What is indirect heating, and how to implement it yourself? The operating concept is the same as that of thermal power plants (CHP). In the process of solving the main problem (operating steam generators), “extra” thermal energy appears. It can be irresponsibly released into the atmosphere, or used to organize heating for the neighborhood.

The indirect heating unit works the same way. We take a heat source (which exists regardless of your need to extract additional benefit from it), and “take away” part of the thermal energy from it.

In this way, residents of communal apartments without hot water supply obtained hot water (mainly for washing dishes, sometimes for taking a shower). To do this, in collaboration with neighbors, we made an indirect heating boiler with our own hands. The solution is simple, but requires at least a gas torch for welding pipes. Or the unit was manufactured using the “left” method at the main place of work (usually a factory or repair shop).

How to make a coil

The coil is an important part of the device.

It can be based on a metal or metal-plastic pipe with a small diameter. Typically, copper or brass is used, as they have a high level of heat transfer. The manufacturer can choose the diameter of the coil at his discretion. The main condition is that its contact with water is maximum.

The serpentine tube is wound in a spiral onto a cylinder-shaped mandrel. For this purpose, a log or pipe with a large diameter is used. When winding the coil, it is necessary to monitor the turns. They shouldn't touch each other.

Do not make the winding tight, as it will be very difficult to remove the coil from the mandrel.

The number of turns on the coil is directly dependent on the volume and height of the tank. Typically, for every 10 liters, 1.5 kW of coil heating power is used.

Thermal insulation

To minimize heat loss, the tank should be wrapped in a layer of thermal insulation.

For this purpose, use:

- construction foam;

- isolon;

- polyurethane foam;

- foam;

- mineral wool.

Some craftsmen use a foil-based backing for the laminate. The water heater is wrapped in this case like a thermos. The insulation is attached using wire, glue or strip ties. We recommend insulating the entire building.

The lining will not only ensure long-term preservation of hot water, but will also shorten the duration of heating of the tank, which will reduce coolant consumption. Without well-equipped thermal insulation, the water in the device will quickly cool down.

Often they resort to the construction of a double tank: a small tank is placed inside a large one. The space created between them also performs a heat-insulating function.

To secure the container, hinges are welded to the top of its body, and a metal corner is installed on the wall to which they are attached.

What you need to know about security

Do not forget that we are dealing with a source of increased danger - an electric heating device, therefore, when assembling and using it, you must follow some rules:

Be sure to use a separate electrical line to connect the induction boiler, and also equip it with a safety group.

- If water circulates naturally in the boiler, be sure to equip it with a temperature sensor so that if it overheats, the device turns off automatically.

- Do not connect a homemade water heater to an outlet; it is better to draw a separate line for this with a larger cable cross-section.

- All exposed sections of wires must be insulated to protect people from electric shock or burns.

- Never turn on the inductor if the pipe is not filled with water. Otherwise, the pipe will melt and the device will short out or it may even catch fire.

- The device must be mounted at a height of 80 cm from the floor, but so that about 30 cm remains from the ceiling. Also, you should not install it in a residential area, since the electromagnetic field has a bad effect on people’s health.

- Don't forget to ground the inductor.

- Be sure to connect the device through an automatic circuit breaker so that in the event of an accident, the latter will cut off the power from the water heater.

- A safety valve must be installed in the pipeline system, which will automatically reduce the pressure in the system.

Calculation of the main parameters of the boiler

Before you begin searching for material and directly manufacturing, you will need to calculate the minimum volume of the tank and the working length of the heat exchanger.

Volume and shape of the tank

The volume of the water tank directly depends on the number of residents permanently residing at the place where the equipment is installed. It is believed that a person uses up to 80 liters of water per day. For the calculated value, it is recommended to take 45–50 liters per person. If the norm is exceeded, the water in the tank will stagnate, which will certainly affect its quality.

The shape of the tank is selected taking into account the pressure in the plumbing system. If the pressure is low, then the use of homemade boilers with a square tank is allowed. If the pressure in the system is high, only equipment with a rounded bottom and top can be used.

Boilers with a storage tank of square and rectangular shape can only be used in water supply systems with low operating pressure

The fact is that increased pressure contributes to the occurrence of bending forces on the walls of the tank, so a square or rectangular tank can become deformed. A container with a round bottom is more resistant to deformation due to better streamlining.

Heat exchanger power and length

In vertical indirect heating models, a copper coil is usually used as a heat exchanger, located between the inlet and outlet.

Boiler coil made of copper pipe

For DIY production, it is best to use a copper pipe with a diameter of 10 mm. This product can be easily bent by hand without using any tools. When using a metal-plastic pipe, it should be taken into account that the heating temperature of the coolant should not be more than 90 °C, otherwise the pipe will be deformed and the joints will leak - this will lead to mixing of water in the tank.

The length of the pipe required for the manufacture of the coil is calculated by the formula L = P / (3.14 ∙d ∙∆T), where:

- L—pipe length (m);

- d—pipe cross-section (m);

- ∆Т – temperature difference between heated and cold water (оC);

- P is the power of the heat exchanger for every 10 liters of water (kW).

According to experts, for every 10 liters of water there should be at least 1.5 kW of thermal energy. Taking this into account, you can calculate the length of the pipe for making the coil.

For example, let’s calculate the material for a coil that will be installed in a boiler with a capacity of 200 liters. The temperature of cold water supplied to the container will be 15 oC, and after heating it is necessary to obtain water with a temperature of 80 oC: L = 1.5 ∙20 / (3.14 ∙0.01 ∙65) ≈ 15 m.

