Penofol is an effective modern insulation material. The material is characterized by high technical characteristics and versatility of use. With its help, you can provide reliable thermal insulation of both internal and external walls of a building. Taking into account all the technological features of installation, insulation with penofol can be done independently.

Characteristics and properties of the material

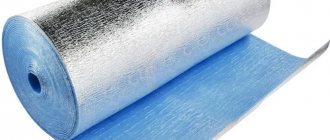

Penofol is a heat-insulating fabric consisting of several layers. The inner part of the material is foamed self-extinguishing closed-cell polyethylene.

The thermoplastic polymer is coated with high quality aluminum film on one or both sides. The thickness of the foil shell is at least 12 microns, and the reflectivity is more than 95 percent.

Such structural features ensure the versatility of the material. Penofol is endowed with good steam, sound, hydro and heat insulating properties. At the same time, the material is environmentally friendly, quite light and flexible.

Among the technical indicators of penofol are:

- volumetric water absorption - no more than 0.35 - 0.7 percent;

- possibility of use at temperatures from -60 to 100 degrees Celsius;

- thermal conductivity coefficient ranging from 0.0.7 to 0.052 Watt/m°C;

- vapor permeability – 0.001 mg/m h Pa;

- sound absorption – 32 dB;

- specific heat capacity – 1.95 J/kg°C;

- the ultimate compressive strength is 0.035 MPa.

What penofol looks like

The maximum thickness of the material is 40 millimeters, which allows it to be widely used in areas with harsh climates.

Advantages and disadvantages of the method

Insulation with foil has a number of features and a minimum of negative aspects. Advantages:

- Foil reflects heat. Thus, the heat remains in the house, on the other hand, it does not allow heat to enter the house in the summer.

- Increased wear resistance.

- Partially applicable as a waterproofing material.

- Easy installation, light weight, simple dismantling.

- The insulation does not allow cold wind to pass through. Maximum insulates from external influences. Resistant to deformation due to sudden temperature changes.

- Keeps out noise from the street.

- Does not rot or mold.

- This material is thinner than others, but is 20-30% more effective.

- The insulation does not emit substances harmful to health and prevents the smallest irritants and allergens from getting inside.

- There is no rigidity, so the top cannot be covered with plaster or wallpaper.

- Special adhesives are required for fixation.

- Sometimes insulation with foil is not enough to insulate a room.

Despite the disadvantages, foil material is widely used for various purposes.

Scope of application

Alufom is used quite widely, today it is used for thermal insulation of various packages, in thermal blankets, in sleeping bags, in tent flooring, in construction, in transport (blinds, awnings), etc., but Alufom is used quite widely in construction. It is used mainly to reduce heat loss;

- in saunas;

- in country houses;

- walls (outside, inside);

- in agricultural buildings;

- roofs;

- climatic equipment;

- when installing heated floors;

- ventilation;

- boilers, heating devices;

- pipelines;

- metal structures.

Insulation of the engine compartment in a car using Alufoma

In addition, Aluf is used in the transport industry in containers and vans to protect bodies and engine compartments.

Features of application

Since most of the heat loss occurs due to infrared radiation (this is approximately 60-65%), massive thermal insulation materials do not provide good enough protection for the house from heat loss. The main material that can return infrared rays back is aluminum foil. The walls of the building, which have such protection, return heat to the inside of the building in winter, and in the summer heat they reflect thermal radiation outside.

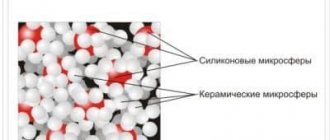

As mentioned above, this is an innovative sound-, hydro-, and heat-insulating material that has a fairly high coefficient of heat reflection. The functionality of Alufom is based mainly on the properties of polished foil with a high aluminum content and the presence of air bubbles in polyethylene microfoam. Such a structure can reflect up to 97 percent of heat radiation in the summer and prevent cooling in the winter.

Advantages

Alufom has many advantages over similar materials. If you look at the reviews, you can use it to create the most reliable and high-quality thermal protection. It also creates hydro-, steam-, and sound insulation and is able to function reliably even in conditions of high humidity. When used, it saves usable space, as it has a small thickness; in addition, during operation it does not wear out, does not rot, and is environmentally friendly. To work with it, you do not need any special clothing; installation of this material is quite simple, since it is light in weight. It has no significant disadvantages.

Types of material

Alufom, depending on the available technical characteristics, can be divided into varieties, such as Alufom A, Alufom B, Alufom S.

- Alufom A

is made on a polyethylene base, which is coated with foil on one side. It can be used as a vapor barrier or as an additional layer of thermal insulation, and sometimes it is laid in two layers. In this case, Alufom is able to provide complete warmth and waterproofing. - Alufom B

- made of polyethylene and covered on both sides with foil. It is used for arranging roofs, insulating attics, floors, etc. - Alufom S

(on a self-adhesive base) - polyethylene is covered with foil on one side, and its other side is covered with glue, and on top of the glue with a special coating material. This type of Alufoma is used mainly only on air vents.

Where is the foil insulation method used?

Foil insulation reflects infrared rays, which are essentially thermal rays. But there is no need to use the material everywhere. In some places it will not work properly.

