The ventilation system is one of the elements that are present in almost every building. Few people even think about this part of the house. If the project is created with high quality, then it will provide comfortable conditions for people to stay inside for a long time. The damper for ventilation is an important part of this particular design. But what is he? This issue is discussed below.

In fact, a gate valve is a type of valve that blocks the flow of air, in full or in part.

operating principle of the gate

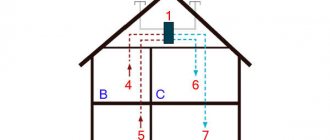

The principle of operation is also characterized by maximum simplicity - the same as that of conventional oven dampers. When the process of igniting the fuel begins, the damper is open. The blower is the starting point, then the air goes to the pipe, and the movement is powerful. This part is closed when combustion enters the active phase. This is necessary so that the fuel does not burn out instantly at such a moment. Complete closure of the valve occurs after the end of decay at the last coal. All that remains is a gap with minimal dimensions.

Stove valves become a kind of regulators for draft. They control the speed and intensity with which air flows through the chimney. Ventilation dampers are based on the same operating principle. This device increases or decreases the current of air jets. There are two additional functions:

- The resistance of air flows is equalized.

- Adjusting the transition from the main part to the branches.

Installation of gate dampers is acceptable for air ducts made of any materials; plastic analogues are no exception.

The main classification involves the presence of retractable and rotating products. Any of these types may include rectangular or round dampers. It is better to study the characteristics and features of specific designs in advance in order to understand which solution will be optimal.

Purpose and application

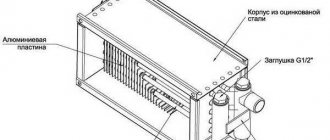

A ventilation damper is an ordinary damper, a valve, the main purpose of which is to regulate air flow. It can be used to increase or decrease air flow, and, if necessary, to stop it completely. In its most general form, a ventilation damper looks like a flat damper with a thickness of about 1 mm. It is made mainly from galvanized steel sheets.

Of course, the ventilation system will work without a damper, but will it be of high quality? After all, the ventilation of premises under any conditions and circumstances will always be the same. It’s another matter when ventilation systems are equipped with dampers. In this case, it becomes possible to completely control the flow of fresh air and reduce or increase its amount in the room if necessary.

So, having figured out what a damper is and why it is used in ventilation systems, let’s look at what they are like.

Description of the concept

The ventilation damper prevents the strong blowing out of air masses.

The ventilation damper serves to limit or completely block the passage of air flow. The device is shaped like a valve. Parts of similar design are used in hoods and water drainage systems. Dampers are used for air ducts made of any material, including polypropylene and plastic in general. Since fire safety regulations require that the chimney be made of fire-resistant material (brick or steel), a metal damper must be used for it.

The mechanism of operation of the part is identical to that of a conventional valve used to control draft in a pipe. When the fuel is ignited, an open damper activates the movement of air flows. While the wood or peat is burning, the part is left only slightly open to prevent smoldering too quickly. When the process is completely completed, the passage can be closed. The damper for ventilation functions in a similar way: it either activates or blocks air flows. The element can control the flows passing from the main node to the outgoing branches.

Types of ventilation dampers

Modern production offers the most diverse range of valves designed for use in ventilation systems. However, the entire existing set of gate types can be grouped into several categories:

| Category | Types of valves |

| Form | Round, rectangular |

| Design | Retractable, rotating |

| Control type | Manual, electric, pneumatic, hydraulic |

| Installation method | Installation in socket, installation using flanges |

| Material | Stainless steel, alloy steel, chrome steel |

The shape of the dampers is determined by the shape of the ventilation shaft - most often round valves are used, but in some cases rectangular valves are needed:

- There is a need to hide the gate while ensuring the minimum possible use of space.

- When installing ventilation systems that use electric heaters, since they themselves are predominantly rectangular.

Installation method

Installation of gate valves is carried out using four methods:

- Welded - the end parts of pipes and fittings are soldered using welding equipment. The result is a reliable, sealed, but non-separable unit.

- Flanged - if the end parts of the valve are equipped with flanges - round or square plates with holes, flange adapters are also installed at the ends of the pipes. To connect pipeline elements, the flanges are aligned and bolted together to form a detachable assembly.

- Threaded - the pipes are threaded, the connection is made using union nuts. The method is rarely used, since the threaded unit becomes loose due to vibration of the working environment and needs periodic tightening.

