The range of heating systems for creating a favorable microclimate in the house is currently huge.

Previously, radiators were mainly used to heat rooms - find out how to install them yourself. But now, most owners of private buildings prefer warm floors. However, using only TP does not always allow creating comfortable conditions in the apartment. Therefore, for private homes, professionals increasingly began to recommend a combined heating scheme - with radiators and heated floors.

Our article will be useful to those who are building their own home and planning to install a combined heating model.

You will learn how to combine radiator heating and heated floors, what advantages this scheme has in comparison with conventional radiators, how to make a project taking into account the calculations made and carry out the installation yourself.

We suggest you read the article - which heating radiators are best to install in an apartment, selection criteria and TOP manufacturing companies.

Norms and restrictions

Warm water floor is a low-temperature heating system. According to existing standards, the maximum temperature level of the coolant should be +55 degrees. During operation, standard heating usually ranges from +35 to +45, with the floor heating up to +26 - +31. The standards for different premises differ:

- for bedroom, kitchen, living room - +26;

- for bath, toilet, hallway—+31.

Liquid circulates through the floor lines using a pump. In addition, it allows you to regulate the heating level in the room. You need to select it based on the speed of water movement. The maximum permissible for hydrofloors is 0.6 m/s.

The difference between the heating of water at the supply and outlet should not be within 10 degrees.

Options for combining heating devices in the system

If a gas main is laid near the house, then there is no problem with choosing equipment.

In other cases, heating devices with a combination of fuels are used:

- Convert a gas boiler with a main fuel supply to use a cylinder-type energy carrier. In this case, only the nozzle is changed.

- Liquid fuel boilers. The equipment is convenient with free access to a large volume of diesel fuel.

- Long-burning solid fuel boilers are quite expensive, but are energy-independent units.

- Condensation device. The equipment is characterized by economical consumption and increased efficiency, it is non-volatile, the burner has electronic ignition.

Advice! In systems with forced circulation of coolant, boilers are equipped with pumps.

Features of the combined system

The combined heating system includes radiators, which are high-temperature sources, and low-temperature sources - heated floors.

There are two ways to connect a water floor in a mixed scheme:

- To an existing heating boiler - this method reduces the cost of equipment and installation time. The disadvantage of this design is the inability to work autonomously. This increases energy consumption and reduces floor efficiency.

- By installing separate boiler equipment for the floor, this significantly increases installation costs. However, such a system has the advantage of being autonomous, its operation does not depend on batteries. This is convenient when radiator heating no longer functions.

There are several recommendations that should be taken into account when deciding to create shared heating in a private house:

- Set temperature conditions separately for radiators and heated floors. Since in batteries the heating of water at the supply and outlet is about 70 and 55 degrees, respectively, and for heating floors 40 and 30 are required, the boilers are not able to cope with this task on their own.

- Use special components to adjust heating. Pumping and mixing units, shut-off valves - they will reduce costs and allow you to correctly connect the system with the container in which the water is heated.

- Configure the combined system using special and correctly installed technical means. For example, a mixing unit with a thermostatic head, its function is to regulate the heating level of the liquid; the thermostat is responsible for controlling the degree of heating of each room individually.

When laying a water floor, there is no point in limiting yourself to only the bathroom and toilet. It is better to place such a system wherever possible, since increasing its area does not significantly affect installation and operating costs.

Indeed, in any case, you will need to install a mixing unit and a device that will ensure liquid circulation. It doesn’t matter what the collector group will be - one-pipe, two-pipe or more.

The cost of screeding also does not change, even if the floor is installed in only one part of the room, the concrete solution will have to be poured over the entire area.

Originality of designs

Combination boilers for individual heating of a private home have several fireboxes for different types of fuel. In one of them, solid fuel is burned - wood and coal, in the other - liquid or gaseous fuel in the form of gas or diesel fuel. In such systems, it is possible to connect several autonomous lines and set different temperatures. For example, one supplies energy to the batteries, the other controls heated floors.

For heating a two-story house, this is an excellent option, you just need to focus on the presence of separate heat exchangers, they are not available in every combination boiler.

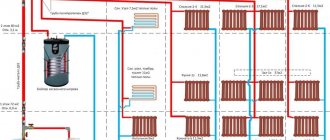

Scheme of combined heating of a two-story house

The latest developed representatives have built-in heating elements for working on existing energy carriers, and there are also burners that allow you to use both gas and diesel fuel by simply turning the switch to the desired mode. In order to save money and obtain the desired effect of heating a large area, it is worth using a heat accumulator; this is most relevant in boilers using coal. When using solid fuel, the power of the boiler system is not adjusted and the room becomes extremely hot. The heat accumulator present:

- removes excess heat and preserves it;

- If there is a lack of heat, hot water is transferred to the hot water supply or to the system.

With this design, you can turn on the boiler less often.

Pumping and mixing unit

It is possible to construct a heating system according to a combined scheme in a private house using a pumping and mixing unit. The design with it is the most effective, but will be more expensive compared to using a 3-way valve, although the operating principle is the same.

Cooled water from the return pipe dilutes the hot coolant, and the presence of balancing taps allows this to be done in the required proportions.

This unit comes in different configurations. It depends on the purpose and cost of the equipment. The standard device includes:

- thermostatic valve;

- immersion temperature sensor;

- balancing valve with fixing spring valve;

- circulation pump;

- immersion thermometer;

- threaded sleeve;

- bypass and shut-off valve;

- drain and ball valve;

- air vent;

- bypass bypass.

Boilers from other manufacturers

The most popular combination in a multi-fuel boiler is: solid fuel + gas.

This is what Zota combi boilers look like

This makes it possible to perfectly heat cottages near which gas mains pass. Along with Finnish boilers, there are also Polish ones from Zota. They can combine solid, gaseous and liquid fuels. However, the burner will need to be replaced. The price of the boiler is low, this model is suitable for those who do not intend to change energy sources often.

For those who want to regularly change fuel, a combined double-flow boiler from Zota - ECO CK Plus is suitable.

