Unit features

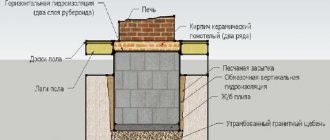

Scheme of operation of the Breneran furnace with a water circuit. (Click to enlarge)

In addition to simple models capable of heating the air in a single room, manufacturers offer a special Aqua series.

These models are powerful enough to heat the coolant and completely warm up the entire house.

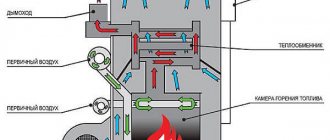

The furnace itself is made of durable steel and consists of 2 combustion boilers: solid fuel is burned in the primary one, and exhaust gas is burned in the secondary one. This allows you to get additional heat without wasting extra firewood.

The stove itself is connected to the general heating system of the house: when it is turned on, the coolant heats up and begins to flow throughout the system, giving off heat to the pipes and returning back after cooling.

Breneran stoves have a number of positive qualities:

- High efficiency and efficiency: the latter reaches 98%.

- The stoves can operate in closed and open heating systems, and are also easily combined with cast iron radiators.

- They have a long-burning function: one load of firewood is enough for 8-12 hours; you can also leave the stove smoldering without wasting wood.

- Possibility to use different solid fuels.

- Low price and wide range of models;

The disadvantages of Breneran include:

- not the most attractive appearance;

- inability to work with aluminum radiators.

When burning, you can use a variety of materials: stoves work well with coal-wood material, peat, and sawdust.

There are several models of Breneran stoves with a water circuit.

They differ in a number of parameters:

- AOTV-06 type 00: the smallest and “weakest” of the models. It has parameters of 93*70*54 cm, has a power of 6 kW and can heat up to 100 cubic meters. meters of air. One bookmark is enough for 8 hours of work;

- AOTV-11 type 01: has a power of 11 kW and dimensions 130*85*67 cm. Can heat up to 200 cubic meters. meters. Can work up to 10 hours on one fill of fuel;

- AOTV-14 type 02: has dimensions of 130*100*70 cm and a power of 14 kW. This is enough to warm up 400 cc. meters. Operating time – up to 10 hours;

- AOTV-16 type 03: its power is 16 kW, which is enough to heat 600 cubic meters. meters. The dimensions of the stove are 140*130*80 cm. The maximum burning time is 12 hours;

- AOTV-19 type 04: the most powerful model. It is used to heat 1000 cubic meters. meters with dimensions of 150*170*80 cm. The power is 19 kW, it can work up to 12 hours without “additive”.

The models presented above belonged to the Breneran Aquaten category. There is another separate model, Breneran Aqua: its power of 27 kW is designed to heat 600 cubic meters. meters of room, and the dimensions are 92*115*69 cm. One bookmark is enough for 6-8 hours of work.

All models are made of high-strength materials and are designed for installation in the basement or boiler rooms. They do not have a flat lid, that is, it is impossible to heat food on them, but still the walls heat up quite strongly.

Breneran stoves, tested by Canada, are firmly rooted in Russian stores. Thanks to their efficiency and high performance, they have received high praise from customers.

Watch the video in which a user shares his experience of using the Breneran stove:

The Breneran Aquaten gas generator stove is a popular device for heating a private home. For owners of private residential buildings, there are several ways to heat a room. One of them is the use of long-burning gas generator furnaces operating on solid fuel. Recently, such devices have gained popularity and this is not surprising, since they help save money and at the same time heat your home with high quality. The leaders among such heating devices were Breneran (Buleryan) stoves.

Features and installation methods of Breneran Aquaten

As already noted, the design of the stove allows the use of any options for connecting water heating. The device can be used in systems with forced and natural coolant circulation.

When carrying out installation work, safety regulations regarding the installation of the stove and the connection of the smoke exhaust system, and the features of closed and open systems are taken into account. The performance and heat transfer are affected by the type of boiler piping and the coolant used.

Fire safety requirements

Manufacturer JSC Laotherm received a fire safety certificate for the Aqua Breneran water circuit furnace. This indicates that the boiler is protected from accidental fire, and with proper operation, the likelihood of a fire is minimized.

Installation in a residential area is carried out taking into account the existing safety regulations applicable to high-pressure boilers:

- The stove is mounted on a solid non-combustible base. For models AOTV 14, 16 and 19, a concrete base is required.

- On the firebox side, the floor is covered with a sheet of steel, at least 1.25 m in length.

