One of the most common problems in functioning heating systems is airing, which leads to uneven heating of radiators or underfloor heating pipes. To combat this negative phenomenon, air vents for heating systems operating in different modes are widely used.

Using an air vent installed at the inlet of the heat exchange devices, air is released from the heating circuits. There are various types of air vents on the market, in order to understand the wide range of models and choose the right device for an individual heating system, you should know the operating principle, existing types and design features of manufactured air vents.

Rice. 1 Air vents

What are air vents and what are they for?

Many owners of radiator systems have encountered a situation where, with hot pipes, some parts of the radiator do not heat well or are generally cold; similar problems arise with insulation with water floors. The main reason for this phenomenon is the presence of air in the pipes, which rises and impedes the movement of the coolant.

If there is a large volume of air, a plug may form, leading to a complete stop of coolant circulation in the pipeline - the line becomes air-filled.

If in an open circuit air bubbles are sent to an unclosed expansion tank located on high floors of a building or attic, and bleeding is not so important, then in a closed system an air bleeder for the heating system is vital on all circuits and individual heat exchange devices.

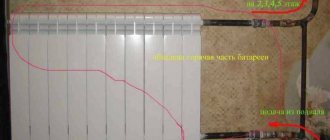

When plugs interfere with the operation of the system, manual or automatic heating drain valves are used to remove accumulated air. One of the simplest devices is a regular valve installed at the top point of heating radiators. To bleed air from the batteries, open the valve and wait for the moment when the stream stops flowing jerkily along with the air - in radiators without air, the water flow will be uniform.

In individual heating lines of private houses, instead of ordinary valves, special locks are installed on the radiators, which function automatically or are manually adjusted. With their help, they remove not only air from devices in which gas formation occurs, but also, when necessary, oxygen from water, which causes accelerated corrosion of metal fittings.

Rice. 2 Air vent for venting air from the heating system - design

Pros of using the device

*

Before installing an air valve for water or heating, you need to understand the main advantages of all models. The main advantage of using the products will be timely prevention of system breakdown, because the design will not allow air to disrupt the normal functioning of the pipeline. Another bonus is the prevention of odors from the sewer pipe, but this also requires the organization of normal supply ventilation in the apartment.

Accessories for the device

Installing an aerator allows you to save on possible subsequent repairs and allows you not to expose the ventilation riser to the street. Such valves can be used on heating systems and plumbing. The device ensures stable, uninterrupted operation of all systems.

Air vents for heating systems - operating principle

To bleed air from the circuit, you can use a regular valve by draining a certain amount of liquid. If in communal houses a decrease in the volume of water in the circuit does not cause negative consequences and it is replenished by utility services, then in individual houses the drained coolant will have to be replenished independently.

For a closed system, adding coolant is quite a big problem - you will have to connect a manual or electric pump, and if there is toxic ethylene glycol antifreeze in the line, carrying out the work while taking the necessary safety measures will take a lot of time.

The main difference between special air vent devices and conventional valve locks is the small diameter of the outlet hole, its location at an angle of 90 degrees and the ability to smoothly adjust the cross-section of the outlet channel using a threaded screw.

As can be seen from Fig. 2, the screw has a cone-shaped shape and a similar seat, thanks to which, when closed, it reliably and hermetically covers the inlet hole. To bleed air, the screw head is turned one or two turns, opening a small-diameter outlet drain hole, and the air-filled coolant along with bubbles will begin to flow out of the tap in small quantities while the air plug will be released more intensively.

The advantage of using an air vent is that when you turn the screw, first of all, with a characteristic hissing sound, the air flow comes out, and then the aired coolant flows out, a small amount of which does not need to be added to the system.

Fig.3 Operating principle of an automatic air vent

Types of Automatic Air Valves

Types of devices

Based on their design, devices are divided into three types.

Straight traditional

The most common vent valves are those with direct connection. They are used to bleed air at the highest points of the pipeline. To do this, they are installed at the top in vertical risers.

Corner

Instead of a conventional valve, corner structures can be installed to automatically release the air lock from the heating system. This type of equipment is most relevant if there are always gases in the line, especially in the radiator section.