The scheme of work here is different. The main solid fuel runs out, and another burner is switched on automatically. Everything is fixed in the settings. This is an interesting model of a multi-variant boiler, but it also has disadvantages - size and cost. Other existing models:

- Finnish Jäspi Triplex and Swedish CTC represent a combination: gas + solid fuel + electricity, and there are also examples: diesel fuel + gas + firewood + coal + electricity;

Drawing with dimensions of Finnish Jäspi Triplex boilers - Czech cast iron combi boilers DAKON FB operate with pellets;

- Finnish boilers Jäspi VPK operate with pellets, gas, diesel fuel, wood, coal, there is an electric heating element;

- Austrian combination boilers Wirbel Eko Sk Pellet Pus have two fireboxes;

- Russian combined boilers "FAX" work on wood and coal, there is a heating element;

- The Russian combined boiler “Dymok” runs on wood or coal.

Diagrams and installation instructions for one boiler

The simplest and most economical way to build a combined heating system in a private house is considered to be a scheme with a radiator and heated floor from one boiler. All elements and the circulation pump are already installed from it.

There are wall-mounted boilers that already have a pump built into them. When using a floor-standing model, it will have to be installed separately.

When directly connected to a gas appliance (this is the model that experts recommend installing when installing a combined heating method in private homes), it is recommended to install a container for condensate. Installing a conventional gas boiler will lead to rapid failure of the heat exchanger.

Gas equipment is placed in rooms with ceilings of at least 2 meters. Ventilation is required.

If a solid fuel model is used, then to connect the heated floor to it, you need to install a buffer tank. Its function is to limit the temperature regime, since it is difficult to directly regulate the temperature.

The principle of operation of heating according to a combined scheme - warm floor and battery from one boiler is as follows. The heated water is directed to the mixing unit, where it rests against the safety head. The thermal head determines its temperature, and if it exceeds the required level, the valve opens and the hot and cold coolant is mixed to the required degree.

Then the water is distributed along the contour lines of the floor and radiators. After passing through the entire pipeline, it returns to the heat generator for heating.

The connection diagram for underfloor heating and radiators from one boiler includes the following elements:

- boiler with expansion tank - heats the coolant;

- hydroarrow - wiring, in the form of a pipe with four branches, through which water moves;

- radiator and sex pump - they supply fluid to the collector unit;

- collector - floor loops are connected to its outputs, and hot water is supplied;

- mixing unit - in it the coolant for the TP is diluted;

- thermostat - a head that opens or closes the flow of water into the circuits.

System installation

After constructing the floor “pie” - leveling the base, hydro and thermal insulation and laying the heating elements, you can proceed to installation work and connecting a combined heating system from one boiler (warm floor and radiators). Let's look at the process step by step:

- The boiler is installed and its piping is made (in a private house it is often installed in a separate building). The room must have a chimney and air flow.

- The pipes from the radiators are connected to the water heater, and a pump is mounted between them.

- The floor circuits are connected through a device in which the water is diluted to the required temperature. For this purpose, the following are used: a mixing unit, a 2- or 3-way valve, they are attached to the supply pipe.

- A circulation pump is installed.

- The floor contours are connected through a comb to a source of hot water; it is the coolant that will heat the room.

Heating radiators

For any combined system operating on the principle of radiators and additional equipment, the batteries themselves are still needed today. You can find the following types of devices:

- cast iron Everyone remembers these radiators from childhood. Their benefits cannot be underestimated. Radiators can withstand up to 10 atmospheres. Service life – more than 50 years. The number of sections varies. Suitable for all types of pipelines. New radiators can produce heat - 120 watts. But if several layers of paint are applied, the indicator drops. The main disadvantage is the inability to change the design of radiator equipment, and an ugly appearance may not always fit into a modern interior;

- aluminum. Despite its small volume and weight, the device dissipates heat well and can withstand 12 atmospheres. Device design more suitable for modern interiors. Sections on the equipment are removable;

- bimetallic. They are made mainly of aluminum, with only steel tubes. Steel tubes can withstand high pressure. Of all types of radiators, this is the most expensive;

- steel. The main advantage is considered to be the moderate price. The downside is that over time, leaks appear in the joints. The heat dissipation is small. They are the same size and do not change.

Radiator in the bedroom

Mixing valve circuits

In private homes, experts advise giving preference to a combined type heating scheme, using a mixing valve; it can be 2 or 3 way.

Heated floor collectors. Pumping and mixing units.

With 3-way mixing valve

In this combined scheme, the liquid is heated to 80 degrees for the radiator, and 40 degrees is required for heated floors.

The main task is to reduce the temperature of the water that comes from the radiators to the required degree for heated floors. This is exactly the problem that the 3-way thermostatic head solves.

The principle of operation of the system is that heated water is supplied from the heat source through this device to the collector, where it is diluted to the required degree with cooled coolant from the return pipe of the TP. In this state, the liquid is supplied to the floor circuits.

This combined scheme has a drawback - there is no way to make adjustments and limit the flow of cooled water from the return. In this regard, both excessively cooled water and hot water will flow into the main, and this can lead to overheating of the floor, or insufficient heating.

But these temperature changes can go unnoticed, since they are compensated by the concrete screed.

The circuit with a three-way valve is easy to install and has low cost. It is especially suitable for a one-story private house, or rooms with a small area.

If a three-way valve with bypass is used, mixing of heated and cooled coolant is carried out inside the device.

Installation is simple:

- a tee is installed on the supply;

- after that, the circulation pump is connected.

With 2-way mixing valve

Two-way valve - its thermostatic head controls the temperature level at the entrance to the floor pipe.

It is recommended to use the scheme in rooms with a large area, but not more than 200 sq. m. The presence of a balancing valve makes it possible to regulate the degree of mixing of liquid for underfloor heating circuits. It is capable of blocking or opening the flow of hot water.

The circulation process of the coolant is designed so that the liquid moves in a circle, and the addition of heated water occurs when the temperature drops. Since the throughput of the device is small, the adjustment is carried out smoothly, without jumps.

It is also mounted on the supply, and requires the installation of a device for forced circulation of liquid.

Radiators and heated floors

Reproduction of articles, as well as their individual parts, is prohibited. We want to reserve the right to exclusive placement of this material on our website home-engineering.net. Here we share the knowledge and experience gained by our team over the years of work in the field of design and installation of engineering systems.