Table: length of copper heat exchanger for boilers with a capacity of 50–200 liters

| Storage tank volume, l | Equipment power, kW | Heat exchanger length, m | Boiler tank diameter, m | Coil diameter, m | Number of turns |

| 200 | 30 | 15 | 0,5 | 0,4 | 12 |

| 150 | 22,5 | 11 | 0,5 | 0,4 | 9 |

| 100 | 15 | 7,5 | 0,4 | 0,3 | 8 |

| 50 | 7,5 | 4 | 0,4 | 0,3 | 5 |

The number of turns of the coil depends on the method of bending and the distance between the elements. Typically, the coil is positioned so that the distance between the coils and the walls of the tank is at least 10–12 cm. The distance between the coils should not be less than 5 cm. The calculated values for storage tanks of various volumes can be seen in the table above.

If an indirect type boiler needs to be equipped with a tubular electric heater, then the power is calculated based on the fact that to quickly heat 50 liters of water, a heating element with a power of at least 1.5 kW is required. In addition, any combi boiler must be equipped with a thermostat.

The law is what the drawbar is, where it is turned there and out

The design on YouTube is not illegal, but it is not very convenient. There is even less chance of setting it up correctly for use. Here are a couple of tips to help you do this somehow:

The radiator in the video resembles something from a car hood. There was no time to figure out what exactly it was, but the point is that you will need not just a coil, but just such a corrugated surface. This will significantly increase the efficiency of the device, on which both efficiency and gas fees (if there is a meter) ultimately depend.

This device is a gas instantaneous water heater, which should produce about 4 liters of warm water per minute. It’s easy to calculate how much power it should have for this:

N = A / t = (4200 x 4 (45 - 8)) / 60 = 10.36 kW, this is the power achievable for a factory gas water heater. You can only find out if you can make an appropriate heat exchanger at home by trying it.

The device itself is a coil, which is connected at one end to a cold riser, and at the other to a shower head or mixer. The flow is regulated by a valve. In this sense, you will have to use an old cast-iron tap at the inlet or a bronze tap at the outlet of the coil. The radiator is placed on the hob grate and heated by one or two burners. It is clear that the hose must be heat-resistant, otherwise various unpleasant consequences are possible.

An adult must supervise the operation of the device and, in case of danger, turn off the supply of blue fuel while someone is washing or doing the dishes. A gas water heater or an electric water heater is much safer from this point of view. I would also like to add that even purchased equipment needs to be configured, which means that the intervention of a qualified technician will be required. Sometimes a set of jets (injectors) needs to be replaced, in other cases a reducer is installed in the gas supply path. In the latter case, the system resembles traditional propane-butane power supply.

Electric water heater market overview

Currently, there are a larger number of manufacturers, both domestic and foreign, on the Russian market of electric water heating equipment. Of course, foreign manufacturers such as MTS and Lorenzi Vasco mainly dominate, but their products cannot be called pure imports. Most companies open their own full-cycle production facilities in Russia, with the production of basic components. This allows us to reduce the cost of production and make it available to a wide range of buyers. One of such companies is the Italian corporation Thermex, whose products have almost become a Russian brand.

It has been successfully operating in Russia for more than twenty years, opening its own factories and providing our market with high-quality electric water heaters. The product range from this manufacturer includes all types of electrical equipment for heating water. The popularity of the Termex water heater among consumers is very high due to the innovative ideas used in its manufacture. The operating principle of the Termex water heater, regardless of the type of device, does not differ from similar products from other manufacturers. But it should be said right away that the company’s products have won the trust of the Russian buyer with their technical characteristics and affordable price.

Why are water heaters from Thermex Corporation so good? Everything is very simple! The product range is very wide and allows almost any consumer to select water heating equipment to suit their needs. Termex electric storage water heaters are available in a wide range of internal volumes from 10 to 300 liters. Flow-through heaters of varying power allow you to almost instantly heat running cold water to the required temperature.

Other advantages of Termex electric water heaters include the following technological and design features:

- the model range of storage water heaters consists of both round and flat models of various volumes with a laconic design;

- high-quality thermal insulation of products and automatic control of operating modes allow significant energy savings;

- various models use both electronic and mechanical control, which allows you to optimize the entire water heating process;

- storage water heater tanks are made of special stainless steel with high corrosion resistance;

- in instantaneous water heaters, the heating module is made entirely of copper, which increases its reliability and durability;

- In some models of storage water heaters, the inner surface of the tanks is covered with bioglass porcelain, which completely eliminates corrosion of the tank.

In addition, the product range includes electric water heaters with a combined water heating system.

How to assemble an induction boiler yourself

The modern market of heating devices offers a large selection of different models of induction heaters for both domestic and industrial use. Despite the fact that today such equipment has not reached the level of widespread use in heating systems, its cost is high. The price for domestic boilers starts from 25,000 rubles, and for industrial boilers - from 100,000 rubles.

To save money, you can make an induction heater yourself. Even a non-specialist can do this kind of work.

Device with welding inverter and plastic pipes

All materials and components used for assembly are available and are often at hand. What is needed for this:

- wire rod or stainless steel wire (diameter up to 0.7 cm);

- copper wire;

- metal grid;

- a fragment of a plastic pipe with thick walls for the heater body (inside diameter 5 cm);

- welding machine;

- adapters for mounting the boiler to the heating system;

- tools;

- pump to ensure water circulation.

Stainless steel wire needs to be cut into pieces 0.5-0.7 cm long. Fill the plastic pipe tightly with them and close it on both sides. There should be no free space in it. A metal mesh is installed at the bottom of the tube, which allows you to keep steel particles inside.

Next, you should make the main heating component - the induction coil. Copper wire is wound onto a plastic pipe. It is necessary to make at least 100 neat turns at the same distance from each other. The induction coil is then connected to the individual heating system. The boiler is installed in any part of the pipeline. To pump water, you need to build in a pump.

