At the moment, the most common heating device in our country is the MS-140 cast iron heating radiator. The reliability, durability and practicality of this device have been tested in practice for many decades. The production technologies of these batteries are already outdated, but they still heat tens of thousands of homes, administrative, office, commercial, industrial and public buildings throughout Russia.

Our citizens have been familiar with these heating devices for a very long time.

Features of painting technology for cast iron batteries

Cast iron batteries have a fairly long service life.

But no matter how well they are looked after, sooner or later their surface will wear out. Scuffs, cracks and peeling paint will ruin any interior. To paint radiators, you need to know the surface area to be coated. Painting heating radiators begins with preparatory activities. It is necessary to clean them from dust, dirt and old coating. To do this, each section is wiped with a wet cloth.

Particular attention is paid to the inside and back sides

Before painting radiators, they must be cleaned.

The paint is removed using one of the available methods. This could be the use of chemicals such as Dufa, SP-6, B52, ACE. But these products are powerless over oil coatings, which were used in the last century. In this case, physical methods are used. These include a drill with a special brush attachment, sandpaper, and a file. A hair dryer or blowtorch works well for peeling off paint. If necessary, you can use several methods in combination.

When the radiators are cleaned, they are coated with a primer. The mixture should not react to high temperatures. It is also chosen according to the type of paint. So that there are no “disagreements” between them, you can take the compositions of one company.

The work of priming and painting batteries can be done with any brush. It is necessary to protect your clothing and the surrounding area. To do this, they put on old clothes and spread newspapers on the floor. Painting activities take place in several stages. It is better to paint the batteries in two layers to get a smoother and better surface. Painting the intersectional space and hard-to-reach places is done with a flexible brush. You can use gauze. A rope is made from it, which is laid between the sections, paint is applied to the middle and the ends are pulled in turn.

Materials and technical characteristics of cast iron radiators MS-140-500

Radiator sections are cast from gray cast iron SCh 10 GOST 1412-85. The radiator sections are connected using a radiator nipple equipped with pipe threads in accordance with GOST 6357-81.

To tighten the radiator sections, there are left and right threads on the nipple from opposite ends. The material from which the nipples are made is malleable cast iron grade KCh30-6-F according to GOST 1215-79, steel 08 KP or 08 PS according to GOST 1050-2013.

The nipple is installed between the sections. Its rotation is carried out using a key with a straight tip. Due to the fact that the nipple is threaded in different directions, the sections are pulled together. It is accessed through the open radiator hole.

The resulting connection is sealed using an annular gasket. The gasket material is heat-resistant rubber ITP or ITC, corresponding to TU 38 105376-82, or ring 9833-73 / 18829-73.

If it is not possible to install a rubber gasket, it is possible to seal the joints using tow.

Tow is impregnated with red lead or drying oil. The end of the radiator battery is closed with a plug made of gray cast iron SCh 10 GOST 1412-85. Table 1. Technical characteristics of radiators MS-140-500

| Manufacturer / Characteristics | Minsk Heating Equipment Plant | OJSC "Santekhlit", Bryansk region | Nizhny Tagil boiler and radiator plant Novosibirsk (Russia) | Lugansk Foundry and Mechanical Plant (Ukraine) | |

| Marking | MS-140-500 | MS-140-500-0.9 | MS-140-M2-500 | MS 140/500 | MS-140-M4-500-0.9 |

| Height, mm | 588 | 590 | 580 | 588 | 588 |

| Width, mm | 108 | 98 | 90 | 93 | 98 |

| Depth, mm | 140 | ||||

| Weight, kg | 7,12 | 6,25 | 6,25 | 7,1 | 6,74 |

| Distance between hole centers, mm | 500 | ||||

| Through hole size, inch | 5/4 | ||||

| Water volume in section, l | 1,45 | 1,45 | 1,4 | 1,45 | 1,33 |

| Number of channels in a section | 2 | ||||

| Permissible coolant temperature, degrees. | 130 | ||||

| Heat transfer value of the section, W (t=70 degrees) | 185 | 160 | 160 | 160 | 184 |

| Warming up area per section sq.m. | 0,244 | ||||

| Permissible coolant acidity, pH | 6–9 | ||||

| Test pressure, MPa | 1,5 | 1,5 | 1,8 | 1,5 | 1,6 |

| Working pressure, MPa | 0,9 | 0,9 | 1,2 | 0,9 | 0,9 |

These models can be used with almost any type of coolant that meets acceptable acidity standards.