→Home →To the list of articles

Introduction Combined home heating systems: radiators and heated floors What are the difficulties of implementing a combined heating system Description of a country house with a typical combined heating system The canonical way of implementing a heating system with radiators and heated floors Folk modifications. Kroilovo and Popadalovo Our proposed solution for a complete heating system Conclusion

Introduction to top

In this article, we want to dwell in detail on one of the most common tasks in the field of organizing heating of a country house: how to organize the heating of a house with a combined (mixed) heating system with radiators and water heated floors in the most optimal way. There are probably dozens of possible solutions to this problem. And as proof of this, there are numerous variations of heating systems in various houses that we have encountered during our work. Almost all of them perform their tasks well, but technically competent, beautiful and reliable solutions are surprisingly very rare. It is precisely in order to have more such solutions - simple and elegant - that we decided to write this material.

First of all, the material will be useful to people who are just thinking about what kind of heating system is needed in their house under construction, what must be included in it, and what may not be there. Without experience in operating a country house and without special training, answering these questions is very difficult. In general, it is clear that the heating system must ensure the comfort of residents and be affordable to install and operate. But what specific elements and how exactly need to be linked into a single system is often not clear.

If you still have questions about heating systems, boiler piping, radiator heating systems, water heated floors, or you need to calculate and install heating systems for your home in Minsk, the Minsk region and the Minsk region, please contact us by phone or email mail posted in the CONTACTS section.

Combined home heating systems: radiators and heated floors top

We call a combined (mixed) heating system a heating system that contains both traditional high-temperature (conventional radiators, convectors) and low-temperature (warm floors, less often warm walls) heating devices. The presence of two different types of heating devices inevitably leads to an increase in the cost and technical complexity of the entire home heating system. However, combined heating systems for country houses are very common. According to our observations, almost 90% of new private houses have water heated floors, albeit in a small area: most often in bathrooms, hallways, and kitchens. This means that the increase in cost and complexity of the home heating system for the average person is not the most important criterion for choosing one or another method of heating their home. Warm floors, as an additional or even the main source of heat, are chosen in a private home for convenience and comfort. And in some cases, a warm floor is generally the only heating system for a country house.

A mixed or combined heating system combines heating with traditional radiators/convectors and water heated floors.

The convenience of heated floors is associated with the ability to get rid of radiators under windows or on walls, where they can interfere with interior design or simply take up space. And the comfort of water heated floors is with better and more uniform heating of rooms and with the elimination of cold-to-touch floors with such practical and common floor coverings as ceramic tiles or porcelain stoneware.

In general, there should be heated floors in a modern house, unless the goal is to save as much as possible on equipment, components and installation of the heating system! Another question is how to correctly implement this combined heating system in this case.

What are the difficulties of implementing a combined heating system up

Errors and difficulties in the implementation of heating systems with radiators and heated floors arise, despite the fact that all the piping components have long been invented, and boiler manufacturers provide appropriate recommendations in their instructions.

Key points to pay attention to when implementing a combined heating system for a private home (radiator heating plus water heated floor):

1. The need for technical organization to obtain two independent temperature conditions in the heating system - for the radiator circuit and the heated floor circuit. The fact is that radiators require a relatively high supply/return temperature (not higher than 70/55°C for modern heating systems). At the same time, a heated floor requires a relatively low temperature (about 40/30°C).

The main difficulty in a mixed heating system is to obtain different temperature schedules for the radiator circuit and the water-heated floor circuits.

Modern wall-mounted gas boilers, as well as solid fuel and electric boilers, cannot solve this problem by themselves with standard means!

2. Therefore, to solve the previous problem, the use of additional components is required: mixing valves, circulation pumps, shut-off valves, etc., which require not only additional purchase costs, but also technically correct connection with the boiler.

In order to obtain a combined heating system, it is necessary to correctly select and install numerous components into a single and balanced system.

3. To regulate the combined heating system, the selection of appropriate technical means and their correct coordination is required. Mixing units with regulation using thermostatic valves, electronic regulation of supply temperature or weather-dependent control by an external controller or by means of the boiler itself, control of heated floors using room sensors (thermostats), operating logic of circulation pumps, etc.

It’s one thing: connecting a radiator heating system to a boiler when all the functionality for this is already included in the boiler. It’s a completely different matter: adding additional components (mixing units, circulation pumps, etc.) to a technically quite complex device (boiler). It’s not enough to just “twist” it all, you need to do it correctly so that the heating system:

- worked efficiently (heated the house properly),

- was reliable in operation (its individual elements must operate in the correct modes, which guarantee a long service life),

- required minimal operating costs (saving time for adjustments, saving electricity for operating additional pumps),

- was easy to maintain (so that in order to clean the coarse filters or check the expansion tank, it was not necessary to drain water from the heating system and spend half a day expelling air from the pipes of the heating system, because there are more interesting things in life).

Description of a country house with a typical combined heating system to the top

So, let's take a typical case as an example. There is a country house with a total heated area of 200 m², 2 floors. It is required to heat it using radiators and water heated floors. The number of radiators in a modern house usually ranges from 0 to 20 pieces (on average - 8-12 pieces, 1-3 pieces in each room). The total area of heated floors is from 5 to 200 m².

A typical example of heating a country private house: heated floors in public areas and radiator heating in bedrooms.

The area and number of floors in our example are very arbitrary. It can be a one-story or two-story house with an attic and a basement (4 levels in total), and its area can be from 50 to 300 m². In all these cases, the heating system can be implemented in it using fairly simple and standard solutions based on wall-mounted gas boilers with the necessary minimum of additional equipment, which means that the cost of implementation will be reasonable, and maintenance of engineering systems will be simple.

It should be noted that if you decide on water heated floors, there is little point in limiting their area . Let's say, do them only in two bathrooms and a hallway (the area of heated floors will be about 20 m²). The best solution would be to make a water-heated floor wherever tiles are planned (usually hallways, halls, kitchens, pantries, and even living rooms, a heated basement), and, if possible, in other rooms of the house, even bedrooms. Why? - There are the following considerations for this - judge for yourself.

When implementing a water heated floor, even in a small area if there are radiators in the heating system, you will have to make a mixing unit with adjustment and pumps, buy a manifold for heated floors and tie it with shut-off valves and pipes. Whether this mixing unit will work on 10 m² or 100 m² of heated floors does not play a significant role. And the cost in both cases will be almost the same, because the shut-off valves, mixing valves and circulation pumps will be the same. Yes, the underfloor heating collector will have, say, not 2-3 circuits, but 10, but it will cost not 3..5 times more, but 2 times.