The homemade device is connected to the inverter using an external copper winding. Electrical and thermal insulation work must be carried out on the boiler. All open areas are covered with special material. Basalt wool is used for insulation. This is necessary so that the pipe is heated without losing heat energy to the air.

Device with transformer

This option is easier to assemble than the previous one. What you will need to make it yourself:

- three-phase transformer with mounting option;

- welding machine;

- copper winding.

It is necessary to insert the pipes into one another and weld them. The design in cross section should resemble the shape of a donut. It performs two tasks simultaneously - a heating element and a conductor. Then the heater body is wrapped with copper wire and connected to the transformer. To prevent heat loss during operation, a protective casing can be installed on the boiler.

Induction heating is a good alternative to standard heating systems. Its efficiency is about 97% efficiency. Such systems are economical, operate on any liquid, operate silently, and do not emit harmful substances.

If the assembly rules are followed, the boilers are safe to use. They are durable. But if any element becomes unusable, replacing it will not be difficult. All materials are easily replaceable and available.

Manufacturing and lining of the firebox

The most difficult task in producing a homemade Titan is rolling the steel sheet into a cylinder. With a significant thickness of the metal, this is not so easy to do; the parts must be welded without stress, because when exposed to high temperatures, the strength characteristics of the weld are greatly reduced.

Initially, you should select the expected internal diameter of the firebox in the range of 50–70 cm and cut two disks to this size. According to the diameter, the circumference is calculated, and a strip is cut out of it from the sheet, from which the walls of the combustion block will be formed. The height of the firebox, as already mentioned, is selected according to the volume of the tank: about 5 kW of heat is consumed to heat every 50 liters of water, which corresponds to approximately 1 kg of dry firewood. Thus, for a 200-liter heater, the firebox should freely accommodate 4 kg of firewood without taking into account the volume of the ash pan. The higher and narrower the heating column, the more efficient the heat transfer occurs, but the stability of the Titan decreases.

The cut steel sheet is laid horizontally, and two disks are installed vertically on its short edge. One is placed parallel to the long edge with a slight indentation - this disk forms the bottom of the combustion block. The second disk is installed parallel to the first with a distance of 20–25 cm from it - this is how a partition is formed between the firebox and the ash pan. You can immediately cut an opening in the partition, the size of which is 40–50 mm smaller than the existing grate.

Two disks act as a rigid mandrel for rolling the cylinder. First, they are welded to the strip on both sides with tacks 10–15 mm long, carefully monitoring the perpendicularity of the installation. Next, the metal is driven over the discs with a sledgehammer; if the metal thickness is more than 5 mm, heating with a propane torch may be required. When the two parts to be welded are pressed tightly, the perpendicularity of the disks is checked, after which the welding seam continues for another 10–15 mm and so on until it goes completely around the circumference. When the seam is completed to its full length, it is covered with another one: the electrode is drawn without separation with heating and surfacing of a wide area, the weld pool is displaced in a zigzag. After welding the discs to the wall, a longitudinal seam is welded on the outside.

When the firebox body is assembled, it is lined from the inside with fireclay bricks without any binder in the seams; the thickness of the lining is about 50–70 mm. To accurately adjust the stones to the size of the firebox, they are first placed vertically on a flat surface in a cylindrical well, the internal diameter of which is approximately equal to the diameter of the firebox. In this case, the bricks are located closely on the inside and with the most uniform indentation from each other on the outside, diverging in rays.

The distance between adjacent stones at the most extreme points must be divided in half and the bevels of the resulting size removed with a diamond wheel, achieving a wedge-shaped shape. After this, the bricks are installed against the walls of the firebox from the inside; if necessary, they are adjusted to each other using an angle grinder. The stability of the lining can be ensured with the help of a steel strip rolled into a ring and installed from the inside. After lining the walls, a grate is placed inside.

Advantages of induction type units

The undoubted advantages of this type of home heating devices include the following characteristics:

- efficiency - the conversion of electrical energy into heat occurs almost completely without significant losses;

- ease of use - constant maintenance of units of this type is not required;

- compact dimensions - induction water heaters are small in size, they can be installed in the heating system in almost any room;

- quiet operation – this equipment operates quite quietly, no noise occurs during its operation;

- long service life - induction units are durable and can operate smoothly for 30 years or more;

- high environmental friendliness - no harmful emissions occur during operation of the device, a chimney installation and a ventilation system are not required.

Many people believe that induction boilers are much more profitable than other home heating options. And compared to equipment equipped with heating elements, the heating time of these units occurs almost twice as fast. Due to the constant circulation and vibration of the liquid, scale does not form in the pipes and inside the device, which greatly facilitates the maintenance and care of the heating system.

But this type of device also has some disadvantages. And the main disadvantage is that induction equipment is quite expensive. But you can try to make such a heater for heating your home yourself.

Advantages of homemade heaters

Why do owners often prefer to make a boiler with their own hands? A homemade boiler has many advantages over factory ones:

- Connects to the heating system.

- Placed next to the boiler.

- Costs much less than purchased

- Allows you to save energy resources.

- Allows you to maintain a constant water temperature.

If we talk about the disadvantages of a DIY boiler, they are:

- You need a fairly spacious room to install or hang the heater.

- If the device is not powerful enough, the water takes a long time to heat up.

- Scale forms quickly, so it is better to soften the water

Important! A home-made unit is also good because during the heating season it operates from a central heating supply, and in the summer – from the electrical network.

Pros and cons of induction water heating devices

The device has a fairly simple design and does not require special documents permitting use and installation. The induction water heater has a high degree of efficiency and optimal reliability for the user. When using it as a heating boiler, you don’t even have to install a pump, since water flows through the pipes due to convection (when heated, the liquid practically turns into steam).

