All single-pipe systems with vertical risers require more materials for equipment, but are distinguished by their convenience and the ability to connect heating devices separately to each riser on all floors. In two-story buildings, it is quite simple to equip a water heating system without a pumping device with horizontal wiring.

To activate the circulation process, a special accelerating manifold can be installed on the second floor, after which several hot water circuits will be distributed throughout the second floor. The additional circuit should go down to the ground floor, where it will be divided into several main branches. In some cases, risers from radiators located at the very end of the circuit are additionally distributed to the first floor.

How a heating system works without a pump - options and methods of installation

In order to be able to live in a built country house at any time of the year, it needs high-quality heating. Among the wide variety of heating devices, it is sometimes difficult to decide what exactly is needed in a given situation. One of the simplest options that you can arrange yourself is a heating system without a pump, that is, with a natural type of coolant circulation. It is this type of heating that we will talk about later in the material.

In what cases can you do without a pump?

The movement of coolant inside the heating circuit occurs under the influence of the laws of physics. This means that when heated, the liquid rises, and as it cools, it falls again, thereby heating the room.

Most of all, a heating system without a circulation pump is in demand precisely in country houses and dachas, since in suburban conditions the power supply is not always stable or absent altogether. In this regard, heating equipment with a forced circulation type is impractical.

It is noteworthy that it is quite possible to install heating with natural coolant circulation yourself. In addition, such a system is very convenient to use.

Pipe selection

Also, the choice of material is greatly influenced by the boiler, since in the case of solid fuel, preference should be given to steel, galvanized pipes or stainless steel products, due to the high temperature of the working fluid.

However, metal-plastic and reinforced pipes require the use of fittings, which significantly narrows the clearance; reinforced polypropylene pipes will be an ideal option at an operating temperature of 70C and a peak temperature of 95C.

Products made from special PPS plastic have an operating temperature of 95C, and a peak temperature of up to 110C, which allows use in an open system.

Structure and types of systems with a natural type of circulation

Typically, a heating circuit without a pump includes a list of required components:

- heating device - a boiler or stove that can be heated with the type of fuel available in a particular region;

- expansion tank, which allows you to relieve excess pressure or add water to the heating circuit;

- pipes that form the circuit along which water will move in the system;

- batteries that allow you to heat the room more efficiently by increasing the area of the heat-transferring surface.

The diameter of heating pipes with natural circulation will be slightly larger than if a circulation pump is used.

Based on what kind of coolant will be used, heating systems with natural circulation can be water or steam.

Here are the distinctive features of each type of heating.

conclusions

Considering the question of how to make water heating from a stove, we started talking about the use of various heating systems. At the same time, as practice shows, stove heating is the most popular in our country. The prevalence is explained by the use of available fuels.

The proposed modern gas or electric units operate on rather expensive sources. Water-heated stoves are more economical systems that can be easily equipped with your own hands, which also guarantees lower costs.

This heating is based on the combination of traditional stoves, known to us for centuries, and modern technologies. The result is the desired warmth in residential buildings, which people have always strived for and strive for.

A heater of this type means long service life without dependence on centralized sources. With proper care of heating units and furnaces, you can not worry about the temperature microclimate for many decades.

Heating with water as coolant

The functional features of water heating systems with a natural type of coolant circulation are determined by a number of characteristics.

Based on which expansion tank is used to equip a heating system with natural coolant circulation, there are:

- Open systems . In this case, the expansion tank is installed as high as possible in order to create excess pressure in the expansion tank. In addition, thanks to this you can get rid of air pockets in the heating circuit. From time to time, water that has partially evaporated during heating operation is added to the pipes through an open expansion tank.

- Closed systems . In such heating with natural circulation, the expansion tank is replaced by a special membrane hydraulic storage cylinder. It provides additional pressure in the circuit within 1.5 atmospheres. For safety reasons, systems of this design are usually equipped with a block with a pressure gauge, the task of which is to adjust the pressure inside the pipeline.

Another fundamental point that distinguishes the design of heating systems with a natural type of water circulation is the connection diagram of the heating elements.

According to the method of connecting heating devices to a gas boiler without a pump, the following options can be distinguished:

- Single-pipe heating distribution . With this type of heating, all radiators are connected in series to the same pipe. That is, water passes through each subsequent heating device and only after that it moves on. Among the advantages of single-pipe distribution equipment are the simplicity of its installation, as well as low material consumption.

- Two-pipe wiring in a heating system with a natural circulation type. In this case, all radiators that are part of the heating system are connected to the pipeline in parallel. In this case, the temperature of the coolant that enters each radiator is the same. After the water has passed through the entire radiator and cooled, it returns through the return pipe to the boiler heat exchanger.

It is believed that a two-pipe wiring diagram is the most appropriate from the point of view of the efficiency of heating a home. True, to equip such a system, you will need quite a lot of pipes and additional elements for installing the heating circuit.