- Embedded - the body is laid horizontally between sections of a vertical pipe or shafts, the assembly is cemented. Used only when installing smoke shafts of heating units.

According to the installation method, there are two types of valves:

- coupling - has a full-fledged body with branch pipes, can be connected using flanged, welded and threaded methods;

- wafer - the body does not have branch pipes, in some cases the body consists only of a frame with saddles; such a valve is installed in a section of the pipeline or grooves in the chimney shaft and is connected using a welded, flanged or embedded method.

What is a gate valve

A damper for ventilation is a special valve, the main task of which is to completely or partially block air flows or bulk and liquid materials. Parts of this kind, in addition to ventilation systems, are also widely used in various drainage systems, wastewater channels, etc.

There are two main types of the described mechanism: horizontal and rotary gate. The second is also sometimes referred to as the "throttle valve". Unlike a horizontal type mechanism, it is quite unreliable, so its use is resorted to only in cases where installing a horizontal gate is impossible for technical reasons.

The duct damper is most often used in chimneys made of brick or steel. To ensure complete closure of the channel, it has a perforated shape. These requirements must be met in order to comply with fire safety requirements. It is also worth noting that there are automatic duct dampers with electric drive. The process of closing and opening such a mechanism is carried out remotely by pressing one button.

Features of cooperation with Vent Center

During the operation of our company (more than 20 years), we have acquired a large client base and earned an impeccable reputation. We value both our customers and our reputation, so we carry out all orders with maximum responsibility, guaranteeing high quality products, as well as reasonable prices. We not only sell finished products, but also accept orders for the manufacture of parts according to individual parameters. All work is completed on time, taking a minimum of time. Delivery is carried out within a few days after payment. You can come to our store, the address of which is listed on the website, or place an order online. The convenience of cooperation is facilitated by the choice of payment method for the client. Call us or leave a request on the website - experienced employees will always help with the selection of products for creating high-quality ventilation systems. We look forward to collaborating!

Classification

Modern industry produces many types of gate valves for ventilation, which differ from each other in many parameters. Gate designs vary:

- in shape - round and rectangular;

- according to its design, the gate can be retractable or rotary;

- by type of control - manual, automatic (electric drive), pneumatic, hydraulic;

- according to the installation method - using flanges or using the method of installation in a socket;

- according to the material of manufacture - anti-corrosion, alloyed or chrome-plated steel.

The external shape of the damper depends on the structure of the ventilation system in which it will be installed. However, in private situations, only rectangular gates can be installed. There are two such cases.

Round

As already mentioned, the shape of the damper used depends on the form of ventilation. Accordingly, the use of a round damper for an air duct is only possible if its shape matches the system pipes.

Rectangular

A rectangular valve for ventilation is used much more often than round valves. In addition to pipes, it can also be installed in chimneys, drains, wastewater systems, etc.

Moreover, in some situations, only a rectangular damper can be used for ventilation. There are two such cases.

- If there is a need to hide the valve, subject to a minimum amount of free space.

- During the installation of ventilation systems, the design of which involves the use of electric heaters.

Without flange connection

Installation may depend on what form is used for the damper in a particular case. For example, in the case of a round shape, the product is inserted directly into the pipe ends. These are the so-called bells. This installation does not require the presence of additional fixing elements. But the joining seam still requires sealing.

The choice of sealant depends on the temperature that will be maintained inside the installation. To solve the problem, heat-shrinkable cuffs with a hot-melt adhesive layer and sealing butyl rubber tapes are often used.

Types of gate valves

- Classic butterfly valve. Such a damper operates due to rotational movement inside the air duct. Such a gate installation consists of a metal body and a removable rotating disk. If used for a long time, it may become faulty, but replacing the part will not be difficult. You can perform this procedure on your own. Even in the absence of certain skills, you can do the entire design of a classic-type throttle installation with your own hands. This type of gate valve is easy to use and does not require constant monitoring by the property owner.

- Air damper for chimney. Refers to control parts that control the amount of fuel in the combustion chamber. Workflow management is carried out automatically.

Structural design of gates

Retractable and rotary damper designs are produced for use as part of various ventilation systems, based on various factors (air flow temperature, shape of the air duct on which the damper is installed).

Direct damper – the ventilation in which it is used is forced. Such devices are made of steel and installed perpendicular to the movement of air masses in the air ducts, which allows you to regulate the volume of their passage.