Special for radiators

Radiator-type devices are designed specifically for installation directly on batteries. For this purpose they have a threaded connection. Such valves are mounted on aluminum and bimetallic radiators, on those devices that come into contact with water. In this case, installation of a radiator device is necessary.

How does an automatic air vent work?

The cold coolant poured into the heating line tends to release air when heated; to bleed it, automatic air release from the heating system is used.

The operating principle of all automatic devices is to open the bleed hole when air appears in the internal area of the air vent housing. The element that reacts to the presence of air is a float immersed in the inlet pipe of the device, which is connected to a valve that closes the air outlet hole. The automatic device works according to the following principle (Fig. 3):

- When the heating is functioning normally, the float located in the space of the cylindrical working chamber is in the upper position and the cone-shaped rod connected to it closes the outlet channel.

- If air accumulates in the upper part of the tank, the float goes down along with the locking rod and the air valve opens, air is released from the device.

Rice. 4 Automatic air release valve from the heating system

Device

There are various designs of automatic air bleed valves on the market; let’s look at the design and operation of one of the most common types.

This model (Fig. 4.) has a composite body made of brass, including the main part 1, which is screwed into the pipeline, and its cover 2 with a locking mechanism, connected to the base through an o-ring 10.

In the non-operating state, the liquid entering through the inlet pipe from below lifts the plastic float 3; it, through a flag, presses on the spring-loaded (spring 7) holder 5 with spool 6, which locks the passage channel in the nozzle 4.

Jet 4 is located in the side part of the air vent and is connected to the body through an o-ring 8; in the upper part of the device there is a plug 9, which regulates the passage channel of the air outlet or closes it completely if necessary.

When air appears in the float chamber, it displaces the water in which float 3 floats, the element lowers along with the flag, and spring 7 pushes the spool holder away from the outlet channel - the air is released. When the volume of discharged air decreases, water enters the working chamber again, the float floats up and closes the channel using a locking mechanism.

Typically, when connecting an air vent, adapters from a shut-off check valve are used, which is a spring-loaded locking mechanism and an associated flag. When the air vent is screwed in, it presses on the shut-off valve flag, the latter goes down and opens the way for water to the vent body.

When dismantling the drain for replacement, maintenance or repair work, the released spring-loaded flag together with the shut-off valve rises up and blocks the coolant flow channel.

Fig.5 Manual air valve of the heating system in the battery

Specifications

The main material used for the manufacture of housings for manual and automatic air valves for bleeding air from heating systems is nickel-plated brass (bronze is used much less frequently); vent valves have the following characteristics:

- Installation - at the highest points of the heating circuits in a straight section.

- The permissible temperature of the working environment is from 100 to 120º C.

- Maximum pressure 10 bar (atmospheres).

- The connecting diameter of the outlet pipes is 1/2″, 3/4″ (the most common sizes are indicated in the metric layout as Dy 15 and Dy 20, which corresponds to 15 and 20 mm), 3/8″, 1″ inch.

- Connection type - straight and angular.

- The location of the outlet fitting is on the top, on the side.

- Contents – sometimes supplied with shut-off valve

- Working medium – water, non-freezing coolants with glycol content up to 50%.

- The material used to make the float is polypropylene, Teflon.

- The service life of brass devices can reach 30 years.

Main task and principle of operation

Moving along the contour of the main line, the coolant will follow the path of less resistance. If there is an air lock in the pipe, this will be an obstacle to the passage of water. As a result, batteries in which air has accumulated warm up only partially or remain completely cold. Airing not only reduces the quality of heating, but also disrupts the operation of all elements of the system. To eliminate the negative consequences, you need to install an automatic air vent.

If your heating system does not have an automatic air bleeder, you may encounter the following problems:

- the boiler will fail as a result of constant overheating;

- the heating device will corrode;

- the boiler will operate at maximum power, but the radiators will remain slightly warm;

- in severe frosts, the risk of freezing of part of the circuit or one of the radiators increases;

- Due to sudden pressure surges, damage will form in the system, which will lead to leakage.

An automatic valve for bleeding air from the heating system will help solve the problem without human intervention. If the system works properly and there is no air in it, the float of the device will float on the surface and press the plug on the outlet hole. If, as a result of the formation of a plug, the water level in the radiator decreases, the float moves down, this opens the valve for bleeding

Types of air vents and their design features

There are air vent valves of automatic and manual operating principles, the former are mainly installed at the top points of collectors and pipelines, manual modifications (Mayevsky valves) are placed on radiator heat exchangers.

