Electrolysis is the breaking down or purification of substances under the influence of electric current. This is a redox process, on one of the electrodes - the anode - an oxidation process occurs - it is destroyed, and on the cathode - a reduction process - positive ions - cations - are attracted to it. During electrolysis, electrolytic dissociation occurs - the breakdown of the electrolyte (conducting substance) into positively and negatively charged ions (several degrees of dissociation are distinguished). When the current is turned on, electrons move from the anode to the cathode, and the electrolyte solution may become depleted (if it is involved in the process), it needs to be constantly replenished. The oxidizing anode can also dissolve in an electrolyte solution - then its particles acquire a positive charge and are attracted to the cathode.

Anode is a positively charged electrode - oxidation occurs on it. Cathode is a negatively charged electrode - reduction occurs on it. Based on the principle that unlike charges attract, at the same time separation or purification of the substance occurs.

The material of the electrodes may be different, depending on the ongoing process. The mass of the substance that is obtained during electrochemical interaction is determined by Faraday’s laws and depends on the charge (the product of the current strength and the time the current flows), also depends on the concentration of the electrolyte and the activity of the materials from which the electrodes are made. Anodes can be inert - insoluble, do not react, and active - they themselves participate in the interaction (they are used much less frequently).

For the manufacture of anodes, graphite, carbon-graphite materials, platinum and its alloys, lead and its alloys, and oxides of some metals are used; Titanium anodes with an active coating of a mixture of ruthenium and titanium oxides, as well as platinum and its alloys, are used.

Insoluble anodes are compositions based on tantalum and titanium, special varieties of graphite, lead dioxide, magnetite. Steel is usually used for cathodes.

The following types of electrolytes can be used for the process: aqueous solutions of salts, acids, bases; non-aqueous solutions in organic and inorganic solvents; molten salts; solid electrolytes. Electrolytes come in varying degrees of concentration.

Depending on the purposes of electrolytic reactions, various combinations of types of anodes and cathodes are used: horizontal with a liquid mercury cathode, with vertical cathodes and a filtering diaphragm, with a horizontal diaphragm, with a flow electrolyte, with moving electrodes, with bulk electrodes, etc. Most processes tend to use products produced at both the anode and cathode, but usually one of the products is less valuable.

Electrolysis is widely used in industry; it is also used in medicine and the national economy.

What is an electrolyzer

An electrolyzer is a special installation used to separate its components from a solution or melt.

The main characteristics of the electrolyzer are:

- The operating voltage for one electrode ranges from 1.8 to 2.0 V;

- Current strength - for the normal course of the electrolysis process, a current with a value of this characteristic from 5 to 10 A is supplied to the electrodes;

- Number of electrodes – the minimum number of electrodes is 2, the maximum is limited by the size of the installation itself and its purpose;

- Dimensions of electrodes - not carbon rods are used as electrodes, but metal plates, the size of which is determined by the purpose of the installation, the current-voltage characteristic of the current supplied to the plates;

- Distance between differently charged electrode surfaces – the minimum distance between electrode plates must be at least 1.5 mm;

- Electrode material - in modern electrolysers, stainless steel sheets with the addition of nickel are used as the material for the anode and cathode.

Also another important characteristic of an electrolysis plant is the use of catalysts.

Such settings are used for the following purposes:

- Production of detonating gas consisting of a mixture of hydrogen and oxygen (Brown's gas);

- Isolation of pure aluminum, magnesium, zinc from molten salts;

- Purification of water from dissolved salts and impurities;

- Applying a thin corrosion-preventing layer of nickel and zinc to the surface of metal parts;

- Disinfection of food products;

- Purification of wastewater from heavy metal salts and other harmful substances dissolved in them.

Important! Platinum electrode made from ordinary iron is used in electrolysis installations less often than from stainless steel, since it oxidizes faster and becomes unusable.

Brief theoretical part

Hydrogen, also known as hydrogen, the first element of the periodic table, is the lightest gaseous substance with high chemical activity. During oxidation (that is, combustion), it releases a huge amount of heat, forming ordinary water. Let us characterize the properties of the element, formatting them in the form of theses:

- The combustion of hydrogen is an environmentally friendly process; no harmful substances are released.