Transportation and storage rules

The MC 140 radiator belongs to the category of thin-walled equipment, therefore, to maintain integrity and prevent cracks, throwing or dropping the product is prohibited.

Equipment can be transported by any type of transport, provided it is protected from mechanical damage, falls, and precipitation.

Cast iron products should be stored in a dry room under a roof or canopy. The temperature conditions of the storage room are from -50ºC to +50ºC. Air humidity indicators at +15ºC – 80%, at +25ºC – up to 100%.

Acceptable ways to stack radiators for storage are in stacks up to 1.5 m high or in bags - no more than two, one above the other.

Loading, moving, unloading of stacks or packages can be done mechanically using forklifts or cranes. The pre-moved lot must be firmly secured to the pallet.

Real heat transfer of the radiator section

As already indicated, the power (heat transfer) of radiators must be indicated in their technical passport. But why, a few weeks after installing the heating system (or even earlier), does it suddenly turn out that the boiler seems to be heating as it should, and the radiators are installed according to all the rules, but it’s cold in the house? There may be several reasons for a decrease in the actual heat transfer of radiators.

Cast iron radiator Viadrus (Czech Republic)

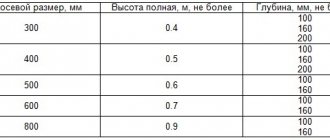

We present the indicators of the heating surface and the declared heat transfer for the most common models of cast iron radiators. We will need these figures in the future for examples of calculating the real power of the radiator section.

As already mentioned, when using such radiators for medium- and low-temperature heating systems (for example, 55/45 or 70/55), the heat transfer of a cast-iron heating radiator will be less than that stated in the passport. Therefore, in order not to make a mistake with the number of sections, its actual capacity must be recalculated using the formula:

K is the heat transfer coefficient;

F is the heating surface area;

∆ t - temperature difference °C (0.5 x (tin. + tout.) - tin.);

tin – temperature of water entering the radiator,

tout – water temperature at the radiator outlet;

tin . - average air temperature in the room.

At an incoming coolant temperature of 90 degrees. coming out 70 gr. and the temperature in the room is 20 degrees.

∆ t = 0.5 x (90 + 70) – 20 = 60

The K coefficient for the most common cast iron radiators can be found here:

Even the actual heat transfer of one section of an average cast iron radiator with an area of 0.299 sq. m (M-140-AO) at an incoming water temperature of 90 degrees. and the output - 70 grams will differ from the declared one. This occurs due to heat loss in the supply pipes, and for other reasons (for example, reduced pressure), which cannot be foreseen in laboratory conditions.

So, the heat transfer of a section with an area of 0.299 sq. m. at a temperature of 90/70 will be:

Considering that heat transfer is always indicated with some margin, we multiply this figure by 1.3 (this coefficient is used for most cast iron radiators) and we get: 125.58 x 1.3 = 163.254 W - compared to the declared 175 W.

There will be an even greater difference in the numbers if the water entering the radiator does not heat above 70 degrees. (and the exiting coolant, accordingly, cools down to 60-50 degrees), so before buying new radiators, it is advisable to find out the real thermal parameters of your heating system.

How to save on heating?

The first rule of reasonable saving is to remember what you should never save on! Radiators should always be taken with a reserve, because you can reduce the temperature in the room by reducing the temperature of the water in the system or using shut-off valves. But if the actual heat transfer turns out to be lower than that declared by the manufacturer, the rooms will be cool at best. By the way, Conner cast iron radiators, which are quite good in most respects in terms of actual operation, have a heat transfer rate that is 20-25 percent lower than indicated in the data sheet.

