Automation for electric heating boilers can be sold together with the unit, but more often than not, it must be installed separately. In this case, the necessary assembly can be purchased at the store, or you can assemble it yourself, which is not at all difficult if you wish. Therefore, I suggest you make such equipment with your own hands, having previously understood the circuit and purpose of certain elements. I don’t want to complicate such a unit for one simple reason - the fewer parts, the more reliable the system’s operation, and this has been proven by time and practice.

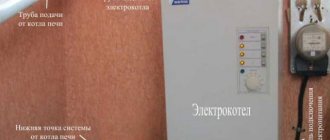

Connecting the electric boiler to the panel

It is recommended to entrust the installation of the shield to a specialist. A metal shield and three-phase input are not enough to operate the heating device. The electrical appliance must be grounded. A separate ground wire must be connected to the electrical panel. Connection to the electric boiler is made through the panel.

Connection to the panel

Connection recommendations:

- ensure reliable grounding to prevent electric current from penetrating the housing;

- The high power consumer must be connected directly from the current input to the house. The circuit can only be interrupted by an automatic device that turns off the electric boiler in the event of a malfunction;

- the cable is selected in accordance with the rated load of the boiler;

- shut-off valves, which are usually used when connected to other types of boiler equipment, must turn off the unit from the common heating circuit. This will be needed when performing maintenance or repair of the electric boiler.

You can make an electric boiler yourself. Any man can do it. But you don’t need to connect the heating unit or make adjustments. It is better to entrust the work to a master. To avoid collisions due to improper installation of the device. Otherwise, the unit will not work efficiently and will break down.

Automation for electric boiler:

average rating

more than 0 ratings

Share link

Types of boilers

Types of boiler equipment:

- gas. Highly effective, but not worth making at home. The units are classified as high-risk devices. Creation requires skills, technology;

A gas boiler

- electric boilers. Unpretentious in terms of creation and operation. You can make a heating device yourself. There are no increased security requirements;

- liquid fuel The design is simple. Any man can handle the job. Difficulty in adjusting the nozzles;

- solid fuel. Effective and versatile. Easy to use and manufacture. Easily modified and converted to other fuels. The units are also used for heating industrial areas.

It is important to choose the material from which the electric boiler will be made.

Heat-resistant stainless steel has good technical parameters. But she's expensive. Equipment is required to process the material. You can choose cast iron.

When making it yourself, it is better to take sheet steel or a pipe with a thickness of at least 4 mm. The properties of cast iron are good. Simple, easy to process. Regular household devices can handle it.

CONNECTING THE ELECTRIC BOILER CONTROL UNIT

We remove the insulation from the input power cable and proceed with the connection according to the following diagram:

IMPORTANT! Before connecting the electric boiler to electricity, be sure to turn off the power!

We connect the WORKING ZERO (blue-white wire) to any of the two terminals marked “X2”; they are connected by a jumper and there is no difference in which of them the wire is placed.

PROTECTIVE ZERO or GROUNDING (Yellow-green wire) must be clamped with a screw located to the right of the “X2” terminals; it is marked with a grounding sign.

To do this, I recommend stripping the insulation from the ground wire and wrapping the copper wire into a ring, as shown in the image below:

Only then tighten this ring with a screw, thus obtaining a safe connection and reliable contact.

It remains to connect the phase wires to the terminals of the three-pole circuit breaker installed in the boiler.

The levers of this machine are independent; they are not united by a common jumper, which allows stepwise control of the power of the electric boiler.

It works as follows: each pole of the circuit breaker is connected to its own phase wire, which then goes to its own heating element.

The total power of the electric boiler is the sum of the powers of the heating elements located in the heat exchanger; if we turn off one of them with an automatic switch, the boiler’s performance drops by a third of the maximum.

The 12 kW ZOTA electric boiler we selected has three stages, each 4 kW respectively, the boiler can operate with a power of 4-8-12 kW, this is a very convenient way of adjustment.

When connecting an electric boiler to a three-phase electrical network, the order of phase rotation is not important, so you can connect the phase conductors to the boiler circuit breaker in any order. But I would advise sticking to the rule that the core colors always follow in alphabetical order:

1 – White conductor

2 – Brown conductor

3 – Black conductor

Now that electricity is supplied to the control unit, we connect it to the heating elements in the heat exchanger using the cable supplied.

I have already said that direct heating of water in this boiler model is carried out in a separate block, so now we will connect the electronic control unit with a block of heating elements - a heat exchanger.

