Connection diagram of an electric boiler to the network

Before connecting an electric heating boiler, please note that the electric boiler must be connected to the network using copper wiring.

The cross-section of the wire must be no smaller than that specified in the document that came with the device. Electrical connections of the external type device must be made through special cable terminals. These pins should be located in the lower left corner. There should also be a brass grounding terminal with an M6 bolt. Power cable connection diagram

When inserting an electric boiler into the heating system and installing grounding, you need to ensure that good and reliable contact is ensured between the metal body of the device and the brass bolt. Before connecting the bolt to the frame of the device, you need to thoroughly clean the connection area.

If electric heating is planned to be organized for a building with a large area, then when purchasing equipment you need to choose one that provides the possibility of installing a cascade. In order for the devices to operate normally in a cascade, the terminals of the control device must be connected to the unit that is being controlled. If the system installation is controlled using a room-type regulator, then the control contacts must be connected to the terminals of the control device.

Diagram of the electrical heating system of a two-story house

The device must be inspected visually and make sure that it is in the correct position, the water pressure in the system is normal, and all communications are connected. All this is defined in the unit documentation.

After this, the installation diagram for an electric heating boiler involves the following steps:

- It is necessary to check the serviceability of the pipeline fittings located in front of the unit. To do this, you need to switch it from the “closed” to “open” position, and vice versa.

- All pipeline fittings of the electric heat generator are moved to the “closed” position. It is also necessary to move the pipeline fittings of the water supply and heating systems to this position.

- On those pipelines that supply cold water to the unit, you need to open the shut-off valves. If you use an electric heating system, it is not recommended to use antifreeze liquids for it. This is because they have properties that can affect the operation of equipment in a negative way. Antifreeze fluids have a composition that can cause aging or rapid wear of rubber components.

- It is necessary to install a sump filter or filter before entering the unit on the return pipeline. You can install both of these elements.

- After the heating system is completely filled with water, you need to check how tight it is.

When the installation of an electric boiler with heating radiators is completed, you need to check how efficient the system sensors are. These include sensors such as: temperature controller, water pressure sensor, signal and control components of the unit, emergency temperature sensor.

During repairs to the heating unit or during unfavorable installation conditions, an electric heating unit can be connected using rubber hoses.

For the heating system it is necessary to use water with a minimum hardness level. Then the service life of the heating elements can be significantly extended.

Heater installation instructions

Electric water heating boilers of all types are designed for wall mounting and are equipped with mounting brackets or clamps. There is no point in explaining the marking and driving of dowels - every homeowner knows how this is done.

For reference. Universal electric wood-burning and coal-fired boilers, described in our other material, are sold in a floor-standing version.

Another question is how to choose the right room and specific location for installing the electric boiler. On the one hand, regulatory documents do not prohibit installing a heat generator in any room. On the other hand, there are rules for the use of electrical installations (PUE), which impose restrictions on the placement of high-power thermal power devices.

The wall version can be hung even in the corridor, but all communications will have to be pulled there

We will give some general recommendations on how to properly install an electric boiler in a private home:

- Considering the high current in the circuit of operating electric heaters, it is better to install the devices in a separate technical room, for example, a furnace room or garage. The goal is to limit access to power electrical equipment and protect devices from moisture.

- New heating elements can be placed in the kitchen or hallway. But keep in mind an important nuance: you will have to pull the main line of the heating system and a powerful power cable there. It is unlikely that these communications will fit harmoniously into the interior, unless the pipes are sealed into the wall.

- When installing the heat generator on a wooden wall or other combustible partition, comply with the requirements for wall-hung gas boilers. Place a sheet of roofing steel or basalt cardboard under the back of the body adjacent to the wood, as shown in the photo.

- Provide approach and access to the heater for ease of connection and maintenance. Install induction and electrode boilers in such a way that an expansion tank and pump are placed nearby. Place the control cabinet at a height of 1.5–1.8 m from the floor.

Recommended clearances to the Proterm Skat boiler unit specified in the instructions - Lay the cables above heating and sewer pipelines so that they are not flooded with water in the event of a breakthrough.

- Heating pipes should not load the connecting fittings of the unit with their weight.

Important! Be sure to connect the body of the electric boiler to the grounding bus. If there is none, make a grounding loop outside and lay it in the boiler room. Find detailed instructions below.

As a rule, an electric heat generator acts as a backup device for the main solid fuel or gas boiler. This means that heat generators and auxiliary equipment need to be configured correctly to ensure a minimum of pipeline crossings. Think and draw a diagram in advance.

Advantages of electrode heating devices

The operation of an autonomous heat source allows you to control not only the microclimate and thermoregulation in the house, but also heat costs. At the same time, electrode boilers have a number of obvious advantages compared to heating elements and induction devices.

All water that enters the electric electrode boiler is heated almost instantly and in full. Due to the absence of uncontrolled inertia of heating the coolant, the design achieves a very high level of efficiency - up to 98%.

Constant contact of the electrodes with the coolant liquid does not lead to the formation of a layer of scale. And, accordingly, rapid failure of the heater. This is due to the fact that in the design of the device there is a constant change in polarity - alternating movement of ions in different directions at a speed of 50 times per second.

The principle of electrode heating of liquid makes it possible to reduce the volume of the heat generator several times compared to heating elements of similar power. Small size and light weight of the equipment are very advantageous features that characterize electrode boilers. Reviews from experienced users confirm the ease of use of household appliances, ease of installation and the possibility of their location in any room.

The presence of a digital adjustment unit on the external panel of the devices allows you to intelligently regulate the intensity of the boiler operation. Operation in a given mode helps save up to 40% of electrical energy in the house.

In case of depressurization of the system or water leakage, there is no fear of electric shock. Without coolant, there will be no current flow, so the boiler simply stops working.

The absence of sound vibrations ensures quiet operation.

The operating principle of an electrode boiler implies the complete absence of combustion products or other types of waste. There is also no need for a reserve of fuel resources.

Absolutely not

- Connect the generator through a regular house socket using a plug-plug wire, turning off the input circuit breaker. Why? We answer:

- The power of the most popular generators for private homes usually ranges from 5-6.5 kW. A household socket, if installed correctly, can hold a load of up to 16A (~3.5 kW), and if installed incorrectly (non-GOST wire, cross-section less than 2.5 sq. cm., Chinese socket, weak contact connections, etc.) 10A or less . When the load increases, a fire hazard arises.