- Due to chemical activity, the gas does not occur in free form on Earth. But its reserves in water are inexhaustible.

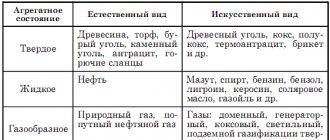

- The element is extracted in industrial production by a chemical method, for example, in the process of gasification (pyrolysis) of coal. Often a by-product.

- Another way to produce hydrogen gas is by electrolysis of water in the presence of catalysts - platinum and other expensive alloys.

- A simple mixture of hydrogen + oxygen gases explodes from the slightest spark, instantly releasing a large amount of energy.

For reference. Scientists who first separated the water molecule into hydrogen and oxygen called the mixture an explosive gas due to its tendency to explode. Subsequently, it received the name Brown's gas (after the name of the inventor) and began to be designated by the hypothetical formula NHO.

Previously, airship cylinders were filled with hydrogen, which often exploded

From the above, the following conclusion suggests itself: 2 hydrogen atoms easily combine with 1 oxygen atom, but they part very reluctantly. The chemical oxidation reaction proceeds with the direct release of thermal energy in accordance with the formula:

2H2 + O2 → 2H2O + Q (energy)

Here lies an important point that will be useful to us in further debriefing: hydrogen reacts spontaneously from combustion, and heat is released directly. To split a water molecule, energy will have to be expended:

2H2O → 2H2 + O2 – Q

This is the formula for an electrolytic reaction that characterizes the process of splitting water by supplying electricity. How to implement this in practice and make a hydrogen generator with your own hands, we will consider further.

Design and principle of operation

The simplest electrolysis installation consists of several “cells”, each of which includes:

- 2 plate electrodes – cathode (negative) and anode (positive);

- A rubber gasket located around the perimeter of two adjacent opposite electrodes.

The outermost cells are equipped with special pipes through which the released gases are removed.

The electrolyzer can contain from 1 to 30-40 or more such “cells”, the plates of the same name are connected in series.

Important! When using AC power supplies, rectifiers are additionally used, the simplest of which is a diode bridge.

This installation works as follows::

- Distilled water with alkali or ordinary baking soda dissolved in it is poured into the space between the electrodes;

- From the power source, a voltage of 1.8-2.0 V is supplied to the electrodes of all cells of the installation;

- As a result of the electrolysis process, anions (positively charged ions) of a substance dissolved in water are attracted to the negatively charged cathode, as a result of which a thin film of sodium is formed on it;

- At the positively charged anode, water molecules are destroyed, each producing 2 hydrogen atoms and 1 oxygen atom;

- The released detonating gas flows through the outlet pipes into the container intended for it.

The intensity of the electrolysis process depends on the voltage and current - at low values of these characteristics the process will not proceed. If the power source supplies current with too high values of the current-voltage characteristic, the solution poured into the electrolyzer will heat up greatly and boil away.

Electrolysis. Industrial electrolysis plants.

— electrolyte circulation to equalize the temperature;

— vibration of electrodes;

- switching power supply.

Electrolysis is one of the types of technological processes. Its essence lies in the separation of particles of a substance from the electrolyte when a direct current flows through it and their deposition on electrodes immersed in the electrolyte (electroextraction) or the transfer of a substance from one electrode through the electrolyte to another (electrolytic refining).

Electrolysis is used:

— in non-ferrous metallurgy for the production of light metals (aluminum, magnesium, cadmium, etc.) and the refining of heavy metals (copper, silver, gold, nickel, lead, etc.);

— in electrochemistry for the production of chlorine, hydrogen, heavy water,

oxygen, fluorine, potassium, sodium, etc.;

— in mechanical engineering for applying protective and decorative coatings to metal and non-metallic products (zinc plating, nickel plating, cadmium plating, lead plating, copper plating, chrome plating, silver plating, oxidation, etc.);

— in ferrous metallurgy for tinning tin and electrolytic cleaning.