Another important detail in the design of a gate valve is a perfectly smooth surface. It promotes: good traction, resistance to sudden changes in temperature of the air flow and the environment, easy cleaning of dirt.

Important! The design of the gate, whatever its configuration, must meet fire safety requirements. This is achieved by the specific design of the plate itself - it is either perforated or has several cuts (holes). This design will not allow, even accidentally, to completely block the air movement.

In addition to the straight horizontal gate, rotary valves are available; they are called a throttle valve. They are a plate mounted on an axis. When the axis rotates, the plate also rotates. The body is made of metal, the damper is removable. This design can be made with your own hands, but it is rarely installed on ventilation due to the frequent breakdown of the plate and its constant replacement. The rotary handle is secured with a bolt and wing nut. Each turn opens the damper by 10°.

Design and operating principle

The gate consists of two elements - a fixed body and a movable shutter. Depending on the direction of movement of the shutter, there are retractable and rotary models. The simplest structure of a retractable valve, which is also called a knife gate valve. In it, the shutter moves perpendicular to the movement of air in the channel - a thin plate extends and easily blocks the flow. In rotary (throttle) models, the shutter rotates around its axis, gradually blocking the passage in the air duct. The simpler the structure of the gate element, the higher its reliability and longer service life. Traditionally, retractable valves are considered the most reliable and unpretentious in operation.

What is a gate and why is it needed?

Let's start with the definition. A damper is an adjustable, metal damper in a chimney that blocks the chimney channel. This is necessary in order to change the intensity of combustion and reduce the flow rate of flue gases. In addition, the damper prevents air from being drawn out of your home through the chimney, and also, on the contrary, does not allow external air flows to penetrate into the house. However, when the damper does not work effectively, it threatens with two problems at once: an unpleasant odor that will penetrate from the chimney into the house and high utility costs.

Typically, the chimney damper is located just above the fireplace at the entrance to the chimney. It forms a seal that prevents air flow. However, due to constant exposure to heat and moisture, the gate can become deformed, becoming a completely ineffective and useless device. But how do you know what condition your gate is in? This is quite easy to do, all you need is any bill, for example 20 hryvnia or one dollar. To find out how tightly the damper in your fireplace fits, leave a bill between the damper plates and close it tightly. Now try to get the money out. If the bill slides out easily, the slide is definitely letting a lot of air through.

If you don't want to use money for an experiment, there is another effective way. For this you only need matches. Light it in the fireplace and extinguish it immediately. Take a close look at where the smoke from the match goes; if it goes up the chimney, it's a sign that you're losing a lot of heat.

It is known that fireplace dampers remain open most of the time, which means that heated air from the house is constantly escaping through the pipe to the street. Because of this, heating costs increase by at least 30%. Therefore, do not forget to close the damper after the fire goes out. Another problem is partially closed dampers while the fireplace is operating. This should not be done; the damper must be open so that the fire receives enough air for clean combustion.

Rotary throttle

rotary butterfly valve

Rotary valves are not as widespread as the previous version. The operation is based on a rod, which is located in the center. A metal sheet is installed on it with rotation around its own axis. Due to this, the space is regulated and blocked if necessary.

This is a simple design that can be made on your own without any problems. But the moving part of the mechanism cannot boast of high reliability. Periodic replacement is required, which involves additional costs.

For installation, the socket and flange method is used. The differences lie in the fastening elements, which become relevant in each case.

Gate for ventilation system

Dampers designed for ventilation consist of a damper in a metal pocket. These structures are used to block a section of the air duct from the network.

The standard damper for ventilation has a nipple connection. The longitudinal size of the product up to the nipple grooves can vary from 70 to 200 mm. If the installation is carried out on round air ducts of impressive diameters, then guide angles are additionally used, which ensure good movement of the damper. Round gate valves can be based on stainless, galvanized or black steel. The thickness does not exceed 1 mm.

DIY making

Independent production and installation is impossible without the following devices at hand:

- Markers.

- Compass.

- Roulette.

- Kern.

- Welding with electrodes.

- Vise.

- Pliers.

- Hammers.

- Tap and oil to lubricate the threads.

- Drill.

- Cutting and grinding abrasive wheels.

- Bulgarian.

gate manufacturing

It is necessary to have a sheet of stainless steel of the domestic brand 12×18n10t. It is acceptable to replace it with an imported analog AISI304. The cost is higher, but the service life is also longer.

The minimum sheet thickness is 1.5-2.5 mm.