It is mainly installed near thermal energy sources:

- heating devices - batteries, air heaters. The insulation is mounted on the wall with foil in the room;

- boiler, fireplace stove.

It is also used when installing “warm floors”. The reflective layer will direct the heat in the desired direction.

Small spaces where every centimeter plays a role. Here, thin insulation would be appropriate on the walls and ceiling.

In the attic. Here the insulation is installed on the roof. Apply 2 layers to combat heat and cold.

In baths and saunas. The heating of the room is not constant; foil material is suitable for such purposes.

Garages, hangars, outbuildings - an installed radiator or potbelly stove.

They also insulate heating pipes, air ducts, wells and wells.

Advantages and disadvantages

Penofol for home insulation has a number of advantages:

- Excellent thermal insulation properties. They are achieved thanks to the reflective qualities of aluminum foil.

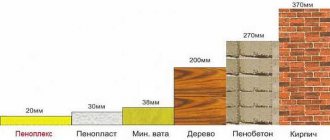

- Space saving. This is especially important when using penofol indoors. It is much thinner than other insulation materials, so it takes up less space and leaves more free space in the room.

- Noise insulation. The material is even used to set up home recording studios when there is no money for professional equipment.

- Environmental friendliness. Both components that penofol consists of are absolutely safe for health. Thus, polyethylene is used to package many food products, and candies and chocolate are wrapped in foil. Therefore, penofol in the bedroom, kitchen or children's room does not cause any harm.

- Fire resistance. Penofol is one of the most flammable insulation materials on the market.

- Rodent resistance. Persistent rats will sooner or later chew off a sheet of penofol, but they will deal with other insulation materials much faster.

- Little weight. This makes foil insulation for walls and ceilings inside a wooden house easy to transport. In addition, there is no need to spend money on delivery.

- Easy to install. An ordinary knife is enough to cut penofol, and staples, nails or construction tape are suitable for fastening. At the same time, the material does not tear, crumble or break.

Like any thermal insulation material, penofol also has disadvantages:

- Soft structure. Because of this, penofol cannot be used for plaster, painting or other types of finishing. It is necessary to make wooden sheathing, which requires time and additional costs.

- Poor vapor permeability. In most cases this is useful, but in hot summers the room can be stuffy. Need air conditioning or good ventilation.

- Partial loss of insulating properties during installation. Nails, screws and (to a lesser extent) staples damage the material, reducing its thermal insulation qualities (albeit slightly). It is best to glue penofol, but this is not always convenient.

Foil insulation design

Thermal insulation with foil is produced in:

They differ in size, thickness and the foil-covered base layer used.

Base layer types:

- polyethylene foam;

- basalt wool;

- expanded polystyrene.

The foil is glued to the base layer or applied by spraying.

Some have layers of foil on both sides. Or with a layer of applied glue - self-adhesive, which allows for easy installation. Self-adhesive is used in corners and on uneven surfaces. The joints of the insulation are taped with foil tape.

When purchasing insulation with a reflector, you need to pay attention to:

- base layer;

- foil thickness;

- taped with a reflector on one side or both.

The thickness of the insulation itself depends on the base material used.

Walls made of aerated blocks

Despite the fact that aerated concrete blocks themselves have a high level of heat-insulating properties, it is still advisable to insulate such walls. However, it is worth understanding that when the thermal insulation properties of the block itself are enhanced, its strength decreases.

Therefore, the materials for insulation are as follows:

- Penoplex. It is presented in slabs that are easy to install on your own. Its thickness varies from 3 to 5 cm.

- Polyurethane foam. It is a special mixture, which after application is subject to foaming, due to which it bonds to the surface. But it is impossible to apply such insulation yourself; for installation it is necessary to use special devices that provide the required level of pressure during coating. This method is very good and reliable in the case of walls made of aerated blocks, but its price is quite high.

- Mineral wool. It is believed that this insulation is not very suitable for aerated concrete walls, because it is capable of absorbing moisture, which has a detrimental effect on aerated concrete. However, this is the simplest and cheapest material that can be applied to walls made of aerated blocks, using a vapor barrier film on both sides of the layer.

Types of foil penofol

There are 3 types of penofol with foil on sale. Each is marked with Latin letters, which indicate the packaging.

Folgoizolon for external and internal work

TYPE A – heat insulator made of polymer, foil layer on one side. Produced in different thicknesses. Suitable for complex insulation of buildings inside. Glass wool is used together with this insulation. They also produce foil insulation with perforation. It is installed in log houses to allow the wood to “breathe.”

How to insulate a balcony

In order to avoid heat losses and the appearance of cold bridges on the balcony after insulation, you should ask to design an insulation plan. Work must be carried out in accordance with the instructions from the plan.

To prevent condensation, you can follow the following steps to insulate with penofol from the inside:

- Method No. 1 - the insulation layer should be attached both to the external wall and to the adjacent walls inside. Walls with ceilings located inside must be insulated at a width of at least 0.3-0.6 m from the external wall. In this option, the formation of condensation and cold bridges becomes impossible. It is worth considering that t- of internal walls and ceilings will be lower. As a result, condensation can occur on the plane of the walls in adjacent corners of adjacent rooms if insulation is not installed on the walls there.