- The distance to plastered walls is at least 1 m, with additional insulation of 0.8 m.

- The dimensions of the room for installing the stove are at least 12 m².

- The boiler room must have a ventilation duct and good natural air ventilation.

- Automatic switches for turning off the heating element and circulation equipment are installed in adjacent rooms.

The presence of a safety group for the Breneran Aquaten solid fuel pyrolysis boiler (including a safety valve, air valve, pressure gauge, membrane expansion tank) is mandatory. Commissioning without safety valves is prohibited.

Installation of a smoke removal system

The rules for installing a chimney are described in detail in SNiP 41-01-2003 (SP 60.13330). According to the standards, the height and diameter are calculated depending on the performance of the furnace. When installing the chimney, closely adhere to the manufacturer's recommendations:

- Distances to structural units, beams and rafters are calculated depending on the chimney material. For a brick and ceramic chimney with insulation, the fire gap is at least 13 cm, without insulation 25 cm.

- The chimney height should be from 5 to 9 m, depending on the stove model.

- A deflector is installed on the chimney head to improve draft characteristics.

Connection to a natural circulation system

The heating system with natural coolant circulation is the most popular due to its ease of installation and the absence of a large number of additional components. There are several rules associated with installation:

- The stove is located at least 0.5 m below the radiators.

- The pipes are placed at an angle - the slope is made in the direction of coolant circulation.

- An open expansion tank is installed at the highest point of the heating system. The tank capacity is selected depending on the total volume of coolant, in a proportion of 10%. Correct installation of an open type expansion tank is carried out on the return line of the heating system. If the container is installed in an unheated attic, be sure to thermally insulate the device.

- A safety group is installed on the coolant supply.

Strict requirements regarding the observance of inclination angles are imposed on the distribution of pipes of a heating system with natural circulation.

Connection to a forced circulation system

The main difference from the previous option is that a closed-type heating system requires a circulation pump. Forced circulation of coolant has many advantages, including better heat transfer, efficiency and heating speed. The only drawback is the dependence on electricity.

Installation of a forced circulation heating system is carried out in accordance with the following recommendations:

- The circulation pump is installed on the return coolant supply, between the expansion tank and the boiler. It is recommended to install a temperature sensor to regulate the operation of the boiler, depending on the heating intensity and pressure created in a closed system.

- The connection is made with a closed expansion tank. No air enters the heating system, which has a positive effect on the service life of pipes, radiators and the boiler itself.

- For uninterrupted operation of the pump, you will need to install a UPS with a built-in voltage regulator.

The maximum pressure in a closed heating system is not higher than 7 atm. High rates lead to rupture of the water circuits located on the stove. To prevent damage, be sure to install a security group.

Which pipes are best for piping?

Piping of the boiler affects further operation, performance and other characteristics of the heating system. The choice of material should be approached consciously. Below are the three most popular options:

- Piping the heating system with steel pipes - the advantages include resistance to overheating, low linear expansion, strength and high thermal conductivity. Disadvantages include the complexity of installation and the need for welding. It is better to do the installation before renovating the premises, so as not to spoil the finish. Another disadvantage can be considered that the diameter of the water circuit pipe will be significantly larger than that of polypropylene or metal-plastic; accordingly, a higher power furnace will be required for heating.

- Heating pipes made of polypropylene - the material has many advantages: low weight, long service life, heat resistance, attractive appearance, smooth inner surface. You can install heating pipes around the house yourself. To do this you will need a soldering iron and several construction tools.

- Metal-plastic pipes are another option for a material intended for a heating system. The advantage of metal-plastic is: quick installation, non-corrosive, high temperature resistance, plasticity. The disadvantage is that the pipe is susceptible to “breaking”. Metal-plastic pipes are used for installation of heating systems with forced circulation of coolant. Allowed for use in industrial environments.

Heating can be done using copper, stainless steel and other pipes. But, as practice shows, the options listed above are the most popular.

What coolant is best to fill into Breneran and the system

Ordinary and distilled water and antifreeze are used as a coolant. Each option has its advantages and disadvantages:

- Water – the main disadvantage is the ability of the liquid to freeze even at a temperature of -1°C. Therefore, distilled and ordinary water is used only if you plan to heat the house throughout the entire season. It is strictly forbidden to pour water saturated with metals. For long-term operation of the furnace, it is recommended to install water treatment and a filtration system.

