To create comfort in residential and industrial premises, a thermal balance is drawn up and the efficiency factor (efficiency) of the heaters is determined. In all calculations, an energy characteristic is used that makes it possible to connect the loads of heating sources with the consumption indicators of consumers - thermal power. The calculation of a physical quantity is carried out using formulas.

Special formulas are used to calculate thermal power

Definition of thermal power

The thermal power of the equipment directly depends on the amount of energy consumed by the boiler.

Heat release power refers to the amount of heat generated when the source medium is converted into heating energy. This indicator is different in value for different types of energy carriers and is calculated for each of them individually. For gas boilers, it depends on the volume of natural or liquefied gas supplied to the burner per unit of time.

When considering electrical analogs, this parameter is directly related to the electrical power consumed by the unit from a 220 or 380 Volt network and its thermal efficiency. The ratio of thermal and electrical powers is specified by special formulas that convert one value into another.

Heat gains from the technological equipment of the canteen.

where: KO is the coefficient of simultaneity of operation of thermal equipment; for canteens KO - 0.8 for restaurants and cafes KO - 0.7NМ - power of installed modulated technological equipment, kW.

Characteristics of thermal equipment of a public catering establishment.

| Thermal equipment | Equipment dimensions | Installed power of a unit of equipment, kW | KZ equipment load factor |

| Sectional modulated equipment | |||

| Plates: PESM - 4sh | 840 x 840 x 860 | 18 | 0,65 |

| PESM - 2k | 420 x 840 x 860 | 3,8 | 0,65 |

| Frying pans: | |||

| SESM - 0.5 | 1470 x 840 x 860 | 13 | 0,65 |

| SESM - 0.2 | |||

| Deep fryer FESM - 2 | |||

| Boiler KPESM - 2 | 420 x 840 x 860 | 7,5 | 0,65 |

| Wardrobe SHZhESM – 2 | 1050 x 840 x 860 840 x 800 x 1500 | 8,6 3,8 | 0,30 0,65 |

NН is the installed electrical power of non-modulated technological equipment, kW;

| Thermal equipment | Equipment dimensions | Installed power of a unit of equipment, kW | KZ equipment load factor |

| Non-modulated equipment | |||

| Digester capacity, l: | |||

| 40 | — | 5 | 0,3 |

| 60 | 6,8 | 0,3 | |

| 125 | — | 8,5 | 0,3 |

| Boiler capacity, l: | |||

| 200 | — | 10 | 0,3 |

| 100 | — | 8,3 | 0,3 |

| 25 | — | 3,3 | 0,3 |

NP is the installed power of electrical equipment in the distribution opening, kW;

| Thermal equipment | Equipment dimensions | Installed power of a unit of equipment, kW | KZ equipment load factor |

| Equipment located in the dispensing opening | |||

| Thermal rack SRTESM | 1470 x 840 x 860 | 2,0 | 0,50 |

| Food warmer MESM-50 | 840 x 840 x 860 | 4,0 | 0,50 |

KZ - equipment load factor (see table); K1 - efficiency coefficient of supply and exhaust localizing devices for modulated equipment - 0.75; K2 - efficiency coefficient of localizing devices for non-modulated equipment: for supply and exhaust localizing devices - 0.75; for curtains - 0.45.

Required characteristics

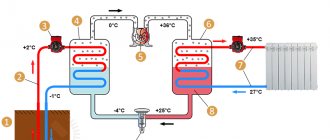

The main component in a heating boiler is the heat exchanger.

Calculation of thermal power is very important, since its results are necessary to determine the parameters of the selected sample of heating equipment. The latter traditionally include:

- electrical power of the unit for volatile models;

- conversion efficiency (or boiler efficiency);

- performance, defined as the amount of heat generated by a device per unit of time.

Models of boilers connected to the electrical network refer to equipment with the power consumption of the heating system, reduced to the amount of solid or gaseous fuel burned. For electricity-independent images, this parameter is determined directly - without recalculating the consumed electricity.

The operating efficiency of any heating unit largely depends on the correct choice of the unit that ensures the conversion of thermal energy (heat exchanger). A competent solution to this issue allows you to obtain the required heating performance and feel comfortable in the house even on the coldest days.