Radiator 1K60P-500 (Minsk)

As already indicated, heat transfer may differ from the declared one due to the fact that the water temperature in the heating system is much lower than the “standard” one, that is, the one at which factory tests were carried out, since the declared radiation power is achievable only under laboratory conditions. Imagine that the MS-140 radiator section (160 W power indicated) at a water temperature of 60/50 degrees. (and the “boiler can’t handle any more”!) will produce a power of no more than 50 W. And if you believed the technical data sheet and decided to install 5 heating sections, then instead of 800 W (160 x 5) you will get only 250.

However, it is quite possible to foresee this situation and even take advantage of it! Based on the calculations given above, the lower ∆ t (that is, the temperature of the coolant water), the larger the radiating surface of the radiator should be. So, at ∆ t 60, for 1 kW radiation, a radiator with a height of 0.5 m x 0.520 m is sufficient, and at ∆ t 30 - 0.5 m x 1.32 m.

“Traditional” cast iron radiator MS-140M2

However, it is precisely due to the low temperature of the medium and increasing the radiating area of the radiator or the number of sections that heating costs can be reduced.

New generation radiators

Cast iron batteries of the new generation look much more attractive in appearance than old-style devices. They have a modern look and visually resemble radiators made of aluminum or steel. They have a flat front panel and a smooth surface. Some products already have factory enamel applied, other models are sold without it, and you will have to paint them yourself.

More recently, new generation cast iron batteries were imported only from Europe (Czech Republic, Italy) and China. Now they are already produced in Russia, Belarus and Ukraine.

Cast iron radiators CONNER HIT, Modern - European design

What are the advantages of modern radiators from European manufacturers? Their advantages include:

- high quality coating, they are marketed painted, while domestic models are only primed;

- smoother shape (both outside and inside);

- sections of smaller volume;

- higher level of heat transfer;

- less weight and dimensions.

Thus, imported models have more advantages than domestic ones, but they also cost significantly more.

Installation Rules

The number of sections has been calculated, the radiators have been purchased, and all that remains is to install them. There are two options here - seek help from specialists or do everything yourself. If financial possibilities are limited, then we carry out the installation process ourselves.

For fastening cast iron radiators, the following are used:

- Pin brackets - when the wall is made of gypsum concrete blocks or bricks.

- Corner brackets - when the wall is wooden.

1 sectional radiator requires 3 brackets, which are secured using a drill and dowels. The next step is to remove the film from the cast iron structure and connect the supplied pipes to the battery so as not to damage the threads and avoid water leakage from the heating system. The distance from the floor to the bottom edge of the radiator is at least 10 centimeters, and between the wall and sections - up to 5 centimeters.

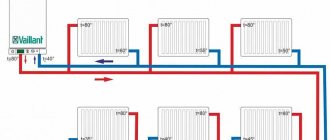

Radiators can be connected either in series or in parallel. Regardless of the method chosen, you first need to turn off the coolant supply through your riser. To do this, you will have to contact a service organization - a housing office or a housing department. After the riser is closed, you need to drain the remaining coolant from the old radiators and pipes. After dismantling the old heating devices, you can connect new cast iron sections.

Assortment in the store

You should work carefully so as not to strip the thread, otherwise you won't have any problems. Having opened the Mayevsky tap, it is necessary to release the air accumulated in the heating system and supply coolant by opening the riser

Installation of radiators with parallel connection is carried out similarly to the first method and differs only in that if there are shut-off valves, you will not have to block the central riser. If desired, modern temperature sensors and thermostats are inserted into the radiators, which allow you to regulate the heating temperature of the radiators.

Installation

The number of sections has been calculated, the radiators have been purchased, all that remains is installation. There are two options here - turn to specialists and spend money, or do everything yourself. Let's consider the second option.

Installation process

Selecting fastenings

The first installation step is choosing a mount for the radiator. In the photo you can see different types of fastenings.

