Tell me, what are the main error codes that Navien boilers produce?

Brief description of errors and malfunctions:

01E – boiler overheating. 02E – low RH level. 03E – no signal about the presence of a flame or an open circuit of the flame sensor. 04E – false signal about the presence of a flame or a short circuit in the flame sensor circuit. 05E – open circuit of the exhaust temperature sensor. 06E – short circuit of the exciter temperature sensor circuit. 07E – hot water supply temperature sensor circuit open. 08E – Short circuit of the hot water temperature sensor circuit. 09E – fan malfunction. 10E – malfunction of the smoke removal system. 12E – flame goes out during boiler operation. 13E – short circuit of the OM flow sensor. 15E – malfunction or control board malfunction. 16E – boiler overheating. 17E – DIP switch setting error. 18E – smoke exhaust sensor overheating. 27E – open or short circuit of the APS air pressure sensor.

I have Navien 24k. For some reason there is a knock, as if someone is opening the door. Recently the indicator turned red and showed 10. The display jumps back and forth. What's the matter? Please tell me. One person came and said that there was scale and the radiator needed to be changed. It happened that when I came home and turned on a higher temperature, dirty water came out. Maybe the radiator is just clogged with rust? and can it be washed rather than replaced?

If you have a knocking sound in the lower right part of the boiler, then the three-way valve needs to be changed. If in the upper part (as if the kettle is boiling), then flush the heating circuit. And dirty water is already a water circuit. Either wash it or just look at the filter, and then draw conclusions.

A Navien 12 boiler is installed; when the burner is turned off, the pressure drops to zero, and when turned on, it rises to normal, and so on continuously. Could the expander diaphragm be torn?

when the boiler is zero, drain the heating water from it (glory below the pump). And check the pressure in the expansion tank. It should be 1.0 atm.

We turned off the lights and now the Navien Ace Coaxial boiler does not turn on at all, even the remote control does not turn on! what to do?

Try to close the wires at the output of the control unit; it should work at full speed; just close it at the output of the boiler and do not confuse it with the 220 power supply.

Please tell me where the Navien boiler is located. After turning off the hot water tap, the water boils and makes noise for a long time. In this case, no error is generated. I set the temperature to 30-36 for hot water, when it heats up it rises to 63 and automatically turns off. after min. 2 the burner lights up again and this continues until I fill the bath.

This is how it should be: a radiator with water is heated in the boiler, in which water is circulated in order to cool it faster after heating. To set up a bath, set the hot water supply to maximum, and mix the bath with cold water, either separately or through a mixer.

My ACE 30KN boiler does not have hot water. it's cold. I changed the secondary heat exchanger - without any effect. Am I right in thinking that the problem is in the three-way valve, taking into account the fact that during heating the water in the pipes is hot! Is it worth dismantling it, cleaning it and installing it back?!

That’s right, it’s a three-way thing. Cleaning will not help, only replacement.

I have a wall-mounted Navien. Can you please tell me how to set the temperature correctly? My batteries are at 80 temp and my house is 20 temp, is this correct or should I set the temperature to one thing?

If the boiler operates at temp. in the room (like yours is 20 degrees), then before this you need to set the temperature of the coolant (battery) to 75-80 degrees as much as possible. Otherwise, if, for example, the coolant temp. costs 50g, the boiler will heat up to 50g. and turn off, after a few seconds turn on. and off again. etc. And room temperature (in this case 20 degrees) may not be achieved.

Tell me I have an ace boiler. First it showed error 03 (no signal about the presence of a flame or an open circuit of the flame sensor), then 10 (malfunction of the smoke removal system) and finally 15 (malfunction or malfunction of the control board), and after opening the lid, water drips from the combustion chamber and there is also water in the fan!!

The main heat exchanger is covered.

I bought and installed Navien 16K today. And after launch, the problem is almost the same as in Nikolai’s previous question. I set, say, room temperature to 23 degrees. The boiler runs for 25 seconds, then turns off, after 30 seconds it turns on and so on constantly, and the temperature. on the remote control only 21 gr.