- Method No2 - the surface of the walls located inside is also insulated, but with a thin, insulating ball. For example, to remove condensation on structures leaning against an insulated wall, it is worth painting the walls and ceilings at the junction points with thermal insulation paint. Creating a thin thermal insulation layer on the wall, where condensation is possible, causes an increase in the temperature of the wall surface by 2-3 degrees. This is sometimes enough to prevent condensation from appearing again.

- Method No. 3 – not the entire external wall is covered with insulation. In the plots connecting floors and walls to the external wall, that is, at the corners and the contour of the insulated wall, strips without an insulating layer are left. Heat-conducting inserts are inserted into the resulting grooves; the temperature of the connecting structures changes little, which prevents condensation from appearing in such places.

- Method No. 4 - to remove condensation, it is often enough to lower the air humidity in the room. Suitable air humidity in the room is 40-60%. You can control humidity in the same way as air temperature. To do this, you can purchase a moisture determination device and install it in the room. Electronic devices are also sold to measure the two properties mentioned.

Reducing air humidity is achieved by improving air ventilation in the apartment.

What is better - foil penofol or basalt insulation?

The building materials market is full of types of insulation. They have their own characteristics, positive and negative sides.

General thermal insulation parameters:

- Weight. The insulation should not weigh much, because when installing it on the structure there should be no weight.

- Thickness. The thinner the material, the more space remains in the room.

- Low thermal conductivity.

- Moisture permeability. The material should absorb moisture as little as possible.

- Noise insulation. Does not allow sounds from the street to pass through.

- Environmentally friendly material. Should not emit harmful substances.

- Easy to install.

When comparing basalt insulation and foil penofol, you need to compare their characteristics.

Basalt wool

Made from rock of volcanic origin. It does not burn, has good sound insulation properties, and does not lose its qualities over time. It is completely safe for health.

Penofol - application

Made from polyethylene foam with a porous structure. A layer of foil is glued on top as a heat reflector. This thermal insulation material is several times thinner than basalt wool. In addition, it reflects heat and practically does not absorb it.

Which insulation to choose depends on the budget for insulation, as well as personal preferences.

Benefits of penofol - debunking myths

Manufacturers and sellers of penofol attribute wonderful thermal insulation characteristics to this insulation, which is actually a myth.

Also, installation diagrams with air gaps, one of which we described at the beginning of the previous section, can be considered misleading the buyer. How the manufacturer proposes to insulate floors and roofs is shown in the figures:

In fact, the presented schemes are nothing more than another way to improve the thermal insulation of external fences using air gaps, since penofol’s own resistance to heat transfer is absolutely not enough.

This can be easily checked by taking as a basis the best thermal conductivity indicator from the technical characteristics table - 0.037 W/m2 °C. Next, we take the canonical formula and determine the thermal resistance of a material 4 mm thick:

R = δ / λ, where:

- δ – penofol thickness in meters, taken 0.004 m;

- λ is its thermal conductivity coefficient, equal to 0.037 W/m2 °C.

We get R = 0.004 / 0.037 = 0.11 m2 °C/W. Now look at the comparison table, which is presented on the same resource as the technical data. It says that 4 mm of penofol can easily replace 77 mm thick mineral wool or 46 mm thick polystyrene foam.

This means that, for comparison, it is necessary to determine the thermal resistance of a 77 mm mineral wool layer (its thermal conductivity is 0.05 W/m2 °C):

Rminwool = 0.077 / 0.05 = 1.54 m2 °C/W, which is 10 times more than that of foamed polyethylene.

Hence the conclusion: the presented comparative table is a pure fake. The data given in it is unreliable, and although the material is a good insulator, it is not better than others. The reason is that it is too thin, although its thermal conductivity is equal to extruded polystyrene foam.

Against this background, all other advantages of penofol fade. However, there is another myth - about the reflection of infrared heat back into the room thanks to the foil surface. But none of the manufacturers explains what the foil will reflect behind the interior trim. After all, infrared radiation spreads across open space; it will not pass through drywall or other obstacles.

What is really good about penofol is its low cost and ability to act as a vapor barrier together with other insulation, as evidenced by reviews on the forums. In addition, it is easy to install and the process does not take much time. You can also note the durability of the insulation, reaching 50 years, provided that it is located inside the building and not outside. By the way, it is better not to use penofol for external insulation of walls; it will be of little use there. You should not use it for thermal insulation of a bathhouse, like any polymer; when heated to 100 ° C, the material will begin to release harmful substances.

The most popular type of insulation with foil for interior finishing is aluform

Bestizol or alufom is a bubble base consisting of aluminum foil (outer layer) and polyethylene (inner layer) on one side. The foil acts as a reflector of solar and heat rays. The polyethylene layer has a cellular structure and neutralizes sound waves and shocks. The advantage of this material is low thermal conductivity.

Bestizol can be used in both cold and hot weather. Due to its small thickness (1 cm), the material is used for hard-to-reach places:

- for winding ventilation pipes;

- air duct coverings;

- insulation of pipelines and other outlet communications.

What is Penofol and its analogues

Thin polymer insulation is made from the following materials:

- The main insulating layer is foamed polyethylene 3...10 mm thick with closed air pores. The thermal conductivity coefficient λ of this layer lies in the range of 0.037–0.051 W/(m • °C) depending on operating conditions.