Please note that on one side the cable cores are crimped with standard lugs - this is for connecting to the terminals of the control unit, and on the other there are ring-shaped lugs - this is for connecting to the contacts of heating elements

The BLUE wire must be connected to terminal “X2” in the electronic control unit, where we previously connected the neutral power wire.

The remaining three wires, two BLACK and one BROWN, are connected alternately to the contacts of the electromechanical relay, as shown in the image below:

The connection is made through a relay, and not directly through the terminals of a three-pole circuit breaker, in order to be able to automatically regulate the operation of the boiler. This is where the air and water temperature sensors included in the delivery kit come into operation.

On the control panel - the front side of the electronic control unit, there are regulators that set the air temperature - "AIR" and water temperature - "WATER", when the set values are reached, the boiler will automatically turn off, this operating algorithm is possible thanks to the relay.

The sensors also need to be connected to the computer; for this there is a special terminal block marked “X1”.

Using the connection diagram, we connect the wires from the sensors to this terminal block as follows.

The blue wires of the sensors are combined and connected to the middle terminal. We place the red wire of the water temperature sensor in the left terminal, and the air temperature sensor in the right. The sensors themselves must be located outside the electronic unit. At this point, the connection inside the ECU is completed, all that remains is to connect the plugs from the ECU board to the front panel and install it in place.

In the next article we will continue to connect the electric boiler to the network; the next step will be to connect the wires coming from the control unit to the heating element contacts in the heat exchanger. We’ll also talk about the method of automating the work used in this boiler model, water and air temperature sensors. Article continues HERE.

Control method

Unlike magnetic starters for controlling motors and other types of consumers, a contactor for convectors works on a different principle. In the case of switching electric heating devices, a self-recovery circuit is not required. Thus, the contactor does not necessarily have to have additional blocking contacts; their presence only leads to an unjustified increase in the cost of the electrical installation.

Since the power supply to the contactor coil is controlled by an additional device, the assembly circuit is extremely simple. A wire of three or more wires is laid to the installation site of the thermostat. Two of them - phase and zero - supply the thermostat itself. In this case, the phase is also used as power supply for the midpoint of the relay group. The third and other additional cores are signal return for connecting one or more contactors.

Connection diagram for convectors via a contactor: 1 - automatic switches; 2 — cross-module; 3 - contactor; 4 — thermostat; 5 - electric convectors

The location of the thermostat is determined taking into account two circumstances. The first is the requirement for ease of access for control, while the thermostat should not disturb the interior composition. The second aspect is the proximity to the location of the temperature sensor. Typically, the temperature-sensitive element is placed on the ceiling, and the cutoff temperature is selected 3–4 °C higher than that which must be observed in the habitable area of the room. The actuation hysteresis is selected within 2–3 °C, thus, the supply of superheated air in the upper zone provides minimal inertia, which provides the room with residual heat when the heating devices are idle.

Looking ahead, we note that such a control scheme is not always the most convenient and therefore is not the only one. The very fact of using contactors allows the possibility of using completely different control systems: remote, timing, as well as combined and even with switching to manual.

The principle of operation of volatile and non-volatile heating systems

All devices installed to control the operating processes of the system are divided into volatile (electronic) and non-volatile (mechanical).

Mechanical ones are cheaper, are very simply designed and do not require electricity. The basic principle is to change the size or position of a structural element that is sensitive to changes in temperature or pressure. In accordance with this, the gas supply, coolant flow intensity, and other system operating parameters are reduced or increased.

Volatile automatic devices are controlled by a microprocessor, the valves are activated based on data processing.

The system operating modes required by the user are set on the device display.

Reference! Electronic devices can be duplicated with mechanical ones, then a breakdown in the electronics will not affect the operation of the heating device. This is especially true if there are long periods without light.

What to consider when assembling the structure

The electric boiler must have a built-in electrical cabinet. It contains input, metering, protection, and control devices for the operation of the heating unit. A function is provided to switch operating modes of the heating system.

The electrical cable from the boiler equipment is inserted into the electrical panel. The boiler is connected to the inlet machine.

Depending on the area of the room, you need to calculate the power of a homemade electric boiler. For 1 sq. m of area accounts for 0.1 kW of thermal power of the heating device. To create a heating system for a house with an area of 100 square meters. m need to make a boiler with a capacity of 10 kW.

Thermal calculations for the house must be done immediately. The cross-section of the wire, elements of the boiler device, and automation depend on the power.

Laying the electrical cable around the house must follow safety rules. If the structure is made of wood, the cable is laid openly or in pipes. For buildings made of stone, brick, foam block, the wire is laid hidden or in boxes.

Homemade boiler

Any twisting, soldering, or welding not provided for by the design of the boiler equipment is prohibited.