Excess thermal power is undesirable, since in this case part of the funds spent is wasted.

Heat gains from electric furnaces.

These heat inputs are calculated as a fraction of the installed electrical power Nset., indicated in the catalog (sometimes this value is called “idle power”).

The maximum heat input occurs from a heated furnace in stationary heat transfer mode. During this period, electrical power will be spent to replenish the heat losses of the furnace and it is this that is called idle power.

There are several ways to determine heat emission into a room from electric stoves:

by idling power Nxx, kW

Qelectric ovens = 1000 Nx.x., W;

as a share of P% of the rated electrical power of the furnace consumed for heat losses by the furnace:

Qelectric furnaces = 1000 (P/100)Nset, W.

If the specified values are unknown, approximately the heat input can be determined by the purpose of the furnace.

The following table shows the values of heat release in W per 1 kW of installed power for furnaces for various purposes.

| Electric oven type | α value |

| Chamber, mine, methodical | 200 |

| Bells | 130 |

| Muffle | 150 |

| Stoves-baths | 400 |

| Furnaces, no type specified | 250 |

Heat gains are determined as:

Qelectric furnaces = α × Nset, kW

where: Nset – installed electric power of the furnace, kW.

Factors influencing heat demand

Thermal power depends on the area of the room, the climate of the region, the degree of insulation of the building

. The main factors determining the need for thermal energy for the room include:

- full volume of heated spaces;

- type and quality of insulation material;

- climatic zone in which the building is located.

The amount of air space that needs heating depends on the volume of the room. The larger the heated room, the more heat will be required to maintain the desired microclimate. With the same ceiling height (about 2.5 meters), a simplified calculation is usually used, in which the area of the room is taken as a basis.

The quality of insulation is judged by the methods of thermal insulation of the walls, as well as by the area and set of windows and doors. The type of glazing is also taken into account - simple and triple glazing differ in heat loss. The influence of the climatic factor is felt, all other things being equal, and is taken into account as the difference in temperature outside and in the room where the boiler is installed.

For appliance (heater)

The degree of thermal conductivity of metals - radiators are made from some of them.

When considering the factors influencing the heating power of heating radiators, three main ones stand out:

- an indicator corresponding to the difference in heating of the coolant and the surrounding air - with its increase, the thermal power increases;

- surface area that gives off heat;

- thermal conductivity of the material used.

In this case, the same linear relationship is observed: as the surface of the battery increases, the amount of thermal output also increases. For this reason, many modern heating radiators are supplemented with special aluminum fins, which increase the overall heat transfer.

How to choose a replacement resistor

The exact same element is always selected for replacement. It is allowed to temporarily use resistances with a parameter 1 order of magnitude higher than that of one that has burned out or failed for other reasons. This is the basic condition for a closed loop in a circuit. Installing a faulty section of the circuit means opening the circuit.

The parameters can be determined approximately by markings and sizes.

Replacement elements are equipped with leads at both ends - they are soldered onto the board. It is recommended not to trim the leads, as they also have additional resistance.

Why do you need to calculate the power indicator?

The boiler power is selected according to the expected number of devices that will have to be serviced.

The need to determine power is explained by the fact that the main characteristics of the boiler depend on the following factors:

- design features and purpose of the heated facility;

- the size and shape of each room;

- total number of residents;

- location on the country map.

The calculated heat transfer power is used to determine the parameters of boiler equipment planned for installation in this particular room. The future boiler must have a performance sufficient to heat it even on the coldest winter days. It is also important to provide for the possibility of coordinated connection of the unit to the main pipeline. The calculations carried out will help determine its length and standard size of pipes, as well as the type of radiators and parameters of the circulation pump.

Calculation of the number of sections of heating devices

The heating system will not be effective if the optimal number of radiator sections is not calculated. An incorrect calculation will lead to the rooms being heated unevenly, the boiler will work at the limit of its capabilities or, conversely, “idlely” wasting fuel.

Some home owners believe that the more batteries the better. However, this lengthens the path of the coolant, which gradually cools, which means that the last rooms in the system risk being left without heat. Forced coolant circulation partly solves this problem. But we must not lose sight of the power of the boiler, which may simply “not cope” with the system.