Automatic devices are distinguished by a wide variety of designs for locking mechanisms; their cost is in the range of 3 – 6 USD; the market offers a wide range of models from domestic and foreign manufacturers. The cost of standard Mayevsky taps is about 1 USD; there are products at a higher price, designed to function in non-standard radiator heaters.

Rice. 6 Example of an air vent design with a rocker mechanism

Automatic

Automatic tappers have different designs depending on the manufacturer; the main differences between the devices are:

- The presence of a reflective plate inside the body. It is placed at the entrance to the working chamber, protecting internal parts from hydraulic shocks.

- Many modifications are supplied complete with a spring shut-off valve into which the air vent is screwed; when it is removed, the spring is compressed and the O-ring closes the outlet channel.

- Some models of automatic diverters are designed for operation in conjunction with radiator heat exchangers; instead of straight ones, they have side threaded pipes of the appropriate size for screwing into the radiator inlet. If necessary, corner automatic air vents of any type can be used, for example, at the connection points of heated floor circuits, hydraulic arrows, if their threaded diameters of the inlet and outlet fittings match.

- There are analogues of air vents on the market - microbubble separators; they are mounted sequentially in the pipeline on two inlet pipes corresponding to the diameter of the pipes. When liquid passes through the body tube with a soldered copper mesh, a vortex water flow is created, which inhibits the dissolved air - this promotes the rise of tiny air bubbles, which are released through the automatic air release valve of the chamber.

- Another common design (an example of the first was given above) is a model with a rocker mechanism. In the chamber of the device there is a float made of plastic; it is connected to a nipple locking needle (like a car one). When the float is lowered in an airy environment, the nipple needle opens the drain hole and air is released; when the water rises and the float rises, the needle closes the outlet.

Rice. 7 Operating principle of separator-type air vents for bleeding microbubbles

Manual

Manual devices for removing air from the system are called Mayevsky valves; due to the simplicity of their design, mechanical air vents are universally installed on radiators. On the market you can find manual taps in a traditional design for installation in various places, and some modifications of shut-off valves are equipped with Mayevsky taps.

The Mayevsky cranes produced do not differ in a wide variety due to their simple design, consisting of a body with an air duct bent at 90 degrees and a cone-shaped locking screw.

A mechanical vent for removing air from a heating system works as follows:

- In operating mode, the conical screw is tightened and reliably seals the outlet hole of the housing.

- When it is necessary to remove excess air from the battery, make one or two turns of the screw - as a result, the air flow under coolant pressure will come out of the side hole.

- After the air is released, the water begins to bleed out; as soon as the water stream becomes intact, the screw is screwed in again and the de-airing operation is considered complete.

Rice. 8 Air vents to prevent air from heating radiators

Radiator

Cheaper manual mechanical air vents are most often installed in radiators; if the body consists of two parts, the element with the outlet pipe can be rotated around its axis to direct the drain hole in the desired direction. The radiator device for bleeding air from the heating system has the following options for unscrewing the bleed screw:

- Rotary handle made of plastic or metal.

- A special plumbing square wrench.

- A slotted screw for a flathead screwdriver.

If desired, you can install an automatic corner air vent in the radiator - this will entail additional costs, but will simplify the de-airing of the batteries.

Air valves and radiator fittings

Almost all modern radiators provide the possibility of installing Mayevsky manual valves for air discharge. Some manufacturers even complete their products with them. If desired, instead of a manual air vent, you can install an automatic one, but in practice it does not look very presentable.

Recently, laying heating lines below floor level and using radiators with bottom connections has become increasingly popular. Then there remains a small gap between the battery and the floor, where it is not always possible to place any fittings. For this case, there is a special connection headset with built-in taps, shown in the picture (left):

On the right is a headset for the bottom connection of a conventional radiator with side plugs; it also has valves plus the ability to connect a thermal head. Such solutions look very aesthetically pleasing, but will require maximum financial costs. More information about the headset is shown in the video:

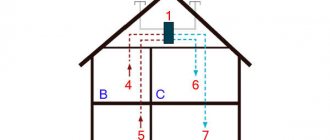

Where should air vents be installed correctly?