- The outer reflective layer is aluminum foil 14 microns thick, securely glued to a polymer base.

- The third layer on the back side of the polyethylene can be glue for ease of installation or the same aluminum.

A special feature of the material is its impermeability to moisture, the declared indicator is simply scanty - 0.001 mg/m • h • Pa. The insulation is quite light - the density ranges from 16...35 kg/m³, and is sold in rolls. Thanks to these parameters, the material serves well as an internal vapor barrier.

"Penofol" is available in 3 versions:

- double layer type A;

- three-layer – the base is coated with aluminum on both sides (type B);

- the same, with an adhesive layer - Type C.

The foil side works as a reflector of the radiant (infrared) component, polyethylene foam resists direct heat transfer. For exterior wall cladding, a perforated version of Penofol, shown in the photo, is offered. Many small holes are designed to allow water vapor to escape from the thickness of building structures.

External wall cladding is made with special insulation with perforation

Installation of rolled foam foam inside and outside: how to stick it?

Basic installation rules:

- The material is mounted straightened, uncompressed, without folds. Fix to the lathing or directly to a clean surface.

- Penofol is secured with foil towards the heat to reflect it. This is an obstacle to the release of thermal energy to the street.

- The material is glued end to end. The borders are taped to seal.

- To glue the insulation, special types of glue or a self-adhesive type are used.

Installation is quick and easy, both inside and outside. The work is identical in sequence and principle inside and outside. It is easy to cut and quickly installed.

Before gluing penofol, you do not need to pay attention to its weight. The material is lightweight and can be supported by universal glue. But, for strength, they purchase adhesive compositions intended for this purpose.

The adhesive must correspond to the characteristics of the thermal insulation material:

- temperature range +100/-600C;

- indoor use, not outdoor use;

- non-toxic;

- good adhesion.

The adhesive composition should not emit harmful substances. Penofol is able to absorb 3% of heat, which means the glue on the back side can also warm up.

How to glue insulation with foil to the wall near the radiator and door

For gluing the surface and penofol, craftsmen recommend purchasing the following brands:

- Weicon Easy-Mix PE-PP 45. Two-component adhesive designed for gluing concrete (brick) surfaces with polyethylene, polypropylene.

- Moment - has many positive aspects, including good adhesion. The glue will quickly and permanently bond the insulation to the surface behind the radiator or near the door.

- Liquid nails are capable of fixing heat-insulating material for a long time.

Other brands: Titan, Tilit, Atlas Stopter K-20 kley, Ceresit (ST83).

Criterias of choice

To choose penofol for wall insulation, you need to consider the following recommendations:

- for quick and convenient installation, you should not buy material whose thickness is less than 5 mm;

- if you need wall decoration in rooms with high humidity and frequent temperature changes, then it is better to choose foil-clad polypropylene;

- when choosing insulation, you need to pay attention to how well the foil part is polished (the quality of reflection of heat rays depends on this parameter);

- The roll contains 9-18 square meters of material. grounds;

- If the material is sewn, then it is better not to buy it.

As for manufacturers, it is better to give preference to those companies that have a positive reputation. They guarantee the necessary technical characteristics of penofol.

Life time

Since foil insulation appeared relatively recently, it is not yet possible to determine the exact expiration date. However, after conducting experiments, we can say that the material does not lose its properties for 200 years.

The service life of the installed insulation depends on the adhesive used. If the adhesive composition has passed its expiration date, then you can re-install it with the same heat insulator.

There are a lot of insulation materials on the construction market. The choice is so wide that the question arises, which is better. To answer, you need to compare the characteristics of the thermal insulation material and the scope of application - street, living room, garage or agricultural building.

Design and drawings

If you don't like plain wallpaper, you can find any pattern theme. There are a lot of such wall covering options today.

Every day, brands develop different prints to attract the attention of customers: this allows you to choose wallpaper taking into account your preferences and your budget.

Vegetable

Since the color green is associated with nature, plant patterns are considered completely natural. Relief patterns look beautiful on a green background: for example, embossed leaves. They seem almost invisible at first glance, but they change the perception of the overall picture. Girls love beautiful floral patterns. The surface of the green wall covering can be covered with exquisite orchids, small daisies or luxurious roses.

Geometric patterns

A universal option that never loses its relevance is simple geometric patterns. It can be small polka dots, large circles, stripes or checkered patterns. Bright shades can serve as additional tones here. The main thing is that they blend organically with other details in your interior.

Monograms

Lace patterns with monograms go with almost any interior details and design ideas. If they are made in silver tones, the wallpaper will look luxurious.

Photo wallpaper

If beautiful textures aren't enough for you, you can check out the beautiful paintings that adorn the walls. Photo wallpaper with a green base looks interesting and bright. Most often they depict landscapes (for example, images of a forest, river or mountain path)

The image can be classic or three-dimensional, changing the perception of space

Most often they depict landscapes (for example, images of a forest, river or mountain path). The image can be classic or three-dimensional, changing the perception of space.

Useful video

Various building materials are used to insulate residential and non-residential buildings. Penofol is also used as insulation. Let's consider what this material is, what its advantages and disadvantages are.