It is worth noting that when deciding how to make heating without a pump, take into account your practical skills, as well as your financial capabilities for purchasing consumables.

Emergency options

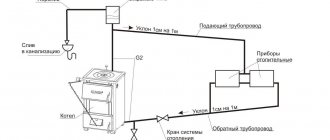

Every piping scheme must include a circuit in case of emergency situations. His task includes:

— protection against pressure drops;

— protection against temperature increases above the permitted limit;

— prevention of moisture formation.

Safety valve in the harness

Its task is precisely to relieve excess pressure from the system. It is mounted at the boiler outlet separately or as part of a safety group.

Emergency heat exchanger in the solid fuel boiler connection system

Its task is most responsible - to prevent overheating of both the boiler and the system in general. Overheating can happen for 2 reasons:

— too much fuel was loaded into the boiler. The heat received exceeded the demand.

— the electricity was turned off and the pump stopped working.

For normal operation of this circuit, it is also necessary to install a temperature sensor with a valve and a cooling unit in the water supply pipe to the boiler. As soon as the coolant temperature exceeds the maximum allowed, the sensor signals this and provokes the opening of the valve.

After the valve is activated, water begins to fill the cooling unit, reducing the temperature of the main coolant.

Auxiliary heating circuit for a solid fuel boiler

One of the options for cooling the system. Its peculiarity is that you will need to connect a storage tank for the DHW circuit.

This scheme will work as follows: in normal operating mode, the pump will operate, creating a certain pressure. It will prevent the auxiliary circuit from coming into operation. But as soon as the electricity is turned off, the pump will stop working, the pressure will disappear, and the backup circuit will come into operation.

Result: the water temperature in the system will drop to the desired value.

Let’s say right away that this scheme is suitable for absolutely any type of heating system!

This mixer maintains the lowest temperature of the coolant at the inlet to the boiler so that condensation does not form on the walls of the device. what we talked about at the very beginning of the article. Thus, in a solid fuel boiler this is one of the most necessary components!

The mixer is installed on the return pipe using a bypass.

If the temperature in the return pipe is low (below the set value), the thermomixer will provide an influx of hot water.

Steam heating type

Some consumers confuse steam heating with water heating. In essence, these systems are very similar, except that the coolant is steam rather than water.

Inside the heating boiler of a natural circulation system, water is heated to boiling point and converted into steam, which is then moved into the pipeline and then supplied to each radiator in the circuit.

The design of a steam heating system with natural coolant circulation includes the following components:

- a special heating boiler, inside which water is heated to boiling point and steam is accumulated;

- valve for releasing steam into the heating system;

- pipeline;

- heating radiators.

Please note that the steam type heating system is operated at very high temperatures, so it is strictly forbidden to use plastic pipes to construct the pipeline.

The classification of steam-type heating according to wiring diagrams and other criteria is exactly the same as for water heating systems. Recently, a boiler has also been used to heat a private home, which also has its advantages.

How to install heating correctly

In order for a finished heating system with a natural circulation type to function correctly and efficiently, it is important to adhere to certain rules when installing it.

In general, the installation diagram looks like this:

- Heating radiators must be installed under the windows, preferably at the same level and maintaining the required indentations.

- Next, install the heat generator, that is, the selected boiler.

- Install the expansion tank.

- The pipes are laid out and the previously fixed elements are joined into a single system.

- The heating circuit is filled with water and a preliminary check for the tightness of the connections is performed.

- The final stage is to start the heating boiler. If everything works correctly, then the house will be warm.

Please pay attention to some nuances:

- The boiler should be located at the lowest point of the system.

- The pipes must be installed with a slope towards the return flow.

- There should be as few turns in the pipeline as possible.

- To increase heating efficiency, pipes with a larger diameter are required.

We hope this article will be useful to you, and you will be able to independently install a heating system without a circulation pump in your country house.

Article source: https://teplospec.com/montazh-remont/kak-ustroena-sistema-otopleniya-bez-nasosa-varianty-i-sposoby-ustroystva.html

Do-it-yourself installation recommendations

To lay the main natural circulation lines, it is better to use polypropylene or steel pipes. The reason is the large diameter, polyethylene Ø40 mm and more is too expensive. We make radiator hoses from any convenient material.

Advice. When assembling a gravity heating network made of metal-plastic, do not install compression fittings - they greatly reduce the internal passage.

How to make the layout correctly and withstand all the slopes:

After applying the markings, punch holes in the partitions and cut grooves for the hidden gasket. Then check the routes again, make adjustments and proceed with installation. Follow the same order: first secure the batteries, then lay the pipes towards the combustion chamber. Install an expansion tank with a drain pipe.

The gravity pipeline network is filled without problems; Mayevsky’s taps do not need to be touched. Just slowly pump water through the fill valve at the lowest point, all the air will go into the open tank. If any radiator remains cold after warming up, use a manual air vent.

Gravity heating system with natural circulation - calculations, slopes, types

For private country houses and cottages, a heating system with natural coolant circulation is often installed. This decision has its positive and negative sides. The scheme is performed in four different ways.