The device also has a number of advantages, which sets it apart from other types of water heaters. So, an induction heater:

- much cheaper than its analogues, such a device can be assembled independently without any problems;

- completely silent (although the coil vibrates during operation, this vibration is not noticeable to humans);

- during operation it vibrates, thanks to which dirt and scale do not stick to its walls, and therefore does not require cleaning;

- has a heat generator that can be easily made sealed due to the operating principle: the coolant is located inside the heating element and the energy is transferred to the heater via an electromagnetic field, no contacts are needed; therefore, there will be no need for rubber seals, seals and other elements that can quickly deteriorate or leak;

- there is simply nothing to break in the heat generator, since the water is heated by an ordinary pipe, which is unable to deteriorate or burn out, unlike a heating element;

Despite the huge number of advantages, an induction water heater also has a number of disadvantages:

- the first and most painful for owners is the electricity bill; the device cannot be called economical, so you will have to shell out a fair amount of money to use it;

- second, the device gets very hot and heats not only itself, but also the surrounding space, so it is better not to touch the body of the heat generator during its operation;

- third, the device has extremely high efficiency and heat transfer, so when using it, be sure to install a temperature sensor, otherwise the system may explode.

Conclusion

An electrode boiler is a good solution for dachas and country houses. Its installation does not require permits or a separate room, and its operation does not require increased safety requirements. You can make such a device yourself, but how practical it is is up to you to decide. Although the water heater has a very high efficiency, its use is still much more expensive than the operation of its gas counterpart . It is also worth noting that the ion boiler is demanding on the coolant and heating system. If you do not comply with the mandatory requirements, the device will work ineffectively and will last much less than the stated period.

Other methods of making a water heater

You can build a water heater powered by the sun. This is a fairly common design, which is distinguished by its efficiency. The device is often found in country houses. Making the device is not particularly difficult, so many can build it with their own hands.

- large capacity tank (100 l or more);

- PVC pipes for filling the container and supplying water to it;

- steel corners measuring 20 mm or square blocks of wood measuring 50 mm for a frame for a container.

It is more advisable to use polyethylene barrels as containers. They are distinguished by their strength. They should be placed in a sunny place where there is no wind. As a rule, the roof of a summer shower is chosen for installation.

In order for the barrel to heat up better, it needs to be painted black. Screens are installed on the leeward side for protection. They are constructed from boards coated with reflective material similar to foil. In this case, the sun's rays are directed towards the tank and increase the temperature of the water. In hot weather, in a container of 200 liters you can get water whose temperature will be 45 ºС.

Required materials and tools

The storage tank of the device is made of heat-resistant plastic, stainless steel, aluminum or ceramic-coated steel. As blanks for the tank, you can take plastic barrels for food products, aluminum tanks or an unnecessary gas cylinder.

To make a heat exchanger, as mentioned above, it is better to use a round or square copper pipe. When assembling a heat exchanger from square pipes, 90° bends will be required.

As a tool you need to prepare:

- angle grinder;

- electric drill with core drill for metal;

- argon-arc welding machine;

- set of wrenches;

- disc for grinding and polishing metal;

- sandpaper.

To assemble the boiler you will need the ability to work with a welding machine.

Fittings, drain valve and other connecting elements are selected based on the size of the connected pipe. Additionally, FUM tape, a safety valve, a magnesium anode and a nozzle for its installation are purchased.

Homemade induction boilers

The simplest circuit of the device, which is assembled, consists of a piece of plastic pipe, into the cavity of which various metal elements are placed in order to create a core. This can be thin stainless wire rolled into balls, wire cut into small pieces - wire rod with a diameter of 6-8 mm, or even a drill with a diameter corresponding to the internal size of the pipe. From the outside, fiberglass sticks are glued to it, and a wire 1.5-1.7 mm thick in glass insulation is wound on them. The length of the wire is about 11 m. The manufacturing technology can be studied by watching the video:

The homemade induction heater was then tested by filling it with water and connecting it to a factory-made ORION 2 kW induction cooktop instead of the stock inductor. The test results are shown in the following video:

Other craftsmen recommend using a low-power welding inverter as a source, connecting the secondary winding terminals to the coil terminals. If you carefully study the work done by the author, the following conclusions arise:

- The author did a good job and his product undoubtedly works.

- No calculations were made on the thickness of the wire, the number and diameter of the coil turns. The winding parameters were adopted by analogy with the hob; accordingly, the induction water heater will have a power of no more than 2 kW.

- In the best case, a homemade unit will be able to heat water for two heating radiators of 1 kW each, which is enough to heat one room. In the worst case, the heating will be weak or disappear altogether, because the tests were carried out without coolant flow.

It is difficult to draw more precise conclusions due to the lack of information on further testing of the device. Another way to independently organize induction heating of water for heating is shown in the following video:

The radiator, welded from several metal pipes, acts as an external core for the eddy currents created by the coil of the same induction hob. The conclusions are as follows:

- The thermal power of the resulting heater does not exceed the electrical power of the panel.

- The number and size of the pipes were chosen randomly but provided sufficient surface area to transfer the heat generated by the eddy currents.

- This induction heater circuit turned out to be successful for a specific case where the apartment is surrounded by the premises of other heated apartments. In addition, the author did not show the operation of the installation in the cold season with recording of the air temperature in the rooms.

To confirm the conclusions drawn, it is proposed to watch a video where the author tried to use a similar heater in a free-standing, insulated building:

What materials will you need?

First of all, you need to select a container for making the tank. The best material choice is stainless steel. You can use a ready-made barrel, order a tank of the required size, or purchase a gas cylinder. It has sufficient strength, suitable dimensions and shape. Another option for making a tank could be a container made of heat-resistant plastic.

Holes of the required size should be made in the tank. Two holes will be needed to connect the cold water supply and hot water supply pipes. One of them is done at the bottom of the tank, and the other at the top of it. Two more holes will be needed for the installation of a coil intended for the passage of coolant.