If you install heated floors only in some of the rooms within the floor, you still face the question of pouring screeds over the entire area of the house (floor). This is necessary so that you do not have steps and thresholds between rooms: this is inconvenient, unsafe, and simply ugly. There is no difference when pouring floors over a floor slab, insulation on a slab, or over insulation with warm pipes - it will cost the same (the price is based on the area of pouring). But then it will be very difficult to redo and in the future add heated floors in other places, and more often - simply impossible.

How many times have we encountered this situation: the customer decided to install heated floors only in part of the premises (usually under tiles or porcelain stoneware), and after living in the house, he realized that it was necessary to install heated floors throughout the entire floor, even in the living rooms. Because Walking on a laminate floor in the bedroom is not at all the same as walking on a laminate floor or a heated floor! Especially if below there is a basement or a floor on the ground. Believe me.

This immediately raises the question of insulating floors in those rooms where, although there is no heated floor, it is necessary to do so. And it is necessary to insulate the floor under the screed above basements if they are unheated or partially heated and for floors on the ground. This is done in order to save heat from being lost downwards and to prevent the floors from being very cold to the touch. Those. You still need to buy and lay insulation.

Thus, the difference between different houses, one of which has little heated floors, and the other has a lot of money, will be determined only by the cost of the pipe for the heated floor and the cost of its installation. The cost of a pipe for a heated floor is about 5-10 USD. per 1 m² of floor, and the cost of installing a heated floor is about the same 5-10 USD per 1 m². Those. the price increase will be 10..20$. per 1 m² of heated floor area of the house. Now look around and find the average price per square meter of decent housing in our kingdom. Prices may unpleasantly surprise (those in the tank).

That is why, from the point of view of investment in the future, and in the comfort of your family, an increase in the price of a square meter of your home, say, from 500 USD. up to 520$ looks insignificant (only 4% if the warm floor is EVERYWHERE). However, with a possible sale in the future, your home with a competent and comfortable heating system with water-heated floors will undoubtedly be in a more advantageous position compared to its competitors. This means you will sell it either faster or more expensive. And, if you think through other details carefully, then it will be both faster and more expensive!

The canonical way to implement a heating system up

In this section we will look at the standard, proven and recommended by equipment manufacturers, piping scheme for wall-mounted gas boilers in combined heating systems with radiators and water heated floors. We will look at its main components and their purpose. Later in this chapter we will analyze what results from rash attempts to “modernize” this standard scheme, when you really want to save money, but don’t really want to understand and think.

But in the next section we will offer an alternative version of the standard scheme, which will be correct and functional, but simpler and cheaper to implement.

In the meantime, here is a generalized standard connection diagram. In order not to clutter it, we do not show additional fittings (taps, etc.).

Connection diagram for radiators and water heated floors to a wall-mounted gas boiler in a combined heating system. An important element of the circuit is the hydraulic separator or hydraulic needle (2).

Designation of the main elements of the circuit:

- wall-mounted gas boiler with built-in circulation pump and expansion tank;

- hydraulic separator (thermo-hydraulic separator or hydraulic arrow);

- collector (collector beam) for connecting heating circuits;

- radiator heating circuit circulation unit;

- mixing unit kennel water thermoplastic floor;

- safety thermostat.

Let's consider the principle of operation and purpose of the main components.

Wall-mounted gas boiler 1 (it can also be an electric boiler, solid fuel, pellet or diesel boiler, heat pump, etc.) heats the coolant (for example, water) and, through a built-in circulation pump, supplies it to the thermal hydraulic separator 2 (hydraulic arrow). A hydraulic needle, in fact, is nothing more than a piece of large diameter pipe with four bends. That. the heated coolant constantly circulates in a closed circuit boiler-arrow (A-B)-boiler.

When the pumps of the radiator circuit 4 and/or the heated floor circuit 5 are turned on, heated water is supplied from the hydraulic needle 2 (C-D) through the manifold 3 to the radiators and the heated floor. Water enters the radiator circuit 4 at the same temperature to which it was heated by the boiler, and in the mixing circuit of the heated floor 5, the water lowers its temperature in the mixing unit (in this example, using a three-way mixing valve) and enters the heated floors.

The hydraulic arrow in this diagram is needed for the following purposes:

- ensures constant circulation of coolant through the boiler, independent of the heating circuits, via a boiler pump;

- ensures the independence of the operation of circulation pumps in the circuits of radiators 4 and heated floors 5 from the boiler pump 1 and from each other;

- facilitates hydraulic calculation of the heating system;

- serves as a place for additional deaeration and collection of sludge from the coolant (see air vent and drain valve on the arrow);

- is a decoration of the boiler room of the proud owner of this device (a joke of humor)

Folk modifications. Kroilovo and Padalovo up

The desire to save money, ineradicable resourcefulness and a thirst for adventure leads to various variations in all schemes of heating systems slightly more complex than a potbelly stove.

For a non-professional, a hydraulic needle is a rather incomprehensible device like “some piece of pipe is exorbitantly expensive” (it’s not cheap). And in a store that sells polypropylene huts, you can very rarely buy it. Therefore, people often have a desire not to use this very squirrel arrow at all, which results in modified connection diagrams for a combined heating system, where this “extra detail” is simply not there.

In this case, it turns out to be possible to abandon both the collector 3 (which is quite reasonable) and the circulation pump of the radiator circuit 4 (now its function can be performed by the boiler pump itself). The safety electric thermostat 6 is quietly thrown out, which should protect heated floors from too hot water getting into the heated floor pipes in emergency situations. Well, at the same time there is a bypass valve in the heated floor circuit. Babble! Total savings.

Here's what it might end up looking like:

A diagram for connecting a wall-mounted boiler in a combined heating system of a private house, modified by the power of popular thought.

Agree, everything has become much simpler, clearer, and most importantly - cheaper! One problem - it's not entirely correct. No, this scheme will work, and it works for many people, but it’s still wrong to do this, because:

- In this scheme there is no decoupling (independence) of the two remaining pumps of boiler 1 and the heated floor circuit 3, because they are connected to the common points of the circuit A and B, between which there is a large hydraulic resistance. Unlike the previous circuit with a hydraulic switch, where there is very little resistance between points A and B (D and C) (that’s why it’s a hydraulic separator).

- In some situations (when all radiators are closed and the heated floor is running), the boiler pump and the underfloor heating pump work sequentially, interfering with each other. This leads to changes in the coolant flow through the boiler heat exchanger.