- According to GOST (12.2.007.0-75 clause 3.1.7), the presence of uninsulated live parts in electrical installations is not allowed, and when using a plug-to-plug connection, we have the possibility of dangerous voltage on one of the plugs.

- This circuit allows for the mechanical possibility of supplying counter voltage to the generator, which will lead to its failure. This is possible if, while the generator is running, one of the household members turns on the input circuit breaker, knowing that there is voltage from the network.

- It is prohibited to connect the generator through a distribution board using a switching circuit on automatic machines. Let's look at an example that we encountered in practice:

Incorrect generator connection diagram

Let's take a look at the build quality of this shield. Why is such a scheme dangerous? When two machines are turned on simultaneously (in this case, “Input” and “External Rose and Generator” at the bottom left), we receive counter voltage on the generator line, which leads to its failure. A family member uninitiated in the scheme or the owner of the house who is thinking about the meaning of life can turn on two machines at once. It is necessary to use three-position reversing switches I-0-II (for example, ABB OT40F3C)

- It is strictly forbidden to connect one of the generator outputs to a common neutral bus unless the neutral is re-grounded in the main panel (TT circuit) and/or on a pole and/or in the metering cabinet. Such grounding, as a rule, is absent in old SNT or in villages where the norms for laying power lines are violated. By violating this rule, we transfer dangerous half-phase voltage from the output of our generator to the “public” neutral. This can lead to electrical injuries to your neighbors and electricians working on the line. How to determine if there is re-grounding? The neutral is grounded either at the top of the pole through the reinforcement terminal, or on a steel strip that runs along the pole and goes into the ground. One example of a circuit with grounding of the neutral on a pole and organization of grounding according to the TN-CS scheme

Grounding the neutral in the ASU

This is interesting: If you connect wires of different sections, which one will burn out first? (video)

Piping diagrams by type of boiler

It is quite simple to link the operation of two units of the same type, but real operating conditions do not always allow this. More often it is necessary to combine the operation of units not only with different power, but also with different energy carriers.

The most popular pairs of two-boiler schemes:

- gas fuel and electricity;

- gas and solid fuel;

- firewood and electricity;

- propane and electric power;

- heating oil and electricity;

- pellets and electricity.

Connecting a gas and floor-standing solid fuel boiler

This is the most technically complex method of piping two boilers, since it requires the implementation of a smoke ventilation system and compliance with the dimensions of the room for the installation of large fire-hazardous objects.

It is best to entrust the development of the diagram to a design organization, since it must take into account all the rules of safe operation for both gas and solid fuel boilers.

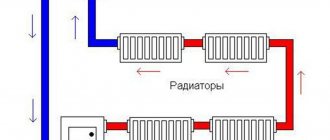

The optimal mode in the heating network is achieved when installing a multi-circuit system; in this case, it is necessary to connect boilers with two independent circuits.

Considering that solid fuel devices are practically impossible to regulate the temperature of the coolant, an open heat supply system with the installation of an expansion tank should be used.

Electric and gas

A very effective and easy to manage scheme. By combining gas and electric boilers in one heating system, it is possible to achieve a much greater thermal effect, and with the correct combination of operating modes of the units, the scheme is more economical than traditional gas boilers.

The leading function in this pair is usually performed by a gas boiler unit, which has the lowest cost of thermal energy. The electric boiler is switched on at night using the cheapest tariff for electricity metering.

When choosing the thermal power of equipment, it is necessary to focus on this boiler piping scheme. The gas unit must be more powerful, and the electric boiler must have peak power to operate at night or at peak heat demand. There are no prohibitions on the joint operation of this pair of boilers in regulatory materials. However, their installation will require approval of the boiler house design from both the gas service and energy supervision.

Connecting a solid fuel and electric boiler

Connecting a solid fuel and electric boiler is also an effective implementation of a combined heat supply source. The basic boiler is solid fuel, which is capable of operating at one load for at least 8 hours. It warms up the heat supply facility well.

After the fuel burns out and the coolant cools down to 60 C, the electric boiler is switched on in the mode of maintaining the temperature schedule. For greater energy efficiency, it is advisable to have a hot water storage tank, which is heated by an electric boiler during the night economy mode.

The solid fuel boiler itself is difficult to regulate due to the inertia of the combustion process; it will produce almost nominal performance until the fuel burns out.

In this case, working to heat the primary circuit in the storage tank, adjustment of the heating mode will be carried out in the secondary heating circuit from the storage tank through a three-way valve by mixing cold water from the return coolant with hot water from the supply line.

What machines should be installed on an electric boiler?

It was said above that an electric boiler, even 3 kW, is best connected with a separate wire and through a circuit breaker. To calculate the rating of the machine, it is enough to know what current the cable can withstand.

A cable with a cross section of 4 mm² can withstand a current of 27 Amps. Therefore, you need to install the closest 32 Ampere circuit breaker, since a 25 Ampere circuit breaker can trip as a result of overloads. As for a cable with a cross-section of 6 mm², it can withstand a current of 40 Amps. Therefore, the circuit breaker must be selected with an appropriate value, no less than 40 Amperes.

So, let's summarize:

- Although they say, it is better to connect electric boilers with a power of up to 3.5 kW through a separate cable and a separate automatic circuit breaker; it is also possible with an RCD;

- Electric boilers with a power of 7-10 kW must be connected through a separate automatic device and, if possible, with an RCD;

- To connect electric boilers with a power of more than 10 kW, permission is most often required.

Economical electric heating

How can you reduce your home heating costs?

Here is a description of three solutions with varying effectiveness.

Remote thermostat

The automation of modern boilers provides for the connection of remote thermostats. They allow the device to flexibly respond to changes in air temperature, adjusting the current heating power to it. Without a thermostat, the boiler maintains the set temperature of the coolant, which is not always justified: during a thaw, at the same temperature of the radiators, the house will become noticeably warmer.

Costs: from 1,500 rubles (if you install the thermostat yourself).

Savings: up to 20% electricity.

A remote thermostat will allow you to maintain a constant temperature of the air, not the coolant.