There are two types of electrolysis used in metallurgy: electrolysis of aqueous solutions and electrolysis of molten salts. The first is used for the production and electrolytic refining of metals with a low normal potential (zinc, chromium, tin, nickel, lead, silver) and is carried out at a temperature not exceeding 100 °C, the second - for the production of metals with a high normal potential (magnesium, aluminum, alkaline earth metals) at a temperature of about 1000 C.

Electrolysis is carried out in specially equipped baths - electrolyzers. The voltage across the bath is several volts, and the currents reach tens and hundreds of thousands of amperes. For the purpose of economical sewerage of high currents, identical baths are connected in series in series, according to the voltage of the converter installation.

Changes in the electrical resistance of the baths due to heating of the electrolyte, changes in its chemical composition, current leaks, violations of normal operating conditions, withdrawal of individual baths of the series from operation, as well as changes in the supply voltage necessitate the regulation of electrical parameters. To ensure the specified productivity of the electrolysis installation, automatic regulation of voltage, power and current of the series is used. The most common method of regulation is to maintain a constant series current.

In non-ferrous metallurgy, the most powerful electrolysis installations include a series of baths for the production of aluminum and magnesium. To produce aluminum, electrolyzers with a voltage of 4–5 V and currents of 100–150 kA are used, series voltages are 450–850 V. The operating modes of electrolysis plants are long and continuous. When individual baths are taken out for repairs, they are bridged with special tires. In terms of reliability, the installations belong to the first category. Some of them, for example, aluminum electrolysis installations, due to the large heat capacity of the baths, allow short-term (several minutes) breaks, but a long stop can lead to solidification of the electrolyte and significant disruption of the technological process, the restoration of which may take up to 10 days.

In electrochemistry, electrolyzers are used with voltages from 2 to 10–12 V, and in some cases up to 10–220 V (installations for water decomposition, made on the principle of a filter press, in which all electrodes are connected in series). The voltages of the series of baths are assumed to be 150–850 V. During the electrolysis of chlorine, the current of the baths is 100–190 kA. The operating mode of electrochemical installations is continuous. Electrochemical installations belong to the first reliability category. For chlorine plants, interruptions in power supply during startup periods are especially dangerous.

In metal coating installations, the bath voltage ranges from 3.5 to 9–10 V and a maximum of 25 V. Bath currents vary in the range of 0.1–5 kA and higher. In most cases, it is necessary to regulate the current within a wide range. The difference in operating modes of individual baths does not allow their sequential inclusion. Baths are most often powered from common mains with a voltage of 6–12 V through individual control rheostats. Metal coating installations used in automatic production lines belong to receivers of the first category, individual baths - to the second category. The total power of converter installations in metal coating shops is 50–200 kW. Their power source is workshop networks with a voltage of 380 V. The operating modes of the installations are cyclic, associated with loading products into baths and unloading them.

For industrial electrolysis, direct current is used. Along with traditional methods of conducting electrolysis on direct current, modes associated with the use of currents of complex shapes and periodic changes in direct current are used. Electrolysis installations are powered with direct current from direct current generators, including unipolar ones, and from static semiconductor converting units.

The converter unit consists of a power transformer, one, two or four rectifier units, as well as switching, control and auxiliary equipment (protection, alarm). Units with a rectified current of up to 6.25 kA have a valve transformer with one secondary winding, with a current of 12.5 kA - with two, with a current of 25 kA - with four windings and, accordingly, with one, two and four rectifier blocks (Fig. 1.1) .

Rice. 1.1. Diagram of one converter unit

For converter units, a six-phase zero circuit is used with the connection of the secondary windings of the transformer according to the “two reverse stars with an equalizing reactor” circuit (Fig. 1.2 a) and a three-phase bridge circuit (Fig. 1.2 b). Low-power converter units are assembled using a three-phase zero circuit (Fig. 1.2 c).

Rice. 1.2. Conversion circuits

Most electrolysis plants require regulation of the rectified current voltage. The need to change the voltage at the terminals of the electrolysis series during normal operation is determined by the following reasons:

a) change in voltage in the AC supply network;

b) a change in the number of baths in the electrolysis series due to the removal of a certain number of baths for repairs or bypassing for technological reasons;

c) changing the operating mode of the baths, in particular, when changing the current strength or the interelectrode space.