The boiler requires strict compliance with safety measures.

Connection diagram of an electric boiler to the network

Before connecting an electric heating boiler, please note that the electric boiler must be connected to the network using copper wiring. The cross-section of the wire must be no smaller than that specified in the document that came with the device. Electrical connections of the external type device must be made through special cable terminals. These pins should be located in the lower left corner. There should also be a brass grounding terminal with an M6 bolt.

Power cable connection diagram

When inserting an electric boiler into the heating system and installing grounding, you need to ensure that good and reliable contact is ensured between the metal body of the device and the brass bolt. Before connecting the bolt to the frame of the device, you need to thoroughly clean the connection area.

If electric heating is planned to be organized for a building with a large area, then when purchasing equipment you need to choose one that provides the possibility of installing a cascade. In order for the devices to operate normally in a cascade, the terminals of the control device must be connected to the unit that is being controlled. If the system installation is controlled using a room-type regulator, then the control contacts must be connected to the terminals of the control device.

Diagram of the electrical heating system of a two-story house

The device must be inspected visually and make sure that it is in the correct position, the water pressure in the system is normal, and all communications are connected. All this is defined in the unit documentation.

After this, the installation diagram for an electric heating boiler involves the following steps:

- It is necessary to check the serviceability of the pipeline fittings located in front of the unit. To do this, you need to switch it from the “closed” to “open” position, and vice versa.

- All pipeline fittings of the electric heat generator are moved to the “closed” position. It is also necessary to move the pipeline fittings of the water supply and heating systems to this position.

- On those pipelines that supply cold water to the unit, you need to open the shut-off valves. If you use an electric heating system, it is not recommended to use antifreeze liquids for it. This is because they have properties that can affect the operation of equipment in a negative way. Antifreeze fluids have a composition that can cause aging or rapid wear of rubber components.

- It is necessary to install a sump filter or filter before entering the unit on the return pipeline. You can install both of these elements.

- After the heating system is completely filled with water, you need to check how tight it is.

When the installation of an electric boiler with heating radiators is completed, you need to check how efficient the system sensors are. These include sensors such as: temperature controller, water pressure sensor, signal and control components of the unit, emergency temperature sensor.

During repairs to the heating unit or during unfavorable installation conditions, an electric heating unit can be connected using rubber hoses.

For the heating system it is necessary to use water with a minimum hardness level. Then the service life of the heating elements can be significantly extended.

Manufacturing technology. Instructions

After familiarizing yourself with the structure of the boiler, you can try to make a similar device at home

This process is not as difficult as it may seem, but it requires utmost care and attention. Otherwise the finished product may be unsafe

Stage 1. Preparing everything you need

To work you will need the following equipment:

- welding machine;

- electrodes;

- iron tee;

- electrode insulation (polyamide);

- neutral wire;

- coupling;

- ground terminals;

- steel pipe of appropriate dimensions;

- insulation for terminals.

Stage 2. Assembling the ion boiler

Assembling the boiler

First, let's clarify a few important aspects. So, the ion boiler needs grounding, as mentioned above, and the neutral cable must be supplied exclusively to the outer pipe. It is also worth remembering that the phase should only be supplied to the electrodes.

Assembling the boiler

With proper preparation, the assembly procedure should not cause any difficulties.

Assembling the boiler

Step 1. First, take a pre-prepared pipe (optimal dimensions - length 25 cm, diameter 8-10 cm). On one side, a set of electrodes is placed in the pipe, and on the other, a coupling is installed for connection to the heating main.

Ion boiler drawing

Step 2. An insulator is installed near the electrode, which, in addition to its direct function, will also serve for additional tightness of the boiler.

Step 3. High quality heat-resistant plastic is used to make the insulator. But not only tightness is important for the device, but also the possibility of threaded connection of the electrode with a tee. That is why it is recommended to entrust the manufacture of the insulator to an experienced specialist who will make the part in accordance with the required dimensions.

Parts for boiler assembly

Step 4. A large bolt is welded to the body. Next, the neutral cable and grounding terminals are attached to the bolt.

Step 5. After connecting to the heating system (this is done using a coupling), all that remains is to hide the finished boiler with a decorative coating. Such a coating is necessary not so much for aesthetic purposes, but for safety and protection from electric shock. This should not be neglected, since it is necessary to limit access to the heat generator as much as possible.

Stage 3. Installation work

Boiler connection diagram Boiler connection diagram

- air vents;

- pressure gauge;

- fuse.

In this case, the shut-off valves are installed after the expansion tank. The above diagram will help you get acquainted with the connection features in more detail.