I set the temperature. according to the coolant, let's say 60 g. The boiler runs for about 40 seconds and reaches 61-62g. and turns off. In 15-20 seconds the temp. drops to 51 gr. and it turns on again and so on constantly. The pump runs all the time. There is suspicion about the three-way valve because... The DHW heat exchanger is hot, but the boiler is new. There are no problems with the hot water supply, when I turn it on and the heating pipes do not heat up. Maybe there are other settings that need to be made.

if there is no error on the display, then the reasons for such operation of the boiler (in addition to setting the temperature) are: the three-way valve does not work properly, the system is clogged somewhere, the pump does not work or does not push water, having lost power, the temperature sensor is fooling, the air is in system, the main heat exchanger is clogged. Well, in other cases an error should light up.

I am redoing the heating system, at first the water in the shower was normal, after two days the water stopped heating up altogether, it gives error 02 (low pressure in the heating system), heating will continue for three more days, what to do with warm water, can it be turned on?

Place plugs on the boiler on the heating circuit, feed the boiler to 1-1.5 bar. And using hot water supply is a pleasure.

I have a Navien Ace 20k boiler. It has been working for less than a year (10 months) and everything seems to be fine with it, but I am confused by the readings of the pressure gauge on its body: the needle does not rise above half a bar, and if the boiler is not in use (not currently heating water or batteries), at all stands at zero.

Error 16 - what does it mean?

According to the instructions from the manufacturer, error 16 on the device display may appear in one case - overheating of the heat exchanger. If such a process occurs, the emergency thermostat immediately transmits a signal to the electronic board and the boiler turns off. Overheating can be caused by a lack of coolant or its slow movement along the heating circuit.

What can be done at the initial stage

If error 16 appears on the display, it is not necessary to immediately call a technician. You can try to deal with the problem yourself. To get started, take the following steps:

- The boiler must be allowed to cool. But he must do it himself and gradually. You cannot “help” with antifreeze. The overheating sensor is activated when the temperature reaches +85 degrees, but as soon as it reaches +95, the unit is blocked. After the boiler has completely cooled down, you can try to restart it using the “On/Off” button. If the appearance of error 16 was caused by a power failure or the sensor itself gave a false signal, the problem will be resolved.

- Check signal circuits. Error 16 in a Navien boiler can be the result of a short circuit in the wires, their breakage, or burnout. During diagnostics, you also need to pay attention to the condition of the contacts.

Check the pressure. The heating circuit should normally be 1.5 bar. If for any reason it is lower, bring it to this indicator yourself.

If all these three methods have been tried, but there is no result and error 16 is still displayed on the display, then the problem is in the boiler itself or the heating circuit.

Operating instructions for Navien gas boilers

This document is a mandatory appendix to the technical documentation provided by the manufacturer when registering the device in the retail chain. Operation is carried out from the control panel, the model offers many modes of use.

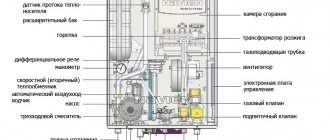

"Navien" mounted boiler operating instructions, structure and description of functions:

- Power (POWER) - on / off;

- combustion (COMBUSTION) displays the combustion process;

- pump (PUMP) status of the network circuit circulation pump;

- hot water (HOT WATER) - water heating temperature;

- low level (LOW LEVEL) - emergency water level in the circuit;

- overheating (OVERHEAT) – unacceptably high water temperature;

- sensor (SENSOR) – sensor malfunction;

- reset (MISFIRE) mode on the panel to factory settings.

Zont H-1 Navien Remote control module for Navien gas boilers

Buying a Zont H-1 Navien means purchasing a smart thermostat with its own SIM card, which allows you to control the indoor climate from any phone (satellite, mobile or fixed line), tablet or PC. The module is designed for remote control of Navien gas boilers (built-in support for the original protocol) or any others that can be controlled by commands from a room thermostat.

Operating instructions Zont H-1 Navien

Zont H-1 Navien is connected to Navien gas boilers to the connector for an external control panel.

Features of the Zont H-1 Navien GSM thermostat:

- Suitable for Navien gas boilers Deluxe models (thermostat with firmware 06/23/2020), ACE, ATMO, GA, GST, LFA, LST.

- Displays the current state of the boiler

- Displays the current room temperature

- There is a choice of preset operating modes to maintain the target temperature (air or coolant).

- Monitors temperature (air, coolant, hot water).

- Weather-dependent control algorithm (PCA). Allows you to control the operation of the heating boiler taking into account data on changes in temperature outside.