Price for material and work

The price of material and work depends on the volume of the order, the complexity of the design, and the quality of the insulation. The installation scheme is simple, but a qualified team will charge more for the work than advertised. The average cost for professionals in large cities is shown in the table:

| City | Price, rub./m2 | |

| Material | Works | |

| Moscow | From 210 | From 180 |

| St. Petersburg | From 220 | From 170 |

| Ufa | From 240 | From 190 |

| Kazan | From 230 | From 180 |

It is cheaper to purchase material in bulk. It is a little expensive to insulate a wooden house from the inside, but insulating a bathroom, nursery and bedrooms costs no money.

What it is?

Penofol is a two-layer heat-insulating building material, which can be made from one or 2 layers of foil applied to a base layer of polyethylene foam. Depending on the type of product, the density and thickness of the foam may vary. Utilitarian and inexpensive insulation is in great demand among buyers, because it has high performance characteristics.

A layer of foil, the thickness of which is 20 microns, provides penofol with excellent heat-reflecting qualities.

This insulation is used in everyday life and industry as the main insulating material or as an auxiliary thermal insulation layer.

Penofol is used as the main insulating material in cases where it is necessary to insulate a room with normal heat loss and where there is a powerful heating source (bathhouse, sauna, underfloor heating system in a wooden house). As an additional insulating building material, penofol is used to create complex heat insulation in residential and industrial premises, and such premises must be equipped with vapor barrier and waterproofing.

New thermal insulation materials are appearing on the market with increased thermal protection and unique qualities. Such a material is penofol.

The use of penofol insulation allows you to achieve serious results due to its reflective and insulating qualities.

Penofol insulation is an excellent way of thermal insulation.

Getting to know Penofol

This insulation consists of several layers. In the middle there is a self-extinguishing polyethylene foam type, and at the edges there is high-quality aluminum foil. Its thickness ranges from 12 to 30 microns, and the proportion of pure substance in it is 99.4 percent. The result is a material of small thickness and weight that does not contain any harmful additives and is absolutely safe.

Being practically unable to absorb thermal radiation, Penofol works on the principle of its reflection. This distinguishes it from the vast majority of thermal insulators, the layers of which retain the heat escaping from the room. It should be noted that the word PENOFOL does not mean the type of insulation at all, but the name of the brand.

To understand how heat is reflected by Penofol, let us remember how a Dewar flask works. This device, usually called a Dewar flask, was invented by a Scotsman - a scientist in the field of physics and chemistry, James Dewar. At the beginning of the twentieth century, he conducted a series of experiments in the laboratory to test how heat would behave when isolated by the walls of a vessel. The same principle applies to all thermoses.

So, Dewar found out that any substance known to people has a certain value of heat transfer resistance “R”. And no matter how important this indicator is, not a single material can stop heat transfer. It is only possible to slow down this process. In this case, the substance absorbs heat waves, accumulating energy. As soon as it is oversaturated with this energy, the reverse process will begin - the release of heat.

But there are a number of materials that do not absorb thermal energy - they reflect it. These are, for example, precious metals such as platinum, silver and gold. And pure aluminum, well polished, also has this ability. Rays of thermal energy that reach the surface of such a material are reflected almost completely (98-99 percent). There is just one “but” - these substances conduct heat well. Therefore, they need to be supplemented with some thermal barriers, for example, foamed polyethylene. It is capable of absorbing heat. Thus, the technical characteristics of Penofol combine both reflection and absorption of thermal rays.

Research was carried out for more than 40 years, and as a result it was found that both the loss of heat in rooms and its accumulation are directly related to the radiation of the infrared spectrum. But everything can be balanced if you use reflective heat-insulating materials, which are easy to install and are very effective and inexpensive reflectors of infrared radiation.

People are gradually starting to get used to reflective heat-insulating materials. They are profitable and convenient, so experts predict that such insulation materials will gradually take a leading position. When using them, the equipment wears out less, and the time and money spent on heating and air conditioning equipment is significantly reduced. Working with reflected thermal energy is much easier than working with absorbed thermal energy.

Since heat rays are reflected, in winter the heat loss for heating the floor, ceiling and walls will be much less. And when using double-sided reflective insulators even in the summer, in the heat, there will also be no negative consequences of absorbing thermal energy from the outside.

Properties and characteristics of penofol

Operating principle

The photo shows a roll of one-sided foam foam used for interior work.

Penofol is a combined material consisting of foamed polyethylene and purified foil with a high reflectivity of infrared waves.

The operating principle of the material is based on complex resistance to the processes of thermal energy propagation.

As you know, there are three ways to distribute heat:

- convection,

- direct heat transfer,

- and radiation.

Most isolators prevent any one of these methods.

Penofol is able to create a barrier to direct heat transfer due to a layer of foamed polyethylene, which has in its structure many sealed pores filled with air or carbon dioxide. Thus, heat transfer through this layer is difficult. Most insulation materials, such as polystyrene foam, mineral wool or polyurethane foam, work on the same principle.

In addition, our insulation has a layer of reflective foil. It is applied to polyethylene by thermal welding and has a reflection coefficient of at least 97%. It should be said that ordinary foil has a reflection coefficient of 50 - 70%.

The foil used in the production of penofol has a thickness of 20 - 30 microns. Polyethylene foam can have different thicknesses, from 2 to 10 mm. Sometimes thicknesses reaching up to 40 mm are used, but this is rare.