Installation of an electrode boilerInstallation of an electrode boilerConnection diagramAssembling a heating systemAssembling a heating systemAssembling a heating systemPolyphosphate filterAdjusting an electrode boiler

Video - DIY ion boiler

Other important installation points.

- The boiler is installed exclusively vertically, which can only be explained by its operating features. Fasteners must be separate.

- Before installing the device, the entire heating system is thoroughly washed. To do this, take clean water diluted with an appropriate product (such as Rothenberger). If a contaminated coolant is used or the line has not been properly flushed, the performance of the ion boiler will decrease significantly.

- For grounding, you can only use a copper cable ø4 mm (or larger) with a resistance of no more than four ohms. The cable is connected to the zero terminal, which, accordingly, is located in the lower part of the unit body.

- Heating devices (batteries) are selected in accordance with the volume of the system. The best option is that a kilowatt of device power corresponds to 8 liters of total volume. If this figure is exceeded, the boiler will operate longer than required, resulting in increased energy costs.

- In addition, when arranging a heating system, preference should be given to bimetallic alloys or aluminum. The use of other alloys is unacceptable, since they contain many different impurities that affect the electrical conductivity of the working fluid.

- If an open system is installed, then the batteries used must in any case have a polymer coating on the inner surface, which will prevent air from entering and, as a result, prevent corrosion. Closed systems do not have this disadvantage.

- Cast iron products should be abandoned altogether, because the impurities they contain in large quantities will reduce the performance of the ion boiler. Also, such batteries are too large, which will increase energy consumption.

Design and principle of operation

Electric boiler with GSM control:

- Allows you to adjust the room temperature from a distance.

- If the temperature in the house increases or decreases, you will immediately receive an alert, so the situation in the house will be under your constant control. The system continuously monitors the temperature in the rooms where the sensors are installed and compares them with the data that you previously entered into the program.

- The system monitors the stability of the electrical voltage in the network and gives a signal if the power decreases or increases.

- You can control air humidity, fire safety and much more. You just need to install and connect additional sensors.

Electric boiler Proterm Skat + GSM control

The configuration of the GSM module depends on the specific model and manufacturer. However, there are a number of elements that are present in each module:

- controller (gsm module) - a device with a different number of inputs, expandable if the user wants to connect auxiliary functions. Cheaper models contain several standard features and operating modes. Those that cost more have a built-in control knob for a week;

- portable temperature sensors, there can be 2.3 or more of them - up to 10, depending on the model. They are used for various premises, there are also outdoor ones;

- GSM antenna, which is designed to amplify the signal. Thanks to this detail, continuous communication is established with the owner of the device and with the towers of the cellular operator. As a result, feedback is formed through the relay with the owner;

- additional sensors (motion sensor, fire sensor). These elements are also important, but often users purchase them separately, depending on their needs.

GSM-Climate ZONT H-1 module for remote control of the boiler

Certain models are equipped with a battery. Manufacturers usually install lithium-ion. This is an important element, since the battery life depends on it. In the event of a power outage, power will automatically be transferred to the battery.

Another detail is the master key, which will prevent third parties from interfering with the heating system and removes the locks you have specified.

Now let's move on to the principle by which the gsm module functions. The process of controlling the operation of the heating device is carried out using a small device in which a processor (controller) is built-in. It collects data, processes it and transmits it from the boiler to the owner and vice versa.

The main task that the module must perform is maintaining the settings set by the user and promptly responding to the slightest changes in the autonomous heating.

DIY heating connection diagrams for a private house

In the case of installing a parapet gas boiler, which can also be double-circuit, you will need to separately install a circulation pump placed on the return pipe, as well as an expansion tank and other additional piping. Even today there are supporters of this method of wiring communications for heating a room.

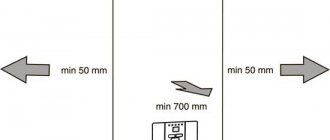

Heating devices

In the absence of special instructions, the following rules are used when installing the boiler: The width of the passage on the front side of the boiler must be at least 1 m. In small private houses, the following types of two-pipe heating systems are used: dead-end; collector beam. The main disadvantage of such wiring is a slight increase in pipe footage. In this case, the hot water coming from the boiler flows to the radiators through one pipe, and the already cooled coolant is removed through another. They are considered one of the most durable and economical boilers.

Fluctuations are recorded by sensors, and if necessary, the system brings them to normal parameters. This pump belongs to the category of emergency equipment and runs on a battery. The main task of the pump is to supply cooled water to the boiler to heat it and distribute the already heated coolant throughout the system. In addition, the use of such a heating scheme with an electric boiler implies a complex balancing process. The equipment must include a box with C16 circuit breakers, which are installed at home next to the unit.