- In situations where both radiators and underfloor heating are operating, the underfloor heating pump 3, at certain positions of the mixing valve 2, reduces the pressure difference between points A and B and thereby reduces the coolant circulation through the radiator circuit.

- And if boiler 1 stops, underfloor heating pump 3 still drives coolant through the boiler and through the radiator circuit, creating parasitic circulation. And if parasitic circulation through the radiator circuit can be dealt with by installing a check valve (at point A towards the radiators), then parasitic circulation through the boiler cannot be dealt with.

- Because did not install (forgot, clogged, drank,...) the protective thermostat 6, then in emergency situations (for example, a jammed mixing valve) if too hot coolant (over 55 ° C) gets into the heated floor pipes, destruction of the floor screed and floor covering may occur. And the pipes won’t say thank you if you apply 80 degrees into them.

- Due to the fact that there is no bypass valve in the heated floor circuit, when all the heated floor loops are closed (automatically or simply with playful hands), the coolant circulation in the circuit stops and pump 3, which, of course, no one turned off (well, they forgot, with whoever it is) works on a closed valve and heats up. Of course, a good circulation pump like Grundfos UPS 25-40(60) can probably work for a year in this mode, but sooner or later it will get tired of such a dog’s life...

A protective (safety) thermostat is always . That’s how it’s supposed to be, that’s the tradition.

But you don’t have to install a bypass valve, but only in cases where:

- or at least one floor loop will always be open;

- or the circulation pump will be frequency controlled;

- or the automatic control of floor heating circuits can also control the circulation pump, turning it off when all the floor heating loops are closed.

The only real salvation here will be case No. 1, because... Those who save on faucets and thermostats do not have either frequency-controlled pumps or smart room automatics for controlling heated floors. They are probably afraid...

Based on the shortcomings of the modified circuit, we urge you not to use it when installing a mixed heating system at home (with radiators and heated floors). Let's look at another full-fledged option, modified and tested by us.

Our proposed solution for a complete heating system top

Here is our proposed solution for a mixed home heating system with radiators and heated floors. The first picture is a version of the mixing unit with a three-way valve, the second is with a two-way valve. Both options are equally functional, however the second option may be more suitable for a larger area of heated floors, it all depends on the characteristics of the mixing valves (Kvs), you need to calculate. Generally speaking, when designing and installing a heating system, it is advisable not to forget to carry out calculations so that it works as it should. But this requires serious preparation and perseverance, and how can you sit here when your hands are itching to create something great...

Connection diagram for a boiler in a mixed (combined) heating system with radiators and heated floors using a three-way mixing valve. The section with a low pressure drop CD plays the role of a hydraulic circuit separator.

Connection diagram for a boiler in a mixed (combined) heating system with radiators and heated floors using a two-way mixing valve. The section with a low pressure drop CD plays the role of a hydraulic circuit separator.

The pictures show:

- heat source (wall-mounted gas or electric boiler) with a built-in pump, expansion tank, safety valve, etc.;

- bypass valve for the radiator circuit;

- mixing valve for underfloor heating (three-way or two-way);

- circulation pump for water heated floors;

- bypass valve for underfloor heating circuit;

- safety thermostat;

- balancing valve on a mixture for a two-way mixing valve.

C-D - section of the circuit with low hydraulic resistance, the distance between the tee branches is no more than 100..200 mm, acts as a hydraulic switch.

So, in our scheme, we also propose to use a boiler pump, which is built into almost any household wall-mounted boiler of reasonable power (up to 35 kW) to circulate the coolant in the radiator circuit. It would be unreasonable not to use its potential and further complicate and increase the cost of the heating system.

The fact is that the circulation pumps built into wall-mounted boilers provide a pressure at the boiler outlet of about 20..25 kPa (2.0..2.5 m.w.c.) at coolant flow rates of about 1000..1500 l/h (1.0 ..1.5m³/h). More precise data depends on the specific boiler and should be found in its instructions. For example, for a Baxi Luna 3 Comfort 24 kW boiler, the coolant flow will be 1100 l/h with a pressure drop at the boiler outlet pipes of 25 kPa. A flow rate of 1100 l/h at a temperature difference ΔT=20°K (standard) can provide a heating power of 24 kW. This means that if the radiator circuit has a hydraulic resistance of no more than 25 kPa, then the pump built into the boiler will be enough to transfer the full power of the boiler (24 kW) to the radiator circuit.

In order to take advantage of the potential of the boiler pump, and even ensure circulation through the heated floors in a separate circuit, they must be properly linked to each other. This is achieved in our scheme by organizing the so-called. ring circuit. This, fortunately, is not our invention, but ring circuits are most often used in heating systems in the United States. You can find out about these interesting solutions here Modern hydronics Multi-boiler heating systems with primary and secondary circulation rings. Let's take a closer look at our scheme.

Schematic representation of the proposed design of a heating system based on primary-secondary rings.

Our piping scheme contains two independent coolant circulation rings:

- Boiler circuit ring (boiler-radiators-boiler);

- Heated floor contour ring.

These two rings have one region C-D in common with each other. Structurally, this section consists of two closely spaced tees with outlets to the heated floor circuit. The close location of the tee branches (at a distance of no more than 100..200 mm from each other) guarantees low hydraulic resistance of this section C-D, and therefore extremely low influence of the circuits on each other. This is a kind of analogue of a hydraulic needle, only without the functions of a sludge trap and air separator. Well, you won’t be able to brag about it much, but it’s almost free, elegant and doesn’t take up space. The function of a sludge trap will be performed by an oblique mud filter with a mesh, which must be installed in the heating system, and there are air vents in the boiler itself (automatic), radiators and on the underfloor heating manifold.

Now how does it all work. The water heated in the boiler enters the radiator circuit supply (point A). Due to the pressure difference between the supply and return pipes of the boiler, the coolant passes through the radiators and returns to the boiler along the path: boiler supply-A-radiators-B-C-D-boiler return.

A bypass valve 2 is installed between points A and B, which we set to a pressure drop of 20..25 kPa. This means that as long as all or most of the radiators are open, the main coolant flow goes through the radiators themselves, and not through bypass valve 2. When part of the radiators is closed, excess coolant begins to pass through bypass valve 2. When the radiators are completely blocked (mode " only underfloor heating"), the entire flow passes through valve 2. Thus, a constant coolant flow is maintained in the boiler circuit. This, firstly, has a positive effect on the operation of the boiler heat exchanger itself, and secondly, the full flow of coolant is also always maintained in the CD ring section, from which we can remove heat for the needs of the heated floor.