- Antifreeze or antifreeze can be added to the system. The heating system does not shrink even when the room temperature drops below 15-20°C. But using antifreeze has its drawbacks. Any leaky connection will definitely leak. The total volume of coolant in the heating system often reaches more than 150 liters. Buying antifreeze requires a serious investment.

It is quite easy to independently calculate the volume of coolant - for calculations you will need to know the power of the furnace, the number and volume of radiators.

Tips and rules for operating the Breneran Aquaten boiler

Reviews from owners of Breneran Aquaten stoves show that from time to time questions arise related to the operation of devices and regarding the following:

- What measures will help prevent the contour from shrinking?

- Is it possible to increase the efficiency and heat output of a boiler if it does not heat well?

- How to heat Aquaten correctly?

- Is it allowed to install the stove outdoors?

Correct connection to batteries and compliance with operating rules increase the heat transfer of the system and service life.

How to prevent the circuit from defrosting

To prevent freezing of the coolant in the system, an electric heating element with a power of 1 kW is provided. After connecting the stove to the power supply, the installed sensor will give a signal to turn on the heater when the temperature drops to the minimum permissible values. {banner_downtext} Of course, the best protection against freezing is the complete drainage of the coolant from the heating system. Once the liquid is removed, the furnace and pipes will withstand temperature drops of over -50°C. Heating element is additional insurance.

Why does the water Breneran not heat well?

Typically, Breneran copes well with heating residential and industrial premises. If there are problems with heating, there may be several reasons:

- Installation errors - if the stove smokes and does not switch to gas generation mode, the reason lies in the insufficient height of the chimney.

- The installation height of the Buleryan water heating boiler is 40-50 cm from the floor level. Failure to comply with this parameter leads to an insufficient volume of oxygen entering the combustion chamber and, accordingly, a decrease in furnace productivity.

- Incorrect calculations - the real power of Breneran is 10-15% lower than indicated in the technical documentation. This difference must be taken into account during calculations.

- The number of connected radiators in systems with natural coolant circulation directly affects the intensity of their heat transfer. The farther the battery is from the stove, the less it warms up. The last radiators, especially if the slopes are broken, will be practically cold.

Before starting operation, you will need to correctly adjust the Breneran Aquaten, set the parameters and heating temperature of the coolant. All settings should be performed following the instructions provided in the technical documentation.

How to properly drown Aquaten Breneran

At first, it seems that heating Breneran on your own is quite difficult, but with some practice, heating the room will become increasingly easier. The principle of kindling is as follows:

- The power regulator and gasifier are set to the maximum open position.

- Using wood chips and paper, a fire is started.

- After the fire has flared up, the combustion chamber is filled to 80-90%.

- The combustion continues until the temperature sensor shows heating to 180-200°C, approximately 20 minutes.

- The gasifier regulator is closed at least 45°.

For kindling, it is better to use unsplit logs. The length of the firewood must match the combustion chamber so that the door closes tightly without effort. There is no need to remove ash; it is necessary for normal fuel gasification.

Breneran gas generator boiler: its advantages and disadvantages

Breneran heating equipment can be used for heating saunas, garages and industrial premises, as well as residential buildings. Reviews about these stoves are usually positive and confirm their stated characteristics.

The advantages of Breneran furnaces are that they are economical, compact and easy to maintain.

Advantages of Breneran stoves:

- Autonomy of the device;

- Ability to work on any solid fuel;

- Cost-effective – the oven can operate for 12 hours on one load;

- High efficiency, which can reach 80%;

- Compact dimensions;

- Simplicity and ease of maintenance;

- Uniform heat distribution throughout the room.

As for the disadvantages, they are related to the structure of this equipment. Since the oven chamber is open, a specific smell appears in the room and the air dries out. And in addition to everything, condensation forms on the pipes.

As for the Breneran-Aquaten stove, which has a water circuit, it “can” work in both open and closed heating systems. It can be used simultaneously with cast iron radiators without converting the system to plastic. True, such a stove does not look very attractive and it is better not to combine it with modern aluminum radiators.

Advantages and important points

Buleryan devices have various configurations and sizes that allow heating rooms with a volume of up to 1100 cubic meters. m. Selecting a suitable model will not be difficult. The use of this equipment for heating a house is in many ways advisable, which is confirmed by the following characteristics:

- Safety . Such a heating furnace does not heat up the metal and does not burn oxygen.

- The heat is distributed evenly throughout the home.

- Heating speed . The Buleryan stove of any configuration can warm up even a large room quite quickly.

- The equipment operates autonomously

on fuel and does not depend on gas or electricity. - One load of fuel can ensure operation of the stove for 8-12 hours without additional fuel.