A prerequisite for proper circulation of water in a gravity system is the installation of pipes at a slight angle. Even when using a multi-tariff system, the cost of heating a house in this way will be an order of magnitude higher than in the case of a wood heater. All solid fuel boilers are based on the Kolpakov principle, when the boiler is first heated, and then the temperature is maintained at a certain level to ensure stability of heating of the coolant. To achieve a good effect in using the generated energy, it is necessary to install a heat accumulator. After all, the batteries will go along the internal perimeter, along the load-bearing walls, and even the last radiator should be located slightly above the boiler. Connecting a heated floor to the heating system. 4 connection methods.

Homemade electric heating boilers

Having the skills to work with metal, having the necessary material and tools, it is easiest to make homemade electric boilers - electrode or heating elements. If a heating element is used as an electricity converter, then you need to make or select a steel housing in which it will be installed. All other components - regulators, sensors, thermostat, pump and expansion tank are purchased separately in specialized stores. Electric boilers can be used in closed or open heating systems.

What is needed and how to make a 220V electric heating boiler with your own hands, efficient and reliable?

You need a steel container in which one or more heating elements are placed in accordance with the drawings or sketches for the product being created. Even at the stage of the project for do-it-yourself heating boilers, the drawings should provide for the possibility of quickly and easily replacing a burnt heating element. For example, the body can be made of a steel pipe with a diameter of 220 mm with a body length of about 0.5 m. Flanges with supply and return pipes and seats in which heating elements are installed are welded to the ends of the pipe. The circulation pump, expansion tank and pressure sensor are connected to the return line.

Features of power supply of electric boilers

Heating elements consume significant power, usually more than 3 kW. Therefore, for electric boilers you need to create a separate power supply line. For units with a power of up to 6 kW, a single-phase network is used, and for higher power values, a three-phase network is required. If you equip a homemade heating boiler with a heating element with a thermostat and connect it through RCD protection, then this is an ideal option. When installing conventional heating elements, the thermostat is purchased and installed separately.

Electrode heating boilers

Boilers of this type impress with their extreme simplicity. It is a container in which an electrode is installed; the second electrode is the boiler body. Two pipes are welded into the container - supply and return, through which the electrode boiler is connected to the heating system. The efficiency of electrode boilers is close, like that of other types of electric boilers, to 100% and its real value is 98%. The famous Scorpion electrode boiler is the subject of heated debate. Opinions are extremely varied, from excessive admiration to complete denial of use for heating circuits.

It is believed that electrode boilers were designed for heating submarines. Indeed, the manufacture of heating boilers requires a minimum of materials, sea water with dissolved salts is an excellent coolant, and the hull of the submarine, to which the heating system is connected, is an ideal grounding. At first glance, this is an excellent heating circuit, but can it be used for heating homes and how to make an electric heating boiler with your own hands, repeating the design of the Scorpio boiler?

Electrode boiler Scorpio

In electrode boilers, the coolant heats the current passing between the two electrodes of the boiler. If distilled water is poured into the system, the electrode boiler will not work. There is a special salt solution for sale for electrode boilers with a specific conductivity of about 150 ohm/cm. The design of the unit is so simple that making a Scorpio electric boiler with your own hands, if you have the necessary skills, is quite simple.

Two pipes are welded to this pipe for connection to the heating system. Inside the device there is an electrode isolated from the body. The boiler body plays the role of a second electrode; the neutral wire and protective grounding are connected to it.

Disadvantages of electrode boilers

The main disadvantage of electrode boilers is the need to use saline solutions, which adversely affect radiators and heating pipelines. The heating system may require a complete replacement of radiators, especially aluminum ones (more information about which you will read here), and piping within a few years. Circulation pumps that are designed to work with antifreeze or clean water are at great risk. The second huge drawback is that electrode boilers require ideal protective grounding of the housing, otherwise they pose a huge risk of electric shock. It is prohibited to sell and install such equipment in foreign countries!

Replacing the contactor in an electric boiler with a modular version

Hello to all readers of my site!

Continuing the topic of electric boilers for the home, I want to tell you one story from practice. A client came to me asking for help in solving a problem.

The electric boiler installed at home turned on/off very loudly during operation.

A boiler with three heating elements with a power of 6 kW, connected to one phase, that’s what I found out in advance over the phone.

There is also a simple automatic temperature control that operates on/off. contactor, which makes loud “slaps” when switching.