To calculate the number of sections, you will need the following values:

- the area of the heated room (plus the adjacent one, where there are no radiators);

- power of one radiator (indicated in the technical specifications);

take into account that per 1 sq. m

living space will require 100 W of power for central Russia (according to SNiP requirements).

The area of the room is multiplied by 100 and the resulting amount is divided by the power parameters of the installed radiator.

Example for a room of 25 square meters. meters and radiator power 120 W: (20x100)/185=10.8=11

This is the simplest formula; if the height of the rooms is not standard or their configuration is complex, other values are used.

How to correctly calculate heating in a private house if the power of the radiator is unknown for some reason? By default, the average static power is 200 W. You can take the average values of certain types of radiators. For bimetallic ones this figure is 185 W, for aluminum ones - 190 W. For cast iron, the value is much lower - 120 W.

If the calculation is carried out for corner rooms, then the result obtained can be safely multiplied by a factor of 1.2.

Calculation of thermal power

To estimate thermal energy, there is a formula for determining power through the amount of heat: N = Q/Δ t, where Q is the amount of heat expressed in joules, and Δ t is the time of energy release in seconds.

In evaluation calculations, a special coefficient (efficiency) is also used, indicating the amount of heat consumed. It is found as the ratio of useful energy to heat loss power and is expressed as a percentage.

The amount of energy expended for premises depends on their construction features. The same indicator for batteries is determined by the materials used in their manufacture and design features.

More accurate thermal calculation

A competent choice of heating equipment is possible only after becoming familiar with the procedure for calculating the thermal power required in each specific case. The formula used to accurately determine it is: P=V∆TK= kcal/hour:

- V is the volume of the heated room, measured in cubic meters.

- ∆T – the difference between the air temperature outside and inside the room.

- K – heat loss coefficient.

The last value depends on the material of the walls. Based on measurements taken by specialists for an uninsulated wooden structure, it is 3.0-4.0. The exact K values for various insulation options are given below:

- For buildings made of single brickwork and with simplified window and roof structures (so-called “simple” thermal insulation) K = 2.0-2.9.

- Insulation of average quality (K=1.0-1.9). This is a typical design, which means double masonry, a conventional roof, and a limited number of windows.

- High-quality insulation (K = 0.6-0.9), involving brick walls with enhanced thermal insulation, a small number of windows with double frames, a solid floor base and a roof with reliable heat insulators.

As an example, we will consider the exact calculation of power for a heated room with a volume of 5 x 16 x 2.5 = 200 cubic meters. ∆T is defined as the difference between the indicator outside -20 °C and indoors +25 °C. The option with average specific thermal insulation (K = 1-1.9) is accepted. Based on average operating conditions, we take 1.7. We calculate: 200 x 45 x 1.7 = 15,300 kcal/hour. Based on the fact that 1 kW = 860 kcal/hour, we ultimately have: 15,300\860 = 17.8 kW.

How much does 1 kW of electricity cost in Kazakhstan 2020?

Payment for electricity, depending on the volume of consumption and with or without the use of an electric stove for the population, increased over the month by 0.5-0.6%. Thus, level 1 tariffs increased by 0.5%, to 1146 tenge per 100 kWh for the population who do not use electric stoves, and to 1129 tenge per 100 kWh for those who do.

Interesting materials:

What organs does the autonomic nervous system innervate? What bodies are included in the government? What are the main beneficial substances in milk? What reports does an individual entrepreneur submit on a patent with employees? What reports does the HR department of Ukraine submit? What sectors of the economy are developed in the Stavropol Territory? What wands did the Harry Potter characters have? What monuments were created in the 16th century? What personal data cannot be disclosed? What podcasts should I listen to in Russian?

Heat gains from people.

They enter the environment in the form of sensible and latent heat. Sensible heat is released to the environment as a result of convective and radiant heat exchange. Latent heat - represents the heat content of water vapor evaporating from the surface of the human body and lungs.

The total amount of heat generated by a person depends mainly on the severity of the work performed and, to a lesser extent, on the temperature of the room and the heat-protective properties of clothing. With increasing work intensity and ambient temperature, the proportion of heat transferred in the form of latent heat of evaporation increases. At an air temperature of 34°C, all the heat generated by the body is released through evaporation.