Other materials you will need:

- Rod for a metal frame.

- 2 bolts 8 mm.

- 6 mm stainless steel tube.

Specifications

The design of the dampers completely depends on the location of their installation, the temperature of the air masses and the shape of the air ducts. All valves have an absolutely smooth surface, which is dictated by operation under conditions of temperature changes and the need for regular cleaning. In addition, the damper must be perforated or equipped with a slotted hole. This will not completely block the flow of fresh air into the room and will ensure the preservation of a favorable microclimate.

The gates are retractable and rotary. The first ones are used in ventilation systems with forced circulation of air flows, and are straight valves made of steel. They are installed perpendicular to the direction of flow. This design allows you to control the volume of air passage and, if necessary, change it.

Rotary models, called butterfly valves, can be installed on natural draft ventilation. The models are presented in the form of a plate fixed to an axis, and are activated using a rotary handle. The handle, in turn, is secured to the plate with a bolt and wing nut, and opens the valve 10 degrees with each turn. All valve parts are made of galvanized steel and, if necessary, additionally painted.

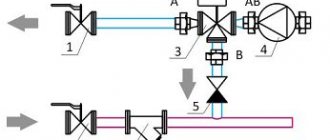

In supply and exhaust systems, dampers are installed in the air duct gap in front of the fan. This arrangement of the damper prevents the fan motor from overheating: when the fan starts, the damper is closed, and after the number of revolutions reaches operating parameters, it is opened. In this case, the gate acts as a starting damper, which increases the efficiency of the fan and extends its service life.

Structural differences

Modern design solutions in ventilation damper models require not only the ability to pull them out/retract, but even install them at a certain angle. The simplest option is a regular retractable gate. It is installed along an axis perpendicular to the movement of the air flow. The use of a damper in this design makes it possible to control the volume of incoming air.

When choosing this type of valve, you should first of all pay attention to the valve itself. For productive and long-term work, it must meet certain criteria:

- Have a perfectly smooth surface.

- Be resistant to sudden temperature changes inside and outside the ventilation system.

- Easy to clean.

The rotary gate is also called a throttle valve. This device is a little more complicated to use, but its capabilities are much wider. This mechanism consists of valves rotating on a central axis, for which a special handle is designed to regulate. It allows you to set a certain angle of inclination of the damper to improve the quality of room ventilation.

The throttle valve is thus a more advanced mechanism that allows you to precisely regulate the flow of air through the ventilation system. However, it also has a certain drawback - the plate tends to break frequently. This classifies this type of ventilation damper as not very practical and, in comparison, expensive.

Whatever the design of the device you purchase, it must be completely safe: meet fire safety requirements and make it impossible to completely stop the flow of air - even accidentally.

Size calculation

Even an extra gap of a few millimeters can be the cause of improper operation of the air vent.

Step-by-step steps to resolve the issue are as follows:

- First, take a tape measure to measure the size of the internal channel.

- 20-30 mm is added to the result. The result is the size of the outer frame.

- An opening for gas release is required for the finished valve.

- The position for the welding holes is also marked as accurately as possible.

Alternatives

These include numerous dampers and valves, differing both in their functions and in their design.

Fire dampers are designed to quickly stop natural or forced ventilation in the event of a fire, and also, conversely, to massively supply air to escape routes.

Depending on the initial position, valves are distinguished:

- Normally open;

- Normally closed;

- Double action.

The photo shows a normally open fire damper.

To activate the valve, the following can be used:

- Solenoid and return spring combinations . The solenoid can open the valve; close it; hold in the open and closed position, counteracting the return spring; be responsible for the operation of the lock that releases the damper.

- Fusible lock complete with spring . Valves with this operating scheme are cheap, but are capable of only one-time operation.

- Servo drive with motor and gearbox.

In addition, instead of oblique gates, throttling valves with manual or electromechanical drives are widely used.

Throttle valve.

Installation features

In most cases, the ventilation damper is installed immediately before the fan outlet. If their location coincides, then the design is called a starting gate, then its task is to protect the fan power unit from overheating.

You need to understand that you need to start the fan only when the damper is in the closed position. Otherwise, it will be affected by additional load, which in turn will quickly lead to failure of electrical equipment.

Important!

If you decide to install a damper in a ventilation system with a direct chimney with your own hands, then you need to know that it is quite difficult to carry out maintenance and cleaning of such a design in the future.