Underfloor heating

A more effective solution is to heat the house with an in-floor heating system. When the heat exchanger pipes are laid in a screed or under a parquet board, the entire floor turns into a heating device.

Savings are achieved due to a more rational distribution of cold and hot zones compared to radiator heating:

- With convection heating at +20 at floor level under the ceiling, the air will heat up to 26-28 ° C, which will give an average room temperature of 23-24 degrees;

- A warm floor, heated to the same +20, will warm the air under the ceiling only to +16. The average temperature is +18 °C.

This is how the air temperature is distributed during convection and underfloor heating.

Expenses: from 1000 rubles per square meter of heated area. Expensive, no doubt. As a bonus, you will receive an unforgettable feeling of comfort: walking on a heated floor is very pleasant, and a child playing on the floor will never catch a cold.

Savings: at an outside temperature of 0 ° C, reducing the average temperature in the house from +24 to +18 degrees will save 33% of electricity.

Laying infrared film under laminate. Installation of underfloor heating can be done after finishing the final finishing of the house or apartment.

Thermal accumulator

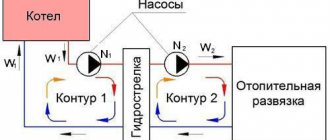

A buffer tank, or heat accumulator, is a volumetric water tank with thermal insulation and several pipes for connection to heating circuits. Its function is clear from the name - the accumulation of thermal energy.

Buffer tanks for connection to heating circuits.

Dimensions, weight and thermal performance of buffer tanks.

What does having a heat accumulator give you: if you have a two-rate meter, you can use electricity for heating only at night, when the cheap tariff is in effect. The heat accumulated during the night by the buffer tank is gradually consumed during the day for the needs of heating the house.

How to connect a heat accumulator to a boiler and heating system: it forms two circuits with a circulation pump in each of them. The first circuit connects the boiler to the buffer tank, the second - the tank to the radiators. A constant temperature of the batteries when the temperature of the water in the tank drops is ensured by a mixing unit with a three-way thermostatic mixer.

Diagram of a heating system with two boilers (solid fuel and electric), a heat accumulator, hot water supply and two heating circuits - radiator and in-floor.

Costs: with a tank volume of 3000 liters, taking into account the cost of an additional circulation pump and mixing unit - from 180,000 rubles.

Savings: reduction in heating costs by 2.5-3 times. Single-rate and night tariffs for Moscow at the beginning of 2022 are equivalent to 5.38/1.64 rubles.

Last year's Moscow electricity tariffs. Compare single-rate and nightly rates to see how much you can save.

https://youtube.com/watch?v=Gynoc8a7lYw

Filling methods built-in mechanism and pumps

Heating filling pump

How to fill the heating system in a private house - using the built-in connection to the water supply using a pump? This directly depends on the composition of the coolant - water or antifreeze. For the first option, it is enough to pre-flush the pipes. Instructions for filling the heating system consist of the following points:

- It is necessary to make sure that all shut-off valves are in the required position - the drain valve is closed as well as the safety valves;

- The Mayevsky tap at the top point of the system must be open. This is necessary to remove air;

- The water is filled until water flows from the Mayevsky tap, which was opened earlier. After this it is blocked;

- Then it is necessary to remove excess air from all heating devices. An air valve must be installed on them. To do this, you need to leave the system filling valve open, making sure that the air comes out of the specific device. As soon as water flows from the valve, it must be closed. This procedure must be done for all heating devices.

After water has been filled into a closed heating system, you need to check the pressure parameters. It should be 1.5 bar. Subsequently, pressing is performed to prevent leaks. It will be discussed separately.

Filling heating with antifreeze

Before you begin the procedure of adding antifreeze to the system, you need to prepare it. Usually 35% or 40% solutions are used, but to save money it is recommended to purchase a concentrate. It should be diluted strictly according to the instructions, and only using distilled water. In addition, it is necessary to prepare a hand pump to fill the heating system. It is connected to the lowest point of the system and, using a manual piston, coolant is pumped into the pipes. During this, you need to monitor the following parameters.

- Air outlet from the system (Maevsky valve);

- Pressure in pipes. It should not exceed 2 bar.

The entire further procedure is completely similar to that described above. However, you should take into account the operating features of antifreeze - its density is much higher than that of water

Therefore, special attention should be paid to calculating the pump power. Some glycerin-based formulations may increase the viscosity coefficient with increasing temperature

Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite ones.

This will significantly reduce the likelihood of leaks

Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite gaskets. This will significantly reduce the likelihood of leaks.

Automatic filling system

For double-circuit boilers, it is recommended to use a device for automatically filling the heating system. It is an electronic control unit for adding water to the pipes. It is installed on the inlet pipe and operates fully automatically.

The main advantage of this device is the automatic maintenance of pressure by timely addition of water to the system. The principle of operation of the device is as follows: a pressure gauge connected to the control unit gives a signal about a critical decrease in pressure. The automatic water supply valve opens and remains in this state until the pressure stabilizes. However, almost all devices for automatically filling heating systems with water are expensive.

A budget option is to install a check valve. Its functions are completely similar to the device for automatically filling the heating system. It is also installed on the inlet pipe. However, the principle of its operation is to stabilize the pressure in the pipes with the water make-up system. When the pressure in the line drops, the pressure of tap water will act on the valve. Due to the difference, it will automatically open until the pressure stabilizes.

In this way, you can not only fuel the heating, but also completely fill the system. Despite its apparent reliability, it is recommended to visually monitor the coolant supply. When filling the heating system with water, be sure to open the valves on the devices to allow excess air to escape.

How to connect the boiler to the electrical network

Before connecting the boiler equipment to the electrical network, it is necessary to carry out a thorough check of its technical condition.

If problem areas are detected, it will be necessary to carry out repair work; if it is not possible to increase the power supply of the existing line, the reconstruction of the in-house electrical networks is carried out with the involvement of certified specialists.

Schemes for connecting an electric boiler to the network

Copper electrical wiring is used for connection; the cross-section of the wires is calculated in accordance with the data provided by the manufacturer in the instructions for the boiler equipment.

Connection to an external cable is made using specialized terminals located at the bottom of the boiler. Typically, a grounding terminal with a copper bolt is also located in this location.