When installing a heating system, installing air vents is a mandatory procedure; to determine the required quantity, you need to know where to place these devices. Air vents are recommended to be located in the following places:

- The highest points of the system. If during installation the pipeline rises upward, bypassing any obstacle, and then descends down to the heat exchangers, an automatic air vent for the heating system should be installed on top. This will prevent airing due to the fact that light air always rises and accumulates in the pipeline on the upper floor.

Rice. 9 Types of automatic air vents

- Heating radiators. Radiator heat exchangers have a complex shape, including a large number of sections - this creates convenient cavities for air accumulation. Therefore, Mayevsky outlet valves are always used in radiators; in an individual heating circuit, they are installed on each radiator, regardless of the connection diagram (one-pipe, two-pipe, bottom, side, diagonal). Radiator manual models of exhaust valves, unlike automatic ones, are small in size, less expensive, fit aesthetically into the radiator contour, and therefore are installed on batteries in the vast majority of cases by the manufacturer and, if necessary, by home owners.

- Heated towel rails. Industrially produced heated towel rails of the complex “ladder” shape, popular in everyday life, are always equipped with an air vent with a straight pipe located in its upper part. It is more convenient if the heated towel rail is equipped with an automatic air vent for the following reasons: the screw located at the top of the manual model is inconvenient to tighten, in residential buildings there may be periodic lack of water and manual adjustment becomes troublesome, in addition, the duct protruding from the side spoils the aesthetic appearance of the heater.

- U-shaped bends and bypasses. Any section of a pipeline with an upward-facing loop collects air; if a shut-off valve is used to turn off the loop, it is installed at the highest point, using a model with a built-in automatic Mayevsky valve (naturally, the air vent at the top can be installed separately from the valve).

- Boiler piping system. It is also recommended to equip the boiler piping with a valve to ensure safe operation of the heating equipment in the event of airing in the main line.

- Hydroshooters. It is not so often that in household heating systems they use hydraulic arrows, to which circulation pumps, radiator and heated floor collectors are connected - if the device is located vertically, an automatic air bleeder is screwed into its upper part.

- Collectors. When installing multi-circuit heated floors, manifolds with combs are used, to which the pipeline of various circuits is connected. The collectors are located above the level of the water floors and are always equipped with automatic air vents, which are installed in their housing by the manufacturer; the system includes two devices for the supply and return lines.

Rice. 10 Manual and automatic air vents in the heating system - location diagram

Installation recommendations

Regardless of the type of automatic air intake for heating, you need to ensure that the exhaust cap faces up during installation. Bleed valves in systems are usually installed after ball valves or shut-off valves. An exception to the rule is the boiler safety group: secondary intermediate fittings are not used in this case.

Thanks to the shut-off check valve, it becomes possible to carry out maintenance or replacement of the air vent without emptying the entire heating system. Therefore, having such a device is very convenient. Only wrenches are suitable for installing an automatic bleeder: they, unlike adjustable ones, allow you to measure the effort required to screw the fastener. During installation work, it is not recommended to hold the device by the body to avoid damage. For these purposes, the design provides a hexagon at the bottom of the cylindrical chamber.

What are the dangers of air in the heating system?

Everyone has probably experienced more than once that the heating is turned on, but some radiator or a whole group does not heat up well or is completely cold. The reason for this is the air in the heating system. It usually accumulates at the highest point, displacing the coolant from this place. If a lot of it accumulates, the circulation of the coolant may stop altogether. Then they say that an air lock has formed in the heating system. In this case, professionals say that the system is airy.

To resume normal heating operation, the accumulated air must be removed. There are two options for this. The first is more often used in central heating systems. Taps are installed on the outer radiators in the branch. They are called descents. This is a regular valve. After filling the system with coolant, open it and keep it open until there is an even stream of water without air bubbles (then the water flows in jerks). If we talk about multi-storey buildings, then when the system is launched, the air vents on the risers must first be opened, and the remainder can already be discharged to the apartments.