In start-up modes of electrolysis plants, voltage regulation within a wide range is usually required. The reasons for this are, firstly, the fact that a series of electrolysis, as a rule, is not started as a whole, but in parts or even in separate baths. Secondly, the starting mode of operation of the bath may differ significantly from normal operation. So, for example, aluminum baths are fired before start-up (without electrolyte) and there is a reduced voltage on them, but in the first period after start-up the voltage on the baths remains higher than in normal mode.

Therefore, voltage regulation is carried out in two ways:

1. step converter transformer (TDNPV - three-phase, D - blow cooling, N - with on-load tap-changer, PV - valve converter; TMNPU-U - with an equalizing reactor);

2. Smooth regulation is carried out by a saturation choke (DN-6300, regulation limit 49 V).

In converter substations, each valve is protected by a fast-acting fuse.

A fast-acting fuse has a current-limiting ability, i.e., the melting time FU is significantly less than the rise time of the short-circuit current. to the maximum value.

The converter substation includes: alternating current switchgear, converter units and rectified current switchgear. In addition to units and auxiliary transformers of converter substations, in some cases, other consumers of the enterprise's electricity are also powered by the alternating current switchgear.

To compensate for reactive power generated by converter installations, longitudinal capacitive compensation, resonant filters, multiphase rectification circuits and compensation rectifier units are used.

Converter substations feeding electrolysis plants for the production of aluminum, magnesium and chlorine are characterized by a significant number of parallel operating rectifier units and high power.

The rectifier unit is a source of higher harmonics of current and voltage, causing deterioration of power factors and additional losses of electricity, as well as interference in communication and television channels. The degree of influence of higher harmonics is inversely proportional to the number of rectification phases. As the power of the unit increases, the influence increases.

An increase in the number of rectification phases leads to the disappearance of harmonic components of order below – 1.

An increase in the number of rectification phases is achieved by specially designing the windings or by creating an equivalent multiphase mode for groups of units, each of which operates in a six-phase rectification mode. A twelve-phase rectification circuit was adopted as optimal.

For other industries that have electrolyzers with lower current, it is typical to operate single units for each electrolysis series.

With a small number (2–4) of units, the AC switchgear substation usually has a single sectionalized busbar system (Fig. 1.3).

Rice. 1.3. Power supply circuits for low and medium power converter substations

With a large number of converter units, preference is given to switchgear with a double bus system (Fig. 1.4).

Rice. 1.4. Power supply circuits for high power converter substations

A double bus system is also preferable in terms of starting conditions. Most electrolysis installations require regulation of the rectified voltage within significant limits during startup. If the rectifier units cannot provide the required range, then to additionally reduce the voltage, a step-down transformer is temporarily installed during the startup period. With two busbar systems, one of them is supplied through an autotransformer with the reduced voltage required for the converting units, and the other busbar system maintains the normal voltage required for other electricity consumers.

High-power converter substations are usually powered by 220/10 kV step-down transformers with a power of 180–200 MVA, which have split windings on the low voltage side. To reduce short-circuit currents On 10 kV buses, separate operation of split windings is used.

High requirements for uninterrupted power supply of electrolysis installations force the use of increased redundancy in their power supply systems, which is achieved by sectioning all parts of the power supply system, using a double busbar system, and installing sectional switches with an ATS device.

Converter units of powerful electrolysis installations are connected to the series directly without switching equipment. Installations of relatively low power are connected using circuit breakers, which are also the protective equipment of the unit. High-current switching equipment is also used when feeding current into series or individual electrolysers, bypassing baths when extinguishing anode flashes, taking them out for repairs, etc.

High-speed circuit breakers of the VAB and VAT series are used for operational shutdowns without loads and rare shutdowns under load. They consist of unified block units, equipped with the same type of relays and control units. Switches of the VAT series differ from the VAB series by the presence of an induction-dynamic drive. The speed of the drive is ensured by the fact that the holding magnetic flux is forced into a parallel section of the magnetic circuit.