So, we get a material that resists not only direct heat transfer, but also prevents the penetration of infrared thermal radiation outside the room, reflecting it inside. In addition, penofol has excellent soundproofing and vapor barrier properties, which is also important and saves money on additional materials.

The price of the material fluctuates in the middle and lower ranges, significantly inferior to the cost of many modern insulation materials, such as polyurethane foam. Installation work can be easily done with your own hands without the involvement of specialists, which also saves money.

Application area

The scope of application of penofol is so wide that it can be found in the most unexpected places.

Penofol is used for insulation:

- Residential buildings: light and country buildings, cottages, private houses, multi-storey buildings;

- Sauna, baths;

- Industrial and administrative buildings;

- Medical institutions, kindergartens;

- Warehouses, hangars, both heated and cold;

- Capital and temporary trade pavilions, shops, supermarkets and shopping and entertainment centers;

- Refrigeration chambers;

- Pipelines for various purposes;

- Heating, air conditioning, ventilation and water supply systems;

- Cars, railway cars, vans, refrigerators.

It is possible to process the following structures:

- External and internal walls;

- Ceilings;

- Roof insulation;

- Ceilings over cold basements;

- Floors.

Important! When using the material, it should be remembered that aluminum foil is an excellent conductor of electric current, so the insulation of electrical wiring must be checked with special care, otherwise people may suffer from electric shock.

Characteristics

Hoods treated with reflective insulation.

How to install thermal protection from penofol

Penofol laying diagram

Installation of insulating structures made of penofol is easy to do with your own hands, since this does not require any special tools, and the design of the insulating layer is extremely simple - a sheathing and an insulating layer.

The only thing that needs to be strictly controlled is the presence of an air gap between the foil side of the heat insulator and other finishing elements.

Cutting the material can be done with a regular mounting knife or scissors.

It is advisable to attach it to the sheathing using adhesive or a furniture stapler.

The seams between the sectors of the heat insulator are sealed with aluminum tape, which can be purchased complete with penofol.

Those who have just started working with penofol often wonder: is it possible to fasten it with self-tapping screws? Can. But it must be taken into account that any violation of the reflective layer is a potential loophole for the cold. Therefore, if you decide to use nails or self-tapping screws, then they must be equipped with special washers with low thermal conductivity.

Installation

Wall treatment from the inside

Wall insulation with penofol is done using self-tapping screws or a stapler.

For interior work, one-sided penofol with a thickness of 4–5 mm is used. You can also use double-sided, but its installation is different, since it is necessary to maintain an air gap on both sides. In ordinary apartments and houses, one-sided material is sufficient, but if the walls are too cold, then they should be additionally insulated with polystyrene foam or cotton wool.

Our instructions will help you understand how to insulate a wall with penofol from the inside:

- We roll out the roll of insulation and cut off a strip equal in length to the length of the wall;

Cut the strip to the required length.

- Starting from the ceiling, we nail the strip to the wall with a stapler;

Carefully attach the insulation strip.

- If the wall is wooden, you can also use a screwdriver. We put large washers on the screws, like on umbrella-type dowels;

We put washers on the screws.

- If the wall is concrete and it is impossible to nail the material to it with staples or screws, use glue;

- We cover the entire wall with penofol end-to-end, without making any overlaps;

We cover all walls without overlaps.

- We glue the joints with aluminum adhesive tape;

We glue the joints with aluminum tape.

- On top of the insulation we place a lathing made of slats or plywood with a thickness of at least 1.5 - 2 cm;

We fill the crate on top.

We stuff the casing on top.

Important! On the side of the foil coating, be sure to leave an air gap 1.5–2 cm thick, otherwise condensation will accumulate on the surface. If the material is double-sided, the gap must be maintained on both sides.

Ceiling and floor

Insulating the ceiling with penofol significantly increases the energy efficiency of the room.

Installation of material on the ceiling is not fundamentally different from similar work on walls.

First, the material is cut, the desired strip is taken and attached along the wall, starting from the middle:

We mount the strip from the middle along the wall into the corner.

We reach one corner, nailing the side closest to the wall:

We fasten one side.

Then from the middle we move in the opposite direction, attaching the strip further:

One side of the strip is nailed.

Next, from the middle point we move perpendicular to the foam sheet and shoot at the line indicated in the photo in green:

We nail the middle line.

Next, we move from the middle to the corners, smoothing and shooting the material towards the ceiling:

We finally fasten the strip.

Similarly, you can insulate the floor with penofol or insulate the loggia. The main thing to remember is the basic rule: leave a gap between the casing and the foil!

Advice! In the case of a loggia, penofol should be used together with expanded polystyrene, since the balcony structures are too thin for serious thermal insulation.

During floor insulation work, the material is placed with the foil facing up. We glue the insulation to the screed or floor slab with any glue suitable for such substances. Then we lay logs on the carpet, on which we mount floorboards or plywood.

When using double-sided material, it is usually placed in the joist space so that there is an air gap on both sides. To do this, you can nail the carpet to the joists in the middle of the distance from the floor to the upper plane, then throw the material over the slats, and fasten it on the other side as well.

Then the insulation is stretched in the middle of the space, between the floor and the boards.