When the circulation pump of the underfloor heating circuit 4 is turned on, the pressure difference it creates forces part of the coolant from point C to flow into the three-way mixing valve and, accordingly, at point D to return cooled from the underfloor heating circuit to the return of the boiler ring. Regardless of the speed at which pump 4 operates, how open valve 3 is, or how many underfloor heating loops are running at the moment, the amount of water entering tee C is equal to the amount of water leaving tee D into the boiler. Those. the amount of coolant passing through the boiler ring is constant.

When the boiler pump is turned off (the boiler stops when the required temperature is reached), parasitic circulation does not occur through the boiler heat exchanger. The coolant circulates around the ring of the heated floor circuit and only in the CD section of the boiler ring.

When the heated floor pump 4 is turned off and the boiler pump is turned on (the “radiators only” mode), the pressure drop in the CD section is not enough to cause parasitic circulation in the heated floor circuit. Check valves become unnecessary.

Bypass valve 5 in the heated floor circuit ensures minimal coolant circulation when the heated floor loops are closed. It can be omitted if the pump is frequency-controlled or if room-by-room automation for heated floors with a circulation pump control module is used.

Safety thermostat 6 is installed on the supply pipe of the heated floor circuit and if the temperature in the circuit exceeds 50°C, it turns off pump 4.

In a circuit with a two-way thermostatic valve, balancing valve 7 is necessary to adjust the degree of mixing of the coolant in the underfloor heating circuit. Its position is adjusted during commissioning of the heating system.

Eventually:

- It is possible to dispense with a hydraulic needle, an additional circulation pump for the radiator circuit and their piping elements without compromising the functionality of the heating system; all that is required is correct calculation ;

- The controllability of the heating system is simplified and the operating costs for electricity for the third pump are reduced (savings of about 20..40 kWh per month).

Conclusion to top

That, in fact, is all we wanted to tell you in this article about the combined heating system of a private house with radiators and heated floors from a wall-mounted gas boiler (electric boiler, heat pump, etc.). We looked at the standard scheme offered by all equipment manufacturers. We looked at typical mistakes that arise from ill-considered simplification of the heating equipment connection diagram. And they proposed their own alternative and fully functional scheme for a mixed heating system for a country house. In examples of work, you can look at the implementation of such a heating scheme at a specific facility, what might be needed for this and what it might look like.

An example of the implementation of a combined heating system. Heating system with radiators and heated floors in a country house based on a Bosch WBN 6000 HR boiler. An example of the implementation of a ring heating system.

If you need to design and install engineering systems for your home in Minsk and the Minsk region; you want to get advice and install a heating system, water supply, sewerage, ventilation, built-in vacuum cleaner, and perform electrical work; make the necessary calculations and select equipment; or you encounter difficulties in implementing your ideas - we will be happy to help you.

Using the built-in boiler pump

This scheme involves the use of boiler equipment with a built-in pump, the power of which is up to 35 kW. It creates a pressure at the outlet of the tank in the range of 20 - 25 kPa, with a water flow of 1000 - 1500 liters per hour.

The installation process is similar to that of a conventional heating element, but an additional pump for underfloor heating is not required.

To fully utilize the potential of the device and create coolant circulation in the heated floor and radiators, it is necessary to correctly connect the device to the circuits.

This can be achieved in this scheme by ring combination - the boiler with the TP, and with the radiator. These two rings are united by a small common area with low hydraulic resistance, thereby one circuit does not affect the other.

In this scheme, the slant filter acts as a slag catcher, and there are air vents in the boiler, radiator and floor circuit.

The essence of the functioning of the ring circuit is that water flows from the container where it is heated into the pipelines. Pressure surges in the supply and return pipes lead to the movement of liquid through the lines and its return back.

The most popular solid fuel boilers

The ranking of the most famous heating systems is headed by Finnish combination boilers. There is an explanation for this:

- The climate of the country is similar to the climate of Russia, the required power of the heating process can be achieved.

- Manufacturing companies already have extensive experience and capabilities in this area.

- The quality of the models is very high.

Jäspi Group is a well-known company specializing in the production of heating equipment. The boilers have good characteristics; they are equipped with heating elements. Another well-known company is Jäspi. Boilers of this representative:

- operate on solid fuel + gas/diesel;

- they have a copper coil and ceramic grates;

- have autonomous fireboxes;

- stand out for their high efficiency;

Diagram of the Tupla combi boiler from the Jäspi factory - capable of completely burning fuel and are cleaned once a year;

- characterized by small emissions of harmful substances.

The Jäspi Biotriplex line represents the latest model: no switching is required during transitions, the two fireboxes exist independently.

When can systems be combined?

It is permissible to install a combined heating system in premises of any purpose. The main thing is to choose the finishing product and the type of heated floor in accordance with the requirements. The combined design is ideal heating for a two-story private house.

When laying a heated water floor on the first floor, warm air masses, rising, will warm up the floors of the second floor, where only radiators can be installed. For the finishing material on the first floor it is better to choose tiles, and for the second floor any material is suitable.

It is not possible to build a combined system in apartment buildings, since it is prohibited to connect hydrofloors to the heat supply source for the entire house. The solution is to install a heat exchanger.

Why is there not a lot of TP in the house?

It should be noted that if you decide on water heated floors, there is little point in limiting their area . Let's say, do them only in two bathrooms and a hallway (the area of the TP will be about 20 m²). The best solution would be to install water heating wherever tiles are planned (usually hallways, halls, kitchens, pantries, and even living rooms, heated basement), and, if possible, in other rooms of the house, even bedrooms.

There are a number of reasons for this:

- A slight increase in price for a comfortable home. When implementing a water heated floor, even in a small area if there are radiators in the heating system, you will have to make a mixing unit with adjustment and pumps, buy a manifold and tie it with shut-off valves and pipes. Whether this mixing unit will work on 10 m² or 100 m² TP does not play a significant role. And the cost in both cases will be almost the same, because the shut-off valves, mixing valves and circulation pumps will be the same. Yes, the TP collector will, say, not have 2-3 circuits, but 10, but it will cost not 3-5 times more, but 2 times more.