Like any other design, a gate valve has its own installation features. There are two main ways to install it:

- pipe-to-pipe method - the mechanism is installed in the chimney due to its design, this principle does not imply the use of additional fasteners;

- the shut-off device is mounted in front of the chimney exit or in the stove, respectively, becoming part of the overall structure; in this case, the maximum height at which the damper can be located cannot exceed one meter.

There is also another method of installing the gate - flange. When using it, you need to pay attention to two factors:

- fasteners that secure the smoke exhaust must be located at a short distance from the gate; they cannot be installed together with the main mechanism;

- all fasteners must be located exclusively on one side of the flange;

- During the installation of a flange type connection, additional sealing must be provided.

Using stove valves allows you to protect yourself from carbon monoxide poisoning. Information about the method of preserving heat in a stove is passed on from generation to generation. Everything is very simple, while the flame is burning - the damper should not be completely closed. Once the fire has gone out, the gate can be closed completely.

The valve, however, like any other mechanism, the creation of which does not necessarily require specialized tools, can be made independently without any problems. To do this, it is enough to have minimal theoretical knowledge and basic work skills.

Wafer connection

| terms of Use | Materials used |

| Temperature up to 40 degrees | Sealing tape 'Guerlain' |

| Temperature up to 70 degrees with a round duct section | Mastic 'Buteprol' |

| Temperature up to 60 degrees with a round duct section | Heat shrink cuffs, heat shrink tape |

In addition: it is practiced to seal socket joints with silicone sealants. SNiP does not prohibit their use: at the end of the list of recommended materials, it stipulates the possibility of using sealing methods not included in this list.

Flange connection

| terms of Use | Materials used |

| Transporting air with temperatures up to 70 degrees | Foam rubber, polymer mastic rope, various types of rubber (including porous) |

| Transporting air with temperatures greater than 70 degrees | Asbestos cardboard, asbestos cord |

| Transportation of acid vapors | Acid resistant rubber |

For flange connections, SNiP separately stipulates some assembly features.

- The hanger or support securing the air duct must not rest on the flange.

- All bolts should be located on one side of the flange.

- When the flange is in a horizontal position, the bolts should be on top of it and the nuts on the bottom.

Practical recommendations for selection and installation: what to look for

Traditionally, the damper is placed at the outlet of the air duct in front of the fan. If the ventilation network is branched, then it makes sense to install a separate damper for each branch branch. Closing them will increase air resistance and increase the efficiency of ventilation. To ensure a tight fit of the shut-off valves to the duct air duct, sealing and sealing compounds are applied to the connecting joints: silicone sealant, heat-shrink tape, bitumen-polymer mastic. But when installing gate valves on pipes of ventilation systems, it is impossible to achieve complete tightness of the unit. Since the gate damper, when closed, does not ensure complete tightness of the ventilation system, such models are not used in emergency ventilation systems intended for fire safety. If the part is mounted on duct equipment using a flange element, then it is secured with at least 4 bolts. In a vertical orientation, the bolts are placed on one side. If the damper is installed in a horizontal position, then the bolt heads are on top. Depending on the operating conditions, products from a certain material are selected. For standard domestic or industrial ventilation, valves made of galvanized steel are suitable. For rooms with high humidity, use a stainless steel option. Stainless steel gates are more expensive, but more durable. The correct operation of the ventilation system as a whole depends on the correct installation of individual elements. Knowledge of the operating principles and design features of dampers will allow homeowners to select the correct valve and use the capabilities of air ducts more effectively.

Self-installation of a gate valve

If you need to mount a damper for a brick kiln located in the house, you should do the following:

- first of all, lay out the first row of the chimney pipe from bricks;

- then make the next brick row and make a hole in it for a gate valve;

- In one of the bricks laid out in the second row, you need to create a groove for the handle for the valve of the fireplace or stove.

A groove is a recess or slot into which an object of a certain size can fit. This is a simple job that anyone can do.

The gate is also installed for heating boilers. It allows you to control the removal of gas particles, which leads to increased efficiency and economical consumption of fuel resources.

The slide damper is the main guarantee of fire safety when organizing stove heating; it is an essential part in the ventilation pipe, chimney and boiler.

A damper is one of the types of regulating and closing devices designed for installation in a ventilation system. The design of this element is not at all complicated; in terms of its operating principle and appearance, the part is similar to a furnace valve for a pipe.

The main component of the damper is a metal sheet that blocks the air flow if necessary.