For example, for sectional radiators, pin and corner brackets are used. The first ones are used to fix the battery on a wall made of brick or plaster, and the corner ones are used if the wall is wooden. You should also remember that for corner fastening you need to stock up on screws and dowels.

Types of fasteners. As you may have guessed, fastenings No. 3 and No. 4 are applicable for our case.

Direct installation

At this stage you need to select places to install the brackets. Remember that one radiator requires at least three brackets. Afterwards, using dowels and a drill, you need to secure the brackets.

The next step is to attach the radiator to the brackets.

Advice. There is no need to immediately tear off the protective film from the radiator; first install it on the brackets, and then, without fear of scratching the radiator, remove the film.

Connection examples

Carefully connect the supplied pipes to the radiator. Fasten carefully and carefully, but do not damage the threads, otherwise you will experience water leakage from the system. Before watching, check out the installation video in our gallery.

During installation, it is important to maintain certain distances. For example, the installation height above the floor should be approximately 10 centimeters. The distance between the wall and the battery should be from 2 to 5 cm.

Find out also about the features of electric double-circuit heating boilers.

Calculation of the mass of domestically produced cast iron radiators

Many Russian manufacturers continue to produce classic finned batteries, since they are still in demand. The material varies (lighter alloys) and the number of sections, the weight of which must be indicated in the technical description for the model. The most popular varieties differ slightly and are classified as FM and MS.

Based on the documentation, the weight of 1 section of FM radiators without coolant (water):

| Model | Weight, kg |

| World Championship1-70-300 | 3,3 |

| World Cup1-70-500 | 4,8 |

| World Championship2-100-300 | 4,5 |

| World Championship2-100-500 | 6,3 |

| World Championship3-120-300 | 4,8 |

| World Championship3-120-500 | 7,0 |

Total weight of 1 section of cast iron radiator with water:

| Model | Weight, kg |

| World Championship1-70-300 | 3,95 |

| World Cup1-70-500 | 5,7 |

| World Championship2-100-300 | 5,2 |

| World Championship2-100-500 | 7,25 |

| World Championship3-120-300 | 5,75 |

| World Championship3-120-500 | 8,4 |

The format (dimensions), thickness of cast iron walls and number of channels determine the weight of one section. Accordingly, multiplying by the total number of compartments, we have the approximate weight of the cast iron battery. ChM radiators are produced in 1-channel (ChM1), 2-channel and 3-channel (ChM3) form.

Classic ribbed cast iron batteries

Dimensions of a cast iron radiator.

In the Soviet Union, the overall dimensions of cast iron radiators had a certain standard. In one section, the distance between the centers of the coolant supply and discharge pipes ranged from 30 to 50 cm. The width of the section was not standardized and varied among different manufacturers. Almost all modern batteries also have these standards. The most popular model among cast iron products is MS-140. (installed in many “Khrushchev” and 9-story buildings of the 60-80s). The distance between the centers of the pipes is 50 cm; battery height 58.8 cm; width 9.3 cm; depth - 14 cm. The variety of overall dimensions of batteries is explained by the needs of customers.

Calculation of the number of sections

Accurately determining the number of sections in a heating battery is a long process. You need to take into account the region, the material of the walls, what kind of windows and doors there are, how many windows are in the room, what their area is, whether the room below is warm or cold, etc. If you need an exact calculation method, look here, but you can roughly calculate based on the area of the room. It is believed that on average 100 W of heat is required to heat 1m2 of area. Knowing the area of your room, determine how much heat will be needed: multiply the area by 100 W. Then divide by the thermal power of the selected radiator model.

For example, in a room of 12 m2 we will install MS-140M-500-0.9 from the Bryansk plant. Thermal power of the section is 160 W. Calculation:

- Total heat required is 12m2 * 100 W = 1200 W

- How many sections are needed 1200 W / 160 W = 7.5 pcs. We round (always up - it’s better if it’s warmer) and we get 8 pieces.