A tube made of brass or copper is perfect for making a coil. These materials transfer heat well and can be easily shaped into the desired shape. You can also use small diameter plastic pipes.

In order to make a coil, a pipe of the required length is wound on a base, which can be a strong metal pipe or a rounded log.

In order for the tube intended for the coil to be bent evenly, without creases, it is completely filled with sand before starting work. Then the coil will be of the correct shape, with the same diameter along its entire length.

Based on the volume of the tank, the temperature of the coolant and the temperature of the incoming water, the required length of the coil is calculated. To do this, use a special calculation formula. For a container with a volume of 200 liters, when using a coil with a diameter of 10 mm, its length will be about 15 meters.

Even before installing the storage boiler, you should decide how its thermal insulation will be carried out. It will not be possible to do without it, since natural heat losses are high and the efficiency of the water heater will be too low. The ideal way to insulate a tank is to place it inside a suitable container and then fill it with foam.

To assemble the boiler, you should ensure that you have fittings, nuts, rubber seals, and ball valves. When making a structure from a gas cylinder, welding equipment will be required.

Watch a video on how to make an indirect heating boiler with your own hands:

DIY induction water heater diagram

The device is a transformer with two windings: primary and secondary. The first circuit converts electrical energy into eddy currents, thereby creating a directed induction field, which provides induction heating. In the secondary circuit, the converted energy is transferred to the coolant (in our case, it is water).

In addition to the transformer, the device contains a generator and a pump (optional).

Heat generator components and parts

The device includes:

- an alternating current generator that increases the frequency of the current;

- the inductor, which transforms electricity into magnetic energy, is a coil of copper wire;

- heating element, most often its role is played by a metal pipe.

Principle of operation

An induction water heater consists of a generator, a coil and a core, the latter is heated by electromagnetic energy

The device converts electrical energy into electromagnetic energy. The latter, in turn, acts on the core (pipe), which heats up and transfers thermal energy to the water. All these energies are converted by an inductor consisting of a coil and a core. The generator is used to increase the frequency of the current, since with a standard frequency of 50 Hz it is difficult to achieve high heating.

Electric indirect heater

The use of heating elements does not apply to indirect heating methods, since there is direct contact of water with the primary heat source. An exception is the induction water heater. The liquid receives energy virtually, as it were, without touching the internal thermoelement. In fact, it is not in the design at all.

The main advantage of the system is that heating occurs not due to direct thermal contact with a source of electrical energy, but with the help of eddy currents. Losses on the heat transfer coefficient are minimal, efficiency tends to 100%. At the same time, both the metal pipe and the liquid itself are heated (if it is sufficiently thermally conductive). In addition, flow-through induction heaters are significantly safer than boilers with a traditional electric heater: there is no contact of water with an element connected to the electrical network.

The disadvantage is obvious: heating requires an electrical connection. That is, the option of indirect heating using a wood-burning (gas) boiler does not work. The room must be electrified.

Indirect heating boiler design

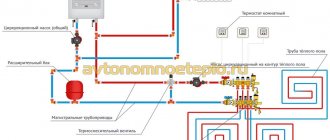

An indirect heating boiler is a storage tank that is not dependent on energy resources (gas, electricity, etc.). Inside the container, made of stainless steel, there is a heating element 1 in the shape of a spiral.

Cold water enters the tank through an inlet tube located at the bottom of the device. The water in the unit is heated using the moving coolant of the heating system. The hot water outlet pipe is located at the top. To make using the tank convenient, it is equipped with taps with a ball design. The outer part of the device is covered with heat-insulating material.

The water heater diagram is shown below.

The advantages of the unit include:

- possibility of connecting to a central heating system;

- installation near a heating boiler;

- low cash costs when installing the circuit;

- economical use of energy resources;

- water supply at a constant temperature.

Preparing the tank for water heater assembly

To make an indirect type boiler, you can use a new or old gas cylinder. This container is made of thick stainless steel 3-4 mm thick and is perfect for working with hot water.

Before assembling the heating structure, you will need to carefully prepare the cylinder. To do this, the product is cut in half using a grinder. The inner surface of the container is cleaned using an angle grinder with an appropriate attachment.

Before assembling the boiler, the cylinder must be opened and the inner surface cleaned

After this, the inside of the cylinder is washed, dried and coated with nitro primer paint. This work must be carried out without fail, otherwise after putting the boiler into operation, the heated water will smell like gas.

When using a tank from other metal containers, preparation is carried out according to a similar scheme.

DIY instantaneous induction water heater

Before you begin installation, you need to stock up on the necessary parts. So, the best option would be a high-frequency welding inverter with a smoothly varying current range. Such a device will cost the least. A more expensive option would be a three-phase transformer, which is the AC power source for the water heater inductor. In this case, you should use a coil of 50-90 turns, and use copper wire with a diameter of 3 or more millimeters as the material.

As a core, you can use either a metal or polymer pipe together with wire (used as a heating element). In the latter case, the thickness of the walls should not be less than 3 mm in order to easily withstand high temperatures.

To assemble the water heater you will need: wire cutters, screwdrivers, a soldering iron and a welding machine if a metal pipe is used.

Installation of an induction water heater

Wrap the pipe with copper wire, making about 90 turns.

There are many options for assembling the device. We suggest trying to assemble the device according to the following scheme:

- Prepare your workplace, materials and tools.

- Fix a small piece of polymer pipe (remember that the minimum wall thickness should be 3 mm).

- Trim the ends of the core to leave 10 cm of wire left for taps.

- Mount a corner on the lower outlet. In the future, the return from the heating should be connected here (if the heater is used as a boiler).

- Place the chopped wire tightly around the pipe. It is necessary to make at least 90 turns.