- It is possible to program the boiler operation according to a weekly schedule for the most optimal gas consumption.

- Monitors the status of additional sensors (leaks, gas leaks, security).

- Several home heating modes: Economy, Comfort, Schedule, Anti-freeze.

- You can simultaneously connect up to 10 temperature sensors (both wired and radio sensors) to the thermostat.

Temperature sensors are designed to monitor the current temperature and regulate the operation of the boiler. The sensors are connected to a special thermostat input. Each sensor has its own unique number, which is automatically determined by the service. After connecting the sensors, information about the temperature they measure is displayed in the web service, on the “Heating”, “Status” and “Settings/Temperature Sensors” pages. In order for the thermostat to control the operation of the boiler, it is necessary to assign a temperature sensor by which the current temperature will be controlled. The thermostat compares the current temperature with the set one and gives a command to turn the boiler on or off. If the boiler must maintain a given air temperature in the room, then in the assignment of sensors you need to indicate this sensor in the “By air” setting, and if the boiler must maintain a given temperature of the coolant, then in the assignment of sensors you need to indicate this sensor in the “By coolant” setting. If the temperature sensor assigned for regulation fails, control is transferred to the sensor designated as “backup”. If a backup sensor is not assigned, the Zont H-1 Navien thermostat goes into emergency mode and turns on the boiler heating at regular intervals: 15 minutes heating is on, 15 minutes – the boiler is cooling down. To measure the outside temperature, you can use the readings of an additionally installed outside temperature sensor or information from the standard boiler sensor (only when controlled via a digital bus). You can also receive information about air temperature via the Internet from a weather server.

How to increase the time between starting and shutting down a gas boiler?

If there is a problem with frequent switching on and off (“clocking”) of a gas boiler, you can change the difference between starting and stopping the unit. This is possible using the Navien engineering menu:

- Turn off the remote control and press two buttons “+” and “-” at the same time.

- A number from 2 to 20 appears on the display. Usually 8 or 10.

- Use the “+” and “-” keys to increase the delta value between start and shutdown.

- After 5 seconds, the remote control goes out.

- The boiler is turned off and then turned on again.

Now the gas unit will operate in a new mode.

The high-tech Korean gas boiler Navien is a leader in the heating equipment market. Units with a wide range of power are produced for heat supply to houses with a main gas subscriber station. By design, they can operate on liquefied gas. The model range allows buyers to make a fine selection of equipment based on real technical conditions and financial capabilities. They have an impeccable minimalist design. The elegant appearance of the boiler fits into kitchens of any size and configuration.

Air in the heating system

Error 16 appears if there is air in the heating system. In this case, we do not mean the presence of one large air plug, but the movement of bubbles along the circuit along with the coolant. As a result, the flow rate decreases and this affects the functioning of the device’s pump.

How to fix

The only way out is to bleed the air. But this must be done not in one specific place in the circuit, but wherever the corresponding fittings are installed. There is no need to rely on the valves to respond automatically, as they often become clogged or the springs weaken. You can effectively bleed air only manually by checking the heating of the radiators in each room.

They remove air not only from the system, but also from the pump. Here the principle is slightly different:

- Find a small washer on the end of the pump.

- Place a deep container under it.

- Unscrew the washer a maximum of 1.5 turns.

- A thin stream of water will appear.

- Drain until only liquid flows, no bubbles.

Rules of operation and timely maintenance

When purchasing a gas unit to heat your apartment or private home, you should remember that modern devices belong to the category of complex, high-tech, full of automation and protective systems. Therefore, in order to extend the life of the boiler and prevent its premature failure, it is necessary to follow certain operating rules.

- Firstly, this is installation in accordance with established requirements, according to the scheme recommended by the manufacturer, and not based on the advice of a familiar master.

- Secondly, these are high-quality materials and components: savings at this stage threaten to develop into financial costs for boiler repairs in the future.

- Thirdly, this is a thorough check of the condition of the sensors, chimney, water/gas supply before starting the boiler. Inspection and cleaning of main components should be done regularly, and not occasionally.

The automation will tell you the probable causes of problems by displaying coded messages on the display. Experience shows that following these recommendations will help avoid possible serious breakdowns and failures, which means that owners will not have to find out what typical malfunctions the Navienace boiler has and what will be required to eliminate them.