Despite the fact that the radiators have the same name: MS-140, their technical characteristics are different. The fact is that they are produced in different countries and meet their own industry standards. But this is good for the end user: you can choose the option that suits you best. And the difference is quite significant in some respects

Why cast iron?

Cast iron radiators have a number of advantages, let’s look at the main ones:

- High resistance to corrosion. This property is due to the fact that during operation the surface of the radiator is covered with “dry rust”, which prevents corrosion from developing. Cast iron is also very wear-resistant; stones and various debris from heating pipes do not cause much harm to it;

- Good thermal inertia. The cast iron heating radiator MC 140 retains 30% of the radiated heat even an hour after the boiler is turned off, while for steel radiators this figure is only 15%;

- Long service life. So for high-quality cast iron radiators it can reach 100 years, although manufacturers talk about 10-30 years of reliable operation;

- Large internal cross-section of radiators. It is for this reason that cast iron heating radiators MC 140 500 rarely require cleaning;

- Cast iron, due to its composition, under no circumstances can cause electrochemical corrosion. In other words, no conflicts can arise with plastic (steel) pipes.

Cast iron battery from USSR times

Let's talk about the characteristics

Now is the time to present to your attention the technical characteristics of cast iron radiators.

| Manufacturer country | Ukraine Russia |

| Maximum coolant temperature | 130.0 (deg) |

| Maximum working pressure | 9.0 (bar) |

| Crimping pressure | 15.0 (bar) |

| Radiator design | Sectional |

| Number of channels in 1 section | 2 |

| Water volume in 1 section | 1.35 (l) |

| Heat dissipation of 1 section | 175.0 (W) |

| Weight of 1 section | 6.2 (kg) |

| Width of 1 section | 98 (mm) |

| Nipple hole diameter | 5/4 (inch) |

| Intersectional gasket material | Heat resistant rubber |

| Material of sections and plugs | SCH-10 GOST-1412 |

| Nipple material | KCh-30-6F GOST-1215 |

But, knowing the advantages of devices and their characteristics, do not rush to run to the store. After all, before this you need to find out how many sections are needed for the heating to be truly effective.

Section counting

The number of sections directly depends on the configuration of the room. Of course, the main parameter here is the area, but there are other important factors, such as: zoning, floor, ceiling height, niche dimensions, presence of double-glazed windows, number of windows.

So, if there are several windows, it is recommended to place radiators under each one. This will significantly reduce heat loss. There are instructions for calculation, which we will provide for you below.

Modern cast iron batteries

Let's consider the formula for calculating the required number of sections for a room with a ceiling height of no more than 3 meters and an area of 50 square meters:

To calculate the required number of sections for a room, you need to multiply the area of the room by 100 W and divide by the heat transfer of one section.

Now that you know how many sections are needed, you can proceed directly to the installation.

General provisions

First of all, let's get acquainted with the characteristic features that are common to all cast iron heating batteries:

Advantages

- Durability . The oldest functioning cast iron heater is already 110 years old. A very respectable period. Of course, manufacturers give a slightly more modest operational period, although also quite impressive, which is equal to fifty years, but with careful care, the established record can be broken;

Decades of trouble-free operation

- Heat retention for a long time even if the coolant supply is turned off, which is due to the weak inertia of cast iron and the structural features of the battery itself;

- Resistance to high pressure , reaching 9-12 atmospheres. This is especially important in high-rise buildings that use a central heating system, through which, at the moment the boiler room starts operating after a summer shutdown, heavy water hammers pass through, capable of destroying less resistant structures;

- Resistant to high temperatures . Calmly withstands liquid heating up to +130 degrees Celsius;

- Lack of strict requirements for coolant quality . Again, if we talk about central heating systems, inside which garbage collected from all the houses in the area moves and created an acidic “cocktail” of incredible strength, it will not be easy to find a more stable material than cast iron;

- The presence of wide channels that allow large insoluble particles to pass through, which eliminates the rapid formation of blockages;

- Quite large, reaching 25%, level of heat radiation . This effect allows you to heat surrounding objects, after which they become additional sources of heat;

- The ability to install and dismantle sections yourself.