- Ease of maintenance

. - The heating process can be controlled.

- Afterburning of gas in a separate chamber ensures Efficiency 85%.

Among the important points that should not be forgotten during the operation of the Buleryan unit with a water circuit are the following:

- Firewood for the stove must be well dried. It is recommended to use wood species that do not emit resins.

- In the second combustion chamber, the gases do not burn completely.

- When installing a chimney, it is necessary to ensure high-quality insulation of the pipe, otherwise condensation may form, which can reduce heat transfer.

- The distance between the stove and the walls must be at least half a meter to meet fire safety requirements. This is quite a serious problem for small houses. This issue can be partially resolved by covering the walls next to which the installation is located with metal using basalt insulation. First, the side structure is sheathed with insulating material, then the metal sheets are fastened. This will not only ensure the fire safety of the room, but will also enhance the heat transfer effect. In this case, the maximum permissible distance is 20 cm.

- Dust and dirt are another important problem with such stoves. Small particles entering the pipes are burned off by high temperatures, resulting in an unpleasant odor. Dirt, attracted by positive ions that form near the stove, spreads throughout the rooms, entering the human body. This contributes to the spread of various viral diseases. In houses heated by such stoves, it is necessary to do wet cleaning more often, as well as ensure good ventilation .

Perhaps a sauna stove of this model will be the ideal heating device in your steam room, so check out the article Sauna stoves Buleryan (Breneran).

When choosing a Buleryan heating device with a water circuit, you should pay attention not only to its configuration, but also to the door material. It can be made of either metal or glass. Of course, the latter option looks quite impressive, but during the operation of the furnace it carries nothing except collected dust and dirt. If the combustion process is visible through such a door, it is only in the first minutes when the wood is ignited. In addition, the glass sash significantly increases the cost of the entire structure.

High-quality Breneran Aquaten stove and its structure

In order to be able to heat not only the space around the stoves, but also the entire room, a water circuit is built into the heating equipment with an operating principle similar to central heating. It looks like an ordinary coil with liquid heated inside. It then spreads through pipes throughout the house and heats it up.

You can familiarize yourself with the design of the Breneran Aquaten stove yourself using the Internet

The body of this furnace is made of steel and treated with heat-resistant enamel, and of :

- Two chambers – the lower one for fuel and the upper one – for afterburning the gas released during combustion;

- Two injection manifolds located on the sides - it is through them that water enters, is heated and exits;

- Two power regulators installed in the chimney and on the door.

Depending on the equipment models, stoves may have different chimneys, volumes, and parameters.

If the stove is used for a closed heating system, then for its operation a circulation pump, safety valve, air vent, pressure gauge and expansion tank are also purchased.

By the way, Breneran-Aquaten stoves operate only on solid fuel. But it does not use coke or coal.

For high-quality and efficient operation of such a stove, you need to completely fill it with fuel, and then one fill will be enough for 8-10 hours.

Design and mechanism of operation

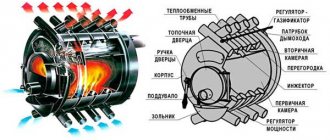

The Buleryan stove consists of a barrel-shaped body, the internal space of which is divided into two sections. The process of kindling and burning wood occurs in the lower part, this is where the temperature begins to rise and heat accumulates. At the same time, as the wood burns out, hot gases accumulate in the upper part of the body.

Scheme of the Buleryan furnace

Radius pipes pass through the center of both parts of the furnace, in which convection occurs. Cold air, entering the furnace through the pipes, encounters a hot circuit, which creates a fast flow that rushes out and carries away the heat of the furnace. The basic principle of operation of the device is the correct combination of several heating options, including: convection, heat transfer and heat exchange. Due to the lack of a ventilation system, heating thus occurs quite quickly.

Heating stove Breneran Aquaten: reviews of owners and types of models

Breneran-Aquaten stoves are distinguished by their diversity and each consumer can choose exactly what he needs.

The most common models are:

- AOTV-6 is a lightweight and compact stove that can heat a room up to 100 cubic meters. cm. One tab can burn for 8 hours. Made in black and should only be placed near the wall. The cheapest model, as it does not have any additional functions.

- AOTV-11 - can heat a room of 200 cubic meters. cm. Burns for 10 hours on one burnt. A little more expensive than the previous one.

- AOTV-14 is a more powerful model. Heats an area of 400 cubic meters. cm. One firebox is enough for 10 hours.