A system with gravity circulation is sensitive to errors made during heating installation.

The principle of operation of a natural circulation system

The heating scheme for a private house with natural circulation is popular due to the following advantages:

- Easy installation and maintenance.

No need to install additional equipment.

- Energy independence – no additional energy costs are required during operation. When the power goes out, the heating system continues to operate.

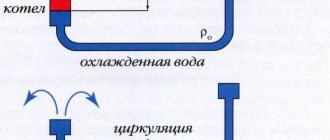

The operating principle of water heating, using gravity circulation, is based on physical laws. When heated, the density and weight of the liquid decreases, and when the liquid medium cools, the parameters return to their original state.

At the same time, there is practically no pressure in the heating system. In thermotechnical formulas, a ratio of 1 atm is accepted for every 10 m of water column pressure. Calculation of the heating system of a 2-story building will show that hydrostatic pressure does not exceed 1 atm, in one-story buildings 0.5-0.7 atm.

Since the liquid increases in volume when heated, an expansion tank is required for natural circulation. The water passing through the boiler water circuit heats up, which leads to an increase in volume. The expansion tank should be located on the coolant supply, at the very top of the heating system. The purpose of the buffer tank is to compensate for the increase in liquid volume.

A self-circulating heating system can be used in private homes, making the following connections possible:

Connection to heated floors - requires installing a circulation pump, only on a water circuit laid in the floor. The rest of the system will continue to operate with natural circulation. After a power outage, the room will continue to be heated using the installed radiators.

Types of heating systems with gravity circulation

Despite the simple design of a water heating system with self-circulation of coolant, there are at least four popular installation schemes. The choice of wiring type depends on the characteristics of the building itself and the expected performance.

To determine which scheme will work, in each individual case it is necessary to perform a hydraulic calculation of the system, take into account the characteristics of the heating unit, calculate the diameter of the pipe, etc. You may need professional help when performing the calculations.

Closed system with gravity circulation

In EU countries, closed systems are the most popular among other solutions. In the Russian Federation, the scheme has not yet received widespread use. The operating principles of a closed-type water heating system with pumpless circulation are as follows:

- When heated, the coolant expands and water is displaced from the heating circuit.

Under pressure, the liquid enters a closed membrane expansion tank. The design of the container consists of a cavity divided by a membrane into two parts. One half of the tank is filled with gas (most models use nitrogen). The second part remains empty for filling with coolant.

How to properly make water heating with natural circulation

All gravity systems have a common drawback - the lack of pressure in the system. Any violations during installation work, a large number of turns, non-compliance with slopes, immediately affect the performance of the water circuit.

To make proper heating without a pump, take into account the following:

Type and diameter of pipes used for the water circuit.

What pipe slope is needed for gravity circulation

The design standards for an in-house heating system with gravity circulation are specified in detail in building codes. The requirements take into account that the movement of liquid inside the water circuit will be hampered by hydraulic resistance, obstacles in the form of corners and turns, etc.

The slope of heating pipes is regulated by SNiP. According to the standards specified in the document, a slope of 10 mm is required for each linear meter. Compliance with this condition guarantees unhindered movement of fluid in the water circuit.

Violation of the slope when laying pipes leads to airing of the system, insufficient heating of radiators remote from the boiler, and, as a result, a decrease in thermal efficiency.

What pipes are used for installation

The choice of pipes for the manufacture of the heating circuit is important. Each material has its own thermal characteristics, hydraulic resistance, etc. When performing installation work yourself, additionally take into account the complexity of installation.

The most commonly used building materials are:

- Steel pipes - the advantages of the material include: affordable cost, resistance to high pressure, thermal conductivity and strength. The disadvantage of steel is its complex installation, which is impossible without the use of welding equipment.

Metal-plastic pipes - have a smooth inner surface that prevents the circuit from clogging, light weight and linear expansion, no corrosion. The popularity of metal-plastic pipes is somewhat limited by their short service life (15 years) and the high cost of the material.

Polypropylene pipes are widely used due to their ease of installation, high tightness and strength, long service life and resistance to freezing. Polypropylene pipes are installed using a soldering iron. Service life of at least 25 years.

Gas generator furnaces

Gas generator furnaces have a number of distinctive features:

- Economical. The stove operates for about 12 hours on one load of fuel.

- Compact sizes.

- High efficiency - about 85%.

- Possibility of adjusting combustion intensity.

- Possibility of using different types of fuel.

- Easy to connect water circuit.

It would seem that the choice in favor of gas generator furnaces is obvious. But before installing such a model, you need to evaluate a number of nuances:

- Essential requirements for the installation of a chimney.

- There is a high probability of condensation forming on the chimney walls.

- Manual adjustment takes some getting used to. Only in this case can all the above benefits be achieved.

- You can use different types of fuel, but there are a number of requirements, non-compliance with which can lead to a deterioration in the quality of heating.