In addition, do not forget to attach the strips end-to-end, and treat the joints with aluminum tape. The material is soft and pliable, making it easy to cover curved and curved areas of walls. The low weight of the coating does not create any noticeable additional load on the structure.

Insulation technology

Insulating a house from the inside with foil foam is a fairly simple procedure. If you stick to the basic technology, there will be no difficulties. You can install this insulation even alone, without outside help.

The technology differs slightly depending on the application of the material:

- for interior walls;

- for external walls;

- for ceilings and roofs;

- for floors and ceilings;

- for insulated floors.

Before you begin installing penofol for wall insulation (and not only), do the following:

- Determined by the type of material. For insulation "from scratch" buy type B, for combination with another insulator - type A or C.

- Check the electrical wiring. Since foil conducts current, you need to make sure that all cables are properly insulated and not damaged. There should be no bare wires.

- Clean the surface. It is necessary to remove all debris and dust from the wall, floor or ceiling. If there are noticeable irregularities and cracks, they should be puttied or sealed. It is better to sand rough wood.

- Prime the surface (when insulating walls). This step is optional, but if you do it, it will only be better.

After all the preparatory work is completed, you can proceed to the installation of insulation.

Tools and materials

When insulating walls with penofol with your own hands, you will need the following tools:

- a long knife (it’s more convenient to cut insulation than with scissors);

- construction stapler (or screwdriver, hammer - depending on the chosen type of fastening);

- glue brush;

- marker;

- roulette.

You will also need materials:

- penofol;

- fastenings (metal staples, nails or screws);

- construction adhesive;

- wooden slats (thickness - from 1.5 to 2 cm);

- aluminum self-adhesive tape (or construction tape).

These are approximate lists - to install penofol on wooden walls, like on any others, you may need some other tool or material. But nothing specific is needed - everything is the same as with other insulation materials.

Ceiling and roof

The list of things that can be insulated with penofol also includes the roof of a residential building. Penofol is installed on the ceiling in a wooden house according to a separate algorithm. It differs from the others in the need to use additional waterproofing, because the water-repellent properties of penofol for the ceiling are not enough.

Strengthening the ceiling in a house with penofol is carried out as follows:

- Place a diffusion membrane on the rafters (with an overlap of at least 10 cm).

- Press the membrane with wooden blocks, which are attached to the rafters.

- The sheathing is stuffed onto the bars. A roof is made on top of it from any chosen covering (slate, tiles, etc.).

- From below, wooden beams with a thickness of 50 to 60 mm are nailed horizontally to the rafters. The optimal gap between the bars is 60 cm.

- Penofol is attached to the bars. The best type of penofol for the ceiling in a wooden house is B (double-sided). Secure with water-repellent glue or self-tapping screws. The joints between the sheets are taped with tape - aluminum or mounting tape.

- Now you can install any cladding or trim on horizontal beams.

External and internal wall insulation

At home, people most often have to attach rolled penofol to a wooden wall. But the procedure for insulating a wooden house outside with penofol, and for internal insulation, in no way depends on the building material. Therefore, you can follow the same algorithm.

Insulating a wooden house from the outside provides excellent protection from precipitation and insulates the room from street noise. It is carried out like this:

- Build a frame around the walls. It is made from wooden blocks or slats, fastening them with dowels. The purpose of the design is to enhance the thermal insulation properties of penofol. The distance between the slats should not exceed 1 m - this will make it more convenient to attach the insulating material.

- Penofol is cut into strips. Dimensions do not matter - the main thing is that it is convenient to work.

- Attach the insulation to the frame. It is best to use a staple gun, but self-tapping screws or nails will also work. Penofol strips should be positioned end to end, but not overlapping. If one strip overlaps another, condensation will form between them.

- Strengthen the joints with aluminum “self-adhesive”.

- On top of the foam foam, another frame is made from the same slats or bars. This is necessary for air circulation.

- Now the top sheathing can be lined or finished with paint at your discretion.

An important point is that penofol should be installed outside the house in dry and warm weather. Temperatures below zero are not suitable for such work, even if the air humidity is suitable.

Inside the house, foil wall insulation is laid using a slightly different technology:

- Install vertical slats on the wall. There is no need to make a full-fledged frame - parallel vertical stripes are enough. The standard width of a penofol roll is 120 cm, so the optimal distance between the slats is 60 cm.

- Apply strips of insulation to the slats so that the edge of the strip is exactly in the middle of the slats. The sheets should be butted one to the other, but not “overlapping”. Fasten using any chosen method - you can use a stapler with staples, self-tapping screws or glue.

- Tape the joints. To do this, you can use self-adhesive tape made from aluminum foil or simple construction tape.

- A wooden sheathing is assembled over the insulation. Cover or finish it to your taste.

So, the answer to the question of whether it is possible to insulate a wooden house from the inside with penofol is definitely affirmative. If you follow the described algorithm, the insulating material will serve for a long time and with high quality. You can insulate both a frame or timber house, and a wooden log house.

An important point is that penofol for insulating internal walls should be placed with foil in the room, and polyethylene against the wall. If the room has not previously been insulated with anything, then you need to buy double-sided material.

Floors and ceilings

Insulating a floor with penofol in a wooden house is quite simple. But if you need to insulate an existing floor, you will have to remove the finishing trim and disassemble the structure down to the floors. The foil insulation is laid there. It is attached to the logs using the same algorithm as when insulating walls, only instead of a frame made of slats, logs are used.