Boiler pump malfunction

Error 16 sometimes occurs when there are problems with the pump. The pump may not be damaged and work properly, but its operation does not correspond to the user-specified mode. In this case, you need to check:

- Pressure in the heating circuit. If there are frequent and sharp surges, these are the first signs of problems with the pump.

- Nutrition. It may be supplied from the board, but not reach the motor due to defective connections. Fixing such a breakdown takes 10-15 minutes.

- Impeller activity. To check it, the boiler is first turned off. Then remove the washer that covers the hole to remove air from the pump. In the center you can see the top of the motor shaft. A horizontal slit is visible on it. The functioning of the pump is checked using a simple screwdriver. They insert it into a horizontal slot and try to turn it. If this is easy to do, everything is fine with the pump, but if it is difficult, it does not work correctly. Reasons: deposits on the blades, bearing destruction, lack of lubrication (heat-resistant composition).

Starting the boiler

After all installation work has been completed and pressure testing has been carried out, the first commissioning start-up of the boiler equipment is carried out. All work is carried out by service center workers with the preparation of appropriate documents, which in the future will preserve the manufacturer’s warranty obligations.

When starting the Navien boiler, the instructions must be followed impeccably. Sequence of work:

- The circuits are filled with water through the unit’s make-up unit, built into the structure, with a special tap at the bottom next to the tap water inlet.

- Monitor the pressure gauge; when the pressure rises to 2.0 atm, close the tap.

- Remove air pockets. At the first start, it is performed in manual mode, and at subsequent starts, through an automatic system. They start the process from the most distant battery, opening the Mayevsky tap, and alternately go through all the points of the heating circuit.

- After etching the air plug, the pressure in the circuit will drop, so re-filling will be required.

- Discharge the air mixture from the circulation pump.

- To turn on the unit, press the “Power” button.

- The electric ignition will work and the unit will start, after which it is necessary to adjust the temperature regime.

Causes of Navien boiler malfunctions

Any malfunctions of Navien boilers that are under warranty must be carried out by a service organization.

Before visiting a service organization, the consumer needs to turn on the diagnostic system, analyze the probable causes of the failure and evaluate the possibility of repair.

Error codes in Navien boilers are classified according to 3 structural elements:

- leaks in the heating circuit;

- the ignition system does not work;

- low parameters in the gas network.

Not all errors require the participation of service specialists. For example, the absence of a torch in a piezo igniter can be caused by a failure of the primary flame sensor, zero gas fuel pressure in the line, when the head valve is mistakenly closed, or in the event of a faulty ground loop.

Therefore, troubleshooting begins with inspecting the primary sensor, which must be clean and without damage. After cleaning the surface of the primary sensor, the boiler operation is checked again.

Navien malfunctions

A gas boiler is a structurally simple device, but to ensure safe operation, any such units are equipped with automatic safety equipment, which serves to prevent serious accidents when operating errors occur. Almost all physical processes occurring during the operation of the unit are controlled by various sensors, information from which is sent to the control unit and continuously processed.

For the convenience of diagnosing and troubleshooting, information is provided to the user on the control panel display in the form of codes, which can be used to determine which specific system the malfunction has occurred and what checks can be carried out to eliminate it. Next we will look at the most common errors of Navien boilers in more detail.

Three way valve

Error 16 may occur if the three-way valve malfunctions. If there is a breakdown, then the boiler cannot switch between DHW and DHW modes. The price of a new crane is from 3 to 5 thousand rubles. But you can try to correct the situation yourself.

- system contamination;

- microswitch is broken;

- the motor is broken (low resistance, open circuit, short circuit);

- destruction of gears of the gearbox.

Only if the system is dirty will it be enough to clean it for error 16 to disappear. In other cases, you need to buy new parts.

Source

No flame

Recommended replacement parts

Troubleshooting methods:

- Problems in the boiler electrical network : we reboot the boiler and wait until the boiler cools down, if after cooling the error goes away, then the thermostat is working, but just in case you should always have such sensors - in reserve, the price is a pittance, and can cause a lot of problems during the season.

It is strictly recommended to connect heating boilers through a stabilizer (for the boiler) or a UPS; this will save you from unnecessary costs for replacing the control board.

- Failures in the gas supply to the house : often the gas supply pressure on the main line decreases and the boiler does not return to operating mode. The check comes down to igniting all the burners on the stove at maximum mode. Flames with a characteristic shade will indicate the absence of problems with the fuel supply, and their intensity and stability will indicate the constancy of the pressure and its normal value.