Operating principle of gate valve

The simple and at the same time reliable principle of operation of gate valves largely predetermined their high popularity and indispensability in the organization of pipelines, designs of production and industrial installations, as well as sewer and other systems. So, the valve is always installed perpendicular to the flow of the working medium (air, liquid, gas with various impurities and components). Under manual mechanical or automated influence, the force from the rod or spindle is transmitted to the gate element, which is driven and completely or partially blocks the passage of the contents in the pipe. At the same time, a spindle installed in a limited space may not have a retractable design. In this case, the tightness on both sides of the gate is ensured by the pressure of the working medium. Also, a tight and reliable connection is achieved through the use of an oil seal made of synthetic fiber, dry or oiled cotton fiber, as well as graphite and other materials.

A polished and sharpened gate, shaped like a knife or guillotine, performs a smooth sliding movement between the working medium and the seal. Such a device helps to avoid temporary delays in the operation of installations or pipelines. The sharp ends of the gate with a strong seal ensure smooth and uninterrupted operation of the valve, reducing the likelihood of premature wear of the main working element, especially in the presence of aggressive environments, as well as many large components and impurities.

Frequent errors and problems during installation

There are several problems that most owners of this design face:

- Install handles that do not allow you to track the position of the valve.

- Carbon monoxide has nowhere to escape, there is no hole.

- The surface is not smooth enough.

- The use of thin grades of steel or stainless steel with a low nickel content. Such products quickly fail due to deformation under the influence of high temperatures.

- A metal chimney with a cast iron part inside. Such parts are not compatible with each other.

- A valve is installed in areas with insulation. Thermal expansion causes jamming.

What material is better to use a gate from?

Chimney valves are most often made of cast iron. True, the material is heavy, and then installing a cast iron gate is quite difficult. Yes, and it is only installed on brick kilns.

Steel gates are made 1 mm thick. What makes steel good is that it can withstand temperatures up to 900°C, has a special mechanical density and is resistant to corrosion. Also, the steel is smooth, and is even specially polished for this purpose to a shine, and therefore soot does not settle on such a gate and does not create a problem. And most importantly, it has sufficient thermal conductivity. This valve closes the chimney by 85%, and carbon monoxide is completely removed.

Why do you need a chimney damper?

Chimney damper

The required elements of stove heating are chimney dampers. Traditionally, their main function was to retain heat. A closed valve blocked the possibility of combustion products escaping into the chimney. As a result, the furnace not only heated up, but accumulated heat, due to the fact that hot flue gases could not escape outside and gave up their thermal energy to the channels. But life, as we know, does not stand still and neither does technological progress. Therefore, it became possible to further increase the efficiency of a brick kiln using an element such as a chimney damper.

What does the gate give?

Just like traditional chimney dampers, a damper allows combustion products to open or close access to the chimney. In addition, it performs several other useful functions:

- Regulates traction.

- Reduces fuel consumption.

In old furnaces, a gate, as a rule, was not installed. If you want to make your stove heating more efficient, you should install this simple device. Modern furnaces, as a rule, already have a flange with a gate included, but it can also be purchased separately. The simplest gate can be made with your own hands.

Before buying or constructing a damper for a chimney with your own hands, it is worth understanding the principle of its operation. During combustion of the furnace, the valve partially blocks the cross-section of the pipe, allowing flue gases to escape through the pipe and, at the same time, regulates the draft force. After stopping the fire, by completely closing the chimney damper, the release of gases stops. Regulating the thrust force simultaneously allows you to control and change the intensity and speed of fuel combustion. In modern heating devices, a damper must be installed in boilers.

The gate valve differs from a traditional gate valve in several ways:

- Resistant to high temperatures (withstands heating up to +900 degrees).

- Corrosion resistant.

- The ability to block the chimney during combustion up to 85% of its cross-section.

- Good thermal conductivity.

Drive types

To regulate the operation of the mechanism, different types of drives are used. This is due to different pipe capacities and different densities of the working medium.

- With the manual method, the valve is adjusted using a handle or lever. It is mounted on pipelines carrying liquids and gases of low density without solid inclusions.

- Electric drives allow you to adjust the position of the damper without physical impact. Such valves are used in large enterprises to regulate the flow of viscous, granular media with solid inclusions.

- Valves with pneumatic actuators have the most complex design. They provide the best tightness and are mounted on pipelines with remote adjustment and allow manual control.