Graphic instructions for assembling a cast iron radiator MS-140

| Designation on the diagram | Item name |

| 1 | Section |

| 2 | Nipple |

| 3 | Pad |

| 4 | Short nipple wrench |

| 5 | Crowbar to strengthen the lever |

| 6 | Long nipple wrench |

- Low price . This type of battery is by far the cheapest, which also plays an important role when choosing suitable heating equipment.

Flaws

Undoubtedly, there are also negative features, which forced the creation of radiators from other materials over time. But it all depends on the specific situation and your preferences.

So:

- The MS 140 radiator is very heavy, like, in general, any cast iron product. This causes certain inconvenience during installation and transportation;

Advice: do not try to lift even batteries with a small number of sections yourself, as this can easily damage your health.

- Low inertia prevents not only rapid cooling, but also rapid heating of the system;

- Fragility. Despite the apparent strength of a cast iron product, it is very fragile;

Tip: when moving a cast iron battery, try not to hit it on the floor or door frames. This can lead to the appearance of microcracks, which will increase over time and cause a lot of problems.

- The need for periodic painting. The M 140 radiator goes on sale primed, so stock up on suitable paint right away. In this case, it is advisable to use acrylic non-toxic enamels;

Radiator MS 140m primed and ready for painting

- Unpresentable appearance. Heating radiators MC 140 do not shine with aesthetics and often require additional decorative design.

Tip: to increase the attractiveness of cast iron batteries, you can always use special decorative grilles that allow you to hide all their visual flaws.

Radiator mesh improves the appearance of both new and old batteries

Technical characteristics of radiators MS-140 - 500

Radiators of the MC group belong to the category of sectional ones - they are assembled into a single whole from separate sections.

MS 140 cast iron radiator section.

The sections are connected into a radiator using intersection gaskets.

Intersectional gasket for cast iron radiator MS 140.

One section is pressed against another using a nipple.

Cast iron radiator nipple ms 140.

The ends of the radiator are closed with plugs, which can be shut-off or pass-through.

Radiator shut-off plug ms 140.

Radiator passage plug ms 140.

Sections are cast from gray cast iron with graphite additives. Individual parameters of MC 140 radiators may vary slightly in models from different manufacturers.

Main characteristics of the cast iron radiator model MC 140:

| Radiator type | sectional |

| Number of coolant channels, pcs. | 2 |

| Number of sections, pcs | from 2 to 10 |

| Nominal heat flow of one section, W | 160 |

| External casing coating | primer GF-021/0119 |

| Section material | gray cast iron in accordance with GOST 1412-85 |

| Intersectional gasket material | rubber according to GOST 1412, capable of withstanding temperatures up to +150ºC |

| Nipple material | cast iron or steel. GOST 1412 or 1050 |

| Heating area of one section, m2 | 0.195 |

| Center distance, mm | 500 |

| Nipple hole thread size | G11/4 |

| Type of coolant | water |

| Maximum coolant temperature, 0C | + 1300С |

| Operating excess coolant pressure, MPa (kgf/cm2) | 0.9 |

Other technical data:

| Number of sections, pcs. | Weight, kg | Length, mm | Nominal heat flow, kW | Capacity, dm3 (l) |

| 2 | 12.8 | 227 | 0.32 | 2.50 |

| 3 | 18.8 | 331 | 0.48 | 3.75 |

| 4 | 24.8 | 435 | 0.64 | 5.00 |

| 5 | 30.8 | 539 | 0.80 | 6.25 |

| 6 | 36.8 | 643 | 0.96 | 7.50 |

| 7 | 42.8 | 747 | 1.12 | 8.75 |

The basic characteristics of the radiator can be determined by the model name and markings.

For example, model MC-140-500-0.9-7 designates a radiator with the name MC, depth 140 mm, center distance 500 mm, maximum system pressure 0.9 MPa, with the number of individual blocks in the radiator equal to 7.