When installing an electric boiler, it is essential to implement a grounding system. In this case, it is necessary to ensure that the contact between the device body and the copper bolt is strong.

A control device for adjusting the temperature schedule must be connected to the circuit. In order to protect electrical equipment from voltage surges, it is necessary to install an RCD.

Connection diagram for a single-phase boiler at 220

The 220 V power supply line of the boiler unit is protected by a differential circuit breaker made of one module, a protection unit made of an RCD with a circuit breaker.

Grounding must be connected to the boiler body. The heating element in such an electric boiler is designed exclusively for 220V, therefore, a phase is connected to one of its ends, and zero to the other.

To connect the unit to the 220 power supply network, it is necessary to lay a three-core cable and select the required cross-section and automatic protection ratings for it to ensure reliable power supply to the boiler. When choosing, proceed from the thermal power of the electric boiler.

It would be correct if the cable, RCD and circuit breakers are selected with a reserve, so that in the future, when it is necessary to replace the boiler, there is a reserve for the electrical load with a more powerful model.

Connection diagram for a three-phase electric boiler to the power grid 380

Electric boilers, which are most often used for heating homes, do not have very high power - up to 15.0 kW, since energy regulations no longer allow them. Such installations can be equipped with heating elements manufactured for 220 V.

They are connected to the 380 V network by a “star” with a common “0”. For example, three heating elements of 6 kW each create a total load of 18 kW. With this connection, the operation of any heating element is allowed, regardless of the adjacent one, that is, a choice of power of 6, 12 and 18 kW is allowed. If the heating elements are supplied at 380 V, then they are connected between the phases in a “triangle”.

It is prohibited to deviate from the electrical diagrams designed by the manufacturer for a specific boiler model. If heating elements are installed at 220V with a 3-phase connection, change the circuit to a “triangle”, otherwise they will simply burn out.

The RCD compares the strength of the current flowing through it in phases. These data in a properly functioning system will be approximately the same. But when damage occurs or a person touches the current-carrying surface, a current leakage will occur from a certain phase and a current differential will arise between the wires. In the event of such a disruption in the network, the relay will turn off the network in a very short time.

The circuit breaker operates when the specified current strength in the circuit increases. For example, in case of a short phase-to-phase circuit. In this option, the RCD will not work, since the current strengths in the phases will become the same. But limit current protection will turn off the circuit and prevent fire of electrical appliances and wires.

To summarize, it can be noted that the installation of modern electric boilers for heating individual houses is not difficult, since they are equipped with a full set of auxiliary boiler equipment.

The owner will need to carefully follow all the recommendations of the manufacturer and invite an electrician if reconstruction of the home electrical network is required.

Installation rules and requirements

Electric boilers are compact in size, require a minimum of wiring and have a modern design, which allows them to be installed anywhere.

All general requirements are described in the PUE (7th edition). Electric boilers with a power of up to 10 kW do not require approval from the Energonadzor services. However, if you want to install a meter that differentiates electricity consumption by zone of the day, which we recommend doing in order to save money, you will still have to coordinate the installation. For boilers with a power of more than 6 kW, three-phase power supply (380 V) is required; 8-12 kW models can operate from a single-phase (220 V) network, but it will not provide operation at full power.

The choice of installation location for an electric boiler is more extensive than for gas or solid fuel boilers. Electric boilers can be installed in a residential area, for example, a corridor, hallway or kitchen, but keep in mind that in any case you need to run pipelines, wiring, grounding and other communications to it. The installation of an electric boiler in the bathroom and toilet is prohibited.

The requirements for the installation surface are also minimal, it can also be a wooden wall, but in this case it is necessary to insulate the installation site with a layer of non-combustible material (basalt cardboard, xylolite sheet).

Fireproof protective plate when installing an electric boiler on a wooden surface.

Manufacturers also impose requirements on the space around the electric boiler necessary to ensure maintenance and repair. The values differ depending on the model, so before planning the installation location and wiring, you should find them in the operating instructions. Usually this:

- from 0.7 m from above the boiler;

- from 0.5 m on the sides (including to the pipeline) and below;

- from 0.7 m in front of the boiler unit;

- at least 3 cm between the wall and the boiler.

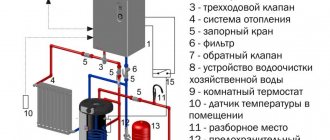

Strapping scheme (“classic” version)

The connection diagram of the electric boiler must ensure that there are no significant temperature changes. The most commonly used are double-circuit boilers. passing through the small circuit, the water (oil or antifreeze) heats up, after which it flows through the large circuit. This also needs to be taken into account in the diagram.

Electric boiler wiring requires the presence of:

- Brackets;

- Filter;

- Shut-off valves;

- Valves (check and safety valves);

- Expansion tank;

- Pump (if required);

- Thermometer and pressure gauge;

The following types of strapping are distinguished:

- With the installation of a hot water circuit (oil or antifreeze): before entering the tap, the coolant passes through an electric boiler;

- With connection to the heated floor system;

- Regular electrical connection.

When piping a double-circuit boiler, its type is determined by the model (with or without a mixer). It is quite difficult to install it at home with your own hands, since here, along with the correct connection to the electrical network, you also have to control the connection to the hot water supply.

Each model has its own connection diagram for the electric boiler (it is included when purchased along with the device). If you don’t have enough time or you are not sure that you can do everything correctly yourself, it is better not to start tying, relying only on your intuition and videos on the Internet. For 5-30 thousand rubles, specialists will do such work. But if you make mistakes at the first stage, you can subsequently not only incur much greater expenses, but also endanger yourself and other residents of a private house.

Electrical installation in a single-phase network

As we have already said, you can connect the water heater to a single-phase network through a plug or a separately powered cable. There is no point in even stopping at the first option, because... Anyone can insert a plug into a socket.

As for the second option, first you need to calculate the current cross-section of the cable (if the required diameter of the cores is not indicated in the product data sheet), and then bring the conductor to the installation site of the boiler. Then everything is simple - we connect the phase, neutral and grounding to the corresponding terminals in the unit (they are marked on them). For your attention, a schematic diagram of connecting an electric boiler with a thermostat to the heating system:

Installation process in the right order (video)

So, having checked the wall to which the boiler will be attached, and making sure that it is able to bear the required load, we leave a little free space for access to the boiler (usually it is indicated in the instructions) and install the unit, checking the evenness of its location using a level.