Current from power sources is supplied to the electrolysis baths through special busbars, consisting of individual rectangular busbars collected in packages. Typically, busbars are made of aluminum busbars; copper is used only where aluminum is unsuitable due to its low corrosion resistance.

Busbar cross-sections are determined based on the economic current density. The calculated cross-section of the busbar is then checked for the permissible voltage loss (no more than 3%), permissible heating in steady state (no more than 343 K) and mechanical strength.

Since the operating currents of electrolysis baths reach tens and hundreds of kiloamperes, the cross-section of the busbar is also large - up to 15 dm2.

Busbars supplying electricity from the rectifier substations to the electrolysis shop are mounted on special overpasses. Between individual electrolysis baths inside the workshop, busbar ducts are laid in special busbar channels covered with reinforced concrete slabs.

Features of converter substations:

1. All converter units at the substation operate in parallel on one rectified busbar system;

2. The number of transformers at powerful converter substations can reach 10–11 pieces;

3. Converter substations are located in close proximity to the electrolysis building and are designed as attached or free-standing.

Attached substations:

“+” – short length of the current conductor on the side of the rectified current (reduction of losses);

“–” – deterioration of cooling conditions.

Freestanding substations: the opposite is true.

Conclusions: electrolysis is a physical and chemical process that occurs when an electric current passes through a solution or molten electrolyte. Electrolysis is used in non-ferrous and ferrous metallurgy, electrochemistry and mechanical engineering

DIY electrolyzer for a car

To improve fuel combustion in a car engine, an electrolyzer is often assembled, consisting of a housing from an old battery with stainless steel plates placed inside, two pipes, one of which is connected to a tank filled with electrolyte, the second to a hose supplying air to the engine (more precisely, with a corrugated pipe going from the air intake to the air filter).

Such a homemade flow electrolyzer is powered from a car battery using a relay and a 10 A fuse.

General information about the electrolyzer

An electrolysis installation is a device for electrolysis that requires an external energy source, structurally consisting of several electrodes that are placed in a container filled with electrolyte. This type of installation may also be called a water splitting device.

In such units, the main technical parameter is productivity, which means the volume of hydrogen produced per hour and is measured in m³/h. Stationary units carry this parameter in the model name, for example, the SEU-40 membrane unit produces 40 cubic meters per hour. m hydrogen.

External view of the stationary industrial unit SEU-40

Other characteristics of such devices completely depend on the intended purpose and type of installation. For example, when carrying out electrolysis of water, the efficiency of the unit depends on the following parameters:

- The level of the lowest electrode potential (voltage). For normal operation of the unit, this characteristic must be in the range of 1.8-2 V per plate. If the power source has a voltage of 14 V, then it makes sense to divide the capacity of the electrolyzer with the electrolyte solution into sheets into 7 cells. Such an installation is called a dry electrolyzer. A lower value will not start electrolysis, and a higher value will greatly increase energy consumption;

Placing plates in an electrolysis bath

- The smaller the distance between the plate components, the lower the resistance will be, which, when a large current passes, will lead to an increase in the production of gaseous substance;

- The surface area of the plates directly affects performance;

- Heat balance and degree of electrolyte concentration;

- Material of electrode elements. Gold is an expensive but ideal material for use in electrolyzers. Due to its high cost, stainless steel is often used.

Important! In constructions of a different type, the values will have different parameters.

Water electrolysis plants can also be used for purposes such as disinfection, purification and water quality assessment.

Overview of electrolyzer manufacturers

The main manufacturers of electrolyzers are both domestic enterprises (RUSAL, NPF RutTech, JSC Uralkhimmash), as well as their foreign competitors - Teledyne Energy Systems, Inc (USA), Hydrogenics Corp. (Belgium).

Thus, the electrolyzer is a fairly simple installation with a wide range of functions, used to produce detonating gas, which in the future is planned to be used as fuel for internal combustion engines and heating boilers.