- AOTV-16 is a large and heavy stove. But at the same time, it can burn for almost 12 hours and is capable of heating a room of up to 600 cubic meters. cm.

- AOTV-19 is the most powerful and efficient stove. It can also burn for 12 hours and efficiently heat a room of up to 1000 cubic meters. see The most expensive boiler in this series.

When choosing a stove, you should pay attention to its characteristics: to heat a small house, you do not need to buy an expensive and powerful boiler.

Opinions of Breneran-Aquaten stove owners:

- Kirill. I bought a Breneran stove for my dacha. It suited me perfectly in terms of price and power. There were no problems with the installation. I just had to tinker a little with the chimney pipe. After I turned on the stove for the first time, a specific smell appeared, but then it disappeared and I didn’t feel anything like that anymore. It takes less than an hour to ignite and heats well. I'm happy.

- Katerina. My husband and I bought a Breneran-Aquaten stove for our wooden house. It was easily connected to the pipes and began to be used. I liked that the boiler turned out to be “omnivorous”. We even used the remains of old furniture. The main thing is that the material is dry. I didn't like the appearance of condensation. It’s bad that there is no special container to collect this liquid.

- Andrey. Breneran purchased a stove for his workshop and lined it with sheets of iron just in case to prevent a fire. I'm happy with everything, although at first there was a lot of soot in the chimney. I had to clean it very often. When I started using dry firewood, the problem practically disappeared.

Types of stoves Aqua Breneran

The boiler manufacturer Aquaten Breneran, JSC Laoterm, has developed and produced several basic modifications of gas-generating furnaces with a water circuit. The advantage of the models is their high efficiency, the presence of an electric heating element, which allows you to continue heating the room after all the solid fuel has burned out.

If necessary, the stove is equipped with an indirect heating boiler, which provides the required amount of hot water.

The model range of Russian-made solid fuel gas generator stoves Breneran Aquaten is represented by the following modifications:

- AOTV 19 is one of the most productive models in the line. Suitable for heating industrial and domestic premises. The design includes an anti-freeze system. Breneran Aquaten AOTV 19 has a powerful ability to heat buildings with a total volume of up to 1000 m³. The efficiency is 70%, and one load of firewood is enough for autonomous operation for 6-10 hours. The weight of the structure with an empty combustion chamber is 350 kg, which requires the preliminary preparation of a foundation for installing the furnace.

AOTV 16 is a model whose performance is significantly inferior to the previous series. A Buleryan wood-burning boiler with an AOTV 16 water circuit is capable of heating a room with a total volume of 600 m³. The weight of the structure with an empty combustion chamber is no more than 320 kg. The model is optimally suited for industrial or warehouse premises, exhibition halls, cottage and country houses.- AOTV 14 is a modification that is optimally suited for heating residential premises. The technical characteristics of Breneran Aquaten AOTV 14 are as follows: weight 250 kg, capacity designed to heat 400 m³, length and width do not exceed a meter. If necessary, you can line the stove with brickwork or cover it with a protective casing.

- AOTV 11 is a lightweight version of the gas generator furnace. The weight of the structure is only 150 kg, allowing installation without special production of a concrete base. The set includes legs to ensure the stability of the oven. The maximum heated volume of the room is no more than 200 m³.

- AOTV 06 is a model in the Breneran series of heat generators with the lowest power. The productivity is enough for only 100 m³, almost for one room with 30-40 m². The weight of the equipment is only 86 kg, which greatly facilitates the installation and installation of the Aqua Breneran AOTV 06 stove.

When choosing a long-burning wood heating stove with a Breneran Aquaten water circuit, pay attention to its performance. The technical documentation indicates the volume of coolant and the actual heated area.

How much does Breneran Aquaten cost?

The cost of the Breneran Aquaten stove is slightly higher than that of models that do not have a water “jacket” and depends on the type of model and its power.

- AOTV 06 - will cost 16,200 rubles.

- AOTV 11 – for this model you will have to pay 23,800 rubles.

- AOTV 14 – the cost will be 27,400 rubles.

- AOTV 16 and 19 – for semi-industrial models you will have to pay 45 and 55 thousand rubles. respectively.

The full cost of long-burning solid fuel pyrolysis boilers Breneran Aquaten is calculated depending on the required additional equipment. Additionally, payment for installation work, connection to the heating system, etc. is taken into account.

Advantages of water heating from Breneran

Breneran gas generator furnaces have several significant advantages over analogues that use the principle of air heating.