You also need to check:

- Position of shut-off valve controls? perhaps the gas supply valve to the house was accidentally turned off or the shut-off valve was activated during a power outage.

- We check the integrity of the electrode/ionization sensor: if the insulator is defective, or the sensitive elements (wires) are incorrectly positioned: they can be knocked down due to careless maintenance of the heat exchanger and combustion chamber. The malfunction is caused by a short circuit in the signal line or dampness.

- Checking the Navien gas valve: a gas leak in the valve often causes error 04 on the remote control display (pressure drops).

The pressure at the boiler inlet is measured with the valve on the pipe closed: you will need a pressure gauge (norm 130–250 mm water column).

Also, the winding often fails and cannot be repaired.

Malfunctions in the operation of the fan: it is not difficult to check the operation of the fan, you need to open the boiler lid and visually and auditorily verify its operation (rotation and noise of the impeller), it often happens that the fan elements wear out (rotor, stator, bearings) and it does not reach operating mode rotation/traction.

If the impeller is clogged, you can clean it with a toothbrush and a vacuum cleaner; it is also a good idea to disassemble and lubricate the bearing.

Error 16 - what does it mean?

According to the instructions from the manufacturer, error 16 on the device display may appear in one case - overheating of the heat exchanger. If such a process occurs, the emergency thermostat immediately transmits a signal to the electronic board and the boiler turns off. Overheating can be caused by a lack of coolant or its slow movement along the heating circuit.

What can be done at the initial stage

If error 16 appears on the display, it is not necessary to immediately call a technician. You can try to deal with the problem yourself. To get started, take the following steps:

- The boiler must be allowed to cool. But he must do it himself and gradually. You cannot “help” with antifreeze. The overheating sensor is activated when the temperature reaches +85 degrees, but as soon as it reaches +95, the unit is blocked. After the boiler has completely cooled down, you can try to restart it using the “On/Off” button. If the appearance of error 16 was caused by a power failure or the sensor itself gave a false signal, the problem will be resolved.

- Check the pressure. The heating circuit should normally be 1.5 bar. If for any reason it is lower, bring it to this indicator yourself.

- Check signal circuits. Error 16 in a Navien boiler can be the result of a short circuit in the wires, their breakage, or burnout. During diagnostics, you also need to pay attention to the condition of the contacts.

If all these three methods have been tried, but there is no result and error 16 is still displayed on the display, then the problem is in the boiler itself or the heating circuit.

Navien boiler error 10

This error is related to the smoke removal system of the gas boiler. Combustion products must be removed; for this purpose, the boilers are equipped with a fan. To control the operation of the fan and determine the presence of permissible draft for boiler operation, a differential relay is used, which is connected to the turbine by two plastic tubes. When the fan is running, a vacuum is created, the relay closes, and the boiler functions normally.

Reasons for error 10

may be a clogged chimney, the presence of reverse draft, or incorrect connection of the air pressure control sensor to the fan. For the latter case, you need to check that the yellow tube is connected to the bottom of the fan, and the transparent one is connected to the top, and the tubes themselves are not damaged, deformed or condensation inside.

Increased resistance in the chimney can occur due to direct gusts of wind or blockage of the chimney (bird nest or cobwebs, freezing in winter). That's right, the location of the chimney should be taken into account the direction of the winds of a particular region at the design stage and the chimney should not be installed on the leeward side of the house.

We focused on the most common malfunctions of Navien boilers, but in fact there are significantly more error codes. Methods for checking and troubleshooting are the topic of a separate article. For convenience, here is a summary table of codes with a brief description:

| Fault number | Brief description of the problem |

| 02 | Low water pressure in the heating system or breakdown of the flow sensor |

| 03 | No signal from the ionization electrode |

| 04 | Incorrect signal from flame sensor or short circuit. Make sure there is no contact of the ionization electrode with the boiler or burner body, and diagnose the control board. |

| 05 | Damage to the heating temperature sensor. Measure the electrical resistance of the sensor and its compliance with the temperature table, and make sure that the connection between the sensor and the control board is secure. |

| 06 | Short circuit of the heating water temperature sensor circuit. Ring or replace the sensor. |