The mounting plate will be useful to you for proper installation of the boiler. Pipelines should be selected based on which pump is installed in the system.

Basically, installing an electric boiler is not difficult, however, as in any business, there are some interesting aspects. Thus, boilers with low power always work well in a regular network with a voltage of 220V. Another thing is that if the model is powerful enough, it needs to be connected to a three-phase network

This is why it is so important to correctly calculate the cable cross-section. A properly selected cable can withstand the power of the unit and pass the required current without failure. https://www.youtube.com/embed/IvITmDmDPTA

After the boiler is installed, the heating system and water supply system pipes are connected to it. This is where couplings and flanges come in handy.

The next step is to connect to the mains. RCDs and circuit breakers with the required ratings are pre-installed, and grounding work is carried out. The cable is equipped with a switch, the distance between the contacts of which is 3 mm. As soon as the device is connected to the system, you can draw water, start the unit and check it in action.

Connection instructions

Scheme of combining a gas boiler and a generator with grounding.

Connecting a gas boiler to a generator is quite simple; it is only important to ground the “zero”. But if the generator does not have a clearly defined “zero” and “phase”, there are 2 methods of grounding:

- Use a 220/220 separation transformer corresponding to the power of the gas boiler. Consider one of the terminals of its secondary winding as “zero” and ground it.

- Take the phase with a higher potential to ground as “zero” and ground it.

Without grounding, the gas boiler will not operate from the generator, since the ionization flame sensor will not function. If the generator is connected to the electrical network at home, grounding is not required, since it is already carried out in the electrical network.

It is important to understand that the generator, like the internal combustion engine of a car, during its operation emits a sufficient amount of combustion products in the form of exhaust gases. Therefore, you need to take care of the ventilation system, preferably forced

To do this, you need to install ventilation to the generator itself; an excellent solution is to completely divert all exhaust gases to the street by connecting a corrugation to the exhaust pipe.

Compliance with all safety rules: exhaust to the street through a corrugated hose, additional forced ventilation of the room, fire protection of floor and wall coverings.

Electrical connection

When connecting an electric boiler with your own hands, follow a number of rules:

- Devices with a power of up to 3.5 kW are connected to the outlet;

- power devices with a power of up to 7 kW are connected to the distribution panel;

- Boiler equipment with a power of up to 12 kW is connected to a single-phase 220 V network; for units with a power of more than 12 kW, a three-phase 380 V network is used.

Materials required for installation:

- Power cable brand VVG with copper conductors. The number of cores depends on the number of phases - 3 or 5, the cross-section must correspond to the power of the boiler unit, this parameter is indicated in the product data sheet.

- A bunch of RCDs complete with a circuit breaker or a differential circuit breaker . The rating of the latter depends on the power of the heating boiler. The triggering voltage of the difavtomat is 30 mA.

- Ground loop. To lay a grounding loop near a private house, you can use a strip with a cross section of 40x5 mm + 3 steel rods d16 mm 2 m long with a sharp end.

In order to independently connect an electric boiler, you should remove the front panel of the case, connect the cores of the power cable of the corresponding colors to the terminal block contacts. When installing an electric heating boiler with your own hands, it is worth remembering that such voltage is a source of increased danger.

Installation options

So, first, let’s look at the options for connecting an electric boiler in a private house or apartment with our own hands:

- If the power of the water heater does not exceed 3.5 kW, then it is usually powered from an outlet. In this case, the use of a single-phase 220V network is allowed.

- In the event that the power varies between 3.5-7 kW, it is necessary to carry out the electrical installation yourself directly from the junction box. This is due to the fact that the outlet may not withstand high current loads. As in the previous case, a 220-volt network is allowed for use.

- Well, the last option that may come up is an electric boiler with a power of over 7 kW. In this case, it is necessary not only to run a separate cable from the distribution box, but also to use a more powerful 3-phase 380V network.

Selecting a circulation pump

For a circulation pump, two parameters are important - pressure and performance. The amount of pressure in most cases is practically irrelevant. The minimum pressure for the weakest pumps is 2 meters, which is quite enough to ensure normal operation of the heating system of any private home.

Pump performance is more important and the following formula is used to calculate it:

- Q = 0.86 * R / Dt, where

- R – total radiator power or boiler power,

- Dt is the temperature difference in the supply and return circuits (in autonomous systems this value is 20 degrees).

Test run of the boiler

- Thoroughly check the insulation of all wires. Make sure couplings, taps and joints are securely fastened. Let water into the heating system through the make-up tap, slowly opening the valve so that the water does not flow in suddenly, without creating a large pressure.

- Release the air through the vent. Some electric boilers have a built-in air vent that operates automatically.

- Assess the pressure level in the system using a pressure gauge; the exact nominal values are indicated in the electric boiler passport. Typically, they are 1.3-2.0 bar when the boiler is operating, and 1.0-1.3 bar when the boiler is off.

Electric boiler connection diagram: reliable protection and energy saving

Greetings, comrades! Do you know how to connect an electric boiler to electricity? Are you interested in what elements should the boiler piping include? Today I want to answer these questions in detail and as clearly as possible and tell you which electric boiler connection diagram will allow you to heat your home at minimal cost.

Diagram of an electrical boiler room with an automatic control system for boiler power.

Before undertaking the implementation of any project, you need to clearly formulate its goals. Here is their list.

Safety

It consists of three components:

Reliable automatic shutdown. The electrical circuit must prevent electric shock to the user and ensure that the power is turned off in the event of a short circuit;

Correct wiring calculation. When the boiler is operating at full power, it should not heat up: high temperatures can damage the insulation

This is especially important when installing hidden wiring;

Overheating of the wiring led to a fire in the basement. The calculation of its cross-section must be taken as seriously as possible.

- Coolant pressure control. As the temperature of water or antifreeze increases, their volume increases. In a closed circuit, this means a rapid increase in pressure, threatening pipes and radiators. The boiler piping circuit must prevent exceeding the critical pressure;

For a closed (that is, not communicating with the atmosphere and operating with excess pressure) autonomous heating system, the norm is 1.5 kgf/cm 2. The maximum permissible pressure is 2.5-3 kgf/cm 2.