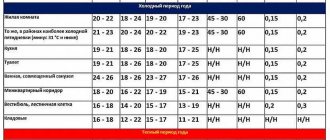

Indicators of human heat emissions into the external environment are given in the table below.

In this regard, several comments can be made:

- regardless of the type of activity, the total amount of thermal energy released by the body at low ambient temperatures is higher than at high temperatures;

- at low ambient temperatures, the value of sensible (sensible) heat is significantly higher than that of latent heat, and vice versa, at high temperatures the release of latent heat predominates;

- at temperatures corresponding to a comfortable state (22 ± 2 ° C), with a sedentary occupation, the total amount of heat generated is distributed approximately in the following proportion:

60 - 65% sensible heat and 40 - 35% latent heat.

With increasing physical activity, the release of latent heat begins to predominate.

Indicators of human heat generation at various ambient temperatures are shown in the following graph.

When calculating heat input from people, one must take into account the fact that the number of people stated in the initial data will not always correspond to their simultaneous presence in a given room. This fact justifies the use of the simultaneous presence coefficient

To perform a calculation that corresponds to reality, this coefficient is usually taken in the range from 0.9 to 0.95. In other cases, for example in hotels, restaurants, etc., such a coefficient should be established on the basis of the Customer’s Technical Specifications.

The amount of heat generated by one person is determined based on the following expressions:

sensible heat amount

amount of total heat

Amount of heat and moisture generated by adult males

| Indicators | Amount of heat, W, and moisture, g/h, emitted by men at room temperature, °C | |||||

| 10 | 15 | 20 | 25 | 30 | 35 | |

| At rest | ||||||

| Warm: | ||||||

| explicit | 140 | 120 | 90 | 60 | 40 | 10 |

| complete | 165 | 145 | 120 | 95 | 95 | 95 |

| Moisture | 30 | 30 | 40 | 50 | 75 | 115 |

| For light work | ||||||

| Warm: | ||||||

| explicit | 150 | 120 | 100 | 65 | 40 | 5 |

| complete | 180 | 160 | 150 | 145 | 145 | 145 |

| Moisture | 40 | 55 | 75 | 115 | 150 | 200 |

| For moderate work | ||||||

| Warm: | ||||||

| explicit | 200 | 165 | 130 | 95 | 50 | 10 |

| complete | 290 | 290 | 290 | 290 | 290 | 290 |

| Moisture | 135 | 185 | 240 | 295 | 355 | 415 |

Note. Women produce 85%, and children 75% of heat and moisture compared to men.

Categories of work depending on the type of activity.

| Categories of work | Energy consumption, W | Types of jobs |

| Lungs (category I) IaIb | No more than 174 No more than 139 Up to 174 | Performed while sitting and accompanied by minor physical strain. Occurred while sitting, standing or walking and accompanied by some physical exertion |

| Moderate severity (category II) IIa IIb | 175-290 175-232 233-290 | Associated with constant walking, moving small (up to 1 kg) products or objects in a standing or sitting position and require a certain amount of physical stress. Associated with walking, moving and carrying heavy objects (up to 10 kg) and accompanied by moderate stress. |

| Heavy (category III) | More than 290 | Associated with constant movement, moving and carrying significant (over 10 kg) weights and requiring great physical effort. |

1. Category of work - differentiation of work by severity based on the body's energy consumption. 2. Under the working area there should be a space limited in height by 2 m above the floor level, or a platform on which there are places for permanent or non-permanent (temporary) stay of people.

Advantages and disadvantages

Like any household appliance, fan heaters have their pros and cons.

| Advantages | Flaws |

| Fast heating | Relatively high noise level due to fan operation |

| High heat dissipation | Low power for normal room ventilation without heating, comparable to a low-power table fan |

| Small dimensions and weight | Models with wire nichrome burn oxygen |

| Easy to use | An unpleasant odor may appear upon first use after a long period of inactivity - dust burns off |

| Mobility (except for stationary models) | |

| Possibility of installation in any room |

The energy consumption of such devices is difficult to categorize because If you take a separate fan heater and use it around the clock, it will “burn” a lot of electricity. There is no such heating device that would consume little electricity; all devices, be it a convector, an electric battery, a conventional heater or a split system, are very “gluttonous”.