- The screed will still be all over the floor. If you install heated floors only in some of the rooms within the floor, you still face the question of pouring screeds over the entire area of the house (floor). This is necessary so that you do not have steps and thresholds between rooms: this is inconvenient, unsafe, and simply ugly. There is no difference when pouring floors over a floor slab, insulation on a slab, or over insulation with warm pipes - it will cost the same (the price is based on the area of pouring). But then it will be very difficult to remodel and add water heating in other places in the future, and more often than not, it will be simply impossible.

- Insulation of the ground floor floor. This immediately raises the question of insulating floors in those rooms where, although there is no water heating, it is necessary to insulate them. This applies to ceilings above basements and floors on the ground. In all houses this is necessary to reduce heat loss.

Thus, the difference in money when increasing the heating area will be determined only by the cost of the pipe for the heated floor and the cost of its installation.

Errors and problems

To save money, many simplify the design, excluding important elements. But this should not be done for the following reasons:

- With closed radiators and a functioning heated floor, the boiler and heat pump pumps will interfere with each other’s operation.

- When radiators and floor heating are operating, the floor pump can reduce the pressure, thereby reducing the circulation of water in the radiators.

- Even when the boiler equipment is stopped, the TP pump moves liquid through the boiler and radiators, which is impractical. And if unnecessary movement of the coolant in the batteries can be dealt with by installing a check valve, then it will not be possible to stop the movement of water flows in the boiler.

- The absence of a protective thermostat can cause failure of the mixing unit, excessively hot water will enter the floor pipes, and there is a risk of damage to the screed.

- In the absence of a bypass valve, if the floor loops are closed, the circulation of liquid in them stops. Moreover, if you forget to turn off the pump, then it works on a closed valve and heats up, which leads to rapid failure.

You may not need to install a bypass valve if:

- one floor contour will be constantly open;

- the pump has frequency regulation;

- TP automation can control the circulation and, if necessary, turn off the equipment.

If you decide to heat a private house using a combined heating system - warm floors and radiators, you should familiarize yourself with all the diagrams, their pros and cons. Only then, you need to move on to choosing a model in accordance with your requirements, financial capabilities and characteristics of the room.

Connecting several boilers or heat sources

The use of several boilers in one heating system is forced by the cold climate and unstable operation of electrical networks. It’s good, of course, to have an automated boiler, but until the electricity is turned off and the automation stops working. If it is -20°C or lower outside, even a few hours of inactivity can result in the system freezing. Therefore, a non-volatile solid fuel boiler is often placed in parallel with an electric automated boiler.

There are many schemes for connecting two boilers into one heating system, but the easiest way to implement this idea is using a heat accumulator. In this case, it is possible to operate one boiler or both at once, which can be a solution during abnormal cold weather. Another good thing about this scheme is that you can connect both underfloor heating and heating. You can also easily add one of the alternative heat sources. Solar radiators have become the most popular recently. They are connected to the free inputs of the heat accumulator.

Heating with electricity

It's no secret that not all communication and engineering networks reach suburban villages. But one network is present always and everywhere. This is a power line. True, in most cases one can argue about the quality of supply, but electricity is available everywhere.

Therefore, heating the house using electric current is the best option. In this case, you can use heating devices such as:

- Oil radiators

- Electric convectors

- Heat fans

- Infrared emitters

- Electric boilers for water heating

The first four options are the simplest. All you need to connect them is an outlet. Such devices can be installed in any room and anywhere. Simplicity, convenience and safety are what characterize them. And the only negative is the receipts that you will receive for the electricity consumed. The numbers in them will be rather large.

But with a heating boiler that runs on electricity, there are more problems:

- Firstly, you will have to install the entire heating system, which includes pipes, heating radiators, shut-off valves and all kinds of devices for monitoring and regulating the temperature.

- Secondly, this is the boiler itself. It's not cheap, plus its wiring and connection. So you can’t do without financial expenses.

There is one more point that is worth paying special attention to. The supply of electricity largely depends on the quality of the laid lines and the power of the transformer. And power outages in most cases are associated with these two factors

And power outages in most cases are associated with these two factors.

The first is fraught with broken lines in winter. And if there is not enough transformer power for all consumers, the boiler will operate inefficiently. What can you do? Option one is to install a combination boiler that runs, for example, on both electricity and wood. You can choose another combination of different types of fuel.

Criteria for choosing a boiler for autonomous heating of a private house

When choosing the type of boiler for heating, there are no alternatives only if gas is supplied to the house; it is the cheapest type of fuel and, in comparison with other sources (electricity is not considered), has a number of operational advantages - it does not require space for storing reserves, highlight There are fewer combustion products released into the environment and does not pollute the chimney system as intensively.

The main parameters that people pay attention to when choosing a boiler are:

- Unit power: directly related to the area of heated premises and temperature conditions, which are usually chosen based on building codes and GOSTs.

- Number of circuits: if the house does not have hot water supply, it is more practical to choose a dual-circuit model that can heat water.

- Location: usually the unit is installed downstairs in the basement on the floor; there are also hanging options for small houses.

- Material of manufacture of the unit and heat exchanger: cast iron, stainless steel, copper.

- Type of combustion chamber according to the method of supplying air to the firebox: open or closed.

- Availability of automatic control and monitoring systems, possibility of programming operating modes.

- The ability of the boiler to work with alternative fuels: relevant for liquid fuel modifications.

Rice. 14 Design of the Rinnai gas boiler

When choosing a boiler, the following tips may be useful:

- If there is no hot water supply in the house, it is rational and cheaper to choose a double-circuit boiler model than to install a separate single-circuit unit and a gas water heater, an electric boiler.

- When using electricity, the night tariff is much cheaper than the day tariff, in this case you can save on the cost of electricity. To do this, at night they warm up the entire house, with the exception of the bedrooms, and during the day they turn off the boiler for a long time or operate it in the minimum heating mode.

- For reliable operation of all boilers controlled by automation powered from the mains, you should purchase an electric generator with automatic switching on in case of power failure - this will allow the boiler equipment to continue operating in case of emergency situations on the power line.