- Heating of rooms is carried out using standard heating radiators, and not through air circulation. Therefore, the models are suitable for heating one- and two-story individual residential buildings, and there is no need for additional equipment in the form of air ducts.

- Installation in a house without a basement is allowed. With proper installation and regular maintenance of the stove, there is no chance of smoke entering the room.

- The Breneran Aquaten stove is welded from steel, 2-3 mm thick for the outer casing, 5 mm for the combustion chamber. Heat-resistant alloys are used in manufacturing, which significantly increases the service life of the device.

- Possibility of connecting to almost any type of heating system. The main thing is to correctly select and calculate the performance of the furnace. Breneran feels equally good when connected to a heating system with natural and forced circulation.

- Easy installation. It makes sense to install a modification of the Breneran stove with the connection of a water heating system if there is no desire and opportunity to connect gas heating. The Aquaten model provides maximum ease of use. If necessary, it can operate in antifreeze mode. The electric heating element will heat the coolant to the required temperature.

Disadvantages of Breneran water boilers

Of course, Breneran Aquaten boilers have disadvantages, but since they are insignificant and inferior to the advantages, practically nothing is reported about them either on construction forums or on other sites. But judging by several comments that we were able to find, the problems with the stove are as follows:

- It will not be possible to use the Breneran Aquaten model without water. The design is intended exclusively for liquid cooling.

- Aquaten has the inherent disadvantages of all gas generator models. The characteristics and performance are affected by the quality of the fuel and errors during the installation of the chimney pipe.

If the installation is carried out in accordance with all the manufacturer’s recommendations, the operation of the stove will be almost problem-free.

Breneran Aquaten boilers (video)

The Breneran Aquaten gas-generator heating stove with a water circuit can heat rooms of very different sizes. Since it does not look very aesthetically pleasing, it is better to arrange a separate boiler room for its location, after which you can enjoy the home warmth it creates.

Many companies are engaged in the production of solid fuel heating equipment. Some of them, even after many years of activity, remain little known.

Others manage to guess the aspirations of consumers from the very beginning and quickly become famous.

The latter can safely include the German company Energetec Gmbh.

It is she who produces the famous Buleryan stove with a water circuit for heating a house, which is worth getting to know better.

Principle of operation

Since 2005, these units have been produced under the Breneran brand.

In Russia, Energetec is producing these stoves under license. At their core, stoves of this brand are gas-generating convectors.

Gas generation or pyrolysis is the process of releasing so-called wood gas from wood heated to the point of smoldering. To prevent the fuel from catching fire, the chamber where it is located (it is called the gas generator chamber) is made sealed, thus preventing fresh air from entering inside.

Wood gas is a mixture of various gases, some of which, such as methane, can burn. Through holes in the partition, this mixture enters the second chamber (afterburning chamber), where it is burned. In most modern boilers of this type, the afterburning chamber is located below the gas generator, which makes it possible to maintain the high temperature in the latter that is so necessary for full pyrolysis.

But the creators of Buleryan, in order to simplify the design, did the opposite - they placed the gas generation chamber at the bottom. For this reason, the efficiency of the furnace does not exceed 80% (with an economizer), while for other gas-generating boilers this figure reaches 90% - 93%.

Now let’s look at the second part of the name – the word “convector”. In principle, convection occurs during the operation of any solid fuel heat generator. But convectors heat the air much faster than a conventional oven. They are equipped with a vertically mounted pipe, open on both sides, that runs directly through the firebox. The air in this pipe heats up much more than from the body, and thanks to the phenomenon of convection, it rushes upward in a powerful flow.

Operating principle of the Buleryan stove

At first glance, it seems that a powerful fan is installed inside the oven. Cold air is sucked into the pipe from below.

The convector very effectively heats the room in which it is located, but it is not able to provide a comfortable temperature in neighboring rooms. To make their creation more functional, the developers released a model with a water jacket. Previously it was called “Aqua-Buleryan”, now – “Breneran-AquaTEN”.

The presence of a water jacket (heat exchanger) allows you to connect the heat generator to a water heating system.

The letters “TEN” are present in the name for a reason: the model is equipped with an electric heater that will prevent the coolant from freezing if the user for some reason forgets to put firewood in the firebox.

Flaws

- When loading wet firewood, resins will form as it burns, so you should only use completely dry fuel.

- When selecting wood for fuel, you need to choose species that do not emit resins.

- In the second furnace in Buleryan, only 70% of the generator gases are burned.