- Install a tee on the top pipe through which hot water will flow out.

- Install the protective circuit of the device. It can be made from either polymer or metal.

- Connect copper wire to the water heater terminals, then fill the core with water.

- Check the functionality of the inductor.

Boiler type heater

Materials:

- Container for the boiler body (gas cylinder).

- Nut (32 mm).

- 2 pieces of metal pipe, ½ inch in diameter (about 15 cm).

- Electric heating element and thermostat.

- Tow or special lubricant for insulating the heating element.

- Fastenings for a boiler on the wall.

- Thermal insulating substrate for laminate.

- Plastic pipes for water supply.

- Wires and terminals for electrical wiring.

Tools:

- Welding machine.

- Tool for cutting threads.

- Drill and drill bits for metal.

- Screwdrivers.

- Gas keys.

- Screwdriver tester.

As a container for the boiler tank, a large 50 liter gas cylinder with the valve removed would be an ideal option. It is not recommended to use used cylinders, otherwise water passing through such a boiler, designed independently, will have a persistent smell of gas.

You can get rid of it by cutting the container in half, thoroughly washing and sanding the surface, and then applying a layer of nitro primer to it and welding the structure again. But it is much easier to contact a service that refills and distributes gas cylinders and purchase a new, unused container there. There, by the way, you can buy a cylinder without a tap, and there will be no need to remove it yourself.

Main types of breakdowns

Modern manufacturers have learned to create excellent luxury water heating equipment. It uses gas to operate efficiently and rarely fails. However, even the best gas heaters cannot avoid breakdowns. The list of inevitable malfunctions includes:

- water leaks;

- poor heating of the liquid;

- discharge of power elements;

- weak water pressure;

- lack of gas.

Owners of gas boilers can repair some faults themselves. Anyone can change the batteries in the power supply. It is also easy to eliminate weak water pressure - perhaps excess scale has simply formed in the heat exchanger. To remove it, remove the heat exchanger and rinse thoroughly. For these purposes, you can also use special descaling liquids.

It is not difficult to solve the problem of poor water heating on your own. The main reason for such a malfunction is often contamination of the heat exchanger with soot. The solution to this problem is to remove the mentioned element and remove plaque. If more significant problems occur, you should contact a professional.

How does a water heater work?

An indirect boiler depends on an additional energy source: solid or diesel fuel. Therefore, it is the most economical among other water heaters.

How does the device work? A coil with coolant is installed inside the housing. When started, it circulates, heating the contents of the tank. The boiler design diagram is as follows:

The storage tank is connected to the boiler. Thanks to the constant circulation of the coolant, the temperature is maintained at the optimal level. The equipment is capable of providing several points of intake, instantly supplying hot water.

Main types of breakdowns

Modern manufacturers have learned to create excellent luxury water heating equipment. It uses gas to operate efficiently and rarely fails. However, even the best gas heaters cannot avoid breakdowns. The list of inevitable malfunctions includes:

- water leaks;

- poor heating of the liquid;

- discharge of power elements;

- weak water pressure;

- lack of gas.

Owners of gas boilers can repair some faults themselves. Anyone can change the batteries in the power supply. It is also easy to eliminate weak water pressure - perhaps excess scale has simply formed in the heat exchanger. To remove it, remove the heat exchanger and rinse thoroughly. For these purposes, you can also use special descaling liquids.

It is not difficult to solve the problem of poor water heating on your own. The main reason for such a malfunction is often contamination of the heat exchanger with soot. The solution to this problem is to remove the mentioned element and remove plaque. If more significant problems occur, you should contact a professional.

Those who have seen enough of the video on YouTube about a homemade gas water heater, which consisted of a coil placed directly on the hob in the kitchen, have probably already dreamed of how they can get a lot of boiling water cheaply. Actually this is not true. Today we will talk about why you should not make a gas water heater with your own hands.

Instructions for connecting and starting the system

When preparing a boiler for operation, the first step is to connect it to the heating system. This could be a network of a home autonomous boiler or a central highway. During the connection process, the lid of the water heater tank must be open. When all the pipes are connected to each other in the required order, open the shut-off valve of the return pipe to make sure that there are no leaks at the joints and the pipes themselves.

If no leaks are found, you can open the coolant supply valve to the coil. After the spiral has warmed up to normal temperature, the structure is once again inspected for leaks.

If everything is in order, close the lid of the tank and fill it with water, and also open the tap for supplying hot water to the water supply. Now you can evaluate the quality of heating.

Work principles

To assemble an induction boiler with your own hands, you need to study what it consists of and understand the principles of its operation.

The device heats up due to the energy of the electromagnetic field. The coolant takes it over itself and converts it into heat.

The magnetic field is created in an inductor (this is a cylindrical coil with a large number of turns). As electricity passes through it, it creates a voltage around itself. The magnetic flux moves in a closed circle perpendicular to the electric field. Alternating current creates eddy currents and generates energy into heat. Electricity is transferred to the heater without direct contact.

Induction heat is consumed efficiently and economically, so water with this heating method reaches high temperatures in a short period of time. The coolant receives about 97% of the energy.

Induction water heater components

Organizing a heating system in your own home using an induction boiler will not require major redevelopment. It is based on a transformer consisting of primary and secondary windings.

Vortex flows are formed in the primary winding from electrical energy and create an electromagnetic field. It goes to the secondary, which functions as a heater.

The secondary winding is the boiler body. It includes elements such as:

- external winding;

- core;

- electrical insulation;

- thermal insulation.

To supply cold water to the device and remove warm water to the heating system, two pipes are installed to the water heater. The lower one is mounted on the inlet section, and the upper one on the hot water outlet part.