Everything would be fine, but the electric boiler is installed not in a separate boiler room, but in the kitchen not far from the bedroom and it really interferes with rest... Imagine - sleeping at night and you are woken up by periodic “BA-BANG!”, “BA-BANG!” )))

Having found out all this, I went to the place to see what could be done to help in this case, how to make the electric boiler silent.

It turned out that the electric boiler had already gone through one contactor replacement; before that, a small-sized KME contactor with a rated contact current of 20 amperes was installed (according to the owners). It broke down and was replaced with exactly the same but larger size - KME-3210.

This is why they changed the contactor, as they explained to me - one heating element on the electric boiler stopped turning on and the contactor sparked strongly during operation. This contactor only worked for a short time and its contacts burned out, the connection of the electrical circuit was broken and the current to one heating element stopped “passing”, naturally this heating element stopped heating.

This surprised me a little, since the load of three heating elements for the starter was fully consistent, 6 kW is approximately 28 amperes, and the contacts of the contactor were paralleled and only the phase was switched through them, and it turns out that a current of up to 60 mA could flow through three contacts for a long time time without any consequences.

And here it turns out that from half the permissible current of 30 amperes the contacts failed...

Something is wrong here. Just in case, I check the resistance of the heating element with a multimeter (by the way, they are connected in a star configuration) - everything is fine, the resistance is the same as it should be, because the heating element is of the same power, 2 kW each.

I check the resistance of the heating element relative to the body - everything is also clean, the insulation is good.

I turn on the machine on the electric boiler and measure the voltage - so this is where “the dog rummaged!”))) And the voltage is low - only 190 volts!

This is the reason for the rapid failure of contacts.

Due to the low voltage, the moving part of the magnetic circuit in the contactor was poorly pulled to the stationary one; as a result, there was poor tension between the power contacts, and because of this, increased wear of the contacts, which led to their burning and breakage.

By the way, you can look at how low voltage affects the switching on of the contactor in my articles

I figured out the reason for the failure of the contactor, recommended that the owners contact the power supply organization about the low voltage, then they still need to resolve the issue of the noisy switching on of the contactor.

Here it is - the reason for the “bang” - the KME contactor:

It’s already difficult to move the electric boiler to another place, winter is coming, there’s no time to remake the heating system, so I suggested replacing the KME contactor with a modular contactor, since when activated, the latter makes much less noise and is also smaller in size than KME- 3210.

A modular contactor was purchased from IEK KM-25-40 with a rated contact current of 25 amperes. Each 2 kW heating element is no more than 10 amperes, and the contact is designed for 25 amperes, so in terms of load everything is in order.

There was a small problem with the fastening of the modular contactor - the seat was not suitable for it, I had to install a DIN rail on top, well, as they say, this is a matter of technology)))

The contactor is connected in the same way as the KME, nothing was changed here, from the terminal block three wires go to the lower contacts (on the terminal block these three wires are connected by jumpers to the phase wire), and from the upper ones they go along the wires to the switch keys installed on the removable front part of the case electric boiler

The neutral wire goes directly to the terminals of the heating element and another neutral wire, through a temperature sensor, to the contactor coil. The phase wire from the terminal block is connected to the second terminal of the coil.

And here is the reverse side of the removable part of the electric boiler body:

After assembling the circuit, I turned on the machine and checked the operation of the contactor; the sound when turned on became much quieter and almost inaudible! The client was very satisfied)))

For those who read my website, I specially recorded a video where I showed how the KME contactor worked and how the electric boiler turned on after installing the modular contactor.

The sound in the video is quite loud - in fact, the sound of turning on the modular contactor is no louder than the sound of clicking key switches - pay attention while watching the video!

And for the most attentive, when I showed the switching on from the KME, it was clear that the third light on the key did not light up well, as if from a bad contact...

In fact, this is how it turned out - in the contactor, one of the wires going to this key was inserted into the clamp along with the insulation and the contact was very poor. Apparently the electrician who connected this boiler was either inattentive or in a hurry)))

So watch the video:

I will be glad to see your comments, if you have any technical questions, please ask them on the forum, that’s where I answer questions - FORUM .

Subscribe to my channel on YouTube ! Watch many more home electrical videos!

Schemes used for connecting solid fuel boilers

The piping of a solid fuel heating boiler is carried out according to certain schemes. Most often, the option that is most suitable in terms of performance or is irreplaceable is selected. However, to achieve optimal results, you do not need to memorize drawings and diagrams. The main thing is to understand the operating principle of the unit, as well as study its advantages and disadvantages.

To calculate the ideal installation scheme for a solid fuel boiler, you need to select the best option for combining the operation of this unit and the thermal energy storage tank. This can be explained as follows: solid fuel boilers are inert devices, this is why they differ from gas, diesel and electric analogues. Consequently, the temperature of the working environment will constantly fluctuate between 60-90 degrees, and maintaining a constant mode in this case is not possible.