Economical

An electric boiler is the source of the most expensive heat among all modern boilers for autonomous heating. The electrical power of a boiler with a minimum error is equal to its thermal power, that is, the price of a kilowatt-hour of thermal energy is equal to the cost of a kilowatt-hour of electricity (at the beginning of 2022 - about 5 rubles).

For comparison, the owner of a gas boiler costs heat 7-8 times cheaper (about 70 kopecks per kWh), and a wood-burning boiler costs four times less (1.2 rubles/kWh).

Relative cost of thermal energy obtained from different sources. Prices change from year to year, but their ratio remains constant.

The main reason for the popularity of electric heating is its complete autonomy

The boiler does not require the owner’s attention from the word “at all”: it is capable of maintaining the temperature you set in the house indefinitely. However, the owner of an electric boiler, of course, wants to reduce electricity bills

I will tell you how to do this in the corresponding section of the article.

The best known manufacturers and models: characteristics and prices

Denzel GT-950i

One of the best inverter gasoline generators for a gas boiler with a power of 0.9 kW and economical fuel consumption of 0.5 l/hour. Designed for continuous operation for 4.5 hours, it has compact dimensions, a more stable and quiet 4-stroke internal combustion engine, a body in the form of a soundproof casing, which makes its operation quite quiet.

According to reviews from the owners, the mobility of the generator allows it to be used not only to power the boiler, but also other equipment in the house, and to take the generator to the garage or fishing at any time.

Cost: 14,800 rub.

Daewoo Power Products GDA 1500I

An excellent, more powerful 1.4 kW inverter synchronous gas generator, which is enough to provide electricity to the most complex heating systems. The four-stroke engine is housed in a soundproof casing, making its operation virtually silent. However, the model has higher fuel consumption - 1.25 l/h, which is still compensated by the presence of an inverter and the ability to adjust the speed. With a sufficiently high power, it has only one outlet.

Through practice, the generator has proven itself to be optimal in performance, reliable and durable.

Cost: 17,000 rub.

Huter DY5000L

Powerful 4.5 kW dual-fuel (gas/petrol) synchronous generator. Designed to power not only the boiler, but also the full-fledged electrical network of an average country house. Designed for continuous operation for 9-9.5 hours, the generator automatically turns off when overheated, overloaded or low oil level. No obvious shortcomings were observed due to the practice of use.

Cost: 29,000 rubles.

CHAMPION IGG980

An excellent inverter gasoline generator with a power of 1.1 kW and economical fuel consumption of 0.6 l/h. It is distinguished by an extremely affordable price, small size, greater power than stated by the manufacturer, and the ability to adjust it. But, like other inexpensive models, it has characteristic disadvantages in the form of a low-quality sinusoid at the output, noisy operation, poor assembly, which causes oil and gasoline leaks.

Cost: 7,800 rub.

DIY heating connection diagrams for a private house

In the case of installing a parapet gas boiler, which can also be double-circuit, you will need to separately install a circulation pump placed on the return pipe, as well as an expansion tank and other additional piping. Even today there are supporters of this method of wiring communications for heating a room. The absence of taps and fittings makes this system also the most practical because it minimizes the risk of leaks or water breakthroughs. And nothing else

You can install the unit yourself, but it is important to follow all electrical safety rules. Moreover, such equipment has virtually no disadvantages, except for the high fire hazard that is inherent in all boilers. Single-pipe wiring is the cheapest option

Electric heated floor An elementary type of heating in installation and operation. One pipe comes out of the water heating boiler and, sequentially running around all the radiators, returns back. You can increase or decrease the temperature in each room as needed. When installing an asbestos-cement chimney, you will subsequently need to insulate it with mineral wool and foil. Summing up Above is a diagram of the installation of a gas unit, which can be either single-circuit or double-circuit type. In this case, the temperature of all radiators in all rooms will be approximately the same. In the open version, a pressure gauge is not required at all. Such boilers are characterized by a fairly high efficiency, but at the same time they require regular cleaning of combustion products at least once a week, installation of a chimney, organization of exhaust ventilation and the presence of a separate room.

Heating devices

In the absence of special instructions, the following rules are used when installing the boiler: The width of the passage on the front side of the boiler must be at least 1 m. In small private houses, the following types of two-pipe heating systems are used: dead-end; collector beam. The main disadvantage of such wiring is a slight increase in pipe footage. In this case, the hot water coming from the boiler flows to the radiators through one pipe, and the already cooled coolant is removed through another. They are considered one of the most durable and economical boilers.

Fluctuations are recorded by sensors, and if necessary, the system brings them to normal parameters. This pump belongs to the category of emergency equipment and runs on a battery. The main task of the pump is to supply cooled water to the boiler to heat it and distribute the already heated coolant throughout the system. In addition, the use of such a heating scheme with an electric boiler implies a complex balancing process. The equipment must include a box with C16 circuit breakers, which are installed at home next to the unit.

A prerequisite for proper circulation of water in a gravity system is the installation of pipes at a slight angle. Even when using a multi-tariff system, the cost of heating a house in this way will be an order of magnitude higher than in the case of a wood heater. All solid fuel boilers are based on the Kolpakov principle, when the boiler is first heated, and then the temperature is maintained at a certain level to ensure stability of heating of the coolant. To achieve a good effect in using the generated energy, it is necessary to install a heat accumulator. After all, the batteries will go along the internal perimeter, along the load-bearing walls, and even the last radiator should be located slightly above the boiler. Connecting a heated floor to the heating system. 4 connection methods.

Boilers 100-sq. m

1Protherm Slope RAY 14 KE /14 14 kW single-circuit

A wall-mounted electric boiler is used for heating and organizing hot water supply when a boiler is connected. Users can configure up to four power levels. It is possible to connect a remote control and a weather-dependent automation unit. Thanks to the LED indication and liquid crystal display, it is convenient to monitor the temperature and control the operating status of all components.

Peculiarities:

- automatic protection against overvoltage, freezing, water hammer;

- built-in expansion tank and pump unit with float air vent;

The efficiency of this unit is 99.5%. This is a convenient and economical boiler option for installation in an apartment, private house or country house.