Technical instructions

1. Installation of heating equipment should be entrusted to organizations specializing in the field of construction and installation work that have the appropriate license.

2. Radiators with a number of sections less than 10 can be connected in any way - bottom, top, diagonal. If there are more than 10 sections, then it is recommended to connect in a diagonal way: the coolant inlet is at the top, the outlet is at the bottom.

Diagonal connection of the radiator ms 140.

3. Before installing the radiator, you should conduct a hydraulic test of the integrity of the device, the tightness of the gaskets, and the strength of the nipple connections. To do this, hydraulic testing is carried out under a pressure of 1.5 MPa. If a leak is detected due to loose nipple connections, they need to be tightened and the test performed again.

4. When changing (increasing or decreasing) the number of blocks in the radiator, it is necessary to use only gaskets that are established by the requirements of GOST 1412. After assembling the radiator, the strength of the intersectional connections is checked.

This is done in a standard way - hydraulic tests are carried out under high pressure of 1.5 MPa, exceeding the maximum permissible loads. During the test, the prefabricated structure must not leak or allow air bubbles to pass through.

5. After completion of the installation work, the entire water heating system is pressure tested, based on the results of which a certificate of commissioning of the facility is drawn up.

MS-140 cast iron radiator: characteristics

Cast iron heating radiator MS 140 is produced in Ukraine, Belarus and Russia. The high practicality and exceptional reliability of such batteries has been proven for decades. Thus, according to statistics conducted over 7 years in the field of marketing, this type of heating device remains widespread in the Russian market to this day. Despite the fact that its production technology is no longer new, cast iron radiators MS 140 500 and other series are still sources of heat in hundreds of thousands of apartment buildings throughout Russia.

Cast iron battery MS-140 - an alternative to modern heating devicesThe basis for casting the cast iron radiator MS 140m 500 and other models is high quality gray cast iron. Its composition contains several modifying impurities that smooth out the influence of an aggressive environment: protect against mechanical stress and corrosion, and also increase the service life.

Today, of course, the design of such radiators has changed and acquired a rather modern appearance. The front surface is made flat and a variety of colors are possible.

Modern cast iron radiator brand MS-140

The technical characteristics of MS-140 batteries are in no way inferior to the best imported models: their operating pressure is from 9 to 11 atmospheres, and the test pressure is 18 atm.

Per 1 section, the maximum heat transfer of heating devices made of MS-140 cast iron is 175 W.

You need to choose a cast iron battery model depending on the number of sections in the following ratio: with a power of this radiator of 1000 W, a room of 10 square meters is heated. m.

Diagram of cast iron heating device MS-140

And you can calculate the weight of a cast iron heating device of the MS-140 brand, knowing the weight of one section of the radiator. The average value is generally considered to be 6.15 kg.

The heating area of such a battery depends directly on the number of radiator sections.

The dimensions of the MS-140 cast iron heating device are determined from:

- Number of sections.

- Volume.

- Country of origin.

Cast iron battery MS-140 made in Belarus

Before going to the store, it is recommended to get advice from a specialist about the number of sections that will be needed to create the most comfortable temperature conditions in the entire room. Of course, there is an alternative - you can independently calculate the required number of sections of cast iron radiators MS 140 500 and other series. How to do this correctly is given below.

Cast iron radiator MS 140m: its varieties

In order to stay afloat for so long, companies producing MS-140 radiators had to expand their product line. And as a result, the following models of cast iron radiators :

- Cast iron radiators ms 140 500. This model is manufactured in Belarus. Today, this radiator model has undergone considerable changes and in most cases its surface is flat. In addition, these batteries are available in a wide range of colors.

Exclusive cast iron battery ms-140 series 500 - The cast iron radiator MS 140m 500 with 7 sections is a type of front battery of the first model.

- Cast iron radiator MS-140 300. This radiator model differs not only in depth, capacity and weight, but also in the so-called. inter-nipple distance - 300 mm. Cast iron heating device ms-140 series 300

- Model of heating cast iron batteries MS-140 108. Its difference is that it requires special care from the resident.