The heat created by the boiler is transferred to the coolant. Most often it is water, since it can quickly absorb heat. Due to the built-in pump, hot water enters the heating system through the pipe. The liquid constantly circulates, so overheating of the equipment is not possible. Cooled water is supplied and hot water is discharged.

When circulating, the heating fluid vibrates, which prevents scale from depositing inside the pipes. An induction water heater can be installed in any room, since no noise is created during operation.

Installation and operation of a heating boiler

Boiler in the heating system

After performing all the necessary calculations of the boiler power and its volume, you can begin to integrate the device into the heating system

An important task is to determine the installation location. Having decided on the purpose of the boiler in the heating system, you need to read the instructions for its installation. The best option would be installation in close proximity to the boiler

In this case, the transfer of thermal energy from the coolant to water is most effective.

But at the same time, you may encounter the following difficulties in organizing heating using a boiler:

- DHW system supply. In a heating system with a solid fuel boiler, it is most convenient to place the boiler directly in the boiler room. But then to supply heated water to the premises you will need a separate pump and control devices for it;

- A large volume of capacity if heating through a boiler is planned for large residential areas. There is a problem with the placement of the heating element;

- Electrical supply to ensure the operation of the heating element. For the normal functioning of the boiler for heating a private house, it is also recommended to install an autonomous source of electricity.

Having resolved these issues, you can proceed directly to installation.

Installation of a heating storage tank

Installed boiler

To install the heat accumulator, it is necessary to prepare a flat area in advance. Its heavy weight should be taken into account - if necessary, a separate foundation is made or the floors are reinforced.

The optimal installation option is on a separate platform. This way you can avoid contact of the housing with the concrete surface, which will reduce heat losses in the electric heating boiler. Almost all manufacturers make containers with special legs. If they are missing, it is recommended to install insulation on the floor.

The procedure for connecting the boiler to the heating system is to perform the following steps:

After installing the container, you need to check its position relative to the horizon. No deviations are allowed. Connect to heating

It is important that the diameter of the pipes is equal. Otherwise, after connecting the boiler to the heating system, excess hydraulic resistance will appear. If installation is carried out in an unheated room, the boiler body is insulated. A connection to the hot water supply is made so that the boiler works not only for heating, but also for hot water supply.

Upon completion of this work, you need to check the tightness of all connections and start the heating system. It is recommended to measure the temperature of the water in the tank and the coolant in the pipes within 2-3 weeks after the boiler is turned off. This way you can determine the actual time of maintaining the required heating level in the heating circuit from the boiler.

Conditions for proper operation of the boiler

Scale on the heating element of the boiler

Servicing a storage tank is practically no different from carrying out the necessary procedures to maintain the functionality of any electric boiler with heating elements. And in this case, in order for the boiler to work normally in the heating system of a private home, you must follow the manufacturer’s recommendations.

This can be ensured even before the heat supply from the boiler is made. It is best to purchase models with the so-called “dry heating element”. On it, scale formation occurs much more slowly. You should also pre-filter the water before feeding it into the storage tank.

In addition to these procedures, you must do the following:

- Once a month, check the integrity of the thermal insulation of the structure;

- Monitor the duration of maintaining the coolant temperature during the heat supply mode through the boiler. The difference between calculated and actual indicators should not exceed 15%;

- Checking the tightness of connections. It is recommended to replace the gaskets before each heating season. This way you can achieve more reliable heating of a private home using a boiler.

The control unit of some models is sensitive to voltage changes. To avoid damage to this expensive device, you should connect a stabilizer for the boiler in the heating system.

Choosing a tank for the boiler

The volume of the storage tank of the water heater should be calculated based on the daily consumption of hot water in the house. If several people live in an apartment or house, a tank of 100 liters will be sufficient. And for a family of 4-5 people, you should choose a container with a volume of 200-300 liters.

The tank used should be made of an aluminum alloy, stainless steel or other metal that is resistant to corrosion. You can use a large-sized gas cylinder, the walls of which are additionally cleaned and primed. If the walls of the cylinder are not primed, the hot water may have an unpleasant gas smell.

Five holes must be drilled in the selected tank. Two at the bottom for the inlet pipe and emergency drain, two at the side for installing the coil and one hole for water extraction at the top. If you plan to use such a boiler outside the heating season, you must also make holes for installing an electric heating element. For the heating element, one or two holes are drilled from below. Ball valves or shut-off elements are installed in the holes made, after which the tightness of the storage container is checked.

Advantages and disadvantages of heating using a water heater

Like any system, this one has its pros and cons. Let's consider the benefits

- reduction of cash costs for the purchase of equipment. Boilers are an order of magnitude more expensive than heaters, and using an old tank will generally reduce costs to a minimum

- ease of installation. Installing heating from a water boiler only with your own hands without involving third-party specialists is a completely solvable task

- minimal energy loss. Any heater model includes a thermal insulation layer, which is almost always absent from the boiler.

The disadvantages of such a complex include the low power level. It will not be possible to achieve high performance, even if you use a device with a high-performance heating element and a significant tank capacity. The maximum that the design is capable of is the preparation of coolant for hot water supply and heating of a small private house, cottage, or apartment. In addition, the life of the boiler is not designed for uninterrupted operation, which is necessary to maintain a comfortable temperature in the premises. Operating at maximum capacity can lead to a significant reduction in its service life.

The simplest heat exchanger

A homemade heater looks like this:

A larger diameter shell is welded onto the central heating pipe. The result is a sealed vessel with hot coolant flowing inside it. On opposite sides of the outer pipe (in fact, this is a boiler), flanges are installed for supplying (draining) cold water. When the coolant is hot enough, the water in the boiler heats up quickly. After which the top tap can be opened and the hot water supply can be used until the hot water is replaced by cold.