Valve installation locations

In each scheme of a water heating system there are areas in which the installation of air vents is mandatory. If we consider Mayevsky valves, then they must be installed on all radiators in order to remove accumulated air. This should be done in the plug in the upper part of the corner, distant from the junction of the supply line with the battery. Air bubbles collect here. Automatic air vents must be installed strictly vertically in the following places of the heating system:

- on all collectors when installing a “warm floor” system;

- in the group safety part of boiler equipment, which is connected to a closed system;

- for an indirect heating water heater and a buffer tank, if the design allows this;

- if the highest point is a pipeline and not a battery, then a float air vent is installed on it;

- to the hydraulic arrow;

- to the distribution comb;

- to the heated towel rail connection areas.

If you don’t want to constantly run around and turn the valve, install an automatic one.

Also, air vents are installed in problem areas of the heating system, where, for certain reasons, the pipeline installation has U-shaped loops turned upward (for example, the pipeline goes around the top of a flight of stairs or a doorway, and then lowers again). In these compensators, air is collected with a 100% guarantee, therefore an automatic air bleed valve is required.

You should never insert the Mayevsky tap directly into the heating pipeline, since air bubbles will pass by it simultaneously with the movement of the coolant. The crane in this case will be simply useless. To function properly, a mechanical bleed valve requires an air collection chamber (automatic systems have their own). It is best to insert a vertical pipe into the main line, which will serve as a chamber for collecting air, and then insert a tap on top.

If a person does not want to run between the radiators with a screwdriver while filling the heating system with water, he needs to install corner automatic air vents instead of Mayevsky taps. This option is also suitable for apartments that are heated centrally: air pockets very often appear in cast iron radiators, and there is simply no way to remove them.

To prevent the air release flask from being in plain sight and not clinging to the curtains, you can use a mini-model of this device, which is built into the radiator cap.

Quality Low Cost Automatic Air Compressor Valve

Reasons for appearance

Air can appear in the heating system for various reasons. If this is a one-time problem, you can simply delete it and not search for the source. If deflation is required several times during the season, you will have to look for the reason. Here are the most common:

Air can accumulate in pipe bends.

These are the most common places and ways in which air gets into radiators and batteries. It is necessary to kick him out of there from time to time, but when starting the heating in the fall, it is necessary.

Fact 2. There are no pipelines without air

Atmospheric air enters the pipe when it is filled with water. If there are no devices to remove it, it collects at high local points. At normal pressure and temperature, water can contain up to 2% (volume) dissolved air. The speed of water flow can change with changes in temperature and pressure, on slopes, with changes in pipe diameters, partially open valves, etc. In this case, dissolved air can be released, collecting at high points. Air can enter the pipe when starting deep-well pumps, from the suction vortices of conventional pumps, through loose connections in areas above the hydraulic gradient (points with negative pressure). Air is also allowed into the pipe by air valves when a vacuum occurs.

Installing air release valves

To remove air from heating, air vents are installed on radiators - manual and automatic air valves. They are called differently: bleeder, air vent, bleeder or air valve, air vent, etc. The essence does not change from this.

Mayevsky air valve

This is a small device for manually bleeding air from heating radiators. It is installed in the upper free radiator manifold. There are different diameters for different collector sections.

Manual air vent - Mayevsky tap

It is a metal disk with a conical through hole. This hole is closed with a cone-shaped screw. By unscrewing the screw a few turns, we allow the air to escape from the radiator.

Device for removing air from radiators

To facilitate air outlet, an additional hole was made perpendicular to the main channel. The air actually comes out through it. When deflating using a Mayevsky tap, point this hole upward. After this you can unscrew the screw. Unscrew it a few turns, but do not unscrew it too much. After the hissing stops, return the screw to its original position and move on to the next radiator.

When starting the system, it may be necessary to bypass all the air collectors several times until air stops escaping altogether. After this, the radiators should heat up evenly.

Automatic air release valve

These small devices are installed both on radiators and at other points in the system. They differ in that they allow you to bleed air in the heating system automatically. To understand the principle of operation, consider the structure of one of the automatic air valves.

The operating principle of the automatic release is as follows:

- In normal condition, the coolant fills the chamber by 70 percent. The float is at the top, pressing the rod.

- When air enters the chamber, the coolant is forced out of the housing and the float lowers.

- He presses the protrusion-flag on the nozzle, squeezing it out.