| 07 | Damage to the DHW temperature sensor. Check the dependence of the resistance on the temperature on the sensor, make sure that the connection of the sensor to the control unit is secure. |

| 08 | Short circuit of the DHW temperature sensor. Ring or replace the sensor. |

| 09 | Fan failure. Measure the resistance of the fan winding (test value is approximately 23 Ohms). Make sure that there is a voltage of 220 V at the fan terminals. There may be a problem with the control board circuit (diagnostics of the Navien board is required) |

| 10 | Malfunction of the combustion products removal system |

| 13 | Short circuit of the CO flow sensor. The sensor is stuck or the control unit is faulty. |

| 15 | Internal control board error (requires diagnosis and repair) |

| 16 | Boiler overheating. Signal from the emergency thermostat. The causes of overheating may be insufficient coolant circulation (see error 02), a clogged heat exchanger, or a malfunction of the thermostat itself. Operation occurs at 98 degrees, the alarm turns off when it cools down to 83 degrees. |

| 27 | Open or short circuit of the air pressure sensor circuit |

Air in the heating system

Error 16 appears if there is air in the heating system. In this case, we do not mean the presence of one large air plug, but the movement of bubbles along the circuit along with the coolant. As a result, the flow rate decreases and this affects the functioning of the device’s pump.

How to fix

The only way out is to bleed the air. But this must be done not in one specific place in the circuit, but wherever the corresponding fittings are installed. There is no need to rely on the valves to respond automatically, as they often become clogged or the springs weaken. You can effectively bleed air only manually by checking the heating of the radiators in each room.

Error codes and how to fix them

Let's look at the most common mistakes in the video. For this, many thanks to the Repair-31 channel.

Error 03

Error 02

Error 10

Automated self-diagnosis complexes, in combination with boiler protection systems, prevent the most serious breakdowns almost at the initial stage. When detecting a particular malfunction, the program turns off the boiler and displays a code on the LCD display.

The most common failures of Navien boilers:

- E01 indicates overheating of the coolant in the boiler unit. For atmospheric ATMO models, the electric pump does not function, since in these modifications there is no heating medium flow sensor, so the pump will need to be replaced. You must first check the operation of the heating system for airiness and the presence of contamination in the filter installed in front of the boiler unit.

- E02 indicates a network water circulation error. Error 02 on the Navien boiler is eliminated by checking the circuit for leaks. The pressure in the network is set from 1 to 2 bar; if necessary, the network must be recharged. Check the operation of the shut-off valves and three-way valve; they may be blocked. Check the operation of the flow sensor. If after these procedures the problem is not resolved, the board must be replaced.

- E03 indicates the absence of an electrical signal due to the presence of a flame in the firebox or a break in the primary sensor line. In the Navien boiler, error 03 is checked in the inspection window for the actual presence of a torch. If it is not there, check the electrical resistance of the coils on the gas line cutoff. Monitor the presence of a spark on the electronic ignition system and the gas pressure in front of the boiler unit. The torch may come off due to the large volume of air supplied by the fan.

- E04, false alarm due to flame in the burner. Error 04 on the Navien boiler is possible due to a leak in the gas shut-off valve or a spark from the ignition system is supplied to the flame sensor. The electrode unit will need to be replaced. If the problem persists after this, the board will need to be replaced. You will first need to check the grounding in the boiler with a resistance limit of at least 4 ohms.

- E05, error 05 - there is a break in the return temperature sensor line or its temperature is less than 14 C. Before carrying out repairs, check the humidity at the sensor connection.

- E06, error 06 - short circuit in the return temperature sensor line or its temperature is above 120 C. Check the electrical resistance of the sensor: 20 C - 10.0 kOhm, and 50 C - 3.6 kOhm. If the value is not normal, the sensor will need to be replaced.

- E07, violation in the DHW sensor line. A similar sensor check as above is needed.

- E08, short circuit in the DHW sensor line. A similar sensor check as above is needed.

- E09, error 09 - fan malfunction. You will need to check the incoming voltage on the board in the inclusion zones of the black and red conductors. If the voltage parameters are normal, but the rotation speed is low, less than 420 rpm, it is necessary to replace the electric fan, since ignition will not occur. If the electric fan speed is 2100 rpm. and the failure is not resolved, most likely there is a short circuit in the triac line; the electronic board must be replaced.