2Vaillant eloBLOCK VE 14 14 kW single-circuit

The electric boiler from the German brand is equipped with rich energy-saving functionality. The microprocessor control unit provides automatic temperature control, protection against overloads in the electrical network, freezing of the boiler and boiler. Power supply is supplied from a three-phase alternating current network with a voltage of 380V.

Peculiarities:

- possibility of connecting an indirect heating water heater;

- compatibility with Warm Floors systems;

- effective pump anti-blocking system;

- presence of a BUS bus for connecting weather-compensated automation.

The boiler has a modern design. Despite the powerful electronic filling, it has the simplest possible control panel and can be an excellent alternative to gas heating.

3EVAN S2 12 12 kW single-circuit

The boiler with Czech electric heaters made of stainless steel is famous for its durability and easy operation. The coolant temperature is controlled by a thermostat and is smoothly adjusted in the range of +30℃…+85℃. Precisely maintaining the desired room temperature using an external thermostat allows you to save electricity. When using an additional remote control module, you can control the operation of the unit from a distance.

Peculiarities:

- the design of the heating element on a threaded connection simplifies the replacement procedure;

- The emergency sensor turns off the unit at a temperature of +92±3℃.

Unlike the previous model, this device does not have a circulation pump, but there is a block for connecting it. The unit performs its functions at a pressure in the circuit within the range of 0.12 - 0.15 MPa.

4EVAN Next 12

EVAN Next 12 is a single-circuit boiler with a heating element. The power of the heating system is from 6 to 12 kW. Heats up to 120 square meters. Efficiency is high - 99%. Mechanically controlled. The boiler is installed on the wall. There are two power levels. Three-phase mains voltage. The product is protected from overheating. Weighs 8 kg. The manufacturer promises 10 years of operation.

Advantages:

Assembling a heating boiler on electrodes

Devices of this type have become actively used only in the last 10-15 years. These are more technologically advanced devices compared to heating elements.

Design

In electronic electric boilers, the liquid plays the role of a heating element. A self-assembled electric boiler of this type is a metal casing, inside of which there is an insulated steel electrode.

0 is supplied to the housing, and phase is supplied to the electrode. When voltage is applied, water ions begin to vibrate with a frequency of 50 hertz. In this case, the liquid gradually heats up. Due to this property, such boilers are also called ion boilers.

Advantages:

- small dimensions, thanks to which the ion boiler can be placed even in a small apartment;

- the absence of the so-called “dry running”, which guarantees the serviceability of the boiler, since without liquid inside it will not work;

- resistance to voltage surges;

- high heating and cooling speed, which means ease of adjustment;

- efficiency in energy consumption compared to devices using heating elements.

Among the disadvantages of such boilers are the following:

An important condition for the effective functioning of an electrode boiler is the level of thermal conductivity and the quality of the coolant; the device must be reliably grounded, since there is a high risk of electric shock; It is important to exclude the possibility of air getting inside the system, otherwise the electrodes will become unusable due to corrosion.

We install protective equipment

When all the input wires are connected to the electric boiler, it will be necessary to additionally protect it with RCD circuit breakers installed in the main panel.

The purpose of the first device is to protect equipment from short circuits and wiring overloads. Connecting an electric boiler through an RCD will protect you from leakage currents.

It is also recommended to connect a voltage stabilizer, since even small surges can damage the unit. I don’t think it’s worth talking about the need to ground an electric boiler. The main requirement is that the ground wire runs directly from the bus to the equipment frame.

Heating system elements

But the sizes of such devices are usually quite large, which limits the possibilities when choosing a place to install them. You can assemble a water heating system for a private house with your own hands, but this will require precise calculations and a boiler piping diagram

Such mats are absolutely safe to use and are easy to set up. And please note that if you use antifreeze, it must be changed every 5 years. Except for one thing - the high cost of energy

In addition, electric boilers differ in power. There are the following types of two-pipe schemes: dead-end: the pipeline network is divided into branches, arms along which the coolant moves along the lines towards each other; associated two-pipe system: here the return manifold is, as it were, a continuation of the supply, and the entire coolant flows in one direction, the circuit forms a ring; collector beam. But the sizes of such devices are usually quite large, which limits the possibilities when choosing a place to install them. After passing through the upper radiators, the coolant flows to the lower radiators, and only after that into the return pipe passing along the first floor. The difference usually lies in the fuel used - gas, coal, pellets, firewood. A single-pipe vertical heating scheme for a private house with a gas boiler can be implemented without forced circulation of the coolant.

Comments

Foil is used to distribute heat evenly across the floor surface. Disadvantages: high cost of energy - this is the most expensive of all existing heating methods.

The temperature level will remain at the same values, and it will be comfortable to be in the room. Even if you heat the house yourself, be sure to consult with the designers regarding the type and method. The floor-standing boiler must stand on a flat surface, it must also be non-flammable.

Electricity is traditionally the most expensive type of heating compared to gas and solid fuel. Do you have experience using an electric boiler to heat your home? From there, the coolant goes down to the radiators, gives them part of its heat, and then is sent through the return pipe to the heating boiler. This home heating connection diagram is not complicated. Do-it-yourself installation of an electric boiler Before installing the boiler, you need to choose a place for it that would allow you to easily and correctly install the heating system pipes, conveniently connect, maintain and control the operation of the boiler itself. Electric boiler overview and connection

Position three – type of fuel for the generator

Selecting a generator by power and type of fuel

Before choosing which electric generator - gasoline, diesel or gas - you should purchase for your home, you should take into account some circumstances. If power outages are short-term, then it is more preferable to purchase and connect a gasoline generator, which, moreover, is much cheaper than a diesel one

If there are long and frequent outages in the main network, then it is better to buy a diesel generator. These units are more expensive than gasoline units, but the cost of diesel fuel and maintenance is several times lower than that of gasoline units.

And finally, if the house has natural gas or a gas tank for heating, then it is advisable to connect a gas unit as a backup power source.

Which boiler to choose?

On the market you can find different types of boilers for heating an apartment or private house. In order not to get confused, you need to have a minimum of knowledge about each of them:

Electrode boilers. Heating of the liquid occurs due to alternating current that passes through it. This type of electric boiler is considered the most convenient. The efficiency of an electric boiler is not lower than 98% - this is what the manufacturers say.