The process is carried out like this:

- Place roll insulation on the floors. The principle is the same as everywhere else - the strips must fit together.

- Attach using a construction stapler. In this case, you need to ensure that there is an air gap both under the insulation and above it.

- The joints between the sheets are taped with aluminum tape. This is a prerequisite to reliably insulate the floor in a wooden house with penofol.

- A subfloor is built on top, and subsequently a finishing coating.

So, the use of penofol in a wooden house for floors is carried out almost in the same way as for the ceiling. Even the type of material is the same. To insulate the floor in a wooden house, a double-sided heat insulator of category B is usually used.

In a heated floor system

Penofol insulation is also used in underfloor heating systems. This increases overall heat transfer by approximately 20%. Insulating material is used:

- as a substrate for a heating circuit;

- on top of the main insulation.

The use of penofol for insulation of heated floors occurs as follows:

- The insulation is laid according to the general principle. The sheets should be end-to-end, not “overlapping” each other. Fasten in any way.

- Tape the joints with aluminum tape. Regular construction tape will not work here.

- A heating circuit is laid on top of the foam layer. If the heating is electric, then you need to make sure that everything is reliably insulated.

In most cases, for heated floors in a wooden house, penofol of the usual one-sided types is used. But if cement-sand filling is used, then it is better to take an insulator of the ALP category - it is the most resistant to aggressive environments.

Where is the best place to insulate?

This material is suitable for insulating walls both from the inside and outside.

Before deciding on which side it is better to use such material, it is better to weigh the pros and cons.

It is generally believed that using insulation on the inside of walls is not recommended due to a reduction in living space, the risk of the formation of fungal microorganisms and mold, the accumulation of large amounts of moisture, etc.

In the case of penofol, there is no reduction in area , but certain classes of material allow moisture to pass through only in one direction - this should be taken into account during installation.

IMPORTANT!

Considering the properties of this material, we can conclude that penofol is best used for internal insulation. In addition, on the outside of the building, penofol is not able to provide the required level of thermal insulation properties.

How to insulate a wall from the outside with penofol

External insulation of the walls of a house, especially a wooden one, according to experts, is more effective than internal thermal insulation.

For this type of insulation, perforated penofol is used, which, in addition to sound and heat insulation, protects the building from wind and precipitation and promotes the release of steam from the structure.

External insulation is suitable in a situation where you do not want to change the interior environment or reduce the usable area of your home due to thick layers of heat insulation . The insulation is installed between the wall of the house and the cladding.

It is very important to carry out external insulation of a house in the warm season, when temperature changes are minimal and the walls of the building are completely dry.

Types of metallized insulation

There are a huge number of insulation materials with a foil layer. Almost every manufacturer of thermal insulation materials has a line with foil coating, and everyone calls their products differently; accordingly, the same material can have a different name. Folgoizol, foil plastic, energoizol, all this is practically the same material.

Let's look at the most popular types of metal-coated insulation.

Foiled polyethylene foam

The most popular foil-coated material is made from polyethylene foam. It can be two or three layers.

It is used everywhere in the construction of houses, baths, saunas. Also used for sound insulation and insulation of cars. Can be used as a backing for laminate and other floor coverings.

The thickness of the foil coating rarely exceeds 15 microns. The foil layer can be applied on both sides of the insulation, due to which the material is able to reflect both internal heat and cold penetrating from the outside of the room.

The base made of foamed polyethylene is environmentally friendly, does not rot and resists moisture well. It has internal pores filled with air, due to which it has good thermal insulation characteristics.

Important! This insulation is most often used for thermal insulation of bath rooms and bathrooms.

Foamed polyethylene with foil coating is produced by the following companies:

It is worth noting that there are several technologies for the production of foamed polyethylene:

- The usual, inexpensive one is produced using foaming technology, after which it does not undergo additional processing; as a result, its resistance to dynamic loads is not high enough. Simply put, the material is subject to shrinkage.

- The second method is cross-linked polyethylene, after production it undergoes special processing, due to which it becomes denser and, after removing the load, tends to restore its original shape and size.

Interesting: builders call foamed polyethylene with a metal film applied to the surface “shiny.”

To install such thermal insulation, no specific skills are required:

- It is enough to unroll the roll, cut off the required amount of material and secure it to the insulated surface.

- For fastening, you can use a construction stapler.

The second option for fixing the “shiny” is to press it down with laths for siding or lining. The insulation is laid with an overlap of no more than 10 cm, the joints are glued with metallized tape and pressed with a lath or fixed with staples.

Foiled mineral wool

Another type of insulation with a metal coating is mineral wool.

It is mainly used for external insulation or for thermal insulation of attic rooms. Mineral wool (glass wool), even without a metal layer, has good thermal insulation qualities. The presence of a metal layer on the surface only enhances its effectiveness.

Mineral wool also has its disadvantages. First of all, it is afraid of moisture, so for interior work it is used only for dry rooms, mainly for insulating roofs. The second feature that must be taken into account is almost zero load resistance. This means that even a slight weight of the load can compress the mineral wool, as a result of which the thermal insulation properties are sharply reduced. Using mineral wool for floor insulation is not effective.