Self-production of an electrolyzer

Hydrogen generator for heating a private home

Anyone can make an electrolyzer with their own hands. For the assembly process of the simplest design, the following materials will be required:

- stainless steel sheet (ideal options are foreign AISI 316L or domestic 03Х16Н15М3);

- bolts M6x150;

- washers and nuts;

- transparent tube - you can use a water level, which is used for construction purposes;

- several herringbone fittings with an outer diameter of 8 mm;

- plastic container with a volume of 1.5 l;

- a small filter that filters running water, for example, a filter for washing machines;

- water check valve.

Build process

Assemble the electrolyzer with your own hands according to the following instructions:

- The first step is to mark and further cut the stainless steel sheet into equal squares. Sawing can be done with an angle grinder (grinder). One of the corners in such squares must be cut at an angle to properly fasten the plates;

- Next, you will need to drill a hole for the bolt on the side of the plate opposite to the corner cut;

- The connection of the plates must be done alternately: one plate on “+”, the next on “-” and so on;

- Between differently charged plates there must be an insulator, which acts as a tube from the water level. It must be cut into rings, which should be cut lengthwise to obtain strips 1 mm thick. This distance between the plates is sufficient for efficient gas release during electrolysis;

- The plates are fastened together using washers in the following way: a washer is placed on the bolt, then a plate, then three washers, then a plate, and so on. The positively charged plates are arranged as mirror images of the negatively charged sheets. This allows you to prevent the sawed edges from touching the electrodes;

Electrolysis plant plates assembled together

- When assembling the plates, you should immediately insulate them and tighten the nuts;

- Also, each plate must be ringed to ensure that there is no short circuit;

- Next, the entire assembly needs to be placed in a plastic box;

- After this, you need to mark the places where the bolts touch the walls of the container, where you drill two holes. If the bolts do not fit into the container, they must be trimmed with a hacksaw;

- Next, the bolts are tightened with nuts and washers to seal the structure;

Plates placed in a plastic container

- After these manipulations, you will need to make holes in the lid of the container and insert fittings into them. In this case, tightness can be ensured by sealing the seams with silicone-based sealants;

- The protective valve and filter in the design are located at the gas outlet and serve as a means of controlling its excessive accumulation, which can lead to disastrous consequences;

- The electrolysis plant has been assembled.

The final stage is testing, which is carried out as follows:

- filling the container with water to the level of the mounting bolts;

- connecting power to the device;

- connecting a tube to the fitting, the opposite end of which is lowered into the water.

If a weak current is applied to the installation, the release of gas through the tube will be almost imperceptible, but it can be observed inside the electrolyzer. By increasing the electric current and adding an alkaline catalyst to water, you can significantly increase the yield of the gaseous substance.

The manufactured electrolyzer can be an integral part of many devices, for example, a hydrogen burner.

Appearance of a hydrogen burner, the basis of which is a self-made electrolyzer

Knowing the types, main characteristics, structure and operating principle of electrolysis plants, you can correctly assemble a home-made structure, which will be an indispensable assistant in various everyday situations: from welding and saving vehicle fuel consumption to the operation of heating systems.

Device characteristics

As you know from a school chemistry course, electrolysis is a process in which the constituent elements of dissolved substances are released on electrodes. For such a process to occur successfully, a current source is required, and the electrolyzer apparatus is precisely designed to enable this very process to be carried out.

The electrolyzer device is a container filled with a special substance - electrolyte. Also, at least two electrodes are placed in this container.

The main characteristic of the device is performance. This is what the numbers used in model names represent. For example, if you compare two models - “SEU 20” and “SEU 40”, then from the name alone it will become clear that the latter is more powerful. The numbers in this case indicate hydrogen production. The number “20” means that the device is capable of producing 20 cubic meters. meters of hydrogen per hour.

Models of industrial electrolyzers

Carbon anodes (and graphite is an allotope of carbon) have a significant drawback - during the reaction, they emit carbon dioxide into the atmosphere, thereby polluting it. Currently, inert anode technology is especially relevant; a well-known aluminum manufacturer is currently testing this technology. Its essence is that a non-reactive carbon-free anode is used, and not carbon dioxide, but pure oxygen is released into the atmosphere as a by-product.

This technology significantly increases the environmental friendliness of production, but it is still at the testing stage.