- E010, error 10 confirms a failure in the smoke exhaust circuit due to clogged smoke exhaust channels. It is necessary to inspect and clean the chimney, and pay attention to the air intake grille to see if it is clogged with foreign substances.

Boiler pump malfunction

Error 16 sometimes occurs when there are problems with the pump. The pump may not be damaged and work properly, but its operation does not correspond to the user-specified mode. In this case, you need to check:

- Pressure in the heating circuit. If there are frequent and sharp surges, these are the first signs of problems with the pump.

- Nutrition. It may be supplied from the board, but not reach the motor due to defective connections. Fixing such a breakdown takes 10-15 minutes.

- Impeller activity. To check it, the boiler is first turned off. Then remove the washer that covers the hole to remove air from the pump. In the center you can see the top of the motor shaft. A horizontal slit is visible on it. The functioning of the pump is checked using a simple screwdriver. They insert it into a horizontal slot and try to turn it. If this is easy to do, everything is fine with the pump, but if it is difficult, it does not work correctly. Reasons: deposits on the blades, bearing destruction, lack of lubrication (heat-resistant composition).

In some cases, the situation can be corrected by installing a new shaft, cleaning the system, or removing air from the circuit. If all this does not help, it is better to contact a specialist.

Navien boiler circulation pump

Tips and recommendations for operating the Navien boiler

The main advice from experts regarding the safe operation of the boiler:

- The room where the unit is located must have good ventilation.

- The unit must have a separate independent connection to the electrical network.

- The boiler must operate in a fully assembled and protective housing.

- The user is prohibited from independently repairing the gas equipment of the boiler.

- The boiler must undergo an annual inspection by representatives of Gorgaz.

- The boiler owner must periodically check the joints of the boiler and the gas pipeline for leaks with a soap solution.

Additional Information. If leaks occur, immediately turn off the gas valve, ventilate the room and call the emergency gas service.

Navien gas boilers have been used by Russian consumers for a long time. They have rightly earned the trust of customers. The lightweight layout with the widest range of modern water heating functions allows you to choose these models from a large list of offers on the heating equipment market.

Three way valve

Error 16 may occur if the three-way valve malfunctions. If there is a breakdown, then the boiler cannot switch between DHW and DHW modes. The price of a new crane is from 3 to 5 thousand rubles. But you can try to correct the situation yourself.

- system contamination;

- microswitch is broken;

- the motor is broken (low resistance, open circuit, short circuit);

- destruction of gears of the gearbox.

Only if the system is dirty will it be enough to clean it for error 16 to disappear. In other cases, you need to buy new parts.

Review of less common errors

There are other less common failures that indicate malfunctions in the operation of Navien boiler units and the need for repairs:

- E011, violation of the established parameters for the level or pressure of the medium in the heating circuit. This failure appears on the LCD display of a unit with an automatic water supply system. To eliminate the breakdown, it is necessary to disconnect the heating system, diagnose the functionality of the water make-up valve, drain the residual water in the electric pump drain, reconnect it and start the boiler again.

- E012, error 12 - no flame in the boiler furnace. There can be many reasons; it is recommended to use the elimination algorithm as for errors E003-E004. First check whether the main gas valve is closed, there is voltage in the boiler supply line and whether the grounding system is reliable.

- E013, error 13 characterizes a short circuit in the line or no power supply to the heating circuit flow sensor.

- E015, error 15 - malfunction of the control board. In the event that there is no response to the supply of electricity, repair or replacement will be required.

- E016, error 16 indicates overheating of the element in the system. Any component can overheat: the electric motor of the blower fan, the heat exchanger, the electric motor of the centrifugal pump. You can independently clean the installed filter in front of the boiler, the heat exchanger and replace the thermostat.

- E017, failure caused by a DIP switch, you will need to adjust the control board options and restart the boiler.

- E027, error 27 - failure of the primary pressure sensor. Check the blockage, the smooth operation of the sensor and the blower fan. If a breakdown is detected, replace the faulty part.

- E030, excessive heating of the smoke thermostat. It is necessary to turn off the boiler unit, allow time for it to cool for at least 30 minutes, after which the unit is restarted. If the failure is not resolved, check the blower fan and the primary air pressure sensor, and clean the smoke ventilation system.

- E 093, “on/off” button is faulty It can be replaced with your own funds.