If we leave aside the legality of re-equipping the collective heating network (there is hardly any serious liability for this), the system works effectively. Hot water is conditionally free, minus one-time investments in materials, and a bottle of strong drink for the welder.

If you install such a instantaneous water heater with your own hands in a private household, there will be no conventional problems.

The only limitation is the volume of the outer container. In real time, the water will not heat up; the reserve of thermal energy in the heating pipe is too small. Therefore, the system works cyclically: heating - use - heating. The higher the diameter ratio (or the longer the pipe), the greater the supply of hot water. Accordingly, the longer it will take to warm up.

Another serious drawback: in the summer (with the heating turned off) such heaters do not work.

What can BKN materials be made from?

- preparation of storage tank;

- heat exchanger production;

- installation of heating elements;

- thermal insulation of the body.

How to make an indirect heating tank

- suitable for food water;

- withstands heating up to 90°.

| Dimensions | Description | 1500 l |

| N | Height | 2285 mm |

| ø ext | External diameter (including insulation) | 1200 mm |

| ø int | Inner diameter | 1000 mm |

| F | Cold water inlet (1″1/4) | 315 - 1″1/4 mm - » inch |

| G | Water outlet from the lower coil (1″1/4) | 470 mm |

| L | Hole for bottom temperature sensor (1/2″) | 582 mm |

| M | Water supply to the lower coil (1″1/4) | 1180 mm |

| N | Water outlet from the upper coil (1″1/4) | 1330 mm |

| P | Hole for top temperature sensor (1/2″) | 1500 mm |

| Q | Recirculation (1″) | 1460 - 1″ mm - » inch |

| R | Water supply to the upper coil (1″1/4) | 1735 mm |

| S | Domestic hot water outlet (1″1/4) | 1935 - 1″1/4 mm - » inch |

| A | Inspection flange (ø internal 114 - ø external 168) | 520 mm |

| B | Additional electrical resistance (1″1/2) | 1255 mm |

| C | Thermometer (1/2″) | 1825 mm |

What material is the heat exchanger made of?

L = Q / D* (Tg – Tx) * 3.14

- coil length - L;

- thermal power - Q;

- heat exchanger diameter - D;

- the expected hot and cold water temperatures are Tr and Tx, respectively.

Heating element for combined BKN

P= 0.0011*m*(tk-tн)/T

- P is the power of the heating element;

- M is the mass of heated water;

- tk is the desired water temperature;

- tн - initial water temperature;

- T is the water heating time.

Indirect heating boiler with electric heating element

How to make thermal insulation BKN

- The body is coated with heat-insulating paint - it contains ceramic components that retain heat. At the same time, the paintwork protects the surface of the tank from corrosion.

- Mineral wool - a thermal insulation layer of about 5 cm. It is optimal to use basalt insulation. The material prevents heat loss, is resistant to moisture and at the same time allows steam to pass through, preventing liquid from accumulating in the layers of the material. The mineral wool is covered on top with any material with a foil base. You can use Penofol and derivatives.

- Instead of three-layer insulation, the use of Polinor is allowed. The insulation is similar to polyurethane foam. Easy to apply and prevents heat loss.

Working principle and purpose of BKN

The hot water supply is heated using heat from the heating system. A storage electric water heater is connected to the boiler. The thermal carrier transfers energy to the TENU: coil or tank. The heated surface of the coil borders the water from the hot water supply, and heat exchange occurs. The outlet produces hot water for household needs at a temperature of 65-70°.

How to calculate the volume of produced BKN

According to rough calculations taken into account during the design of a private house, the average statistical family, which consists of 4 people, spends an average of 280 liters per day. For normal water supply to the family, you will need a 200 liter electric storage water heater. If you plan to use hot water exclusively for showering and washing, 100-120 liters is quite enough. containers.

To calculate the approximate needs for domestic hot water, use the following table:

Approximate water consumption (l)

Water consumption from electric storage water heater (l)

When calculating the volume of an electric storage water heater, one more factor is taken into account. If you plan to install a mounted BKN, then its capacity is limited to 150-160 liters, which is due to the load on the wall. If a larger volume is required, install a floor-mounted storage electric water heater.

What container to make a tank from?

Any corrosion-resistant container is suitable for this.

- The tank can be made of enameled metal, stainless steel, plastic or other containers.

- Containers coated with a layer of glass ceramics and enamel will require replacement within a year after use, since they are not particularly resistant to corrosion.

- If the tank is made from a metal container, then a welding machine will be needed to manufacture the structure.

- Much more durable and reliable than stainless steel containers.

- To make a boiler, you can use a gas cylinder. It is advisable to purchase a new one, but if this is not possible, then you can make a tank from a used cylinder. The cylinder is cut into two parts, thoroughly cleaned and primed. This should be done so that the water entering the container does not smell of propane.

Four holes are made in the selected container:

- one for the tap through which hot water will be poured;

- one for supplying cold water;

- two for mounting a coil with coolant.

Do-it-yourself indirection - simple and practical

The problem of hot water becomes important where there is no centralized hot water supply: in country houses, private city houses and houses outside the city. Today, installing a ready-made device to heat water to the required temperatures requires significant investment. An alternative way to supply hot water is considered to be an indirect one, which you can make yourself. Its advantage is that hot water supply to residential premises is carried out in an economical mode and at the lowest material costs.

Recommendations for use

Ensuring long-term and uninterrupted operation of the heater is possible with systematic maintenance, which includes

- Cleaning the storage tank. If this is an electrical device, then so is the heating element. It is necessary to remove scale, which quickly corrodes metal walls.

- Timely replacement of the magnesium anode. This point also applies to electric boilers.

- Check the integrity of the thermal insulation layer, as damage to it will cause serious heat loss.

- Checking pipe connections and fittings for leaks. A leak that is not detected in time can cause a decrease in the efficiency of the entire system.