC) - at the boiler inlet.

Advantages and disadvantages

The advantages include:

- The ability to normalize the operation of the system, organize uniform and stable movement of the coolant.

- The ability to change the operating mode, which saves fuel.

- The high speed of movement allows you to heat the room in a short time.

- Some pipeline design flaws can be corrected after circulation is started.

- Reliability, ability to work in difficult conditions.

- Durability, undemanding, long service life.

- The ability to choose a model that is affordable and has suitable characteristics.

Disadvantages of devices:

- To operate the pump, you must be connected to a power supply.

- Electricity consumption increases, which will require additional costs.

- If there is a sudden power outage, the coolant circulation stops.

- Purchasing and installing the device into the system will also require certain expenses.