It is also not always possible to install a circulation pump for forced movement of the working medium when piping a solid fuel boiler for the simplest reasons. One of them is the lack of power lines in the immediate vicinity of the house or voltage drops in the electrical network that cannot be stabilized using special devices.

The cost of a heating system without additional equipment is significantly lower, but the installation of such systems requires a more careful approach to the process, since slopes must be observed.

Design and principle of operation of a heating element boiler: a few words about the main thing

Construction of a heating element boiler

It is no secret that the main element is a heating element - a tubular electric heater. It is a twisted copper tube that heats up when the boiler is turned on and heats the circulating coolant. Any suitable material, for example, a metal pipe, can be used as the boiler body. You can buy the remaining important elements (sensors, relays, etc.) separately in the store.

There are 4 main components that must be included in the design of an electric boiler.

- Expansion tank. It is necessary to collect excess coolant that may form due to increased pressure/temperature in the system.

- Pump. Serves to maintain water circulation in the system.

- Safety valve. It works in tandem with an expansion tank: it is responsible for relieving pressure in the heating system when it needs to be adjusted. Otherwise, this may lead to damage to the boiler itself.

- Filters. Installed to clean the coolant from excess suspended matter and debris. Installing filters also helps to increase the operating life of the equipment.

Methods for installing heating elements

It is the heating element that is responsible for heating the coolant, which then flows through the pipes and enters the heating radiators. However, here too we have a choice, since the heating element can be installed in different ways. We have 2 options:

- Install into the heating system. This is considered a simple method, since implementing such a system is quite simple: the boiler is connected to radiators connected in a single circuit. By the way, you can use this method not only as the main source of heat, but also as a backup if the main boiler temporarily fails for any reason.

Please note that with this option, the diameter of the pipe (tank) of the boiler itself must be much larger than the diameter of the pipes that make up the heating system. In addition, we recommend making a removable boiler to make it easier to “remove” it from the system in case of any problems.

- Separation from the heating system. That is, the boiler is located separately from the main system. Yes, this option will be a little more difficult to implement, however, according to experts, this method is more reliable. The advantage is that the boiler can be repaired. disconnected from the system, without any damage to the system. In addition, this will make it much more convenient for you to install sensors and regulators on the boiler. With their help, you will significantly increase the efficiency of the boiler, as well as the safety of its operation.

Another advantage is its easy replacement with a boiler running on a different type of fuel, if necessary. This way you create a universal system to which you can connect almost any heat source.

Choosing the power of the heating element will also not present any difficulties. For example, for a house/apartment with an area of about 50 sq.m. you will need a 6 kW element. And for premises with a total area of about 80 sq.m. – up to 12 kW.

It is better to use two heating elements connected in parallel. This way you will be able to regulate the power of the boiler. In addition, the system will not defrost if one heating element fails.

Automation, electrics for manufacturing

The electrical part is responsible for the normal operation of boiler equipment. For operation, an electrical panel and three-phase input are assembled. The electrical panel is often metal. Comprises:

- toggle switch;

- machine;

- control buttons;

- relay;

- magnetic starter.

Automation is designed to simplify and conveniently control the unit. Responsible for equipment safety.

Automation

Sensors may be used. They are installed to maintain a comfortable microclimate according to specified parameters. If there are deviations from the normal operation of the heating system, the sensors turn everything off. Allows you to protect the owners and preserve property.

Making an electric boiler

Step 1. First we need to take care of the pipes connecting the boiler to the heating system. Therefore, we cut out several pipes in advance from pipes prepared for this (2 pieces with a diameter of 1.25″ and one piece with a diameter of 3″).

Step 2. Now it’s the turn of the tank itself, that is, large-diameter pipes. In the places that you previously marked (see diagram), cut holes using a welding machine and process the edges with a grinder so that there are no metal shavings and sloppy cuts. Connecting pipes to the boiler body

Step 3. Weld the manufactured pipes to the holes made.

Step 4. Take a sheet of steel and cut out 2 circles from it, whose diameters should coincide with the outer diameter of the boiler tank pipe. Next you will need to weld them to the ends of this pipe.

Circles can be cut with a diameter slightly larger than the size of the bottom of the boiler. This will help you weld the sheets more accurately and firmly. The unnecessary edges can then be trimmed with a grinder.

Sand the joints.

Step 5. A 1.25″ pipe is welded into the upper part of the future boiler. In the future, a second heating element will be welded to it.