Cast iron battery ms-140 series 180 - The MS-140 98 heating device, like the previous model, also depends only on the distance between the centers of the nipple holes. All models of MS-140 cast iron radiator differ in characteristics: size, pressure and temperature of the coolant.

Methods for installing a cast iron radiator

Since cast iron radiators have considerable weight, when choosing a model it is better to think about the installation method in advance. The battery can simply be placed on the legs. Many designer radiators are already available with legs. If we are talking about other models, then you can also select and purchase legs for them separately.

If you plan to attach the battery to the wall, then it is recommended to do this on a load-bearing wall. You can mount the heating device on the partition, but first it must be further strengthened. To do this, the fastenings must be as reliable as possible. It is better to use hooks or brackets.

Installation of a cast iron radiator

Sources

- https://teplosten24.ru/teplootdacha-chugunnyh-radiatorov-ms-140.html

- https://fb.ru/article/281193/ms—-radiator-chugunnyiy-harakteristiki-obzor-vidyi-i-otzyivyi

- https://fb.ru/article/283114/ms–m—-radiator-chugunnyiy-harakteristiki-preimuschestva-i-nedostatki-proizvoditel

- https://gopb.ru/radiatory/kakie-luchshe-chugunnye-radiatory-otopleniya-ms-140m-500-ms-110-500-ms-110-300-texnicheskie-xarakteristiki/

Total information

Batteries offered by manufacturers differ in the number of sections.

They are made:

- in 10-section form;

- in 7-section design;

- in 4-section form.

Types of MC batteries

MS-140-500 have a flat surface and are painted in different colors.

To compete with more modern types of devices, manufacturers of cast iron heating batteries had to expand this product line.

The following models are currently available on the Russian market.

- Cast iron heating radiators MS-140-500 are produced by the Republic of Belarus. This device has undergone several improvements. Now its surface, as a rule, has a flat appearance. In addition, the product comes already painted in different colors.

- Battery MS-140-500 with 7 heating elements. This is a frontal variation of the previous model.

- Analogue MS-140-300. This device has a gap between nipples of 300 millimeters.

- The MS-140-108 model does not require significant care and does not require constant maintenance.

Difference between different device models.

- Cast iron heating radiators grade MS-140-180 and 98 have gaps between nipples of 108 and 98 millimeters. The devices, like the previous one, are produced in Russia and Ukraine.

Thanks to such a wide selection of products, property owners can optimally arrange heating in their home.

MS-140 - cast iron classic of “Soviet” times

Cast iron heating radiators MC 140 can be called an undying classic. Despite the abundance of different models of heating devices made of the same cast iron, this one - a Soviet-era “accordion” - is still in demand. It is produced in most countries that were formerly part of the USSR. They are precisely produced in Russia, Ukraine and Belarus. Perhaps production has been established in other countries, but why transport goods far away if there are factories nearby.

Dimensions and weight of cast iron heating radiators

The parameters of cast iron radiators using the example of the domestic product MS-140 are as follows:

- height – 59 centimeters;

- section width – 9.3 centimeters;

- section depth – 14 centimeters;

- section capacity – 1.4 liters;

- weight – 7 kilograms;

- section power 160 watts.

You can hear complaints from property owners that it is quite difficult to move and install radiators consisting of 10 sections, the weight of which reaches 70 kilograms, but the good news is that such work in an apartment or house is done only once, so the dimensions of cast iron heating radiators must be correctly calculated.

Since the amount of coolant in such a battery is only 14 liters, when thermal energy comes from the boiler of an autonomous heating system, then you will have to pay for the extra kilowatts of electricity or cubic meters of gas.

terms of Use

The radiator is used in water/steam heating systems with any type of boiler, in which the coolant is ordinary water, without specific requirements for its quality.

Installation should only be carried out in a heating network that is designed, installed and operated in accordance with regulatory documentation adopted by government industry organizations.

For Russia, such a regulatory act is the rules SP 60.13330.2012 or 73.13330.2012.