Operating principle of automatic air release valve

Various designs of automatic air valves operate on this principle. They can be straight or angular. They are placed at the highest points of the system and are present in the security group. They can be installed in identified problem areas - where the pipeline has an incorrect slope, which is why air accumulates there.

Instead of Mayevsky's manual taps, you can install an automatic drain for radiators. It is only slightly larger in size, but works automatically.

Automatic air release valve

Cleaning from salts

The main problem with automatic valves for venting air from the heating system is that the air outlet hole is often overgrown with salt crystals. In this case, either the air does not come out or the valve begins to “cry”. In any case, you need to remove it and clean it.

Automatic air vent disassembled

So that this can be done without stopping the heating, automatic air valves are installed in pairs with non-return valves. The check valve is installed first, followed by the air valve. If necessary, the automatic air collector for the heating system is simply unscrewed, disassembled (unscrew the lid), cleaned and reassembled. After this, the device is again ready to bleed air from the heating system.

What and how to bleed air from a heating radiator

In order to control the gas contamination of the system both in an apartment and in a private house, use a manual or automatic air release valve. They should be discussed in more detail.

- Automatic air valve;

- Air separator;

- Mayevsky crane.

The automatic air valve is capable of independently releasing air that has accumulated in the radiator. It consists of a brass body, float, articulated arm and valve. A special cap protects against leakage, and the protection located under the spring protects against the ingress of external contaminants.

The system works on the following principle:

- While there is no air, the float keeps the valve closed;

- As gas accumulates, the float begins to descend and gradually open the valve;

- The accumulation of air leaves the compartments, and the system returns to its original state.

It is important to note the fact that all automatic versions are equipped with connectors that are suitable for a screwdriver or octagonal keys. Thanks to this shape, you can open the valve even in manual mode if the automatic mode suddenly breaks down

As for the air separator, this system is a little more complicated. The principle of its operation is to absorb air, turn it into bubbles and remove it out. Most often, separators are combined with sludge, which is capable of trapping dirt, sand or rust. If we talk about the design, it is presented in the form of a metal cylinder, which includes an air vent at the top and a valve at the bottom, which serves to discharge foreign contaminants. Inside such an installation there is a mesh that creates a vortex flow.

The same method is used when there is a water circuit that is connected to heating. The release in the water supply is carried out as a bleed. That is, a stream of air or water with impurities can be released through the bleeder.

How to get rid of an air lock

Unfortunately, the air lock is not always in an easily accessible place. If there are design or installation errors, air can accumulate in the pipes. It is very difficult to get him out of there. First we determine the location of the plug. In the area of the plug, the pipes are cold and a babbling sound can be heard. If there are no obvious signs, they check the pipes by sound - tapping on the pipes. In a place where air accumulates, the sound will be louder and louder.

Any air lock found must be removed. If we are talking about the heating system of a private house, this is done by raising the temperature and/or pressure. Let's start with pressure. Open the nearest drain valve (in the direction of flow of the coolant) and the make-up tap. Water begins to flow into the system, increasing the pressure. It forces the traffic jam to move forward. When air gets to the bleeder, it comes out. Stop feeding after all the air has escaped - the drain valve stops hissing.

This is a security group. An automatic air vent is installed at the middle outlet

Not all air locks give up so easily. For particularly stubborn ones, it is necessary to simultaneously raise the temperature and pressure. These parameters are brought to values close to maximum. You cannot exceed them - it is too dangerous. If the plug does not go away after this, you can try to open the drain valve (to drain the system) and the make-up valve at the same time. Maybe this way it will be possible to move the air lock or get rid of it altogether.

If a similar problem occurs constantly in one place, there is an error in the design or wiring. In order not to suffer every heating season, a valve is installed in the problem area to remove air. You can cut a tee into the main line and install an air vent at the free entrance. In this case, the problem will be solved simply.

Why is this device needed?

A signal that a valve needs to be installed is the following symptoms: the appearance of unpleasant odors and/or the appearance of extraneous sounds.

Any deviation from the norm is a clue about improper sewer design. The valve is needed to compensate for the pressure in the system. It not only replaces the ventilation riser, but also allows you to solve the following problems:

- Helps out when you can’t install a fan riser.

- Reduces heat loss through ventilation.

- Improves the functionality of the entire sewer system.

- One of its tasks is to protect against the failure of the fan element.