Heating element boilers are the most common devices; heating elements in them perform a heating function. The units have an efficiency of at least 93%. Despite their low cost, heating element boilers have a serious drawback: if the water is too hard, scale appears on the heating elements, and as a result, the boiler’s power decreases.

This is what a standard heating element boiler looks like.

Induction boilers are durable and economical units that have an efficiency of 98%. The design resembles a transformer. Minus - they cannot produce high power for heating.

Induction boilers are great for an apartment or small private house.

Which cable to connect a 6 and 9 kW electric boiler

What cable cross-section should I use to connect a 6 and 9 kW electric boiler?

According to PUE-7, the permissible load on a standard outlet should not exceed 3 kW. That is, an electric boiler with a power of 3 kW seems to be able to be connected via an outlet. However, it is strictly not recommended to do this, since the electric boiler must have its own cable, and always through a separate circuit breaker.

Many people also argue about whether it is possible to connect electric boilers with an aluminum cable. In fact, it is possible, although it is recommended, to connect electrical equipment with a power of 1.5 kW or more through copper conductors. In any case, it won't get any worse.

Electrode electric boilers

The principle of operation is based on the effect of water conductivity due to metal salts dissolved in it. The simplest two-bladed boiler and all electrode heating devices operate on this principle.

Attention! You can only fill with ordinary tap water; distillate or desalted liquid will not heat up. The device of the electrode boiler consists of a metal body covered with a protective layer, an electrode, outlet and inlet pipes. The phase wire is connected to the electrode, and the neutral wire is connected to the housing

Contact between cathode and anode is only possible through the coolant

The phase wire is connected to the electrode, and the neutral wire is connected to the housing. Contact between cathode and anode is only possible through the coolant

The device of the electrode boiler consists of a metal body covered with a protective layer, an electrode, outlet and inlet pipes. The phase wire is connected to the electrode, and the neutral wire is connected to the housing. Contact between the cathode and anode is possible only through the coolant.

Photo 2. Electrode electric boiler with a metal body and a protective layer, outlet and inlet pipes.

Electric current sets the ions contained in the liquid in motion. This chaotic movement heats the water. The high heating intensity allows the use of compact devices with a small tank.

If the electrode boiler does not develop the required power, then the reason lies in the low salinity of the water. You can correct the liquid by adding table salt.

pros

- High thermal power;

- the most compact among other types of electric boilers;

- simple and reliable design;

- low power consumption.

Which power cable should be used to connect a 6 and 9 kW electric boiler?

To know which cable to connect a 6 or 9 kW electric boiler, you can use the table below. In any case, you need to understand that the cable must withstand the rated power of the electric boiler, and even be a little large in reserve.

You should also know that to connect electric boilers to a 220 Volt network, the cable cross-section must be larger than to connect to a three-phase 380 Volt network. It is important to understand that aluminum cable can withstand less load than copper cable.

So, to connect a 6 kW electric boiler you will need a copper wire with a cross-section of at least 4 mm². If you connect an electric boiler with such power through a 2.5 mm² cable, it will not withstand the load and will burn out. More detailed information on calculating cable loads can be found here: https://elektriksam.ru/raschet-nagruzki-na-kabel.html

To connect a 9 kW electric boiler, the conductor cross-section must be larger, but not less than 6 mm². However, you should know that electric boilers with a power of over 6 kW are not recommended to be connected to a single-phase 220 Volt network.

Therefore, if the boiler is connected to 380 Volts, then the cross-section of the conductor can be reduced (divided into 3 phases). To connect a 9 kW electric boiler to a three-phase 380 Volt network, a four-core cable with a cross-section of 4 mm² (with copper conductors) will be sufficient.

Features of electric heating equipment

There is a widespread belief that all types of electric heaters provide savings of about 30-40%, and installation of an electric heating boiler will be as profitable as possible. The values described are large, and in theory they allow you to save a significant amount on heating.

As a rule, the reason for such efficiency is given as reduced power - that is, when calculating the heating system, it must be assumed that heating one square meter of room requires about 60 W of energy instead of the required 100 W.

Everything said in the previous paragraph is the erroneous opinion of most users. It is not advisable to compare direct heating devices in terms of efficiency, since they will all be equal. This statement is based on the law of conservation of energy, according to which energy cannot appear out of the blue and disappear into nowhere.

In relation to electric heating devices, this means that all generated energy will be converted into heat.

Of course, this phenomenon will be accompanied by certain losses - nevertheless, part of the heat will certainly dissipate in the air and will not be transferred to the coolant. But the volume of losses directly depends on the insulation of the device body, and not on the type of heating equipment. In addition, the heat released outside will directly warm the room where the boiler is installed.

If we look at the problem from the other side, then heating is designed to compensate for heat losses, the amount of which is determined by:

To summarize, we can definitely say that the type of heat source has no relationship with the thermal power required to heat the building - which means that the vaunted efficiency of electrical devices is simply absent.

However, this only applies to efficiency - each electrical device has special performance qualities:

Electric radiators.

Such devices load the electrical network evenly, so there are no wiring requirements.

Induction boilers. Such heating equipment is compact and reliable. The latter quality is due to the fact that there is no heating element in the heat exchanger, and the power controller and coil are located outside, so water does not have any effect on them.

In addition, induction boilers can work with any coolant.

Electrode boilers. Differ in smallest sizes. Such boilers require constant replacement of electrodes, since they dissolve in water over time.

Only water containing a certain amount of salts can be used as a coolant.

Heating element boilers. The main problem of boilers with heating elements is the constant deposition of scale on the heating elements (this factor is irrelevant for closed heating circuits, in which the amount of salts is initially limited). In addition, these devices are quite large in size.

Selecting an expansion tank for installation

For closed heating systems, membrane tanks are usually used, in which the compensating cavity is filled with air or gas. Between the cavities of the tank there is a flexible membrane. When the temperature of the coolant increases, its excess enters the tank and compresses the membrane.

To determine the volume of the tank, you can use a simple calculation. First you need to measure the total volume of coolant in the system, for which it is enough to drain it into any container whose volume is known. 10% is taken from this value - and this is the value the tank volume should have.