- If the chimney was not insulated before the Breneran sauna stove was installed, then condensation may be released, which will reduce the performance of the device.

- Due to the metal body of the device, in addition to the additional protective coating and sheathing of the surrounding walls with basalt insulation, a distance from the walls of at least half a meter will also be required, which is not always convenient in small spaces.

- Due to dust getting into the pipe opening, an unpleasant odor may occur when the oven heats up.

- The rooms in which the stove is located require daily cleaning and ventilation, since during its operation charged ions are formed that can have a negative effect on the human body.

Main features of the oven

The pyrolysis used in Breneran stoves allows the heat generator to operate on one load of fuel much longer than with conventional combustion.

A conventional solid fuel boiler has to be refilled every 4 hours, while Breneran-Buleryan can work without user intervention for as long as 8 hours. Such units are called long-burning furnaces or boilers.

Note that 8 hours is far from a record. There are heaters that can operate on one heater for several days. But they are much more massive than Buleryan, and, unlike him, cannot be considered mobile.

The combustion process in heat generators of the Buleryan brand is manually regulated by two dampers or throttles: one is installed on the front door and is used to regulate power, the other (gate) is in the smoke exhaust channel (switches the flame/smoldering combustion modes). Thus, the furnace does not require power supply and can be operated in the field conditions for which it was originally created (by order of mobile logging crews in Canada).

The front damper handle of most models has a temperature scale (outside temperature) and a lock in the form of a movable stop. The damper has a cutout in the shape of a sector, due to which complete blocking of the chimney, leading to carbon monoxide entering the room, is impossible.

Note to the user. A mandatory element for Buleryan is a horizontal pipe section with a length of 0.8 to 1 m, through which the heat generator is connected to a vertical chimney. This part (called a “pig” or “hog”) slows down the combustion of exhaust gases. It is behind it that the gate is installed.

The vertical section of the chimney, 1.5 - 3 m long, with powerful thermal insulation, following the damper, is called an economizer. This is a very important element. Here the final combustion of the flue gases occurs, which flare up in the center of the gas jet when exposed to infrared radiation reflected by the walls (the “flame jump” effect).

Aqua Breneran after installation

The ignited gas expands sharply and turns into a kind of plug, inhibiting combustion in the furnace. Then it cools down and leaves the chimney, and combustion resumes. Only thanks to this cunning technique did the developers manage to make the combustion mode on the verge of smoldering and flame in conditions of relatively low temperature stable. Another positive effect: due to operation in the self-oscillation mode, the stove automatically adjusts in accordance with the quality of the fuel used.

Without the use of an economizer, Buleryan's efficiency drops to 65%.

The Buleryan-Breneran stove with a water circuit is designed for wood fuel and smoldering mode, which requires a temperature of 550 - 650 degrees. If you heat it with coal (combustion temperature - 800 - 900 degrees), then after 1 - 2 seasons the stove will burn out.

The kindling of Buleryan is carried out as follows:

- Having moved both dampers to the fully open position, the furnace firebox is filled with some flammable fuel (even paper or cardboard will do), which is then set on fire. The stove operates in flame mode for some time, which allows you to quickly warm up the room. It is advisable to add such a portion of fuel so that it completely turns into coals 3 - 4 minutes before the room is completely warmed up. It is most convenient to monitor the combustion process through a transparent door made of heat-resistant glass, but if your model does not provide such an option, you can look into the ash pit.

- Large logs are placed on top of the fuel that has burned down to coals. You can also use pellet granules or peat briquettes. The chamber must be filled to capacity - then the oven will be able to operate on one filling for a maximum period of time.

Installation of a water jacket furnace

The Buleryan stove is installed on a fireproof stand at a distance of at least 1 m from the wall (if there is fire-resistant plaster with a thickness of 25 mm or more, the distance can be reduced to 0.8 m).

The dimensions of the stand should be 600 mm larger than the dimensions of the oven (300 mm on each side).

On the floor in front of the door, within a radius of 1.2 m from it, there should be a steel flooring (thickness - 1.5 mm) on an asbestos pad.

Since solid fuel equipment provides much less power control capabilities than gas equipment, it is connected to the heating system according to a special circuit. It is necessary to prevent the coolant from boiling (which can rupture the pipes) or from entering the heat exchanger at temperatures below 50 degrees (leading to the formation of chemically aggressive condensate on the walls of the circuit).

This scheme provides for the presence of a bypass connecting the “supply” and “return” lines, and a safety group:

- safety valve;

- automatic air vent;

- pressure gauge.