Step 6. Now we will need to prepare a place for installing the first heating element. To do this, you need to make 2 holes in the welded bottom of the boiler. After this, also sand the holes and install the heating element.

Electrical diagram for connecting the boiler

Step 7. An important and exciting moment: the boiler must be connected to the heating system itself. This is what the pipes that we welded in advance are designed for.

Separately, it is worth mentioning the connection of the electrical part. If you do not have sufficient skills and knowledge, then invite an experienced electrician.

If you yourself have a mustache, then we have attached an electrical diagram of the boiler to help you.

Step 8. Now we have to install a second heating element (with less power), which is equipped with a thermostat. It is connected to the upper pipe.

Step 9. You're done. The boiler is connected. Now all that remains is to “flood” the system and wait for the device to reach operating capacity. Next, use a multimeter to measure the temperature of the coolant in the system: it should be about 70˚C. If everything is so, then you can be proud of yourself!

Electrical products: circuit breaker and magnetic starter

Electrical products for single-phase electric boiler

| Boiler name | Unit change | EOU 1/2 | EOU 1/3 | EOU 1/4 | EOU 1/5 | EOU 1/6 | EOU 1/7 | EOU 1/8 | EOU 1/9 | EOU 1/10 | EOU 1/12 | |

| Machine | rub. | 700 | 700 | 700 | 800 | 800 | 900 | 1500 | 1500 | 1500 | 1500 | |

| Electromagnetic starter (contactor) | rub. | 3800 | 3800 | 4600 | 8400 | 8400 | 8400 | 10300 | 10300 | 10300 | 10300 | |

| Total: | rub. | 4500 | 4500 | 5300 | 9200 | 9200 | 9300 | 11800 | 11800 | 11800 | 11800 | |

| Machine | rub. | 550 | 550 | 550 | 600 | 600 | 650 | 700 | 700 | 700 | 700 | |

| Electromagnetic starter (contactor) | rub. | 3750 | 3750 | 3750 | 5400 | 5400 | 5450 | 7800 | 7800 | 7800 | 7800 | |

| Total: | rub. | 4300 | 4300 | 4300 | 6000 | 6000 | 6100 | 8500 | 8500 | 8500 | 8500 | |

| Machine | rub. | 280 | 280 | 280 | 300 | 300 | 300 | 350 | 350 | 350 | 350 | |

| Electromagnetic starter (contactor) | rub. | 1920 | 1920 | 1920 | 2700 | 2700 | 2700 | 2750 | 2750 | 2750 | 2750 | |

| Total: | rub. | 2200 | 2200 | 2200 | 3000 | 3000 | 3000 | 3100 | 3100 | 3100 | 3100 | |

| rub. | ||||||||||||

Electrical products for a three-phase electric boiler

| Boiler name | Unit change | EOU 3/6 | EOU 3/9 | EOU 3/12 | EOU 3/15 | EOU 3/18 | EOU 3/21 | EOU 3/24 | EOU 3/27 | EOU 3/30 | EOU 3/36 | EOU 3/60 | EOU 3/90 | EOU 3/120 | |

| ABB company | Machine | rub. | 2500 | 2500 | 2500 | 2800 | 2800 | 2900 | 3600 | 3600 | 3800 | 3800 | order | order | order |

| Electromagnetic starter (contactor) | rub. | 4400 | 4400 | 4400 | 8200 | 8200 | 8200 | 10300 | 10300 | 10300 | 10300 | order | order | order | |

| Total: | rub. | 6900 | 6900 | 6900 | 11000 | 11000 | 11100 | 13900 | 13900 | 14100 | 14100 | ||||

| Machine | rub. | 1100 | 1100 | 1100 | 1300 | 1300 | 1500 | 1700 | 1700 | 1800 | 1800 | order | order | order | |

| Electromagnetic starter (contactor) | rub. | 7200 | 7200 | 7200 | 7500 | 7500 | 7500 | 10300 | 10300 | 10400 | 10400 | order | order | order | |

| Total: | rub. | 8300 | 8300 | 8300 | 8800 | 8800 | 9000 | 12000 | 12000 | 12200 | 12200 | ||||

| Machine | rub. | 500 | 500 | 500 | 500 | 500 | 500 | 600 | 600 | 600 | 600 | ||||

| Electromagnetic starter (contactor) | rub. | 2800 | 2800 | 2800 | 3400 | 3400 | 3400 | 3400 | 3400 | 3400 | 3400 | ||||

| Total: | rub. | 3300 | 3300 | 3300 | 3900 | 3900 | 3900 | 4000 | 4000 | 4000 | 4000 | ||||

Prices on the website are not a public offer.