Despite the wide variety of electrolytes, electrodes, and electrolyzers, there are common problems in technical electrolysis. These include the transfer of charges, heat, mass, and the distribution of electric fields. To speed up the transfer process, it is advisable to increase the speed of all flows and use forced convection. Electrode processes can be controlled by measuring limiting currents.

Principle of operation

The electrolyzer works as follows: electrodes are connected to a direct current source, which are lowered into a container with an aqueous electrolyte solution. The passing current must have a voltage that exceeds the decomposition point of triatomic water molecules.

After some time, oxygen is formed on one of the electrodes, and hydrogen on the other. Since the number of hydrogen molecules in water is exactly 2.5 more than the number of oxygen molecules, 2 times more hydrogen is released. This is exactly how a simple electrolyzer works.

Other

Electricity costs for hydrogen production are no more than 5.0 kW*h/Nm3.

Structure of maintenance and repair cycles for the FS-T.25 installation:

TO-1 - with the unit turned off, once a month.

TO-2 - with the unit turned off, once every 6 months.

TO-3 - with the unit turned off, once a year.

TO-4 (current repairs) - with the unit turned off, once every 3 years.

TO-5 (overhaul) - with the unit switched off, once every 10 (6) years*.

* In accordance with clause 6.22.1.3 STO 70238424.27.100.050-2009 “Electrolysis installations of power plants. Organization of operation and maintenance. Standards and requirements" major repairs must be carried out once every 6 years.

Installations of the FS-T.25 series are subject to major repairs once every 10 years, subject to technical maintenance by the service department of IFTI LLC.

The electrolysis plant is powered from the existing 0.4 kV switchgear in accordance with the requirements of the PUE.

Types of devices

Electrolyzers can be used not only in the industrial sector, but also in home life. The hydrogen they produce can be converted into fuel and used to enrich the gas-air mixture, thereby increasing the performance of a car engine.

There are several types of electrolysers, which differ from each other in design features.

Dry devices

Using them, you can change the number of cells. The device should be connected to a current source whose voltage exceeds the lowest electrode potential.

Flow electrolyzers

This design consists of a container with electrodes, which is filled to the top with a solution. Another large element of such a device is a tank, which also contains a solution, but there is still empty space at the top. Both containers are connected to each other by a pair of pipes.

A flow electrolyzer works as follows : in a container where there is no free space, an electrochemical reaction occurs in the electrodes under the influence of electric current. The resulting gas, together with the electrolyte, passes through one of the pipes into the second container. There it is separated from the electrolyte solution and exits through a special valve located at the top of the tank. The electrolyte, deprived of gas, returns through the second pipe to the electrode bath.

This process is repeated many times until the required volume of gas is obtained: until the device is disconnected from the network.

Membrane devices

They are among the most common types of electrolyzers. Their work is based on the use of a membrane: that is, not a liquid electrolyte, but a solid one.

Moreover, the membrane performs two functions at once:

- It transports microparticles.

- Separates electrodes and electrochemical reaction products.

The simplest diaphragm electrolysis

In cases where diffusion between the electrode chambers cannot be allowed, a porous diaphragm is used, which can be glass, asbestos or ceramics. Sometimes glass wool or polymer fibers can be used. Accordingly, devices equipped with this element are called diaphragm.

Application of electrolyzers

The constant rise in energy prices has made it possible to take a new approach to electrolytic processes. Various types of installations have been developed to obtain:

- aluminum;

- chlorine;

- hydrogen for plasma cutting and welding machines.

The devices also work as part of units that purify and disinfect drinking water and swimming pool water, as an additive to fuel for cars, allowing the full potential of hydrocarbons to be used. Hydrogen burns much earlier than gasoline. Gasoline is no longer ignited by a spark, but by a flame, which increases the force pressing on the piston of the car’s engine.

Some craftsmen use electrolysis of water at home to heat rooms. But here it is worth noting that the cost of the resulting combustible hydrogen is significantly higher in price than the same natural gas. In addition, the combustion temperature of hydrogen is quite high and not every metal can withstand prolonged exposure without destruction. But the use of heat-resistant materials is not economically justified.