Rice. 15 Construction of a Kolton solid fuel boiler

Which pipes are suitable for combined heating

It is very convenient to install the water circuit for underfloor heating using cross-linked polyethylene pipes. Due to the flexibility of the material, products can be laid in rooms with complex configurations, and not just in a straight line. Installation of such pipes in a screed is allowed. Products are delivered to places of sale in coils, so it is not difficult to deliver them to the place of work.

As for connecting radiators, polypropylene pipes are suitable for these purposes. They are quite cheap and easy to work with. To install them, you will need to prepare a chamfer, nozzles, a socket welding machine and a shaver if the pipes are reinforced. In addition, for the installation of radiators, locking elements are also needed.

Heating with solid fuel boiler

Combined heating with a solid fuel boiler is a closed gravity system with a heat storage device. Both one-pipe and two-pipe wiring are allowed. To increase efficiency, it is worth installing chokes on each of the heating devices.

During operation of a solid fuel boiler, a large amount of heat is generated. It is better not to interfere with this process, but to redirect the excess heat to the heat generator. Then the fuel will be consumed efficiently, and the system will not quickly cool down after the fuel burns out in the boiler.

When the coolant in the main circuit begins to cool, hotter water from the heat generator will be supplied to the system. If the electricity goes out, the water supply from the heat storage tank stops and the bypass opens.

One of the best options for solid fuel boilers will be a unit with a pyrolysis type of combustion. The fuel in it is burned in two stages, which releases more heat and less carbon monoxide. Almost only carbon dioxide and steam remain at the boiler outlet.

Each consumer makes the final choice of a heating boiler, radiators, pipes for connecting them and for heated floors, as well as the wiring diagram, taking into account many factors. Among them are not only the costs of arranging the system, purchasing fuel and the principle of operation, but also personal preferences. If necessary, all work on system design can be ordered from professionals.

Features of assembling a forced circuit

In order for the forced system to justify itself and function properly, it is necessary to correctly select the circulation pump and correctly “embed” it into the heat supply line.

Selecting a circulation pump

The main parameters for choosing pumping equipment: device power and pressure. These characteristics are determined based on the area of the heated room.

Indicative indicators:

- for houses of 250 sq.m., a pump with a power of 3.5 cubic meters per hour and a pressure of 0.4 atm is suitable;

- in rooms measuring 250-350 sq.m, install the device at 4.5 cubic meters per hour with a pressure of 0.6 atm;

- if the area of the house is 350-800 sq.m, then it is advisable to purchase a pump with a capacity of 11 cubic meters per hour, the pressure of which is at least 0.8 atm.

In a more scrupulous selection, specialists take into account the length of the heating system, the type and number of radiators, the material of manufacture and the diameter of the pipes, as well as the type of boiler.

Installing the pump in the main

The pump is placed on the return line so that the coolant that is not too hot passes through the device. It is possible to install modern models made of high-temperature resistant materials on the supply line.

When inserting the pump, the water circulation should not be disrupted

It is important that at any point in the pipeline when the pumping unit is operating, the hydrostatic pressure remains excessive

Four acceptable schemes for heating systems with pump circulation and an open expansion tank. Hydrostatic pressure is maintained at the desired level

Option 1. Raising the expansion tank. A simple way to convert a natural circulation system to a forced one. To implement the project you will need a high attic space.

Option 2. Moving the tank to a distant riser. The labor-intensive process of reconstructing the old system and installing a new one is not justified. Simpler and more successful methods are possible.

Option 3. Expansion tank pipe near the pump nozzle. To change the type of circulation, it is necessary to cut off the tank from the supply line, and then connect it to the return line - behind the circulation pump.

Option 4. The pump is included in the supply line. The simplest way to reconstruct the system. The disadvantage of the method is unfavorable operating conditions for the pump. Not every device can withstand high temperatures.

Schemes for organizing water heating

To heat cottages, heating systems with water as a coolant are installed, consisting of:

- water heating boiler (single-circuit or double-circuit);

- pipelines and fittings (metal or polypropylene);

- bypasses that allow you to disconnect individual heaters from the network;

- batteries (cast iron, aluminum, steel and bimetallic);

- expansion tank.

Gas heating units are equipped with a specific safety system, including a solenoid valve and a thermocouple. The devices are connected to each other by wires.

If the heating unit is functioning normally, the thermocouple junction is heated by the igniter. At this time, current flows freely through the winding of the solenoid valve, which ensures the open position of the valve.

When the thermocouple cools down, the gas access is blocked by an electromagnetic valve.

According to the battery connection diagram, they are single-pipe and double-pipe. In the first case, water is supplied and discharged from the radiator using one pipe. In the second, the heating device is connected to two separate pipelines (supply and return).

Heating pipes to the radiators can be connected in a bottom, top, side or diagonal pattern

Heating circuits, based on the principle of water movement in pipes, come with natural and forced circulation. When installing the second option, the coolant circulates in the system due to convection and gravity. And the forced scheme involves the installation of a circulation pump.

To ensure normal operation of a system with two or more circuits connected to the manifold, it provides for the installation of a hydraulic arrow. The hydraulic arrow eliminates pressure drops and the possibility of water hammer.

The expansion tank can be open or closed (divided inside into two parts by a sealed membrane). For gravity heating systems, an open option will be sufficient. A closed tank is designed for forced circulation circuits.

When using an open expansion tank, the water is saturated with air, so that this does not become a problem, the system should be supplemented with an air removal circuit

For small cottages, the natural principle of water movement will be sufficient. However, if a residential building has two or three floors, then you cannot do without a pump. The length of the circulation circuit in the first scheme is limited to 30 meters. The boiler will not be able to “push” water over a greater distance.

With natural circulation of the coolant in the gas heating circuit of a private house, there is no pump. If the boiler is chosen to be non-volatile, then the entire heating system is independent of the power supply. There are simply no elements that consume electricity.

On the one hand, it is more stable in operation, but on the other, the quality of heating in it is lower (the water reaches the radiators farthest from the water heater when it is very cold).

The latter especially applies to pipelines and batteries made of steel or cast iron. These materials have high hydraulic resistance, which reduces the coolant current.

In addition to using standard radiators in a country house, you can organize gas heating using “warm floors”

It is also possible to organize a combined heating system. In it, the circulation pump is connected to the main line through a bypass. If it is necessary to quickly warm up the air in the rooms, it is turned on to accelerate the water circulation.

In other cases, it is cut off from the main pipe by shut-off valves, while the system continues to function in a natural (gravitational) mode.