When the coolant boils, the safety valve will release excess pressure.

A 3-way valve with a servo drive is installed on the bypass, which is controlled by a temperature sensor. If the temperature in the “return” turns out to be unacceptably low, the temperature sensor will open the 3-way valve and the cold coolant will be diluted with hot coolant through the bypass.

Schematic diagram of using the Buleryan stove

Starting a heating system equipped with a solid fuel boiler is also somewhat more difficult than with a gas heat generator. First, the coolant in the small circuit is heated and only then cold water from the main system is added to it in small portions.

Efficiency compared to gas heating

Today, gas heating is undoubtedly the best in terms of cost of operation and ease of use. However, in some ways it still loses to Buleryan:

- A gas boiler cannot be connected without the approval of the gas utility.

- The operation of a gas boiler depends on the operation of the gas supply system, while Buleryan is completely autonomous.

Gas fuel is poisonous and explosive. Moreover, due to its volatility, it can easily spread throughout the room. Buleryan in this regard does not pose any danger.

Under the Breneran (formerly Buleryan) brand, a whole range of heat generators are produced, differing in power, purpose and, accordingly, price. Let's consider several options:

Burelyan stove with cooking burners

The unit has a weight of 60 kg and dimensions 455x620x555 mm. Designed to heat a room with a volume of up to 100 cubic meters. m.

Cost: 8 thousand rubles.

Long-burning furnaces (gas generators)

They are designed to heat rooms with a volume of 100 to 1000 cubic meters. m.

The smallest oven has dimensions 640x436x605 mm (weighs 52 kg), the largest - 950x676x1505 mm (weighs 235 kg).

Cost: from 8.3 thousand rubles. up to 35 thousand rubles.

Buleryan stove with water circuit

The line includes models with a power range from 6 to 35 kW. The dimensions of the smallest are 700x450x650 mm (weighs 57 kg), the largest are 1030x770x1200 (weighs 160 kg).

Average cost – 41 thousand rubles.

Functional Features

A heating device with a water circuit operates on the principle of convection, but with one significant addition: instead of air, a coolant liquid is used. This prevents oxygen from penetrating through the partitions. The effectiveness of such equipment is obvious due to the following features:

- Inside the casing there is a combustion chamber, which is tightly fitted with pipes containing liquid. Due to this fit, heat is transferred much faster. The number of rolled metal products can vary from 6 to 12 pieces.

- The required pressure in the system is provided by a special pressure manifold, which raises the coolant to a height of up to 8 m.

- Natural circulation in the heating system is ensured by heating the liquid substance used to transfer energy.

- The principle of operation of the furnace is to raise the coolant to the maximum height, and then distribute it among the batteries. Next, the liquid substance used to transfer thermal energy is returned to the furnace via the return line.

- Increased device performance and reduced fuel consumption are achieved due to the gas generation process used. After burning wood, the resulting gas is burned in a separate chamber.

- The drain valve is installed on the return line. Circular equipment is also installed at this location, which can significantly increase the efficiency of the entire system.

Reviews

Although this brand cannot boast of a long history, consumers have managed to fully appreciate the merits of its products. First of all, we are attracted by the simplicity of the stove’s design and its maintainability: the entire unit is made of ordinary structural steel, so it can be repaired in any workshop.

The advantages of Buleryan include its safety: carbon monoxide will go into the pipe in any position of the damper, and the body does not heat up above 65 degrees. As users testify, the air in the room really warms up very quickly.

At the same time, it is impossible not to note a significant drawback of Buleryan: due to the fact that it operates in a low-temperature mode, condensation intensively forms in the chimney, which is extremely toxic. Due to its toxicity, it is not even allowed to be poured into the ground near a vegetable garden or garden. To avoid accidental poisoning, they try to place the vertical part of the chimney only on the outside.

If Buleryan is used in a greenhouse with edible plants, it is operated without an economizer and in full combustion mode. In such conditions, the furnace’s service life is exhausted in a couple of seasons (the walls burn out), but no toxic condensate is formed. But in greenhouses and flower beds the stove can be used as intended by the developer, that is, in smoldering mode and with an economizer.

Some users even use condensate to water flowers, after filtering it first. By the way, Buleryan stoves are often called greenhouse stoves.

Did you know that Buleryan stoves were invented by Canadian lumberjacks? We will talk about the pros and cons of such a stove and how to make it yourself later in the article.

Types of garage stoves and instructions for making brick stoves and long-burning stoves can be found on this page.